Internal heating type low-temperature oxygen-enriched destructive coal distillation process and system for quality-divided returned coal gas

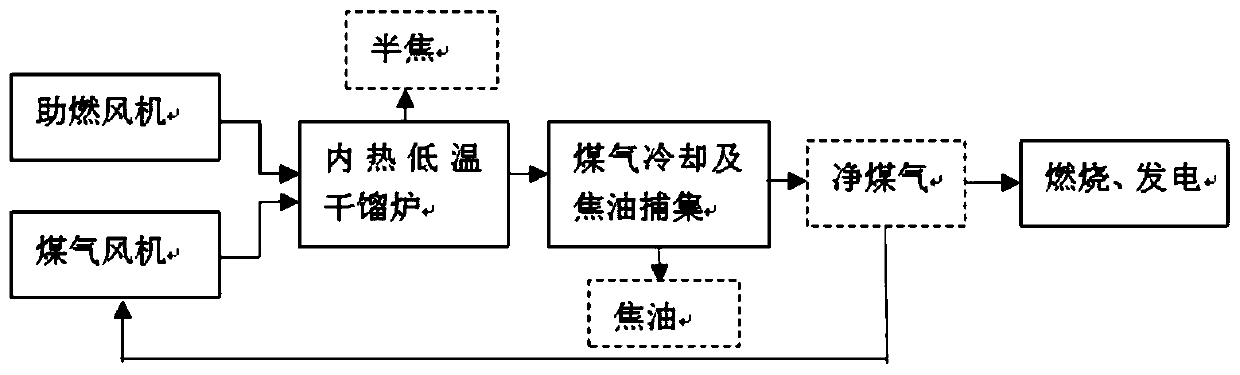

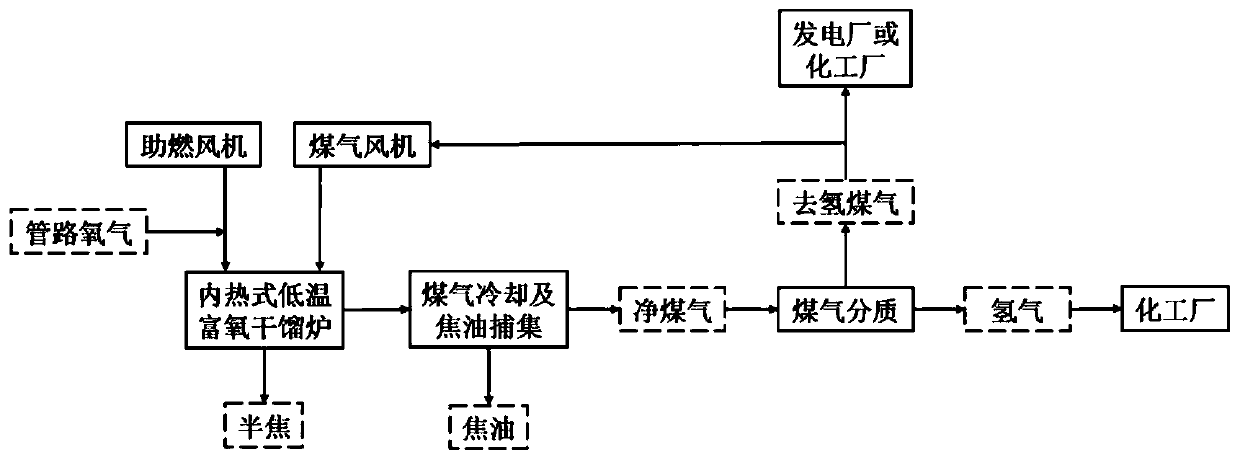

A process method and coal dry distillation technology, which is applied in special forms of dry distillation, coke ovens, petroleum industry, etc., can solve the problems of high local flame temperature, shortening the flame length of the low temperature dry distillation furnace, and unreasonable temperature and airflow distribution in the furnace. , to achieve the effect of improving gas quality, avoiding slagging in the furnace and unstable product quality, and improving the calorific value and utilization value of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1 Reconstruction of gas separation and oxygen-enriched dry distillation in semi-coke production plant with an annual output of 900,000 tons

[0059] (1) Basic information

[0060] There are 2 sets of vertical square furnaces as the basic production equipment (the annual output of a single furnace is 75,000 tons of semi-coke, 6 sets), air-assisted combustion, and the coal-to-coke ratio is 1.67:1. The tar yield is about 7.8% (Shenmu dry-based raw coal is used as the benchmark), and the remaining gas volume per ton of coal is 560m 3 Left and right (Shenmu coal), coal gas is used for small gas-fired power generation. Gas composition before transformation: H 2 18.27%, CO 8.55%, CH 4 5.69%, C2-C52.35%, CO 2 6.18%, N 2 58.96%. Gas low calorific value 7365.16kJ / m 3 . The adjacent factory is a CNG production enterprise, which uses coal gasification to produce raw material gas and further prepares synthesis gas. The CNG company has oxygen production equipment...

Embodiment 2

[0066] Example 2 Transformation of synthetic medium carbonization in a low-temperature carbonization enterprise with an annual output of 1.2 million tons of semi-coke

[0067] (1) Basic information:

[0068] There are 4 groups of semi-coke production plants with an annual processing capacity of 300,000 tons (each group is composed of 6 conjoined single furnaces with an annual output of 50,000 tons), and conventional vertical square furnaces are used as basic production equipment. The coal gas is supplied to the downstream synthetic ammonia enterprises as raw material gas. The gas composition is: H 2 19.07%, CO 8.62%, CO 2 6.25%, CH 4 5.52%, C2-C5 3.01%, N 2 57.53%. Gas low calorific value 7541.81kJ / m 3 . The downstream synthetic ammonia enterprises are equipped with PSA pressure swing adsorption gas separation device, which can be used for gas separation in this process.

[0069] (2) Application method

[0070] According to the method of the present invention, duri...

Embodiment 3

[0073] Example 3 Transformation of synthetic medium carbonization in a low-temperature carbonization enterprise with an annual output of 1.8 million tons of semi-coke

[0074] (1) Basic information:

[0075] There are 4 groups of semi-coke production plants with an annual processing capacity of 450,000 tons (each group is composed of 6 connected single furnaces with an annual output of 75,000 tons), using oxygen-enriched dry distillation with an oxygen-enriched ratio of 50%. Oxygen is provided by synthetic ammonia enterprises, which has surplus oxygen production capacity. The coal gas is supplied to the downstream synthetic ammonia enterprises as raw material gas. The gas composition is: H 2 28.01%, CO 10.68%, CO 2 11.45%, CH4 13.32%, C2-C5 3.01%, N 2 37.53%. The downstream synthetic ammonia enterprises are equipped with PSA pressure swing adsorption gas separation device, which can be used for gas separation in this process.

[0076] When the oxygen enrichment ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com