Biomass boiler feeding system

A biomass boiler and feeding system technology, which is applied in the directions of fuel supply, solid fuel combustion, and fuel supply regulation, etc., can solve the problem of broken shaft without shaft screw, the inability of the unit to achieve long-term operation, and the material blocking of the feeding system, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

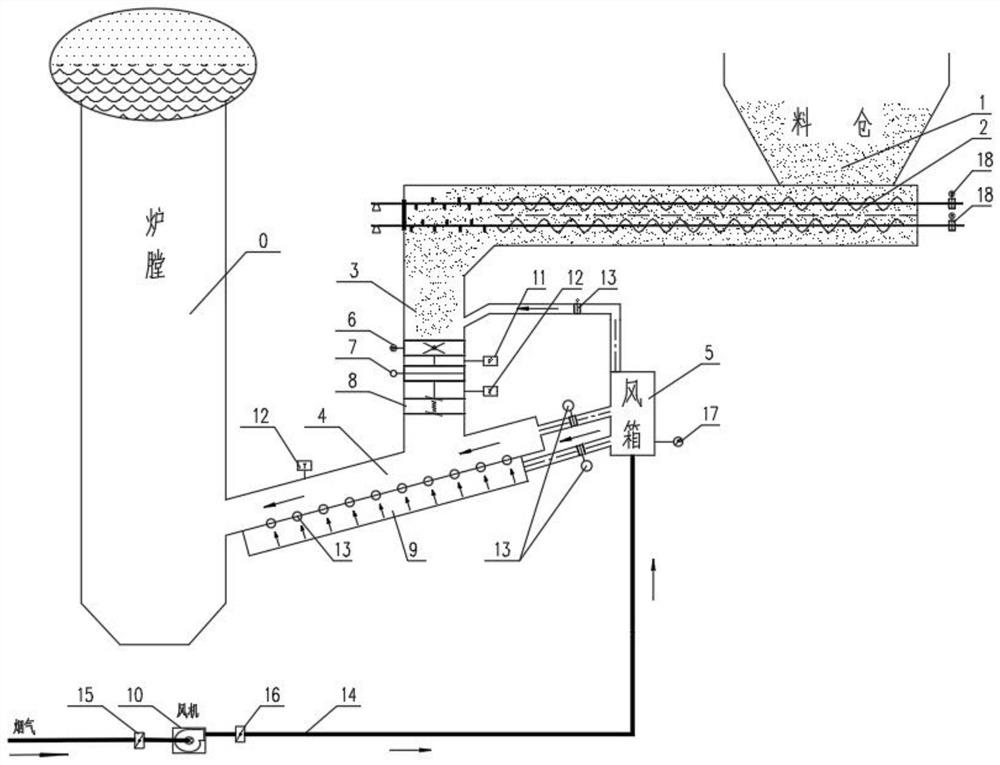

[0046] Specific implementation mode one: combine figure 1 Describe this embodiment, a biomass boiler feeding system of this embodiment, including a feed bin 1, a secondary screw feeder 2, a feed pipe 3, a drop pipe 4, a bellows 5, and a pneumatic quick shut-off valve 6 , heavy hammer lever valve 7, metal expansion joint 8, fluidization wind bellows 9 and fan 10, the bottom of silo 1 is connected and installed with secondary screw feeder 2, and secondary screw feeder 2 is connected with feeding pipe 3 Connecting and matching installation, feeding pipe 3 and feeding pipe 4 are connected and installed, feeding pipe 4 is connected and installed with furnace 0, bellows 5 are respectively connected and installed with feeding pipe 3 and feeding pipe 4, feeding pipe 3 is connected and installed from Pneumatic quick shut-off valve 6, heavy hammer lever valve 7 and metal expansion joint 8 are installed sequentially from top to bottom. Fluidization wind bellows 9 are installed on the bot...

specific Embodiment approach 2

[0054] Specific implementation mode two: combination figure 1 Describe this embodiment, a biomass boiler feeding system of this embodiment, a pressure sensor 11 is installed on the feed pipe 3 between the pneumatic quick shut-off valve 6 and the weight lever valve 7 .

specific Embodiment approach 3

[0055] Specific implementation mode three: combination figure 1 Describe this embodiment, a biomass boiler feeding system of this embodiment, a pressure sensor 11 is installed on the feed pipe 3 between the pneumatic quick shut-off valve 6 and the weight lever valve 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com