Comprehensive utilization method of hydrocracking tail oil

A technology of hydrocracking tail oil and hydrogen oil, applied in cracking, non-catalytic thermal cracking, organic chemistry, etc., can solve the problem that the quality of lubricating oil base oil is difficult to meet the requirements, shorten the operation period of cracking furnace, and improve the yield of lubricating oil base oil Low-level problems, to achieve the effect of increasing the yield of liquid products in the device, improving product quality, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

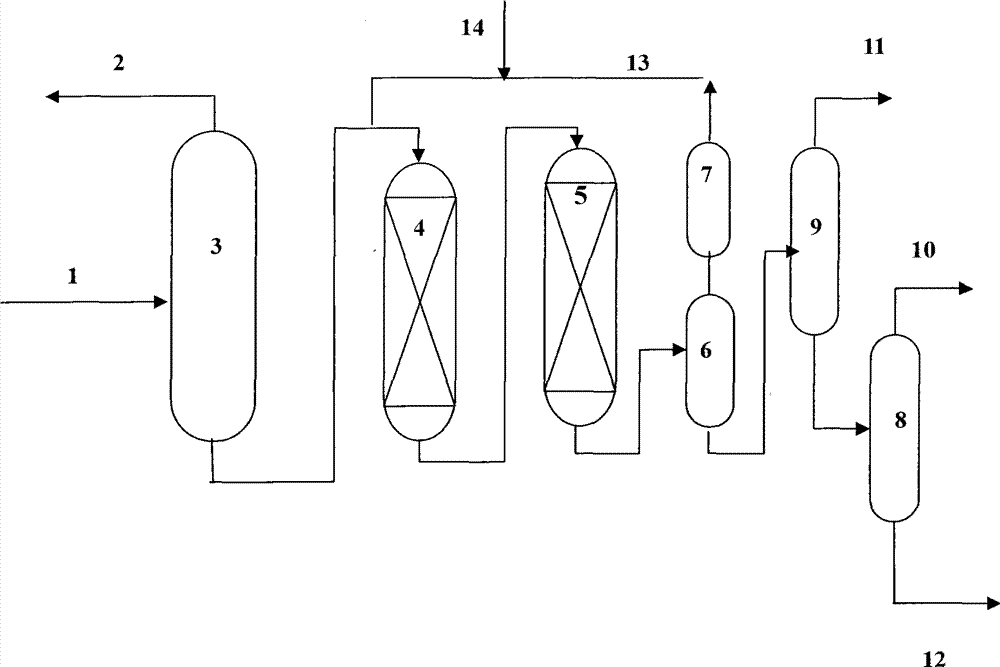

Method used

Image

Examples

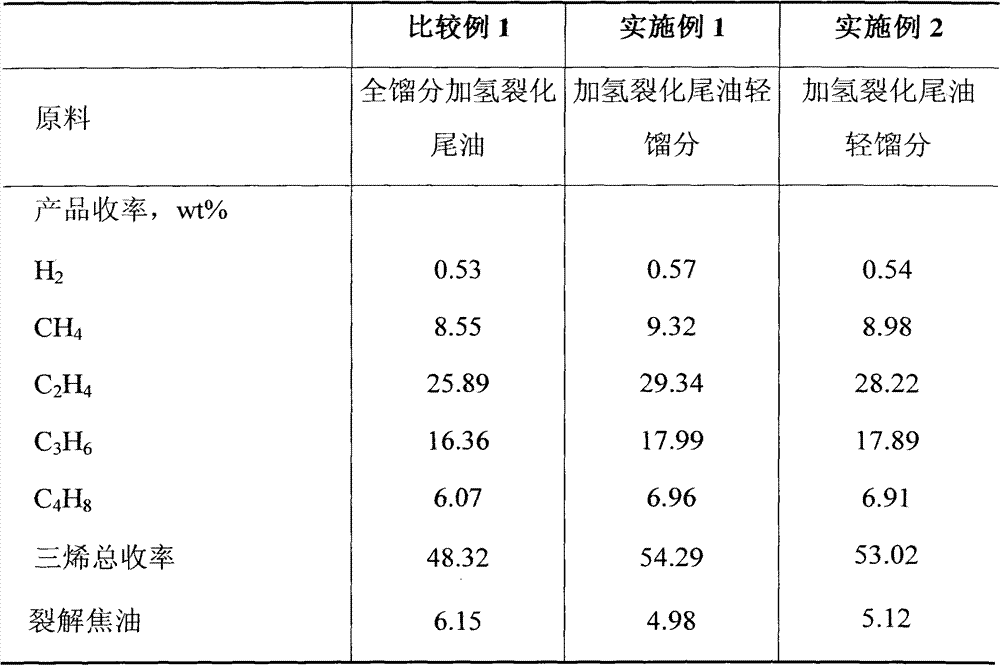

Embodiment 1

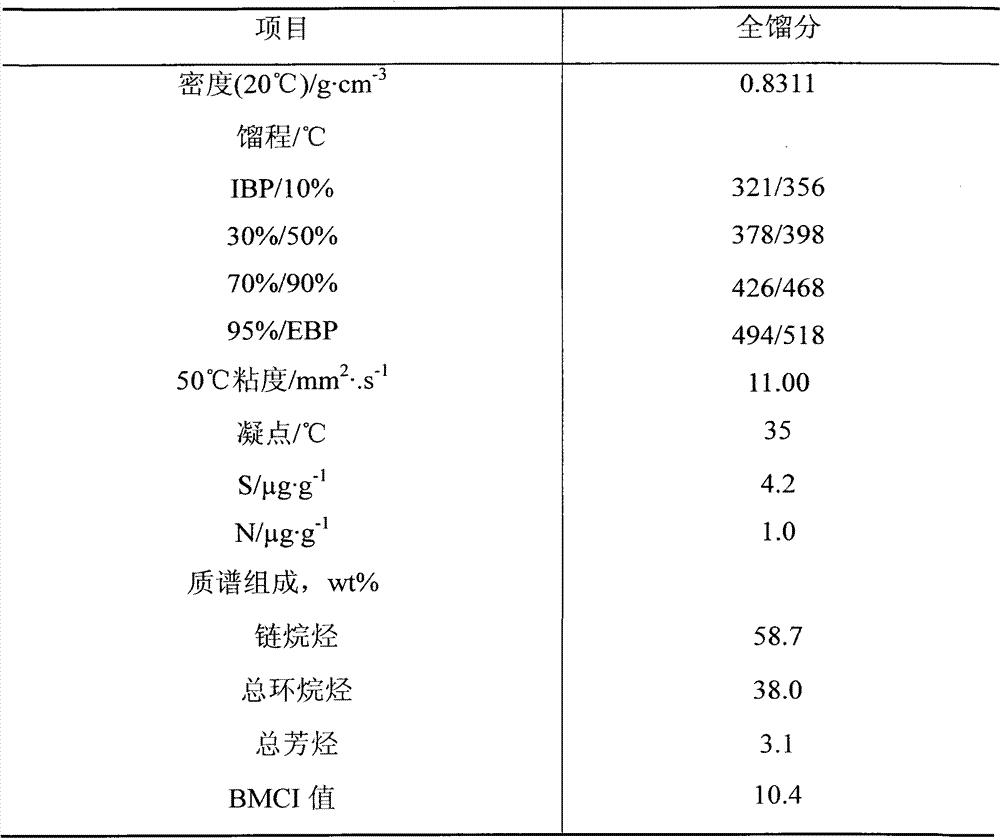

[0029] First, hydrocracking tail oil (see Table 1 for properties) enters the vacuum tower for vacuum fractionation. The cut point of vacuum fractionation is 380°C, and the light fraction of hydrocracking tail oil at 380 ° C hydrocracking tail oil heavy fraction and hydrogen are mixed and then go through two reaction zones of hydroisomerization dewaxing and supplementary refining (the catalyst used is shown in Table 2); the reaction product is gas-liquid Separation, the gas is desulfurized and mixed with supplemental hydrogen before recycling, and the liquid product is often distilled under reduced pressure to obtain different lubricating oil base oil products. The process conditions and results of the reaction are shown in Table 4, and the properties of different lubricating base oil products are shown in Table 5 and Table 6.

Embodiment 2

[0031] The cut point of vacuum fractionation of hydrocracking tail oil is 420°C, and other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com