Method for preparing hydrogenated petroleum resin by using dicyclopentadiene as a raw material

A technology of dicyclopentadiene and petroleum resin, which is applied in the field of preparing high-quality hydrogenated petroleum resin, can solve the problems of large material loss, high cost, and no simple and effective method to solve harmful impurities and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

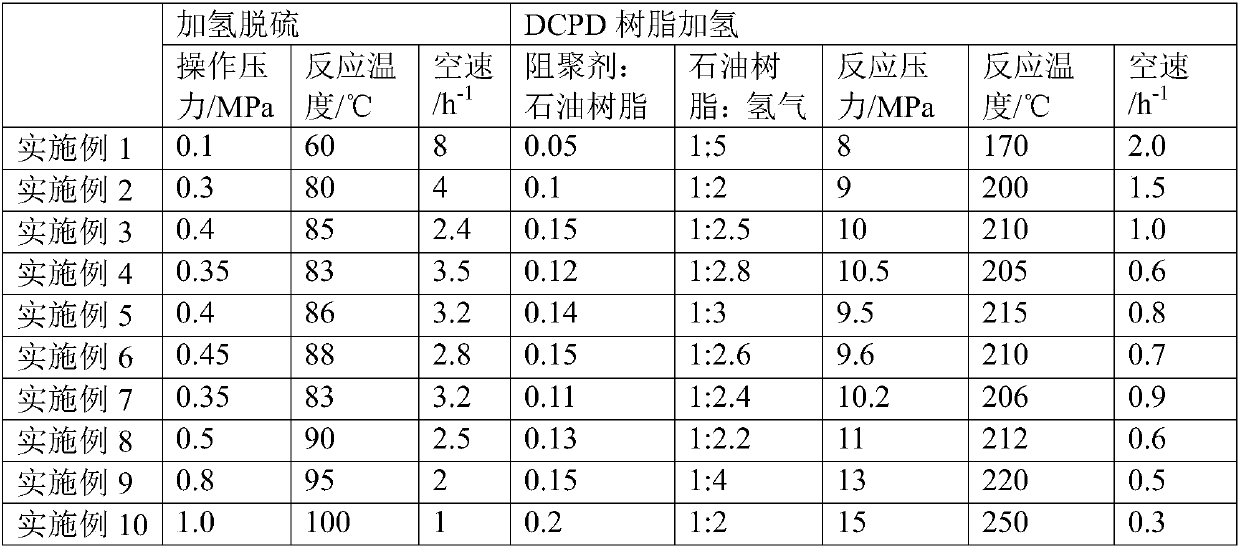

Embodiment 1~10

[0026] The dicyclopentadiene used in Examples 1-10 is derived from the crude dicyclopentadiene product separated from the C5 separation device. Its components are shown in Table 1.

[0027] Table 1.

[0028] components

Content (wt.%)

CPD

0.3

DCPD

84.0

NB

9.5

carbon six

1.2

other

5.0

[0029] Crude dicyclopentadiene is processed and synthesized hydrogenated petroleum resin according to the following process:

[0030] 1) The DCPD raw material is mixed with an organic solvent and then continuously passed through a tubular reactor with a static mixing element for thermal polymerization to generate petroleum resin;

[0031] 2) The DCPD polymerization solution obtained in step 1) is passed through a fixed bed filled with a high-nickel catalyst, and harmful impurities such as sulfur in the raw material are removed in an atmosphere facing hydrogen;

[0032] 3) adding a colloidal polymerization inhibitor to the petr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com