Method and device for feeding rotational flow cushion layer of hydrogenation reactor

A technology for a hydrogenation reactor and a feeding method, which is applied in refining to remove heteroatoms, etc., can solve the problems of difficult adjustment of the flow ratio of the cooling layer and the inner layer, accumulation near the wall of the high temperature vessel, and clogging of pipes, etc. Periodic operation to avoid the effect of condensation reaction coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] 1. Device name

[0075] 5000L / h ebullating bed hydrogenation reactor cold mold device

[0076] 2. Technological process

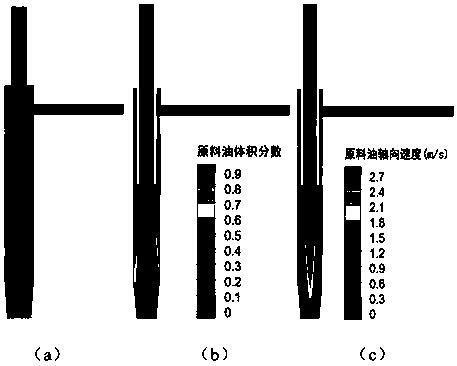

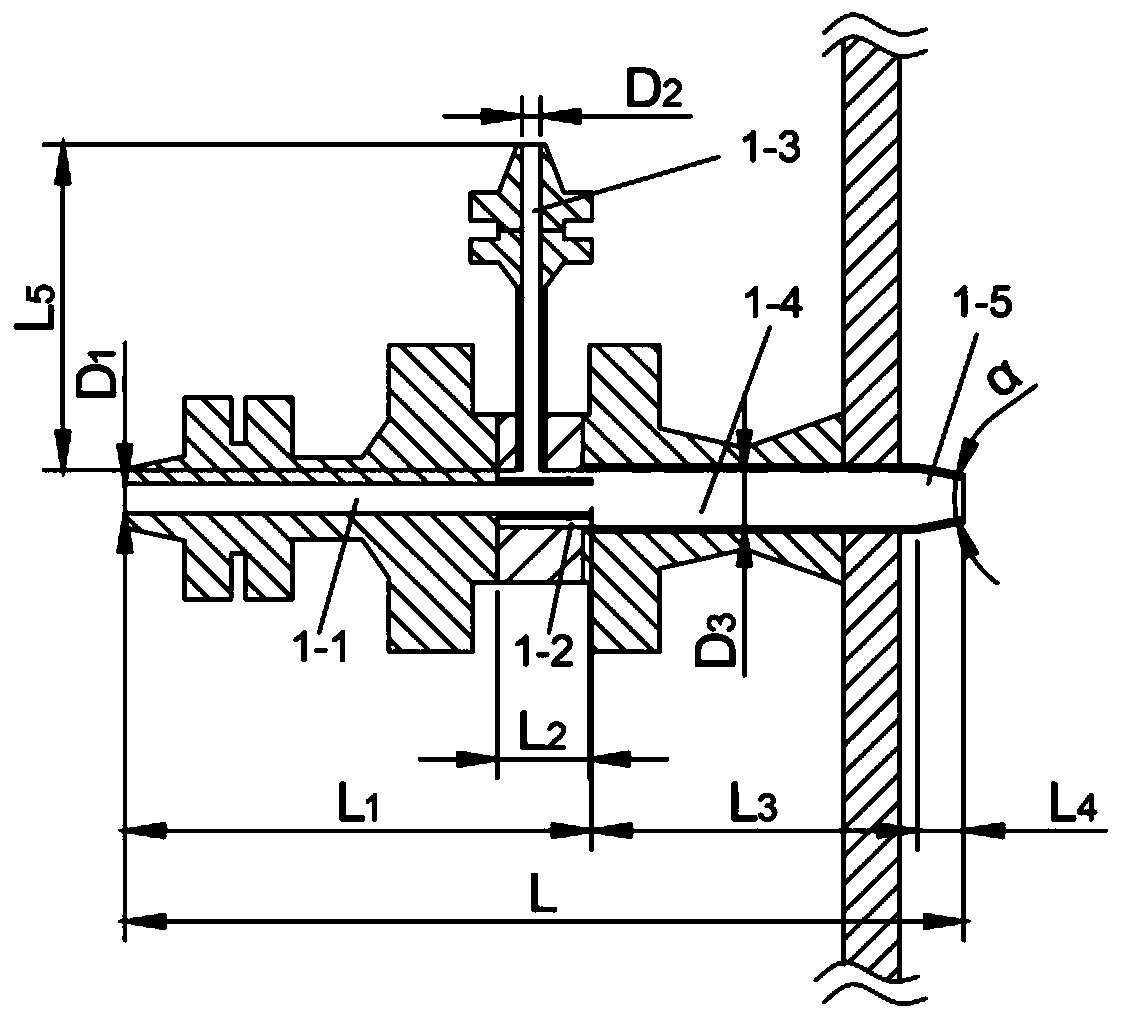

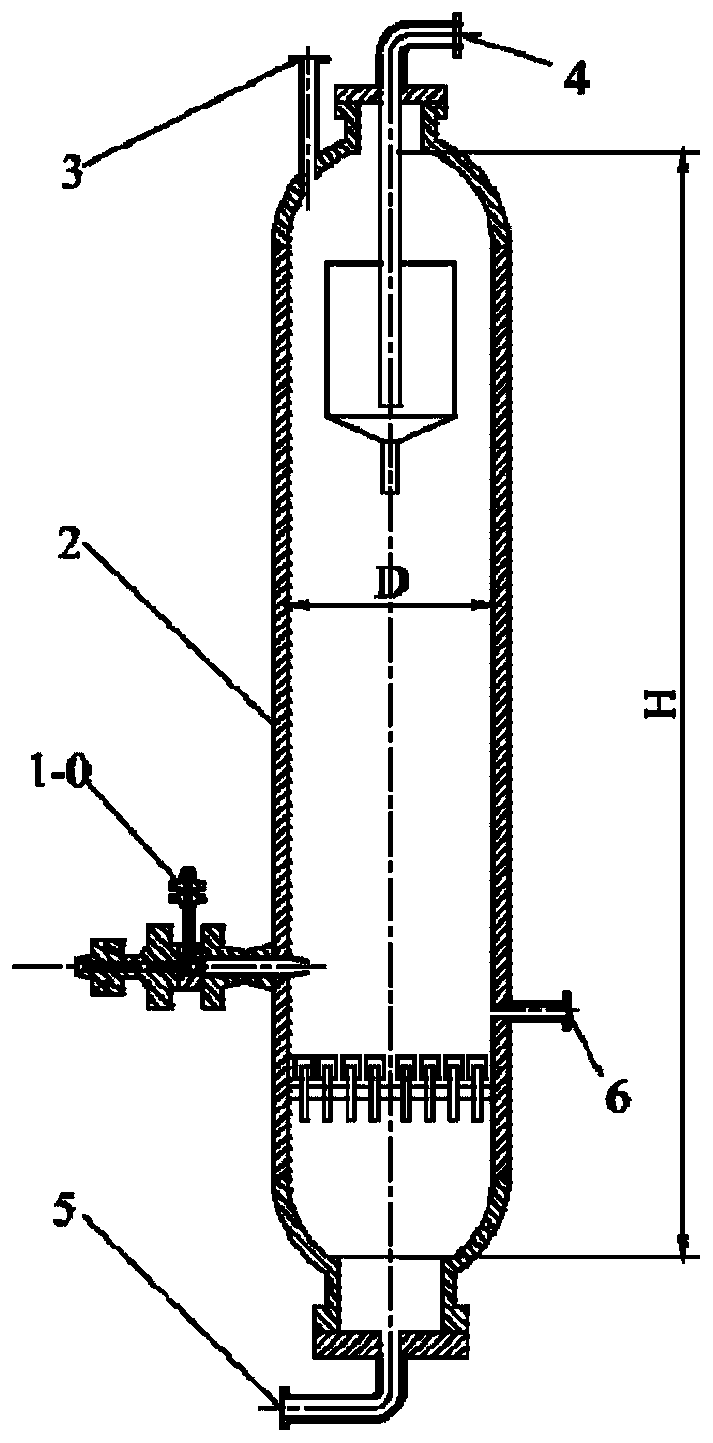

[0077] Such as figure 1 shown. The raw material oil and circulating hydrogen donor enter the reactor from the swirl bed feeder on the side of the hydrogenation reactor. The control range of the feed temperature of the raw material oil and the circulating hydrogen donor is from room temperature to 45° C., and the mass ratio of the circulating hydrogen donor and the raw material oil is controlled to be 0.25-2. The feedstock oil enters the swirl cushion feeder through the feedstock oil axial introduction pipe 1-1, and at the same time, the hydrogen-supply circulating oil enters the ring of the swirl-flow cushion feeder through the swirl introduction pipe 1-3 of the circulating hydrogen supply agent. Gap swirl chamber 1-2, and the swirl flow stream is formed under the diversion action of the swirl blades in the annular gap swirl chamber 1-2. After th...

Embodiment 2

[0085] 1. Device name

[0086] 200 tons / year sludge cracking liquid hydrodeoxygenation unit

[0087] 2. Technological process

[0088] Such as figure 1shown. The raw material oil and circulating hydrogen donor enter the reactor from the swirl bed feeder on the side of the hydrogenation reactor. The control range of the feeding temperature of the raw material oil and the circulating hydrogen donor is from room temperature to 45° C., and the mass ratio of the circulating hydrogen donor and the raw material oil is controlled to be 0.25-5. The feedstock oil enters the swirl cushion feeder through the feedstock oil axial introduction pipe 1-1, and at the same time, the hydrogen-supply circulating oil enters the ring of the swirl-flow cushion feeder through the swirl introduction pipe 1-3 of the circulating hydrogen supply agent. Gap swirl chamber 1-2, and the swirl flow stream is formed under the diversion action of the swirl blades in the annular gap swirl chamber 1-2. After t...

Embodiment 3

[0096] 1. Device name

[0097] 100 tons / year wood chip cracking liquid hydrodeoxygenation device

[0098] 2. Technological process

[0099] Such as figure 1 shown. The raw material oil and circulating hydrogen donor enter the reactor from the swirl bed feeder on the side of the hydrogenation reactor. The control range of the feed temperature of the raw material oil and the circulating hydrogen donor is from room temperature to 45°C, and the mass ratio of the circulating hydrogen donor and the raw material oil is controlled to be 0.25-10. The feedstock oil enters the swirl cushion feeder through the feedstock oil axial introduction pipe 1-1, and at the same time, the hydrogen-supply circulating oil enters the ring of the swirl-flow cushion feeder through the swirl introduction pipe 1-3 of the circulating hydrogen supply agent. Gap swirl chamber 1-2, and the swirl flow stream is formed under the diversion action of the swirl blades in the annular gap swirl chamber 1-2. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com