A flexible hydrocracking process for the production of lube base stocks

A technology for hydrocracking and hydroisomerization cracking, which can be used in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., and can solve problems such as poor operation flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

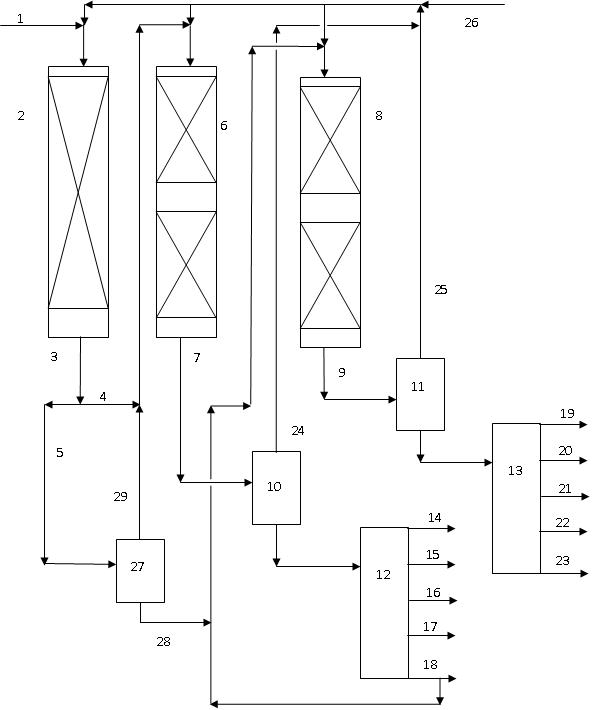

Image

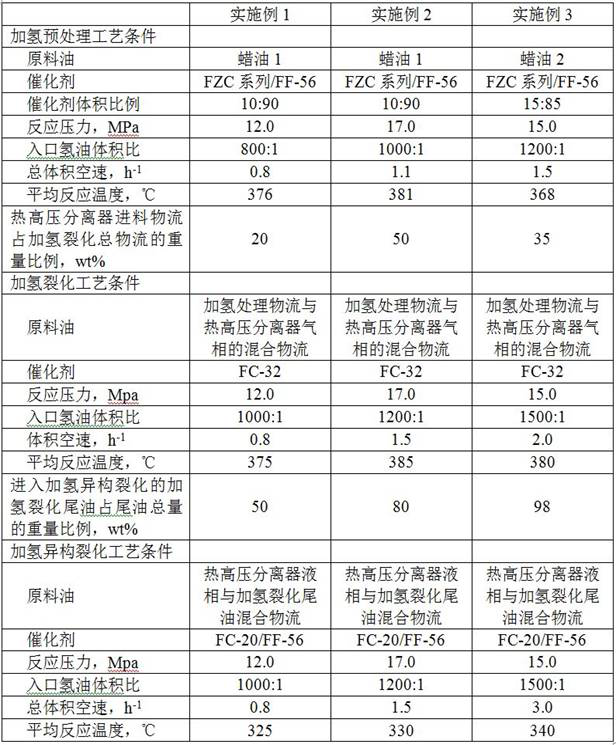

Examples

Embodiment 1-3

[0045] Protective agents FZC-100, FZC-105 and FZC106 are hydrogenation protective agents developed and produced by Sinopec Fushun Petrochemical Research Institute; catalyst FF-56 is developed and produced by Sinopec Fushun Petrochemical Research Institute Hydrotreating catalyst; Catalyst FC-32 is a hydrogenation upgrading catalyst developed and produced by Fushun Petrochemical Research Institute of China Petrochemical Corporation, containing Y-type molecular sieve; Catalyst FC-20 is a research and development product of Fushun Petrochemical Research The hydroisomerization cracking catalyst developed and produced by the Institute contains β-type molecular sieves.

[0046] Table 1 Main properties of wax oil feedstock

[0047]

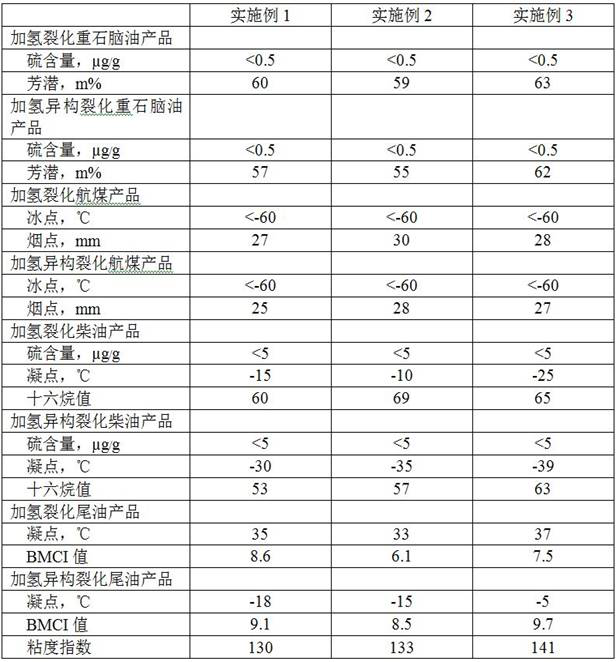

[0048] Table 2 Example process conditions

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com