Grading method of hydrocracking catalyst

A hydrocracking and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as poor economic benefits, reduce the amount of cold hydrogen, increase adsorption selectivity, and reduce equipment The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

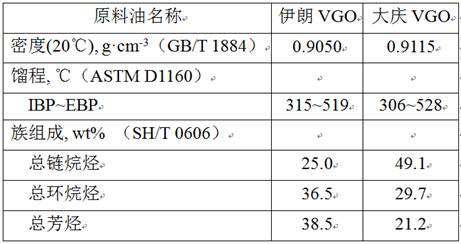

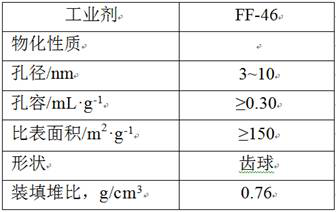

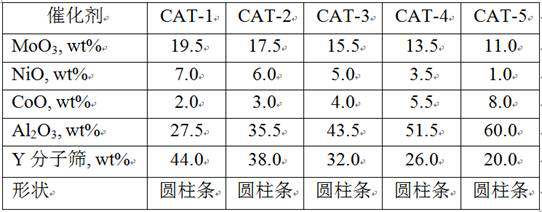

[0046] The hydrotreating reactors are all filled with FF-46 refining catalysts, and the three beds of the hydrocracking reactors are respectively filled with CAT-1, CAT-2 and CAT-3 in equal volumes. Using Iranian VGO as the raw material and using the process evaluation conditions in Table 4, the cracked oil is cut at the real boiling point to obtain a hydrocracking product.

Embodiment 2

[0048] The hydrotreating reactors are all filled with FF-46 refining catalysts, and the three beds of the hydrocracking reactors are respectively filled with CAT-2, CAT-3 and CAT-4 in equal volumes. Using Iranian VGO as the raw material and using the process evaluation conditions in Table 4, the cracked oil is cut by the real boiling point to obtain a hydrocracking product.

Embodiment 3

[0050] The hydrotreating reactors are all filled with FF-46 refining catalysts, and the three beds of the hydrocracking reactors are respectively filled with CAT-3, CAT-4 and CAT-5 in equal volumes. Using Iranian VGO as the raw material and using the process evaluation conditions in Table 4, the cracked oil is cut at the real boiling point to obtain a hydrocracking product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com