Patents

Literature

38results about How to "High in paraffins" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

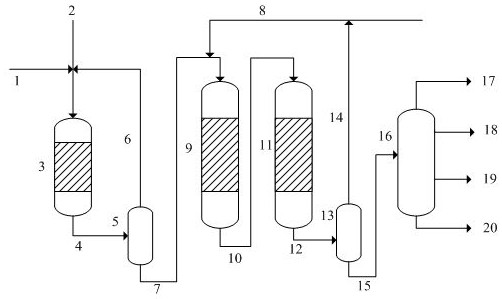

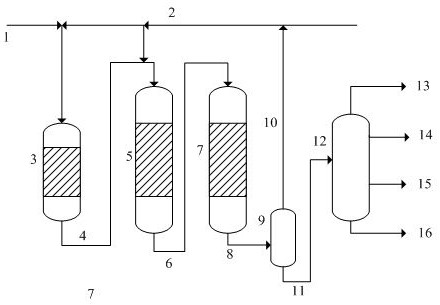

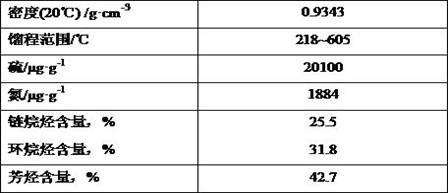

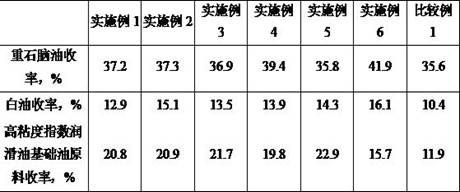

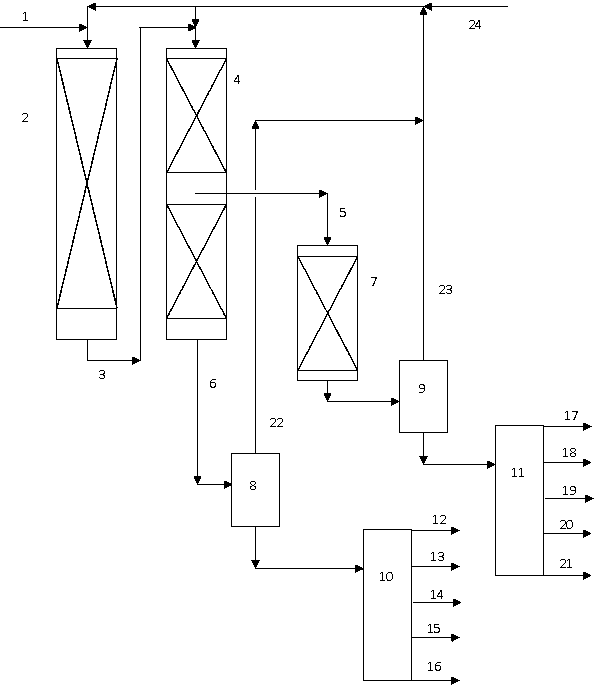

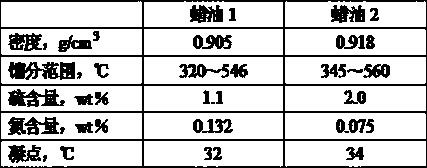

Hydro-cracking method for producing middle distillate and tail oil rich in chain alkane

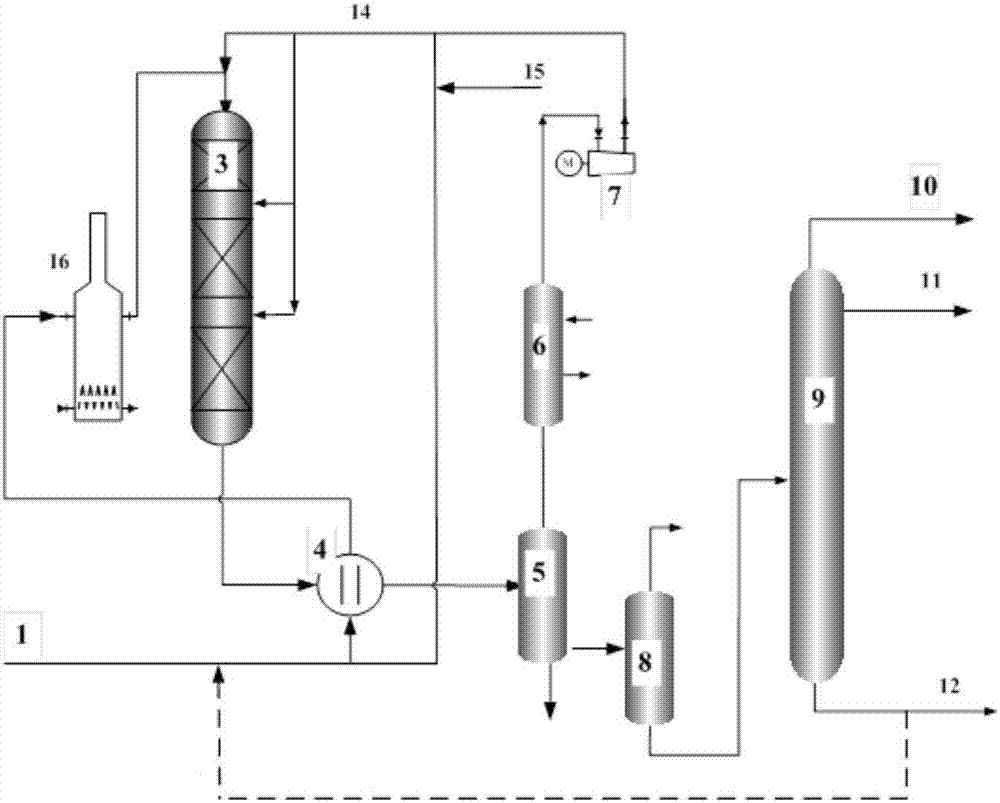

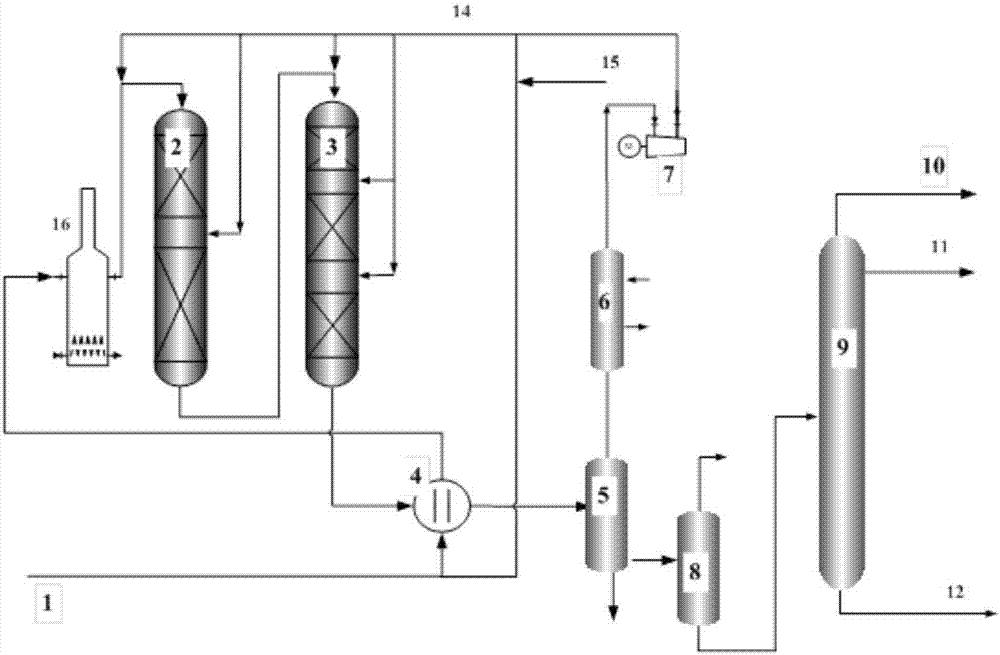

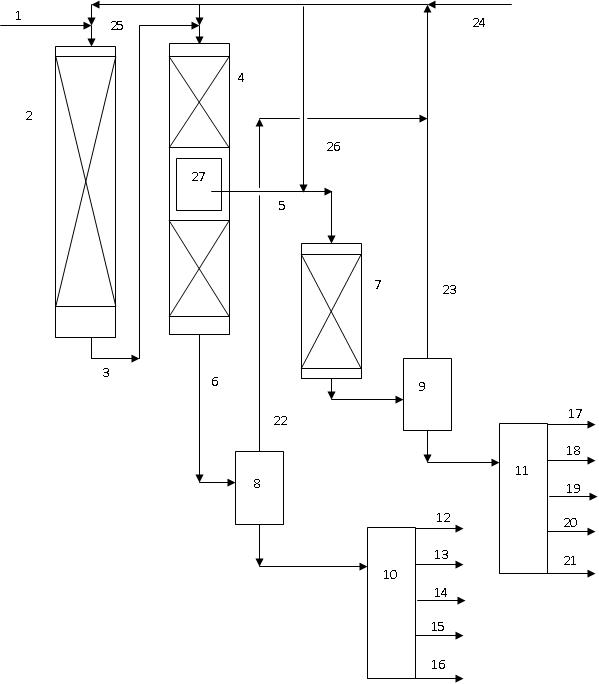

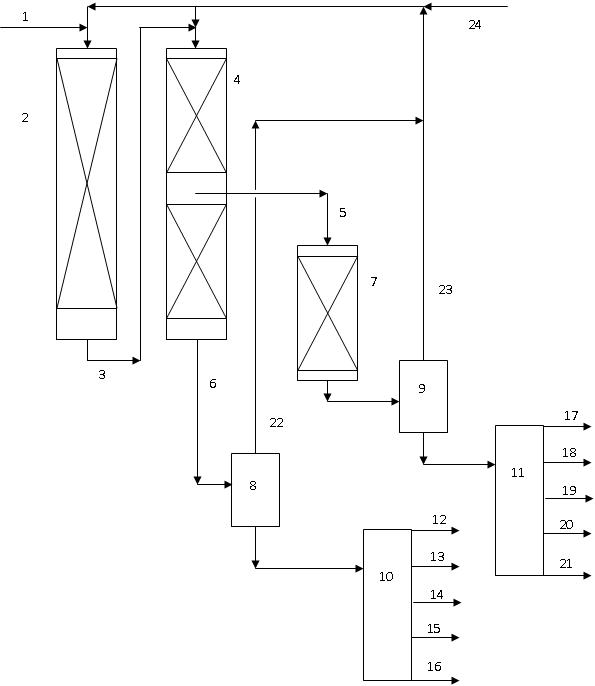

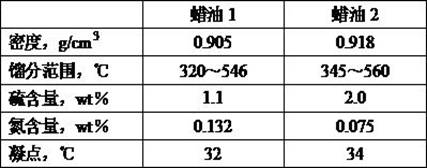

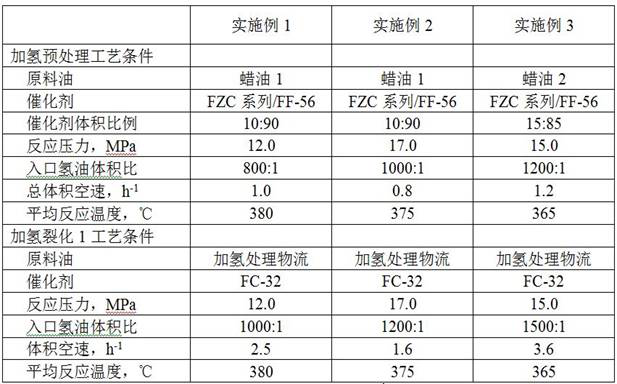

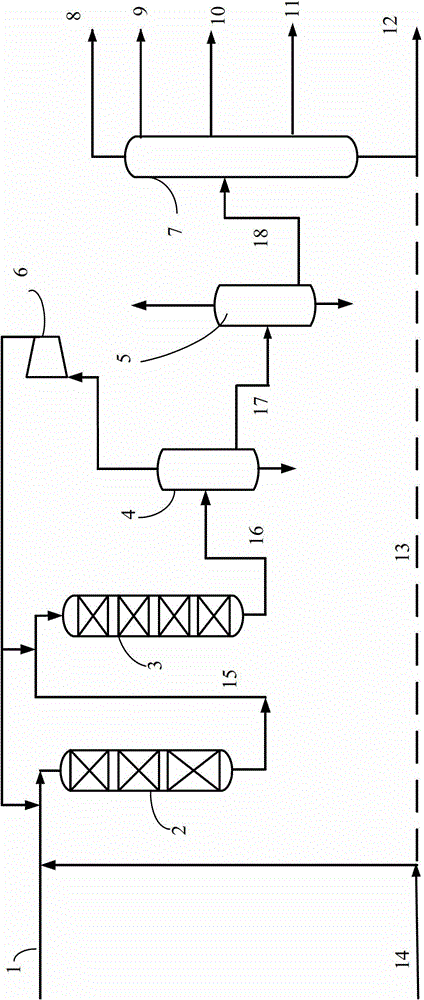

The invention discloses a hydro-cracking method for producing middle distillate and tail oil rich in chain alkane. The method comprises the following steps: mixing raw material oil with hydrogen gas, subjecting the mixture to orderly contact with a hydro-refining catalyst and a hydro-cracking catalyst to carry out reactions, and subjecting the reaction product to processes of separation and fractionation so as to obtain the following components: gas rich in hydrogen, a naphtha fraction, a kerosene fraction, a diesel oil fraction, and a tail oil fraction; wherein the tail oil fraction is totally extracted, or part of the tail oil fraction is recycled and returned to the reaction system. By adopting the method provided by the invention, heavy fraction oil can be processed, the output of the middle distillate is increased, and at the same time high quality tail oil with a high content of chain alkane is produced. Compared to the prior art, the hydro-cracking method has the advantages of good selectivity and high yield of middle distillate and high chain alkane content and viscosity index of tail oil, and the middle distillate and tail oil are suitable for being taken as high-quality raw materials for steam cracking method for producing ethylene or lubricant basic oil production.

Owner:CHINA PETROLEUM & CHEM CORP +1

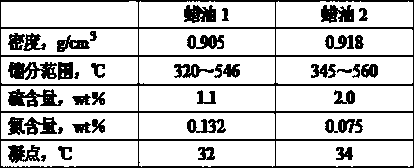

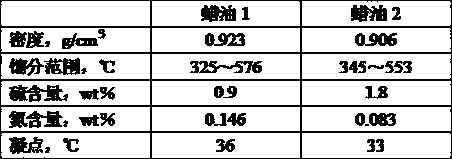

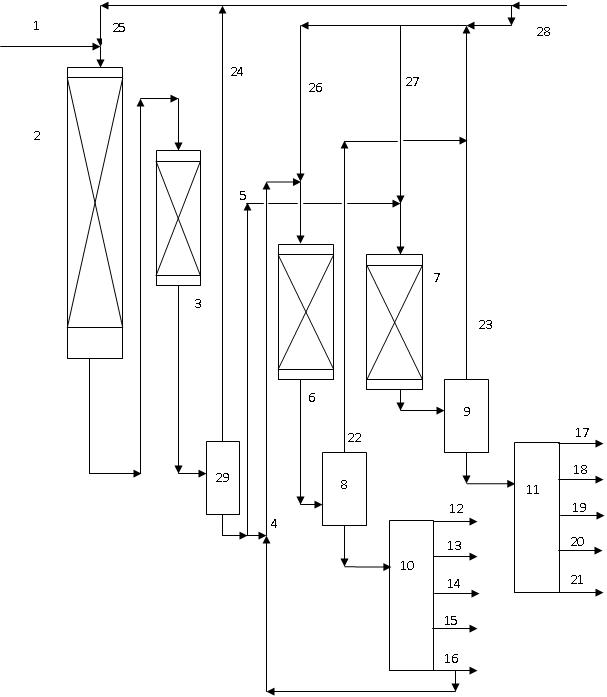

Method for producing diesel fuel by using coal direct liquefication oil and delayed coking heavy diesel fuel fraction and application of method

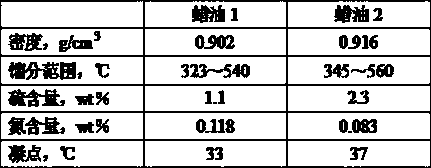

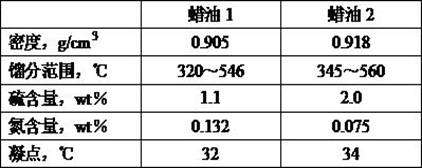

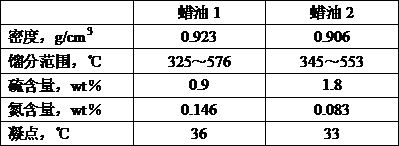

ActiveCN102206511AHigh in paraffinsIncrease cetane numberTreatment with hydrotreatment processesCoalSulfur content

The invention provides a method for producing diesel fuel by using coal direct liquefication oil and delayed coking heavy diesel fuel fraction and application of the method. The method comprises the following steps of: a) mixing coal direct liquefication hydrogenation stabilization oil and the delayed coking heavy diesel fuel fraction; and b) performing hydrogenation modification on mixed oil obtained in the step a). A diesel fuel product produced by the method has a low condensation point, low content of sulfur, nitrogen and aromatic hydrocarbon, a high cetane value and a high lubricating property, and the quality of the product meets the standard of national IV diesel fuel; in addition, the delayed coking heavy diesel fuel fraction with higher sulfur content is mixed with the coal direct liquefication oil, so that the ratio of the content of S to the content of N in crude oil can reach 1:1-5:1; and the sulfur is not required to be additionally added into the crude oil, so that operation cost is reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

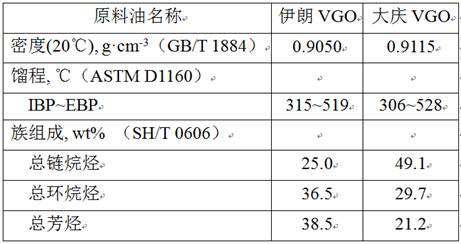

Hydrocracking method for producing chemical industry raw materials from diesel oil distillate

ActiveCN108003933AQuality improvementFang QiangaoHydrocarbon oil crackingTreatment with hydrotreatment processesChemical industryAlkane

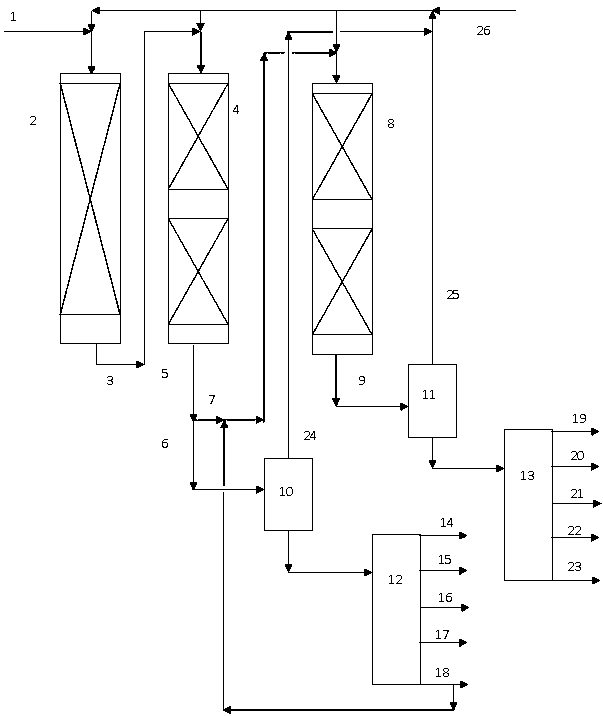

The present invention relates to the field of diesel oil processing, and discloses a hydrocracking method for producing chemical industry raw materials from diesel oil distillates. The hydrocracking method comprises: introducing diesel oil distillates into a hydrocracking reaction zone containing a hydrocracking catalyst, carrying out a hydrocracking reaction, and separating the reaction productsobtained after the hydrocracking reaction to obtain light naphtha, heavy naphtha and a tail oil distillate, wherein the chain alkane content in the diesel oil distillates is 20-50 wt%. According to the present invention, with the hydrocracking method, the chemical industrial raw material can be produced from the diesel oil distillate under the medium-low pressure condition, wherein the heavy naphtha can be used as the high-aromatic-potential-content reforming raw material, and the light naphtha and the tail oil can be used as the high-quality steam cracking raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

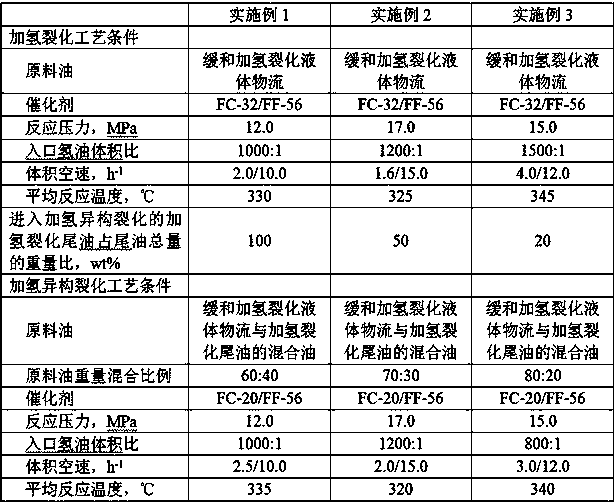

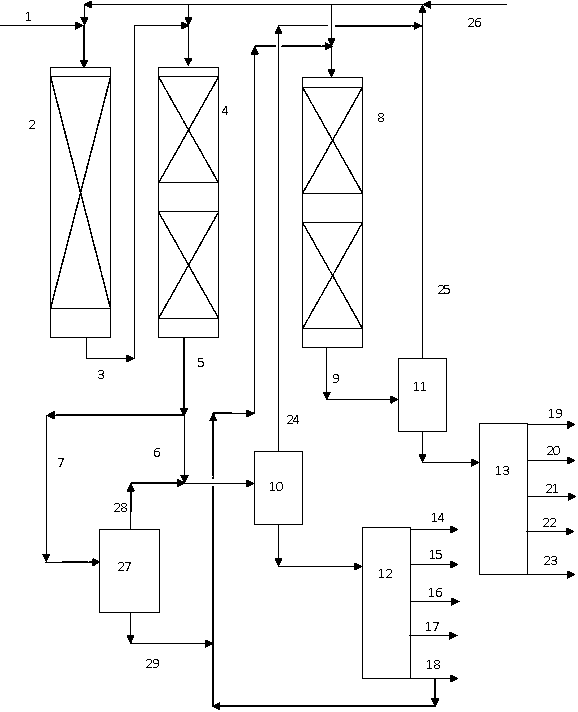

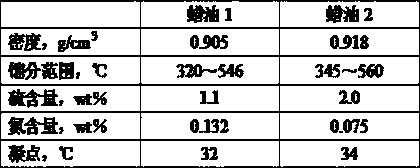

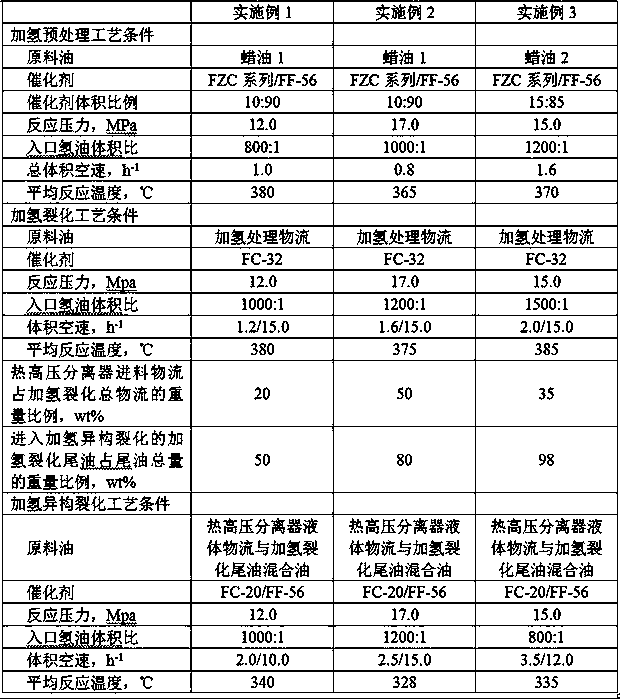

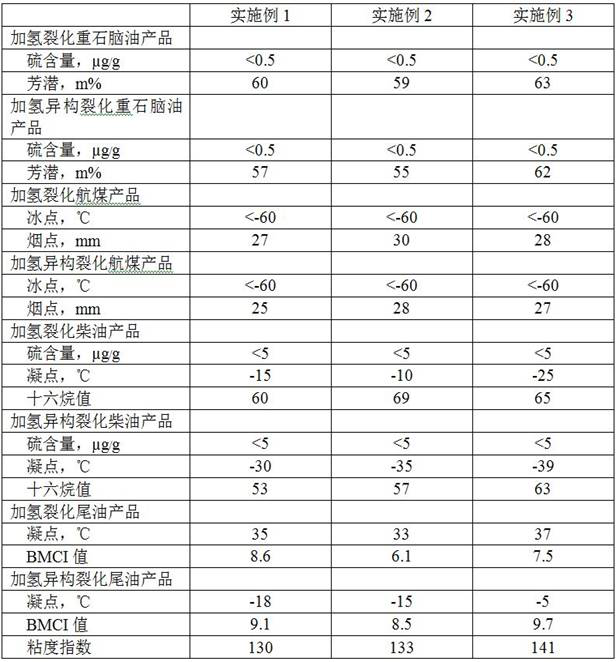

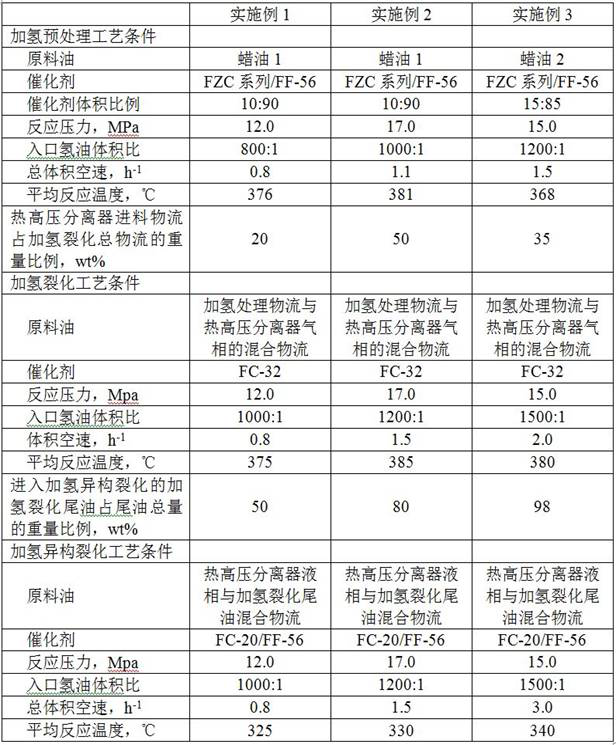

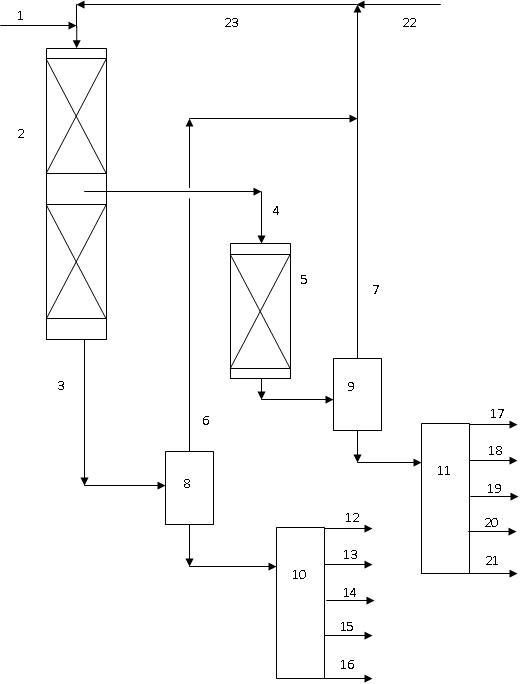

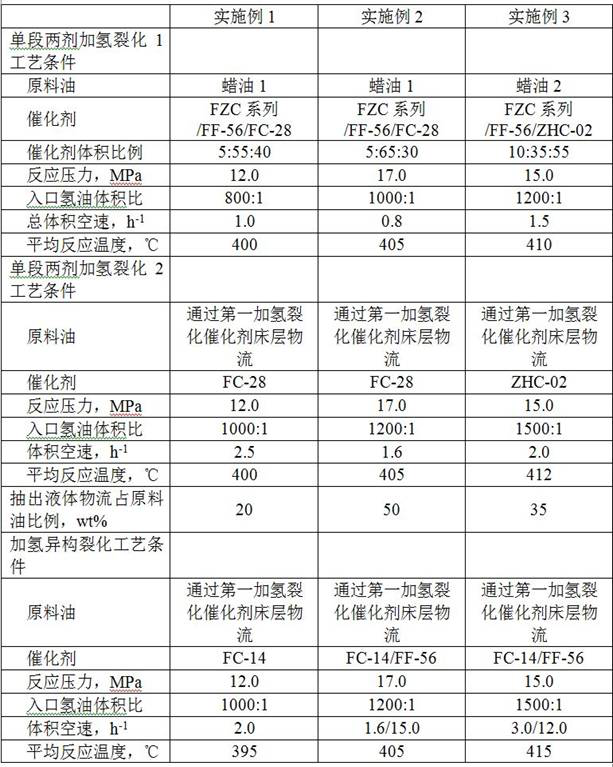

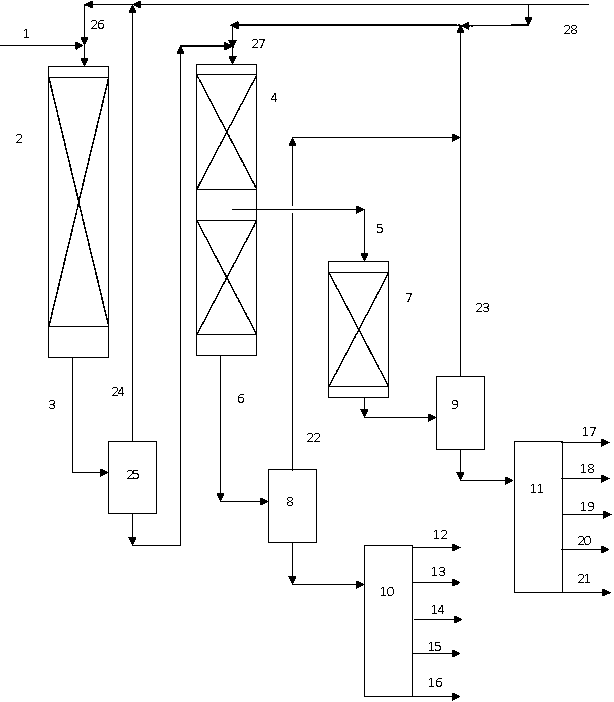

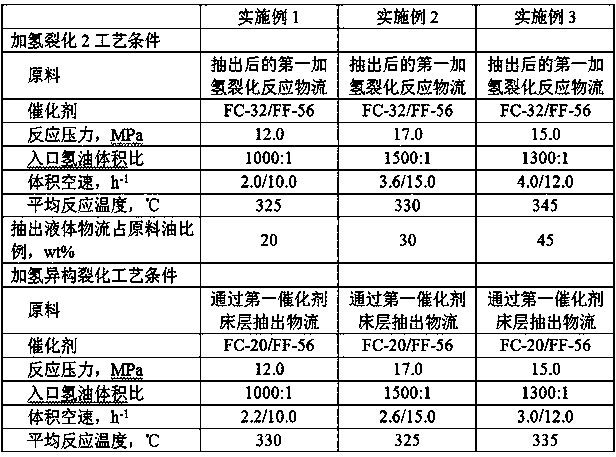

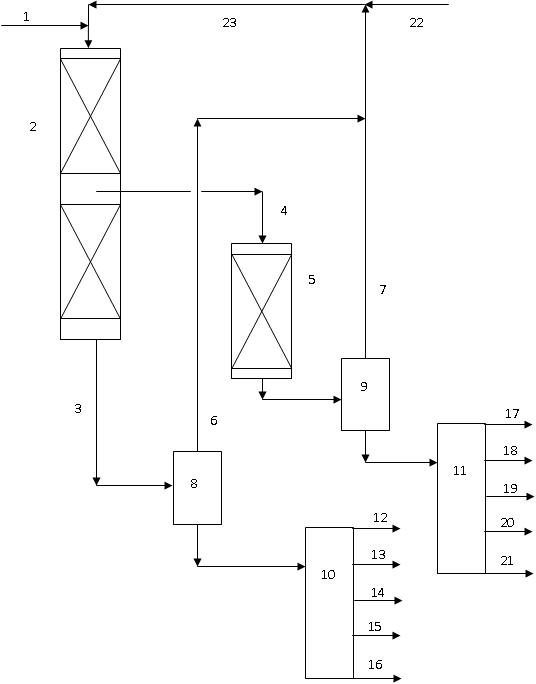

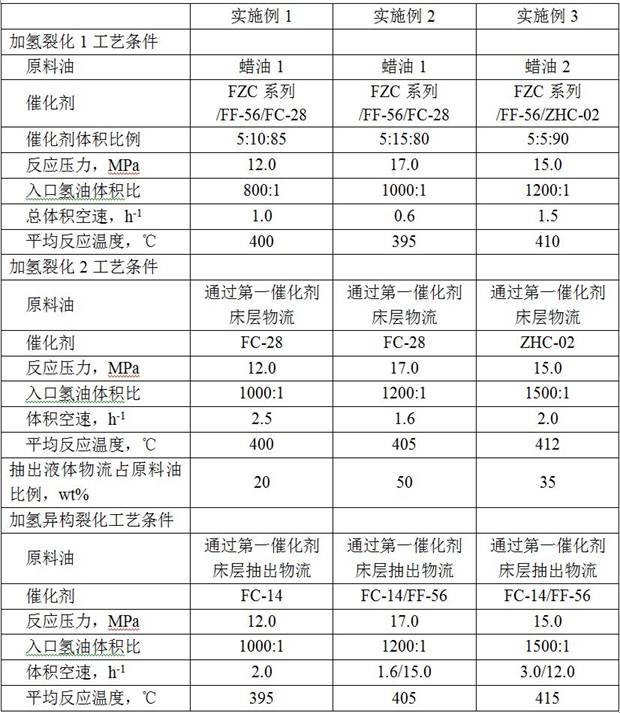

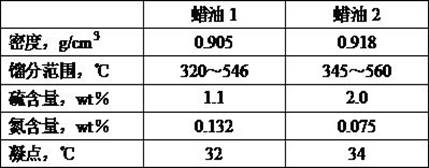

A hydrocracking process for flexibly producing diesel oil

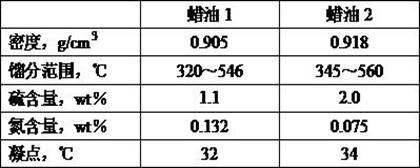

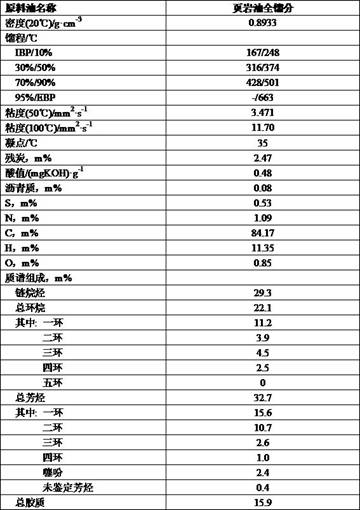

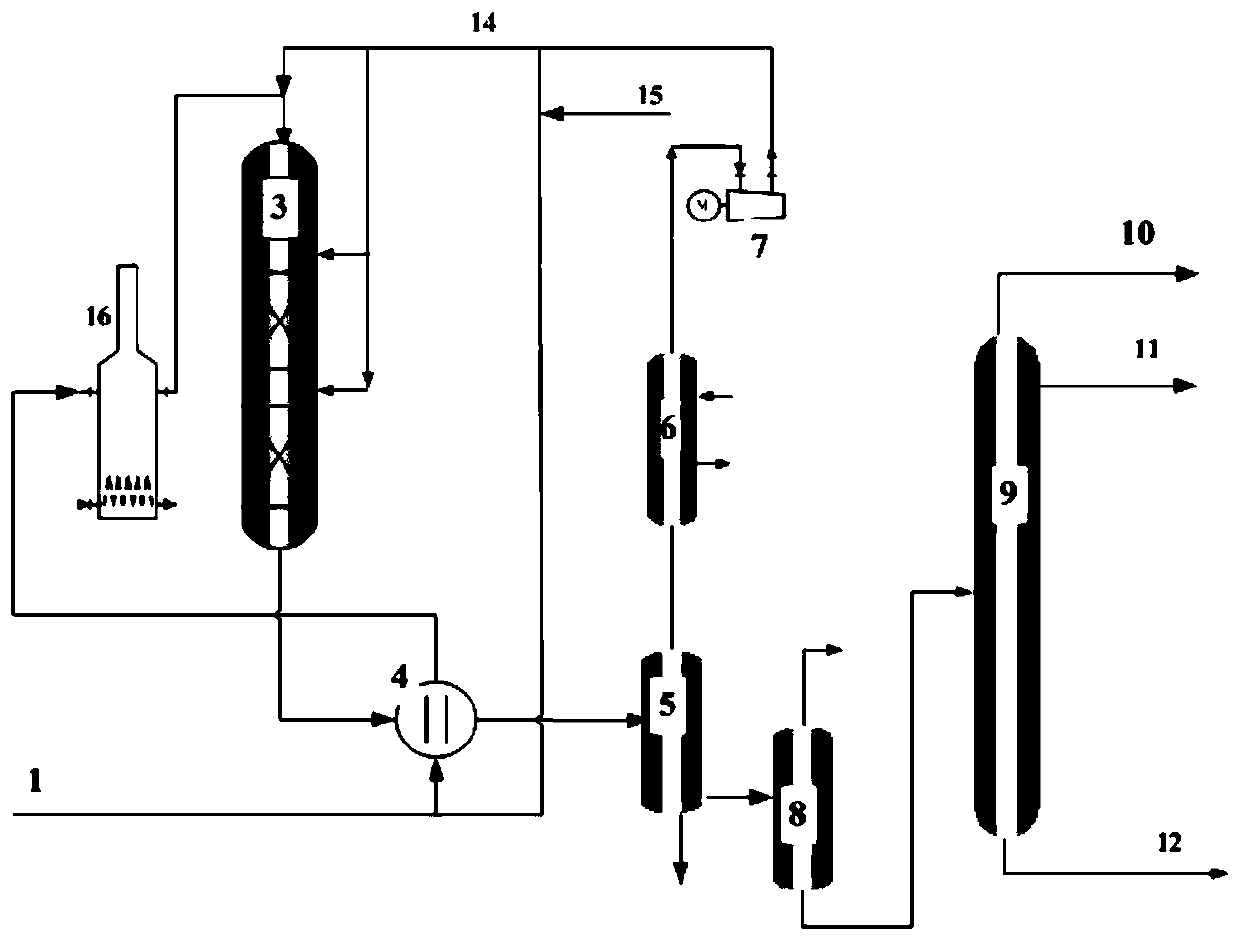

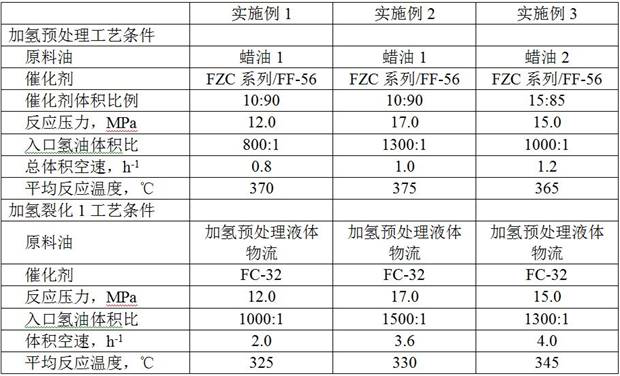

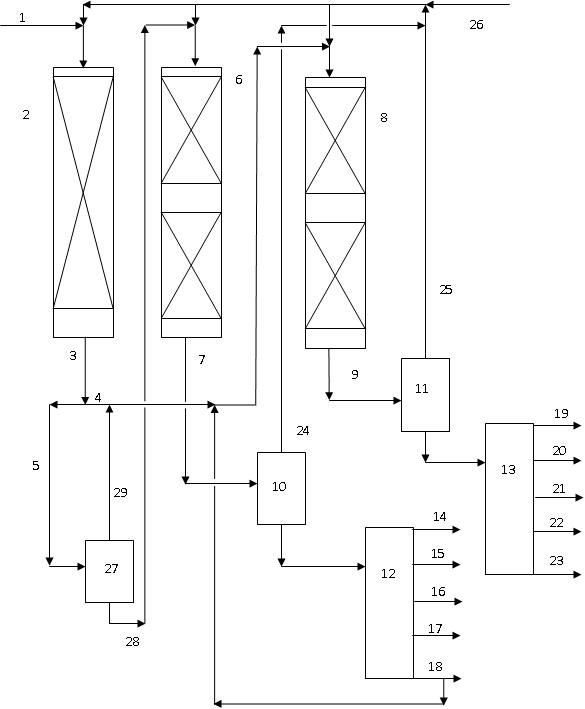

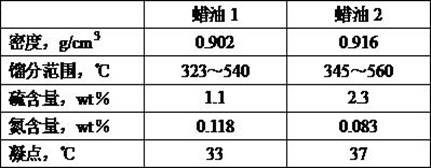

ActiveCN109988648ALower freezing pointHigh viscosity indexTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxChemistry

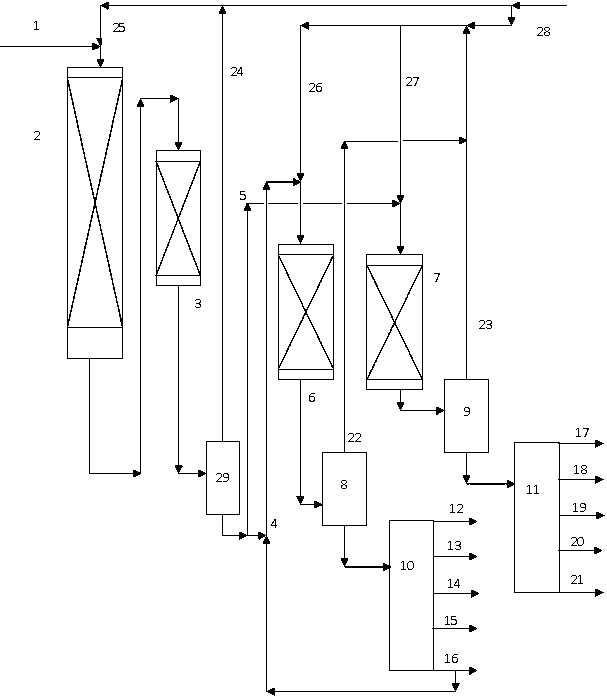

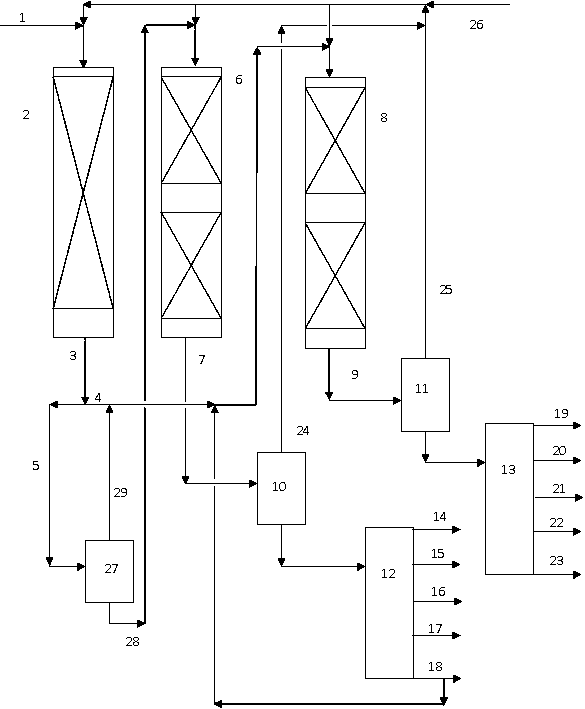

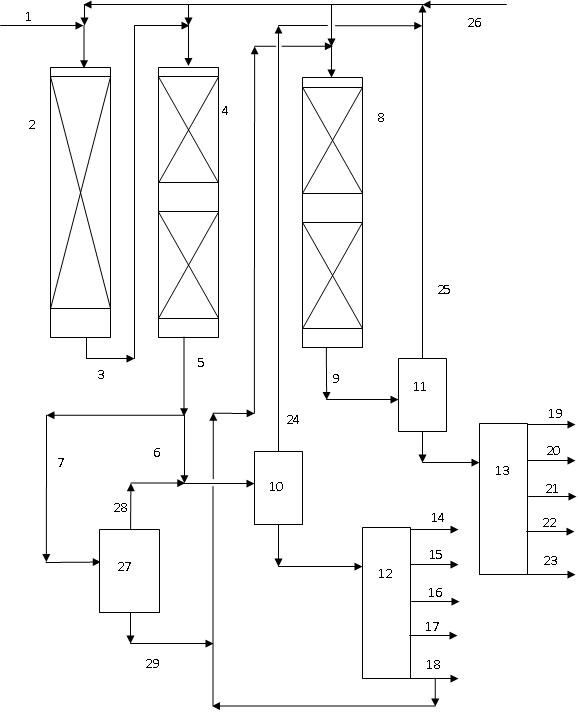

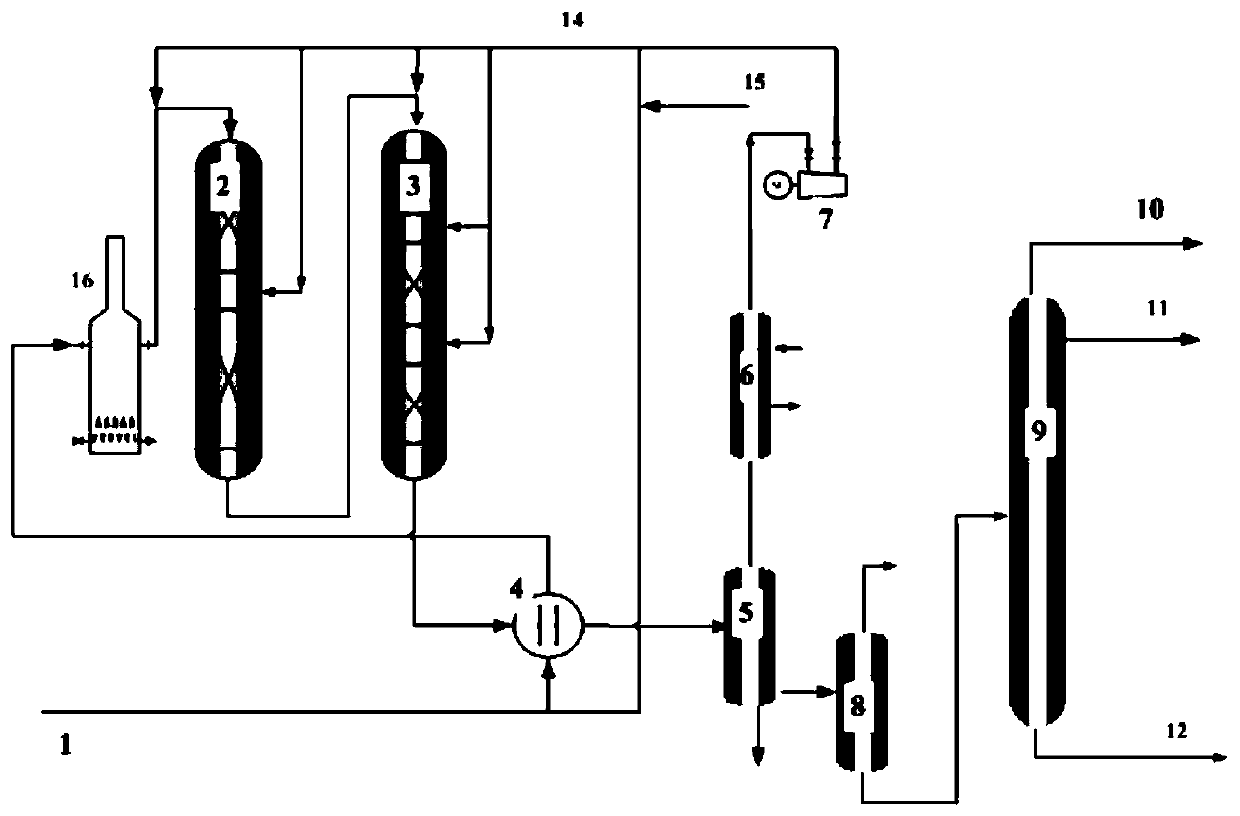

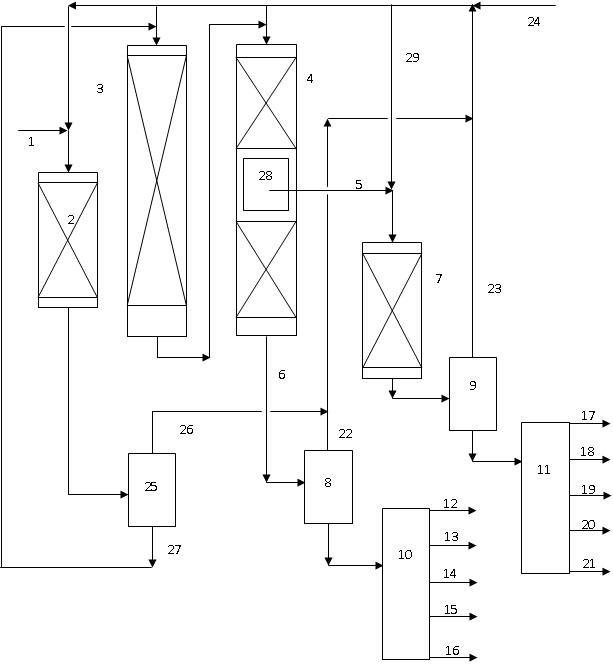

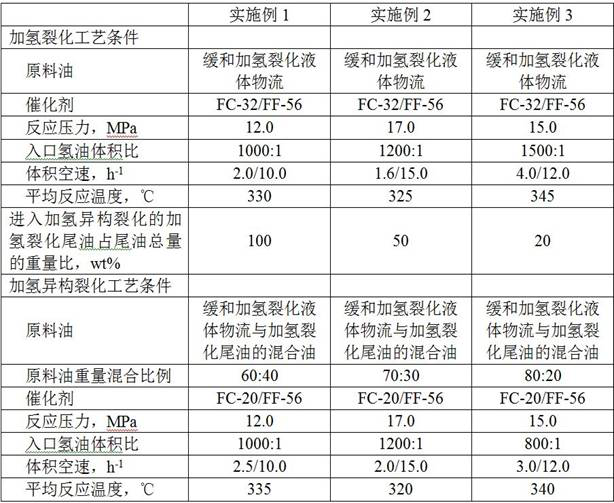

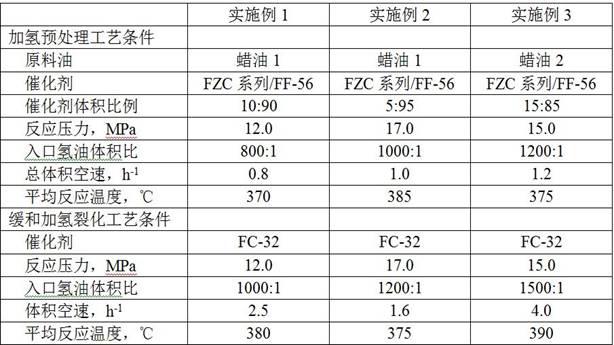

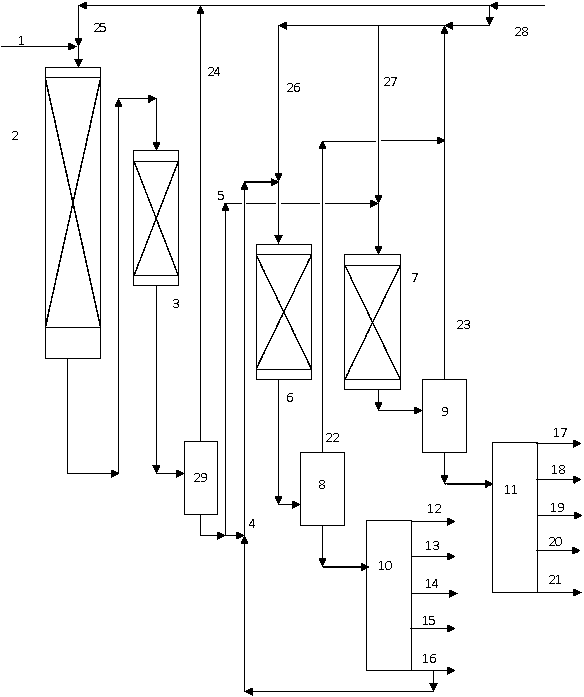

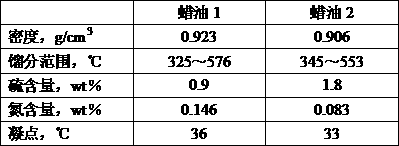

The invention discloses a hydrocracking process for flexibly producing diesel oil. A wax oil raw material is subjected to hydrogenation pretreatment and then enters a hydrocracking reactor, and a hydrocracked material passing through a hydrocracking catalyst bed layer is divided into two streams; one stream of the hydrocracked material is subjected to gas-liquid separation and fractionation to obtain naphtha, aviation kerosene, diesel oil and tail oil; and the other stream of the hydrocracked material is mixed with a part or all of hydrocracking tail oil, and the mixture is fed into a hydrogenation isomerization cracking reactor and subjected to isomerization cracking; and a hydrogenation isomerization cracking product is subjected to gas-liquid separation and fractionation to obtain naphtha, aviation kerosene, diesel oil and tail oil. The invention provides the process for simultaneously producing more than two types of aviation kerosene, diesel oil and tail oil products with different specifications on one set of hydrogenation process equipment, especially diesel oil products with different condensation points, heat carried by a part of cracked materials can be fully utilized, and coupling operation of the hydrocracking reactor and the hydrogenation isomerization cracking reactor can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

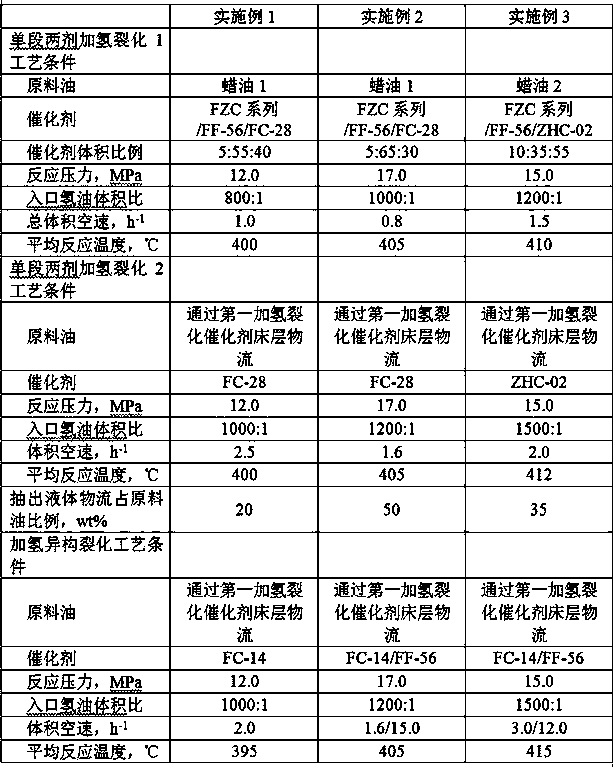

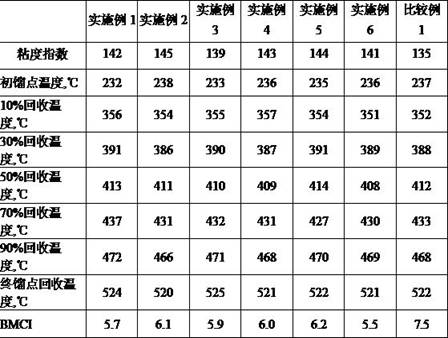

Flexible two-stage hydrocracking method

ActiveCN109988610AHigh normal hydrocarbon contentLow aromatic contentTreatment with hydrotreatment processesFractionationCracking reaction

The invention discloses a flexible two-stage hydrocracking method. A wax oil raw material enters a separation system after hydrogenation pretreatment and mild hydrocracking; a separated liquid phase without impurities is divided into two parts; one part of the liquid phase enters a hydrocracking reactor using a reduction state hydrocracking catalyst; the other part of the liquid phase and hydrocracking tail oil are mixed and enter a hydroisomerization cracking reactor using a reduction state hydroisomerization cracking catalyst; an obtained hydrocracking reaction material and an obtained hydroisomerization cracking reaction material are subjected to gas-liquid separation and fractionation respectively to obtain naphtha, aviation kerosene, diesel oil and tail oil products of different specifications. The invention provides the two-stage hydrocracking process for simultaneously producing more than two types of light naphtha, heavy naphtha, aviation kerosene, diesel oil and tail oil products with different specifications on one set of hydrogenation process equipment for the first time.

Owner:CHINA PETROLEUM & CHEM CORP +1

A cracking method aimed at producing more light olefins and light aromatics from feedstock oil containing many naphthenic rings

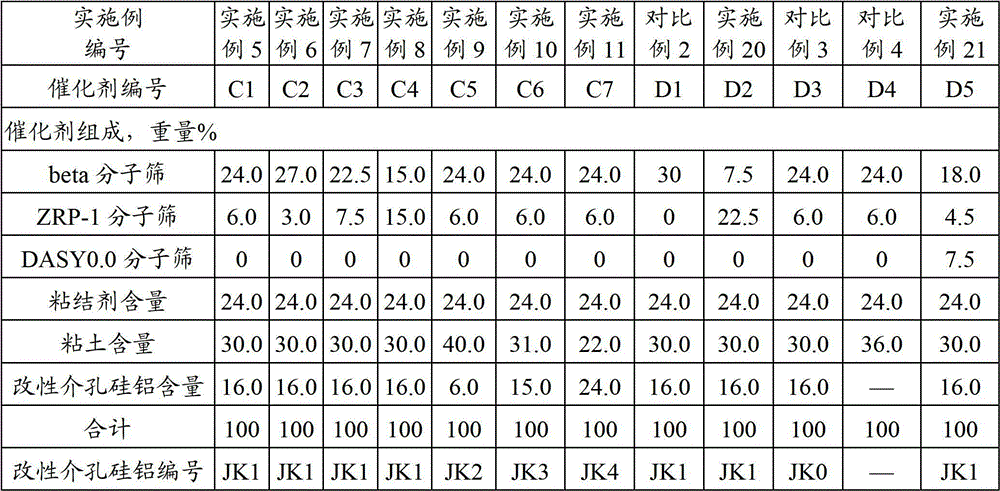

ActiveCN103509588BReduce yieldHigh yieldCatalytic crackingHydrocarbon by hydrocarbon crackingMolecular sieveGasoline

The invention discloses a method for cracking raw oil containing multi naphthenic rings to produce multi light olefins and light aromatic hydrocarbons and relates to a method for producing light olefins through a hydrocarbon oil raw material containing multi naphthenic rings. The method comprises: carrying out a haptoreaction on the hydrocarbon oil raw material containing multi naphthenic rings and a catalyst in a reactor, wherein the catalyst mainly comprises 5-35 wt% of heat resistant inorganic oxide, 0-65 wt% of clay, 5-50 wt% of modified mesoporous aluminosilicate material and 15-60 wt% of molecular sieve; and the molecular sieve comprises a beta molecular sieve and an MFI molecular sieve, and the weight ratio of the molecular sieve to the MFI molecular sieve is not less than 1 / 3. By adopting the method, the yield of propene and isobutene is high, and the BTX proportion in gasoline fraction aromatic hydrocarbon is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

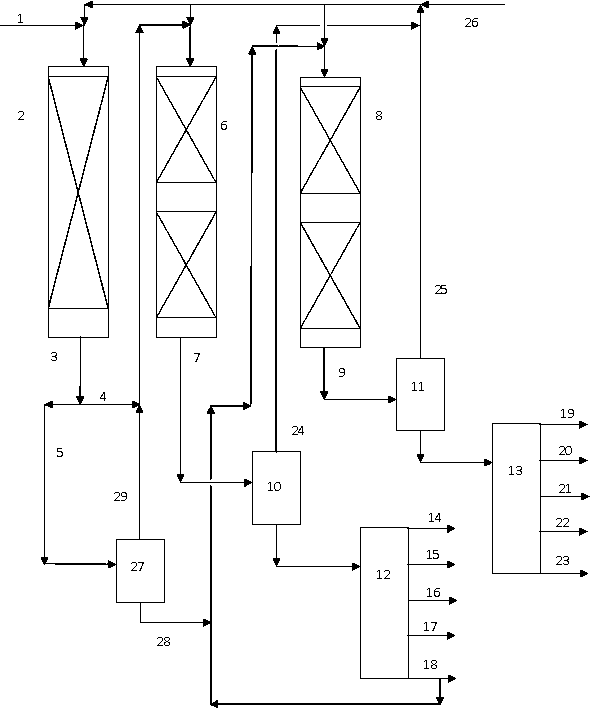

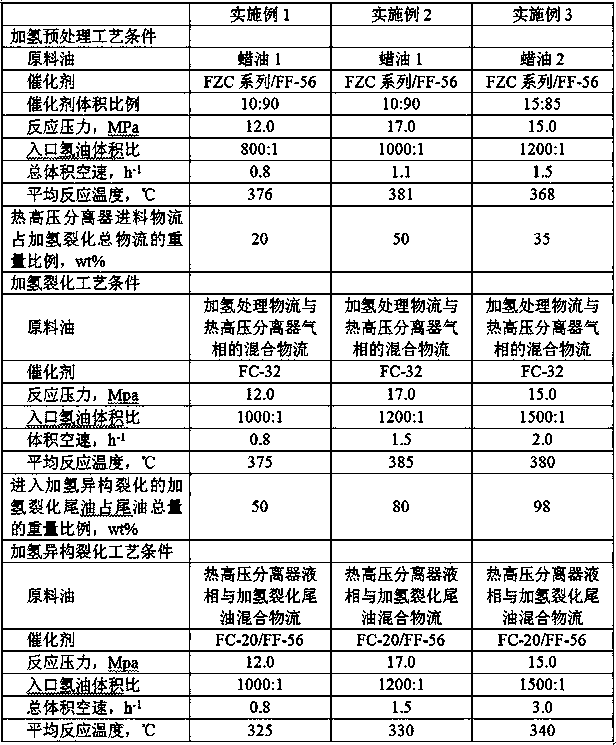

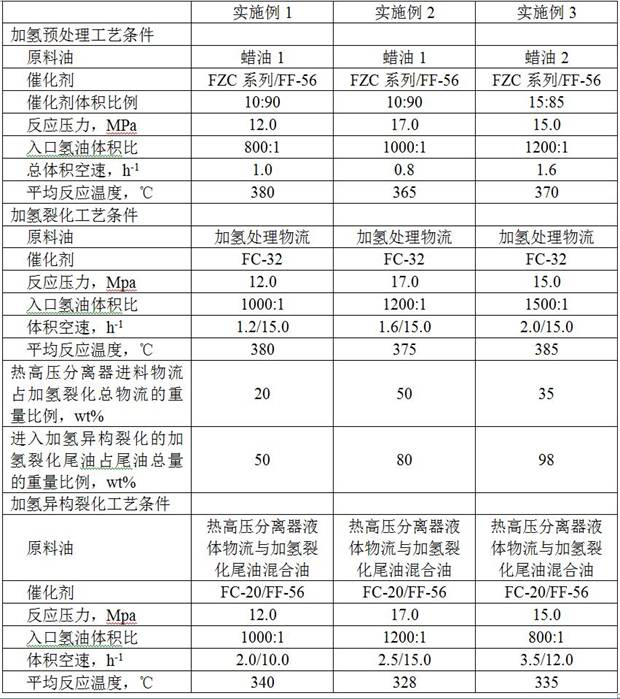

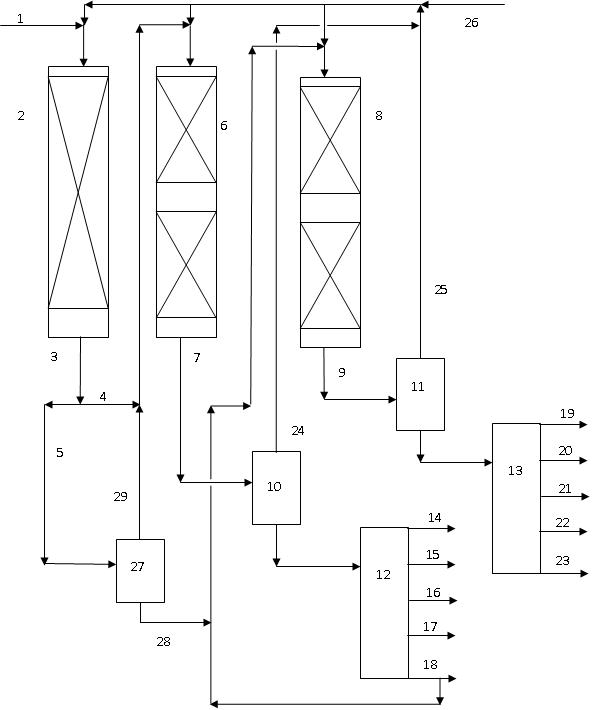

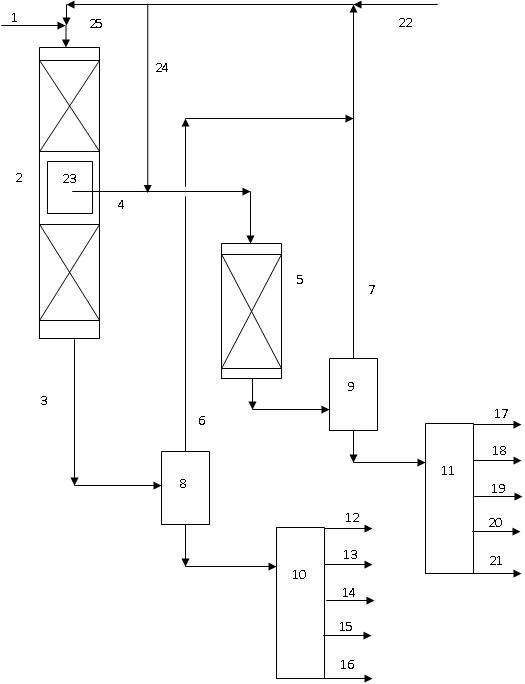

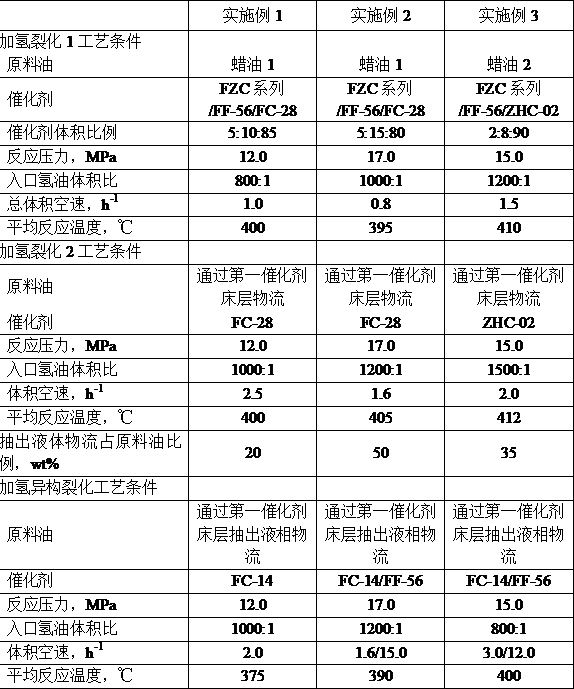

A flexible hydrocracking process for producing lubricant base oil

ActiveCN109988620AFlexible Hydrocracking ProcessFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsIsomerizationGas phase

The invention discloses a flexible hydrocracking process for producing lubricant base oil. A material obtained after a wax oil raw material is subjected to hydrogenation pretreatment is divided into two parts; a part of the material is separated by a hot high-pressure separator to obtain a liquid phase, and the liquid phase is mixed with hydrogen and then passes through a hydrocracking catalyst bed layer containing a Y-type molecular sieve; the other part of the material is mixed with a gas phase obtained by hot high-pressure separation and hydrocracking tail oil and then passes through a hydroisomerization cracking catalyst bed layer containing an isomerization cracking type molecular sieve; a hydrocracking reaction product and a hydroisomerization cracking reaction product are subjectedto gas-liquid separation and fractionation separately to obtain distillate oil and tail oil products with different specifications; and the hydrocracking tail oil is partially or completely circulatedinto the isomerization cracking reactor. The process provided by the invention can be used for simultaneously producing more than two kinds of naphtha, aviation kerosene, diesel oil and tail oil products with different specifications on one set of hydrogenation process equipment, especially producing high-quality lubricant base oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

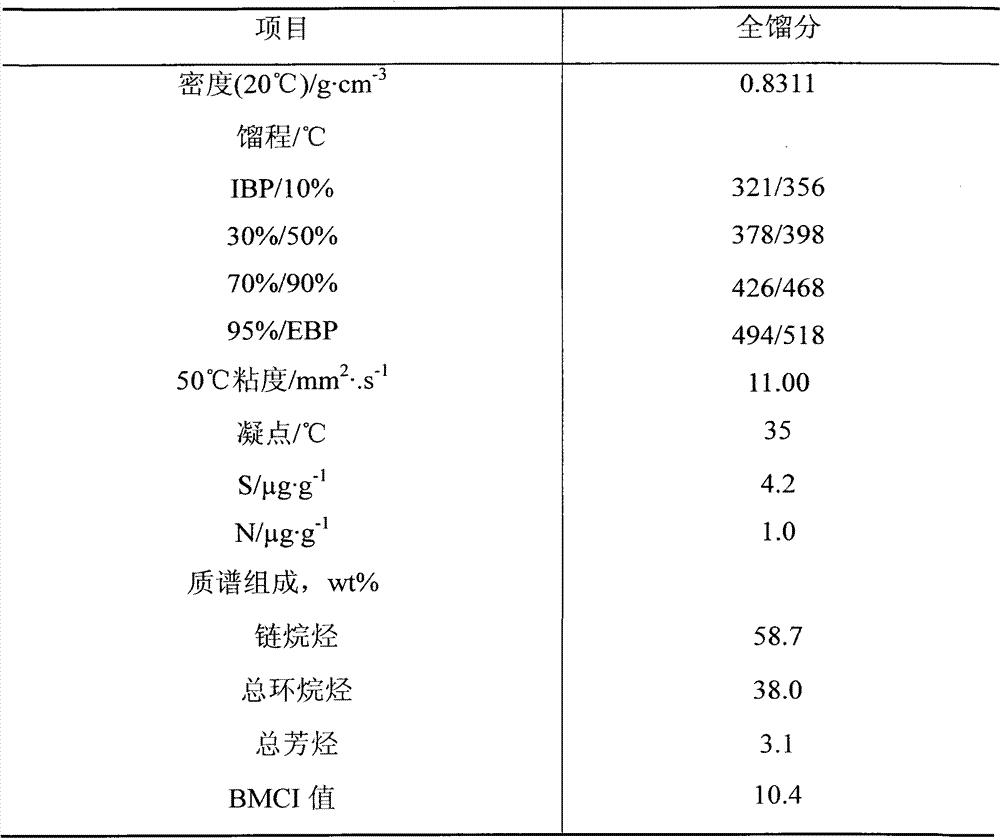

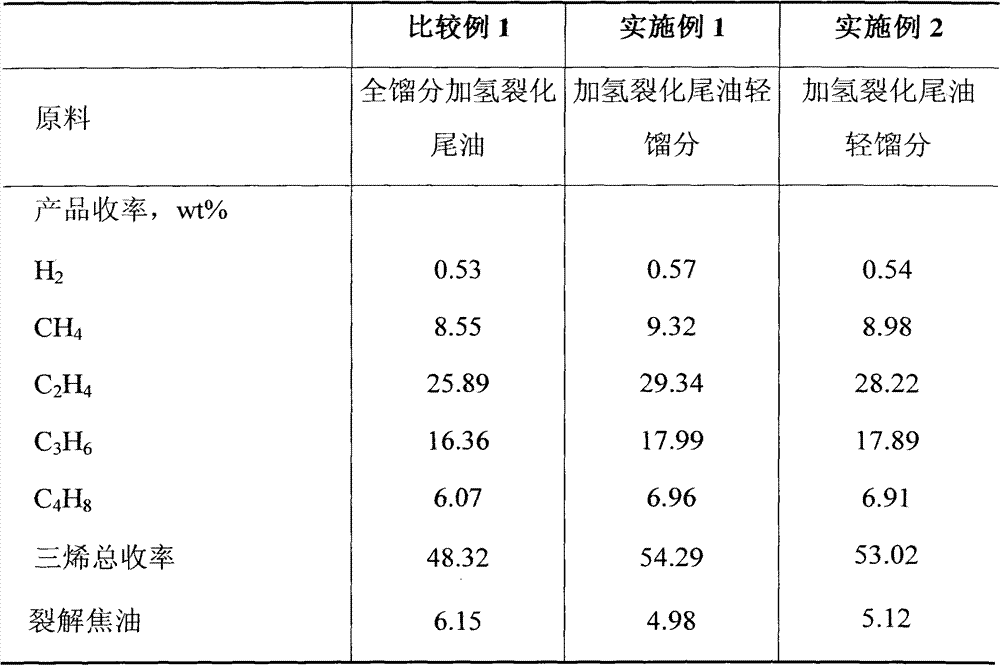

Comprehensive utilization method of hydrocracking tail oil

ActiveCN102041029BHigh in paraffinsLow aromatic contentThermal non-catalytic crackingOrganic chemistryEngineeringBase oil

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible hydrocracking method for producing lubricant base oil

ActiveCN109988642AHigh normal hydrocarbon contentHigh viscosity indexTreatment with hydrotreatment processesHydrocarbon oils treatment productsIsomerizationGas phase

The invention discloses a flexible hydrocracking method for producing lubricant base oil. The method includes dividing a wax oil raw material subjected to hydrogenation pretreatment into two parts; separating one part of the material by a hot high-pressure separator to obtain a gas phase and a liquid phase; mixing the other part of the material with the gas phase obtained by hot high-pressure separation and circulating hydrogen, and allowing the mixture to pass through a hydrocracking catalyst bed layer containing a Y-type molecular sieve; mixing the liquid phase obtained by hot high-pressureseparation with hydrocracking tail oil and circulating hydrogen, and allowing the mixture to pass through a hydroisomerization cracking catalyst bed layer containing an isomerization cracking type molecular sieve; respectively carrying out gas-liquid separation and fractionation on a hydrocracking reaction product and a hydroisomerization cracking reaction product to obtain distillate oil and tailoil products with different specifications; and partially or completely circulating the hydrocracking tail oil to an isomerization cracking reactor. The invention provides the flexible hydrocrackingmethod for simultaneously producing more than two kinds of naphtha, aviation kerosene, diesel oil and tail oil products with different specifications on a set of hydrogenation process equipment for the first time, especially high-quality lubricant base oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking Process for Flexible Diesel Production

ActiveCN109988611BFlexible productionHigh content of saturated hydrocarbonsTreatment with hydrotreatment processesHydrocarbon oils treatment productsThermodynamicsNaphtha

The invention discloses a hydrocracking process for flexibly producing diesel oil. After the wax oil raw material is pretreated by hydrogenation, it enters the hydrocracking reactor, and the obtained hydrocracking material is divided into two streams, one of which enters the hot high-pressure separator to separate the gas phase and liquid phase; the one that does not enter the high-pressure separator The hydrocracked material is mixed with the gas phase separated by the hot high-pressure separator for gas-liquid separation and fractionation to obtain hydrocracked naphtha, jet fuel, diesel oil and tail oil; the liquid phase separated by the hot high-pressure separator and / or After all the hydrocracking tail oil is mixed, continue to mix with hydrogen for hydroisomerization cracking reaction, and the hydroisomerization cracking material undergoes gas-liquid separation and fractionation to obtain hydroisomerization cracking naphtha, jet fuel, diesel oil and tail oil . The invention provides for the first time a hydrocracking process for simultaneously producing more than two types of jet fuel, diesel oil and tail oil products of different specifications, especially diesel oil with different freezing points, on a set of hydrogenation process equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible single-stage two-catalyst hydrocracking process

ActiveCN109988618AFlexible productionLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystIsomerization

The invention discloses a flexible single-stage two-catalyst hydrocracking process. A wax oil raw material and hydrogen are mixed and then enter a single-stage two-catalyst hydrocracking reactor, andthe material passing through an upper hydrogenation pretreatment catalyst bed layer and a single-stage hydrocracking catalyst bed layer is divided into two streams; one material stream is extracted out of the single-stage reactor from the middle of the bed layers, enters a hydroisomerization cracking reactor and subjected to isomerization cracking reaction; the other material stream flows downwards through a single-stage hydrocracking catalyst bed layer at the lower part; and a single-stage hydrocracking reaction product and a hydroisomerization cracking reaction product are respectively separated and fractionated to obtain distillate oil and tail oil products with different specifications. The invention provides the process for simultaneously producing more than two types of light naphtha, heavy naphtha, aviation kerosene, diesel oil and tail oil products with different specifications on a set of hydrogenation process equipment. In the process, heat carried by part of cracked materials can be fully utilized, and coupling operation of the single-stage two-catalyst hydrocracking reactor and the hydroisomerization cracking reactor is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking process for flexibly producing diesel oil

ActiveCN109988611ALower freezing pointIncreased isoparaffin contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxNaphtha

The invention discloses a hydrocracking process for flexibly producing diesel oil. A wax oil raw material is subjected to hydrogenation pretreatment and then enters a hydrocracking reactor; the obtained hydrocracked material is divided into two streams; one stream enters a hot high-pressure separator to be separated to obtain a gas phase and a liquid phase; one hydrocracked material stream which does not enter the high-pressure separator is mixed with the gas phase separated by the hot high-pressure separator, and the mixture is subjected to gas-liquid separation and fractionation to obtain hydrocracked naphtha, aviation kerosene, diesel oil and tail oil; the liquid phase obtained through separation by the hot high-pressure separator is mixed with a part or all of the hydrocracking tail oil and then mixed with hydrogen, the mixture is subjected to a hydroisomerization cracking reaction, and an obtained hydroisomerization cracking material is subjected to gas-liquid separation and fractionation to obtain hydroisomerization cracked naphtha, aviation kerosene, diesel oil and tail oil. The invention provides, for the first time, the hydrocracking process for simultaneously producing more than two aviation kerosene, diesel oil and tail oil products with different specifications on one set of hydrogenation process equipment, particularly diesel oil products with different condensation points.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible hydrocracking process for the production of lube base stocks

ActiveCN109988642BFlexible productionFang QiangaoTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sievePtru catalyst

The invention discloses a flexible hydrocracking method for producing lubricating oil base oil. The wax oil raw material after hydrogenation pretreatment is divided into two parts; one part of the material is separated by a hot high-pressure separator to obtain a gas phase and a liquid phase, and the other part of the material is mixed with a hot high-fraction gas phase and circulating hydrogen and passed through a hydrogenation system containing a Y-type molecular sieve. Cracking catalyst bed; after the hot high-resolution liquid phase is mixed with hydrocracking tail oil and circulating hydrogen, it passes through the hydroisomerization cracking catalyst bed containing isomerization cracking type molecular sieve; hydrocracking reaction product and hydroisomerization cracking The reaction products are subjected to gas-liquid separation and fractionation respectively to obtain distillate oil and tail oil of different specifications, and part or all of the hydrocracking tail oil is recycled into the isomerization cracking reactor. The present invention provides for the first time a flexible hydrocracking method for simultaneously producing two or more different specifications of naphtha, aviation fuel, diesel oil, and tail oil products, especially high-quality lubricating oil base oil, on a set of hydrogenation process equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method

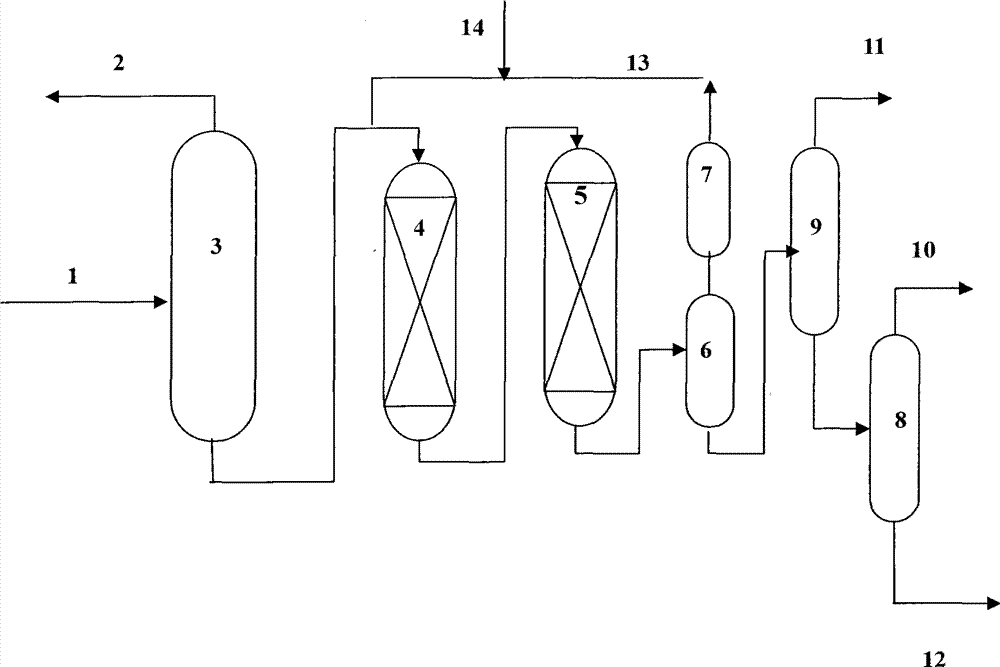

ActiveCN114437799ASimple processEasy to operateTreatment with hydrotreatment processesFluid phasePhysical chemistry

The invention discloses a hydrocracking method. The method comprises the following steps: (1) high-nitrogen raw oil and hydrogen are mixed and enter a hydrogenation pretreatment reaction zone for reaction; (2) carrying out heat exchange on the reaction effluent in the step (1) or a liquid phase separated from the reaction flow in the step (1), and then, carrying out reaction in a hydrofining reaction zone; (3) effluent of the hydrofining reaction zone in the step (2) enters a hydrocracking reaction zone for hydrocracking reaction, the outlet temperature of the hydrofining reaction zone is T1, the inlet temperature of the hydrocracking reaction zone is T2, T1-T2 = T, and T is controlled to be greater than 5 DEG C; and (4) treating the reaction effluent in the step (3) through a separator to obtain different products. The method can be used for directly processing the full-fraction shale oil, and can run for a long period to produce high-quality diesel oil and gasoline by adopting a once-through process flow.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible single-stage two-agent hydrocracking process

ActiveCN109988618BFlexible productionLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsThermodynamicsNaphtha

The invention discloses a flexible single-stage two-agent hydrocracking process. The wax oil raw material is mixed with hydrogen and enters the single-stage two-component hydrocracking reactor. The material after passing through the upper hydrogenation pretreatment catalyst and the single-stage hydrocracking catalyst bed is divided into two streams; one stream of material is drawn out from the middle of the bed. stage reactor, enters the hydroisomerization cracking reactor for isomerization cracking reaction; another stream of material continues to flow down through the lower single-stage hydrocracking catalyst bed; the single-stage hydrocracking reaction material and hydroisomerization cracking The reaction materials are separated and fractionated separately to obtain distillate oil and tail oil products of different specifications. The invention provides a single-stage two-dose hydrocracking process for simultaneously producing two or more different specifications of light naphtha, heavy naphtha, jet fuel, diesel oil, and tail oil products on a set of hydrogenation process equipment, which can fully Using the heat carried by part of the cracked material, the coupling operation of the single-stage two-component hydrocracking reactor and the hydroisomerization cracking reactor is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible Hydrocracking Process

ActiveCN109988621BEffective distributionFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaPtru catalyst

The invention discloses a flexible hydrocracking process. After hydrogenation pretreatment, the wax oil raw material enters the hydrocracking reactor, and the material after passing through the first hydrocracking catalyst bed is divided into two streams; one stream of material is separated, and the obtained liquid is pumped out of the hydrocracking reactor and mixed with hydrogen Then enter the hydroisomerization cracking reactor for isomerization cracking reaction; another stream of material mixture continues to flow downward through the second hydrocracking catalyst bed; the obtained hydrocracking reaction product and hydroisomerization cracking reaction product respectively Carry out gas-liquid separation and fractionation to obtain naphtha, jet fuel, diesel and tail oil products of different specifications. The present invention provides for the first time a hydrocracking process for simultaneous production of two or more different specifications of light naphtha, heavy naphtha, jet fuel, diesel, and tail oil products on a set of hydrogenation process equipment, which can make full use of partial cracking The heat carried by the material realizes the coupled operation of the hydrocracking reactor and the hydroisomerization cracking reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

A hydrocracking method for producing chemical raw materials from diesel fractions

ActiveCN108003933BFang QiangaoHigh in paraffinsHydrocarbon oil crackingTreatment with hydrotreatment processesChemical industryOil processing

The present invention relates to the field of diesel oil processing, and discloses a hydrocracking method for producing chemical industry raw materials from diesel oil distillates. The hydrocracking method comprises: introducing diesel oil distillates into a hydrocracking reaction zone containing a hydrocracking catalyst, carrying out a hydrocracking reaction, and separating the reaction productsobtained after the hydrocracking reaction to obtain light naphtha, heavy naphtha and a tail oil distillate, wherein the chain alkane content in the diesel oil distillates is 20-50 wt%. According to the present invention, with the hydrocracking method, the chemical industrial raw material can be produced from the diesel oil distillate under the medium-low pressure condition, wherein the heavy naphtha can be used as the high-aromatic-potential-content reforming raw material, and the light naphtha and the tail oil can be used as the high-quality steam cracking raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible two-stage hydrocracking process

ActiveCN109988626AEffective distributionFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxIsomerization

The invention discloses a flexible two-stage hydrocracking process. A wax oil raw material is subjected to hydrogenation pretreatment and then enters a separation system, an obtained liquid phase without impurities enters a hydrocracking reactor containing a reduction state hydrocracking catalyst, and an obtained first hydrocracked material is divided into two streams; one material stream is extracted out of the hydrocracking reactor through the middle of a bed layer and enters an isomerization cracking reactor containing a reduction state hydroisomerization cracking catalyst for reaction; theother material stream flows through a hydrocracking catalyst bed layer at the lower part; and an obtained hydrocracking reaction material and an obtained hydroisomerization cracking reaction materialare subjected to gas-liquid separation and fractionation separately to obtain distillate oil and tail oil products with different specifications. The invention provides the hydrocracking process forsimultaneously producing more than two distillate oil and tail oil products with different specifications on one set of hydrogenation equipment for the first time, heat carried by part of cracked materials can be fully utilized, and coupling operation of the hydrocracking reactor and the hydroisomerization cracking reactor can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible hydrocracking process

ActiveCN109988640BEffective distributionFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaPtru catalyst

The invention discloses a flexible hydrocracking process. After the wax oil raw material is pretreated by hydrogenation, it enters the hydrocracking reactor, and the material passing through the upper hydrocracking catalyst bed is divided into two strands; one strand of material is extracted from the hydrocracking reactor through the middle of the bed, and enters the hydrocracking reactor. The isomerization cracking reactor carries out the isomerization cracking reaction; another stream of material continues to flow downward through the lower hydrocracking catalyst bed; the obtained hydrocracking reaction material and hydroisomerization cracking reaction material are subjected to gas-liquid separation and fractionation respectively Get different specifications of naphtha, jet fuel, diesel and tail oil products. The present invention provides for the first time a hydrocracking process for simultaneously producing two or more different specifications of light naphtha, heavy naphtha, jet fuel, diesel oil, and tail oil products on a set of hydrogenation process equipment, which can make full use of partial cracking The heat carried by the material realizes the coupled operation of the hydrocracking reactor and the hydroisomerization cracking reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible two-stage hydrocracking process

ActiveCN109988607BEffective distributionFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaPtru catalyst

The invention discloses a combined process of hydrotreating and hydrocracking. The wax oil raw material passes through the first hydrogenation pretreatment catalyst bed, and the obtained material is divided into two streams; one stream of material is drawn out of the hydrogenation pretreatment reactor through the middle of the bed, and mixed with LCO to pass through the hydrotreatment reactor, and the hydrotreatment stream Carry out gas-liquid separation and fractional distillation to obtain catalytic cracking raw materials; another stream of material continues to pass through the second hydrogenation pretreatment catalyst bed, and the hydrogenation pretreatment stream passes through the hydrocracking catalyst bed for hydrocracking reaction, and the obtained hydrocracking reaction The material is subjected to gas-liquid separation and fractional distillation to obtain hydrocracking products such as naphtha, jet fuel, diesel oil and tail oil. The present invention provides for the first time a combined hydrogenation process for simultaneous production of hydrocracking light products and catalytic cracking raw materials on a set of hydrogenation process equipment, which can make full use of the heat carried by the hydrogenation pretreatment material to realize hydrogenation pretreatment Coupling operation of treatment reactor and hydrotreating reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible hydrocracking process for the production of lube base stocks

ActiveCN109988620BFlexible productionFang QiangaoTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sievePtru catalyst

The invention discloses a flexible hydrocracking process for producing lubricating oil base oil. The wax oil raw material after hydrogenation pretreatment is divided into two parts; one part of the material is separated by a hot high-pressure separator to obtain a liquid phase, and after being mixed with hydrogen, it passes through a hydrocracking catalyst bed containing Y-type molecular sieve; After the gas phase and hydrocracking tail oil are mixed, they pass through the hydroisomerization cracking catalyst bed containing isomerization cracking type molecular sieve; Standard distillate oil and tail oil; part or all of the hydrocracking tail oil is recycled into the isomerization cracking reactor. The process of the present invention can simultaneously produce more than two kinds of naphtha, aviation fuel, diesel oil and tail oil products of different specifications on a set of hydrogenation process equipment, especially high-quality lubricating oil base oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

A hydrocracking method for producing middle distillate oil and paraffin-rich tail oil

The invention discloses a hydro-cracking method for producing middle distillate and tail oil rich in chain alkane. The method comprises the following steps: mixing raw material oil with hydrogen gas, subjecting the mixture to orderly contact with a hydro-refining catalyst and a hydro-cracking catalyst to carry out reactions, and subjecting the reaction product to processes of separation and fractionation so as to obtain the following components: gas rich in hydrogen, a naphtha fraction, a kerosene fraction, a diesel oil fraction, and a tail oil fraction; wherein the tail oil fraction is totally extracted, or part of the tail oil fraction is recycled and returned to the reaction system. By adopting the method provided by the invention, heavy fraction oil can be processed, the output of the middle distillate is increased, and at the same time high quality tail oil with a high content of chain alkane is produced. Compared to the prior art, the hydro-cracking method has the advantages of good selectivity and high yield of middle distillate and high chain alkane content and viscosity index of tail oil, and the middle distillate and tail oil are suitable for being taken as high-quality raw materials for steam cracking method for producing ethylene or lubricant basic oil production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible shale oil hydrocracking process

ActiveCN109988641BReduce the impactExtended service lifeTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystNaphtha

The invention discloses a flexible shale oil hydrocracking process. After the shale oil raw material is subjected to hydrocracking pretreatment, gas-liquid separation is carried out. The separated liquid phase first passes through the hydrocracking pretreatment reactor, and then continues to enter the hydrocracking reactor, and passes through the first hydrocracking catalyst bed. The material is divided into two streams; one stream of material is obtained through the gas-liquid separator in the middle of the bed to obtain the liquid phase, and then extracted from the hydrocracking reactor, which enters the hydroisomerization cracking reactor for isomerization cracking reaction; after the liquid phase is drawn out, the The material continues to flow downward through the second hydrocracking catalyst bed; the hydrocracking reaction material and the hydroisomerization cracking reaction material are subjected to gas-liquid separation and fractionation respectively to obtain naphtha, aviation kerosene, diesel oil and tail oil products. The invention provides for the first time a hydrocracking process for simultaneous production of two or more different specifications of light naphtha, heavy naphtha, jet fuel, diesel oil and tail oil products on a set of hydrogenation process equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible single-stage hydrocracking process

ActiveCN109988636BFlexible productionLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsThermodynamicsNaphtha

The invention discloses a flexible single-stage hydrocracking process. The wax oil raw material is mixed with hydrogen and enters the single-stage hydrocracking reactor. After passing through the upper single-stage hydrocracking catalyst bed, the material is divided into two streams; The hydrocracking reactor and hydrogen enter the hydroisomerization cracking reactor for isomerization cracking reaction; the other material is a gas-liquid mixture flow, and the mixture flow continues to flow down through the lower single-stage hydrocracking catalyst bed; single-stage The hydrocracking reaction material and the hydroisomerization cracking reaction material are subjected to gas-liquid separation and fractionation respectively to obtain naphtha, aviation kerosene, diesel oil and tail oil products of different specifications. The invention provides a single-stage hydrocracking process for simultaneously producing two or more distillate oil products of different specifications on a set of hydrogenation devices, which can fully utilize the heat carried by partly cracked materials to realize a single-stage hydrocracking reactor Coupling operation with hydroisomerization cracking reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

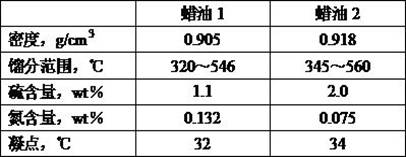

Wax oil processing method

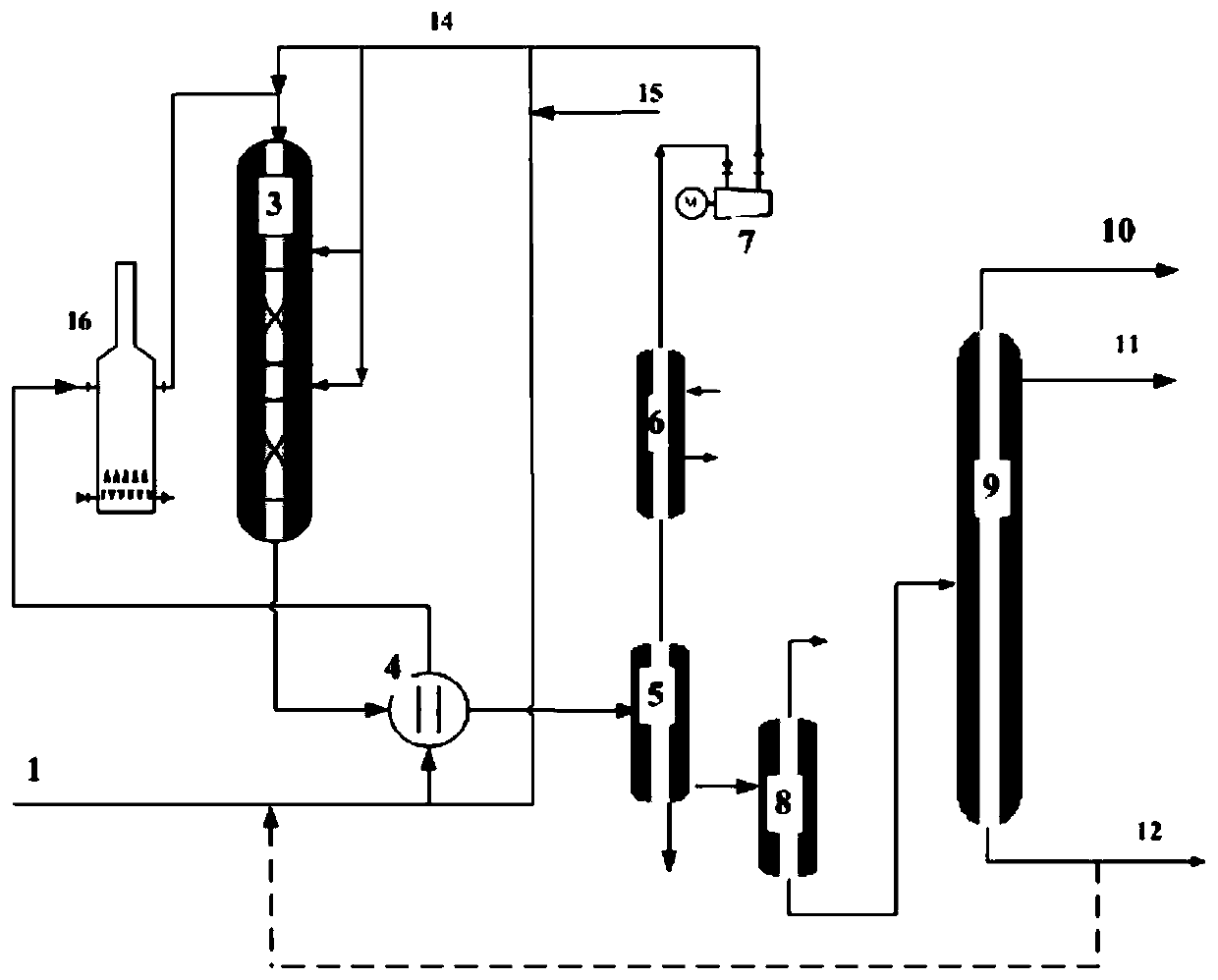

ActiveCN114736709AHigh in paraffinsSolve the shortageTreatment with hydrotreatment processesBio-feedstockOil processingWax

The invention discloses a wax oil processing method which comprises the following steps: (1) separating a wax oil fraction to generate a wax oil fraction rich in saturated components and a wax oil fraction rich in unsaturated components; (2) the wax oil fraction rich in saturated components enters a hydrofining reaction zone A and a hydrocracking reaction zone B for a reaction, and products are separated to obtain a naphtha fraction, an aviation kerosene fraction, a diesel oil fraction and a high-viscosity index tail oil fraction; and (3) allowing the wax oil fraction rich in unsaturated components to enter a hydrofining reaction zone C and a hydrocracking reaction zone D for a reaction, and separating a product to obtain a naphtha fraction, an aviation fuel fraction and a diesel fraction optionally. The method can be used for producing high-added-value products such as high-viscosity-index lubricating oil basic raw materials and high-grade special oil products, and the utilization rate of the wax oil fraction and the added value of the products are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

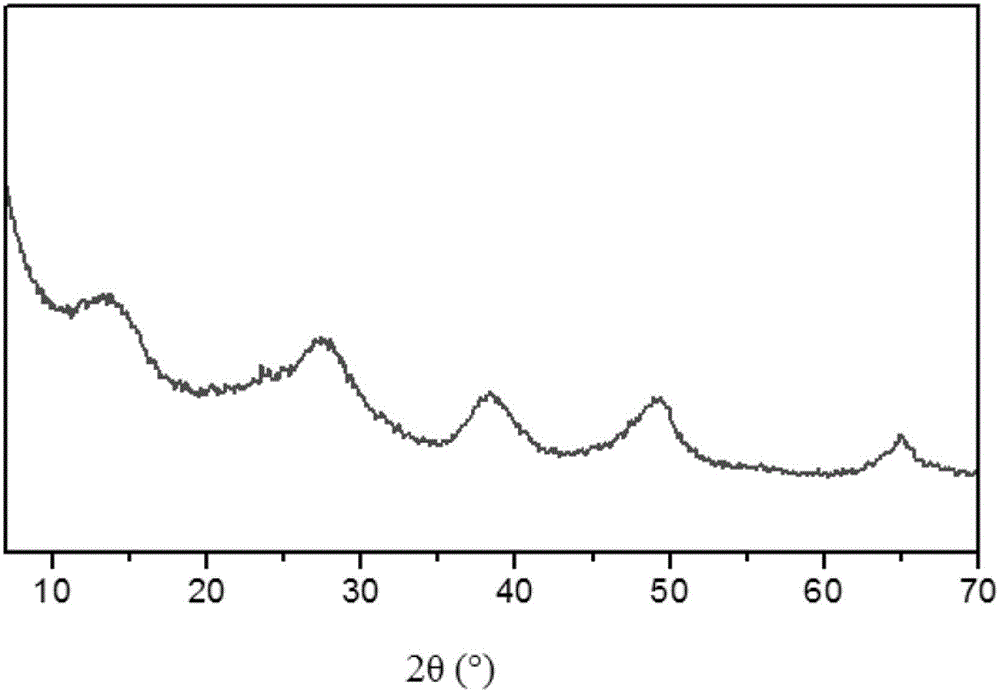

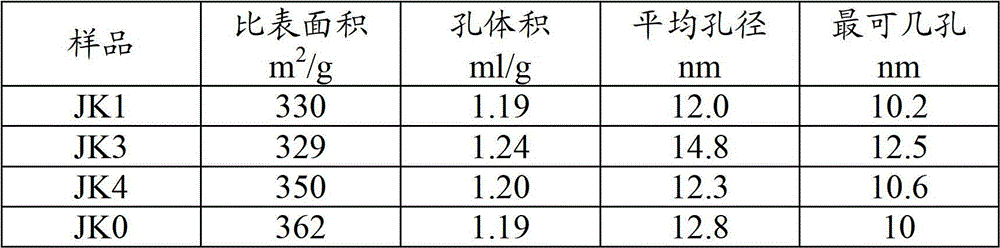

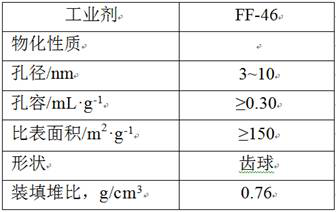

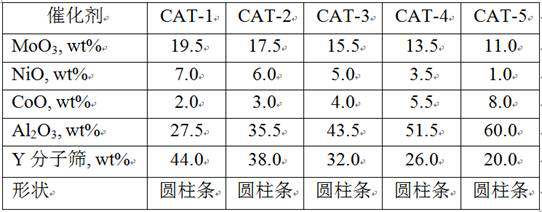

Grading method of hydrocracking catalyst

PendingCN114686256AHigh selectivity of adsorptionHigh aromatic contentMolecular sieve catalystsHeterogenous catalyst chemical elementsMolecular sievePtru catalyst

The invention discloses a grading method of a hydrocracking catalyst. Raw oil and hydrogen enter a hydrofining reaction zone together, and a hydrofining reaction effluent directly enters a hydrocracking reactor without being separated and is sequentially subjected to contact reaction with more than two hydrocracking catalyst bed layers; wherein the mass fraction of NiO is reduced, the mass fraction of CoO is increased, the mass fraction of MoO3 is reduced, the mass fraction of total active metal oxide is reduced and the molecular sieve content is reduced in comparison with the downstream catalyst bed layer and the adjacent upstream catalyst bed layer along the material flow direction. According to the method disclosed by the invention, through reasonable grading of hydrocracking catalysts of different bed layers, the hydrocracking reaction temperature is reduced under the condition of the same conversion rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible hydrocracking process

ActiveCN109988640AHigh normal hydrocarbon contentLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxIsomerization

The invention discloses a flexible hydrocracking process. A wax oil raw material is subjected to hydrogenation pretreatment and then enters a hydrocracking reactor, and the material passing through anupper hydrocracking catalyst bed layer is divided into two streams; one material stream is extracted out of the hydrocracking reactor through the middle of the bed layer and enters a hydroisomerization cracking reactor for an isomerization cracking reaction; the other material stream flows downwards through a hydrocracking catalyst bed layer at the lower part; and an obtained hydrocracking reaction material and an obtained hydroisomerization cracking reaction material are subjected to gas-liquid separation and fractionation separately to obtain naphtha, aviation kerosene, diesel oil and tailoil products with different specifications. The invention provides the hydrocracking process for simultaneously producing more than two different-specification light naphtha, heavy naphtha, aviation kerosene, diesel oil and tail oil products on one set of hydrogenation process equipment for the first time, heat carried by part of cracked materials can be fully utilized, and coupling operation of the hydrocracking reactor and the hydroisomerization cracking reactor can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible two-stage hydrocracking process

ActiveCN109988610BEffective distributionFlexible productionTreatment with hydrotreatment processesPtru catalystNaphtha

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible two-stage hydrocracking process

ActiveCN109988617AHigh normal hydrocarbon contentLow aromatic contentTreatment with hydrotreatment processesWaxNaphtha

The invention discloses a flexible two-stage hydrocracking process. A wax oil raw material is subjected to hydrogenation pretreatment and mild hydrocracking and then enters a separation system; the separated liquid phase is divided into two parts; one part of the liquid phase enters a hydrocracking reactor using a sulfided hydrocracking catalyst; the other part of the liquid phase is mixed with hydrocracking tail oil, and the mixture is fed into a hydroisomerization cracking reactor using a sulfurized hydroisomerization cracking catalyst; and an obtained hydrocracking reaction material and anobtained hydroisomerization cracking reaction material are subjected to gas-liquid separation and fractionation separately to obtain naphtha, aviation kerosene, diesel oil and tail oil products with different specifications. The invention provides the two-stage hydrocracking process for simultaneously producing more than two different-specification light naphtha, heavy naphtha, aviation kerosene,diesel oil and tail oil products on a set of hydrogenation process equipment for the first time.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible single-stage hydrocracking process

ActiveCN109988628BEffective distributionFlexible productionTreatment with hydrotreatment processesPtru catalystIsomerization

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com