Patents

Literature

88results about How to "Low BMCI" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

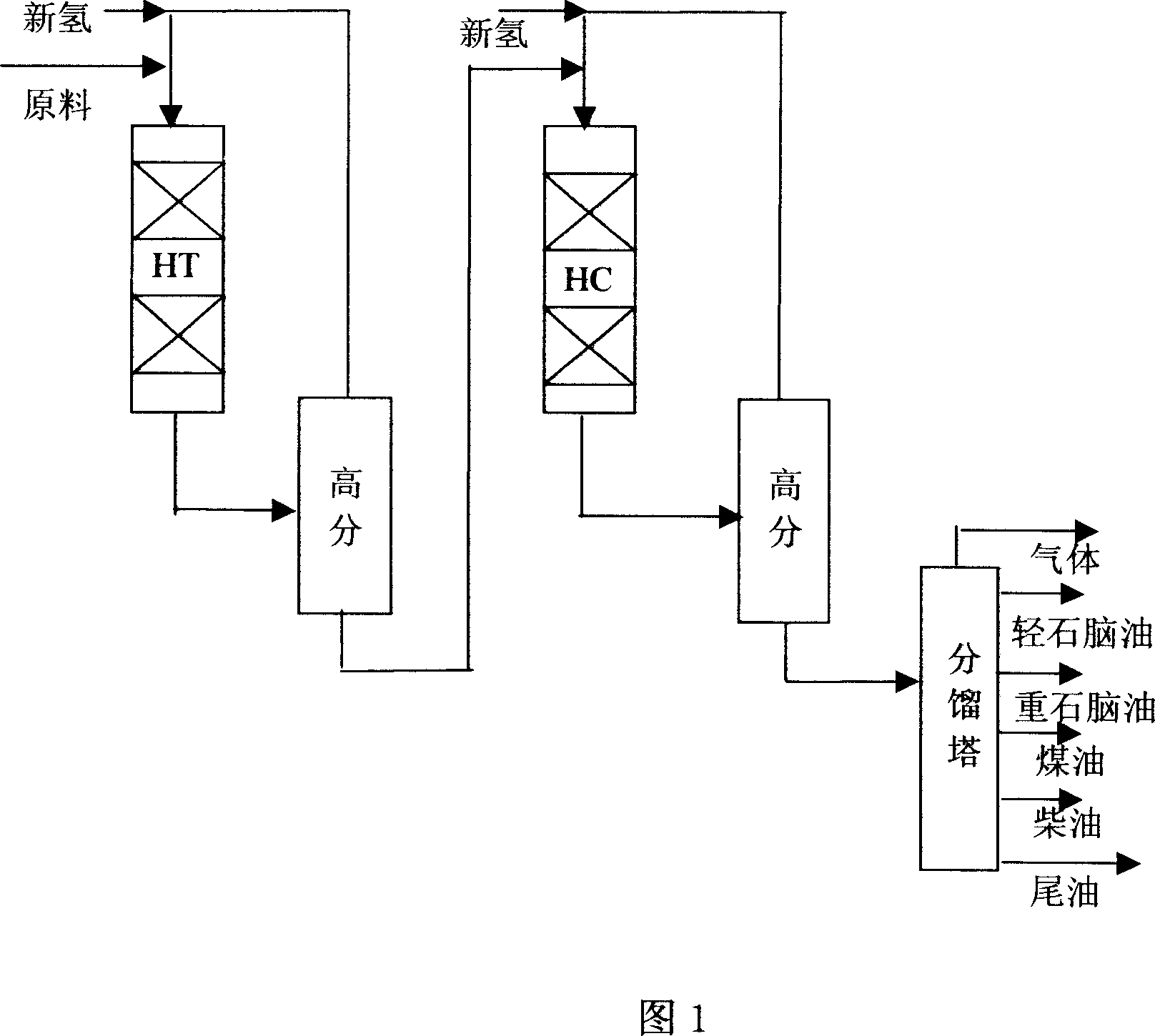

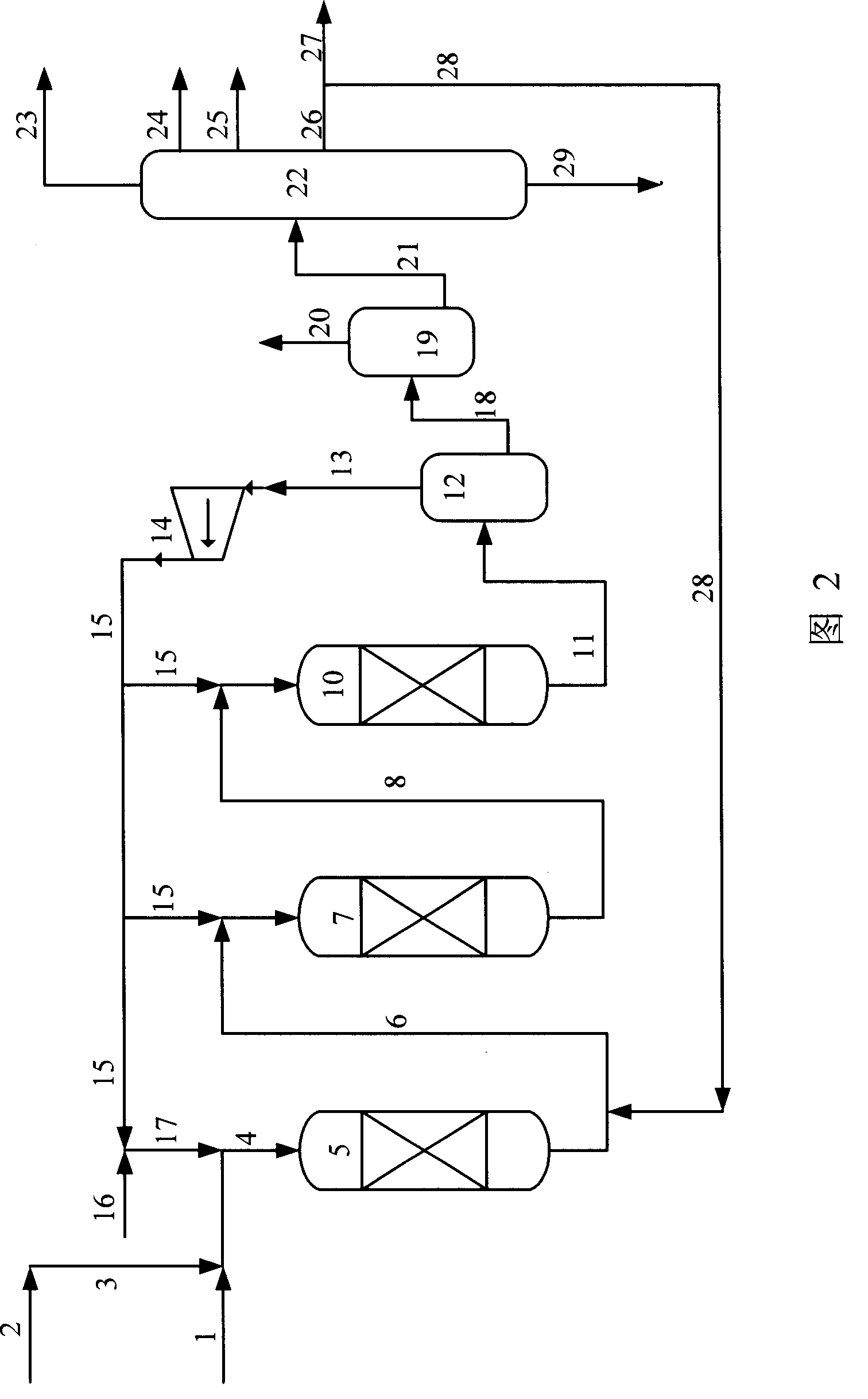

Two-stage hydrocracking method

ActiveCN1955262AEfficient processingLow BMCITreatment with hydrotreatment processesHexadecaneNaphtha

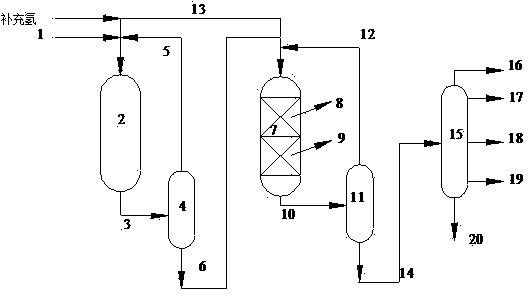

This invention discloses a poor quality catalytic cracking diesel hydrogenation method. This invention includes two stages hydrocracking dealing with catalytic cracking diesel, especially the poor quality catalytic cracking diesel from catalytic hydrogen transfer process. The density of the related poor quality catalytic cracking diesel is 0.90g / ml at 20deg.C, and its aromatic hydrocarbon is over 60wt%, and the value of hexadecane is less than 30. Mixing poor quality catalytic cracking diesel and heavy cracking material and conducting hydrogenation, hydrocracking is conducted after removal of sulphur, nitrogen and other impurities from reaction oil. It is a sufficient utilization of the feature that low hydrogen and high aromatic hydrocarbon content of catalytic cracking diesel to produce Gaofangqian heavy naphtha in order to realize the effective utilization of the poor quality catalytic cracking diesel.

Owner:CHINA PETROLEUM & CHEM CORP +2

Composite mesoporous molecular sieve hydrocracking catalyst and uses thereof

ActiveCN101269343AHigh activityHigh oil selectivityMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveAdhesive

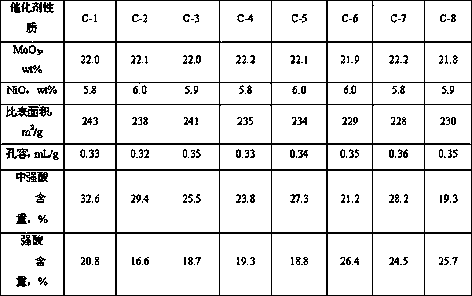

The invention relates to a composite mesoporous molecular sieve hydrocracking catalyst and the application thereof. The catalyst composed of following components of 20 to 50 percent of amorphous silica-alumina, 5 to 30 percent of alumina, 10 to 25 percent of adhesives, 10 to 40 percent of Group VIB-the metal oxides, 1 to 20 percent of Group VIII-the metal oxides, 0.1 to 10 percent of Group VA-the metal oxides, and 1 to 40 percent of composite mesoporous molecular sieve, wherein, the composite mesoporous molecular sieve is a composite molecular sieve composed of a mesoporous molecular sieve AlSBA-15 and / or AlSBA-15 / Y; the weight ratio of the composite molecular sieve AlSBA-15 / Y in the AlSBA-15 and a Y molecular sieve is 9:1 to 1:9; the weight ratio of the mesoporous molecular sieve and a pore molecular sieve is 3:1 to 1:3, the silica alumina ratio is 10:1 to 40:1, and the silica alumina ratio of the Y molecular sieve is 5:1to 20 :1. The catalyst used for hydrocracking for heavy oil shows high activity for hydrocracking and high medium oil selectivity.

Owner:PETROCHINA CO LTD

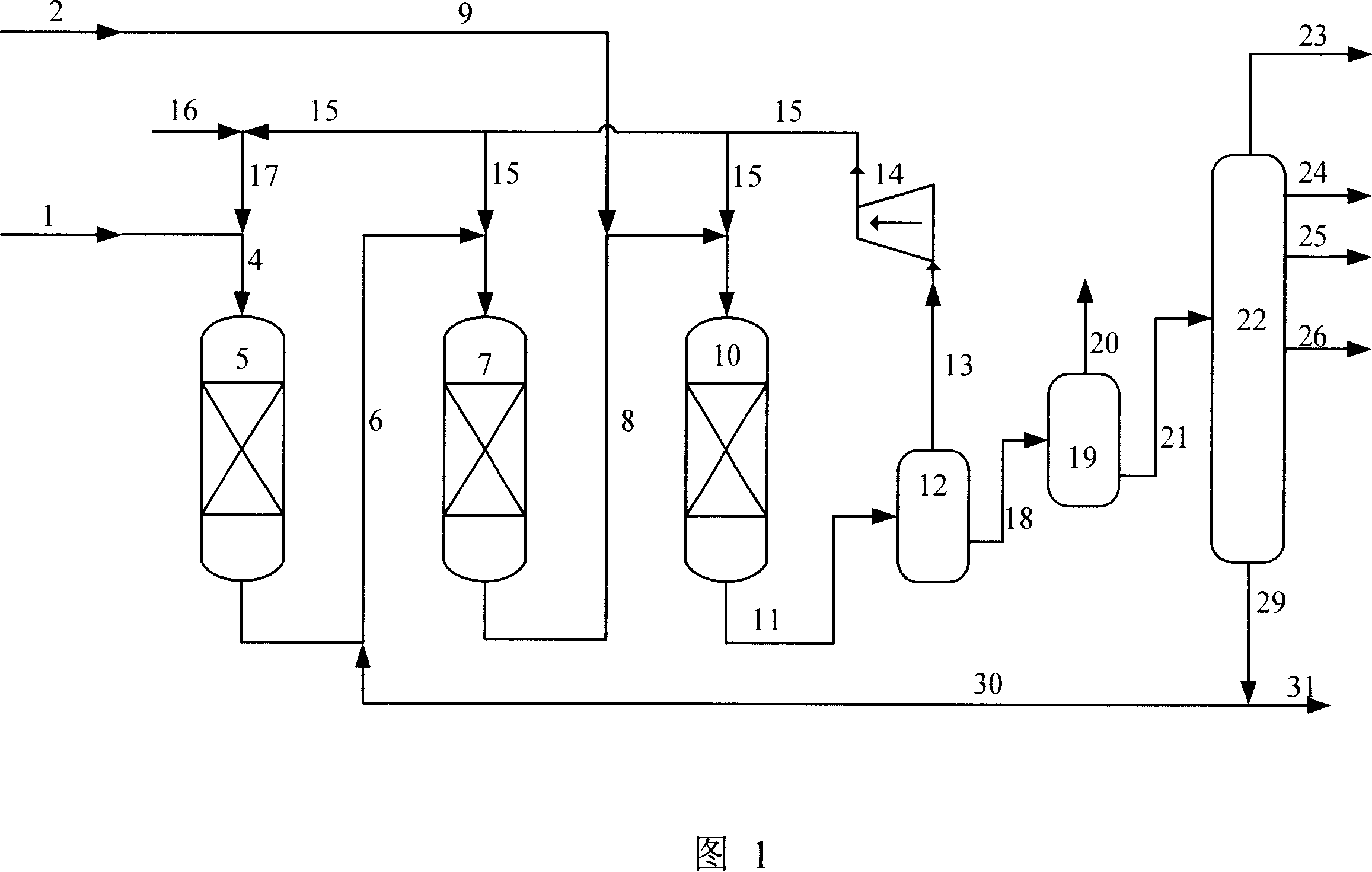

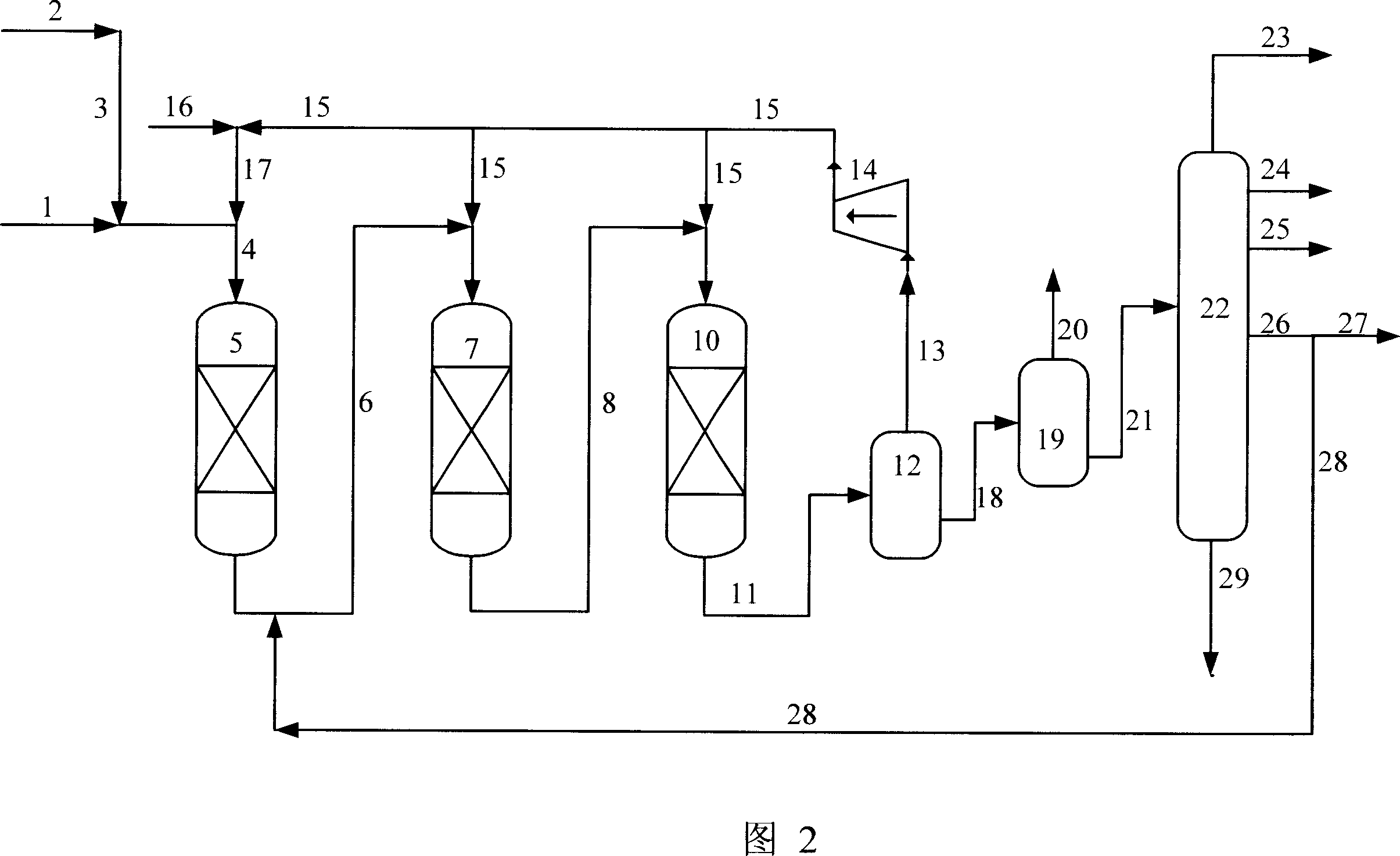

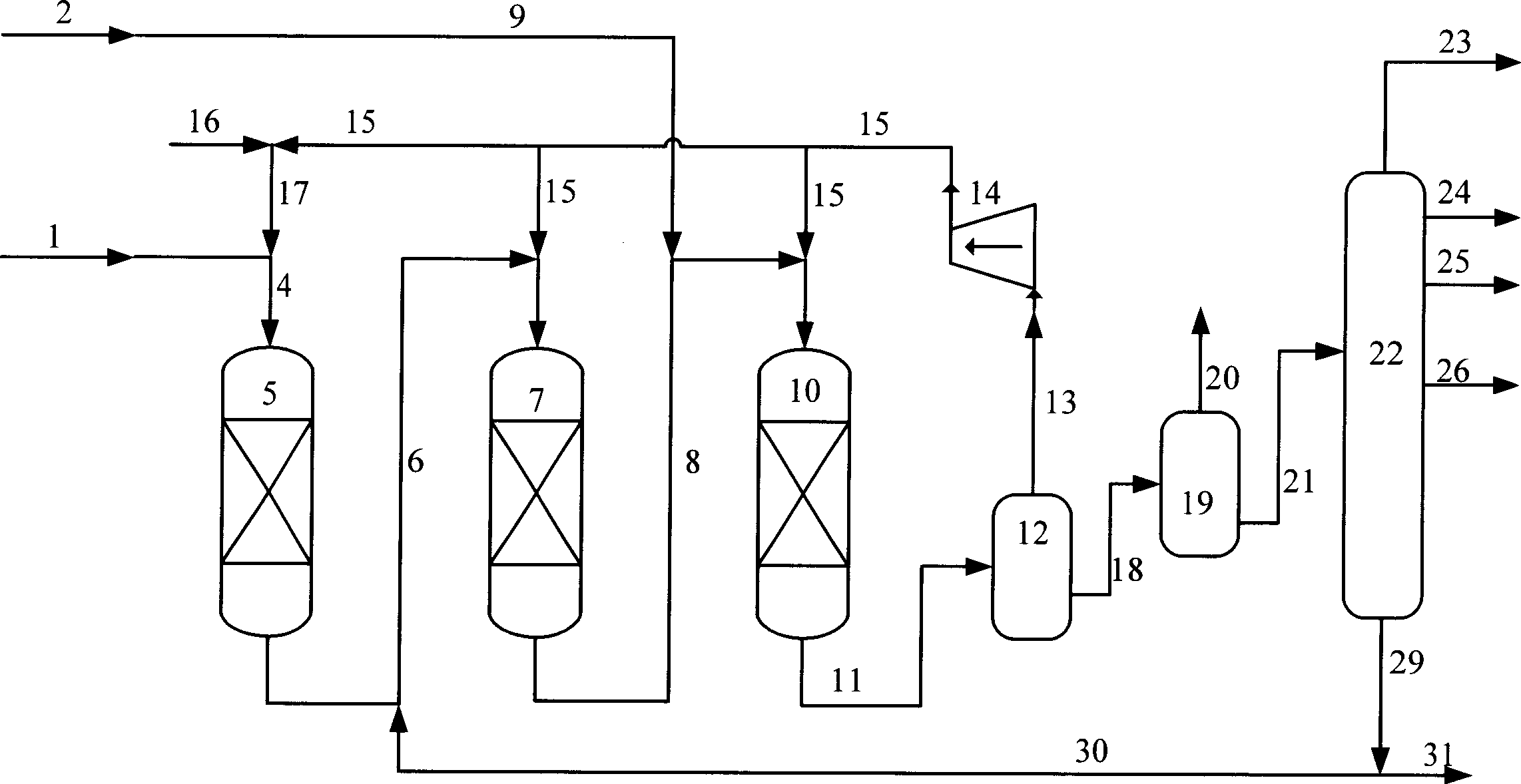

Hydrogenation method capable of producing diesel oil and chemical materials flexibly

ActiveCN101117596AMeet specificationsFlexible adjustment and operationTreatment with hydrotreatment processesNaphthaHydrogen

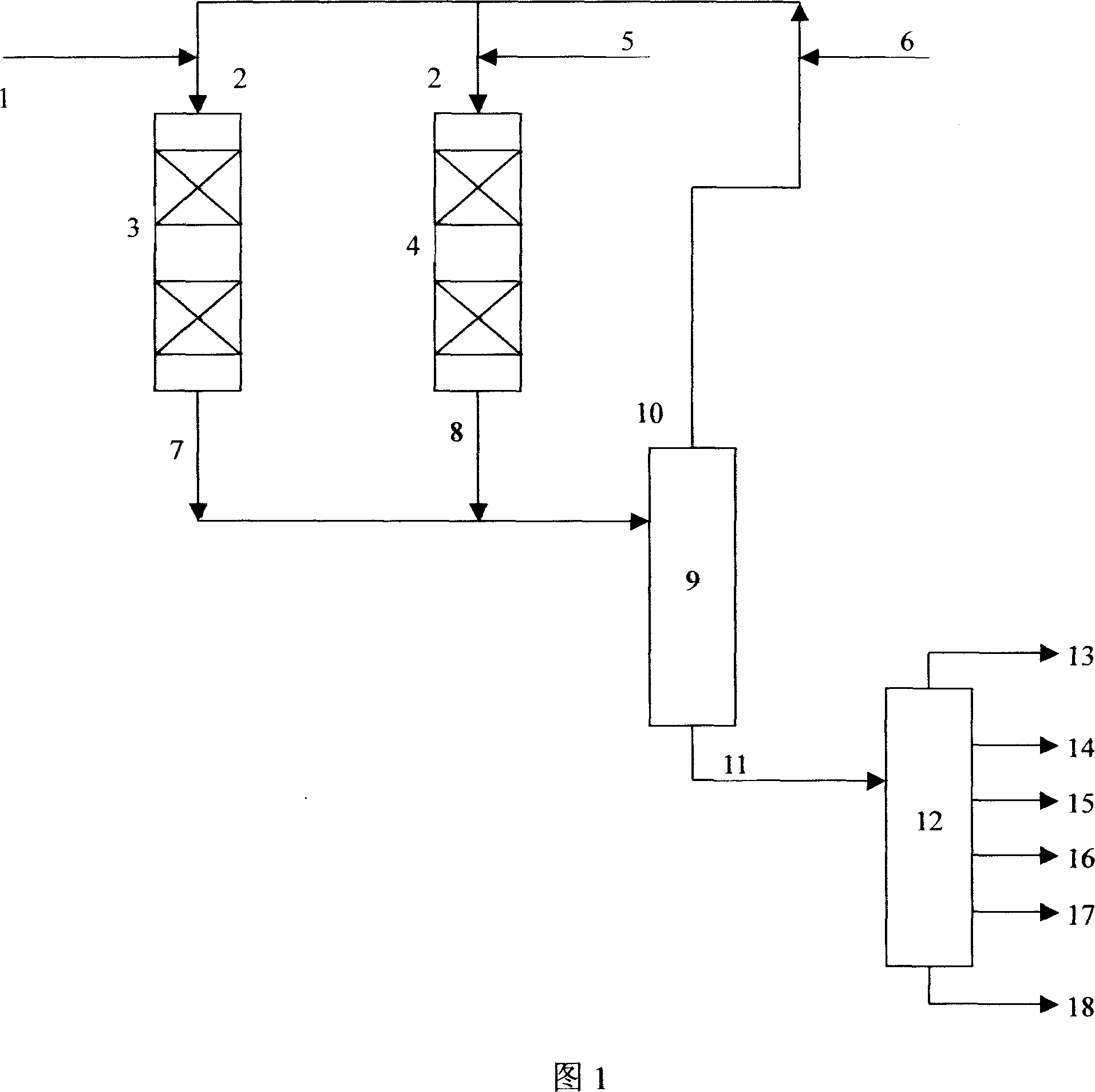

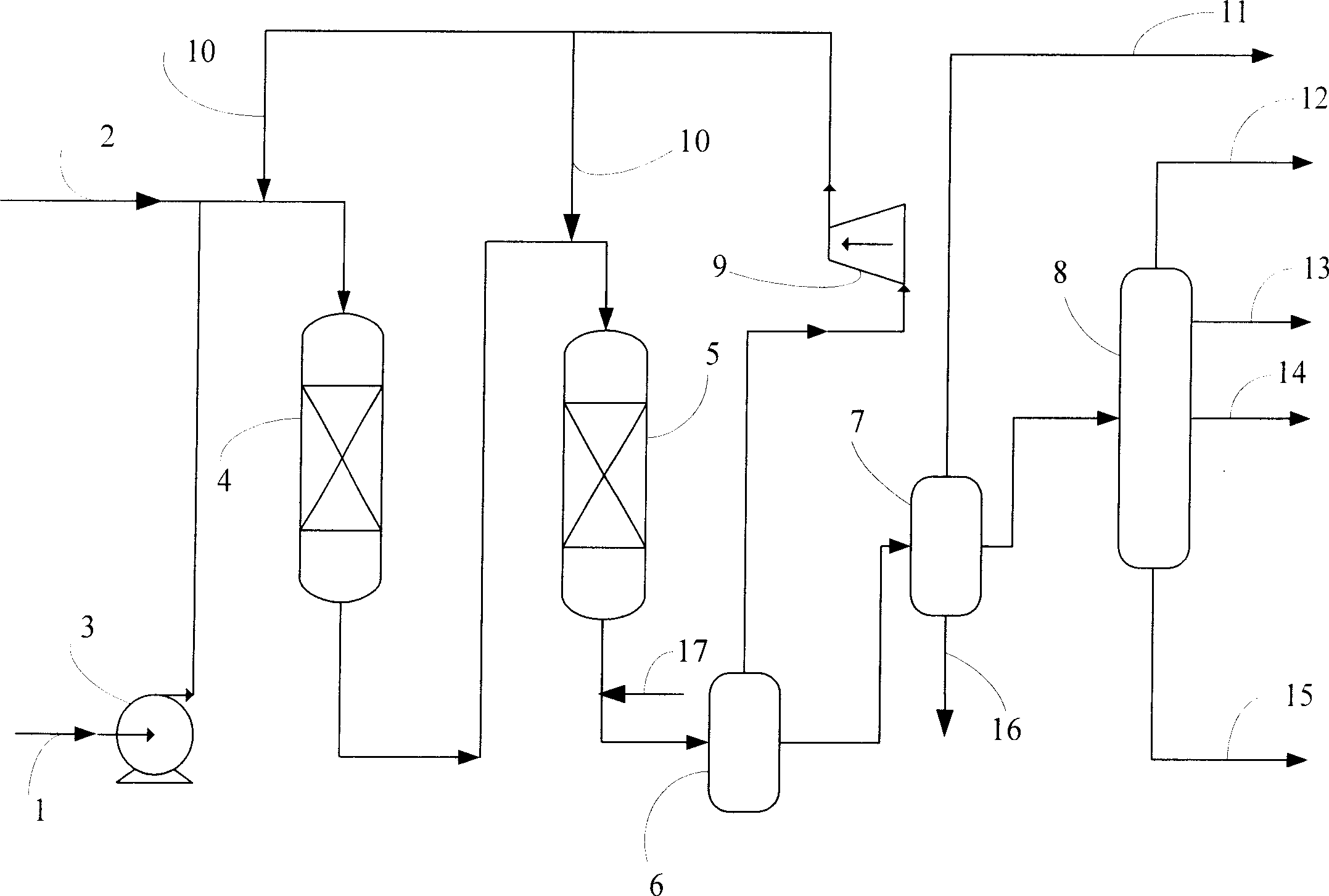

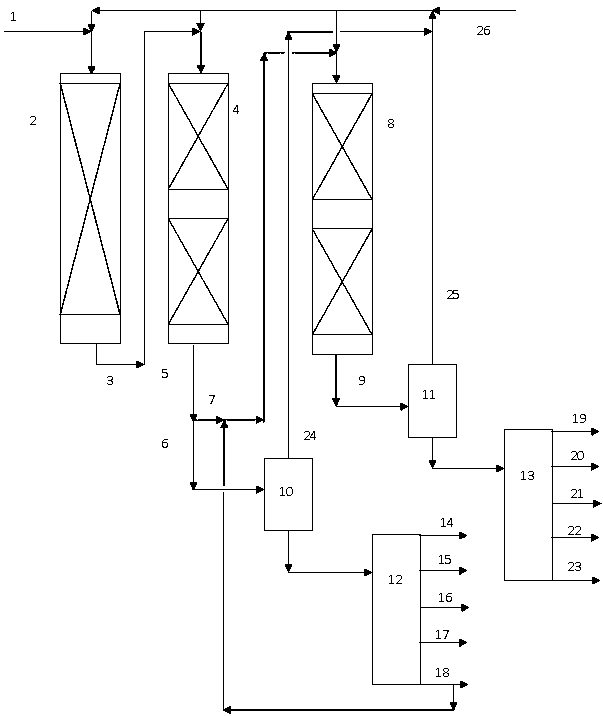

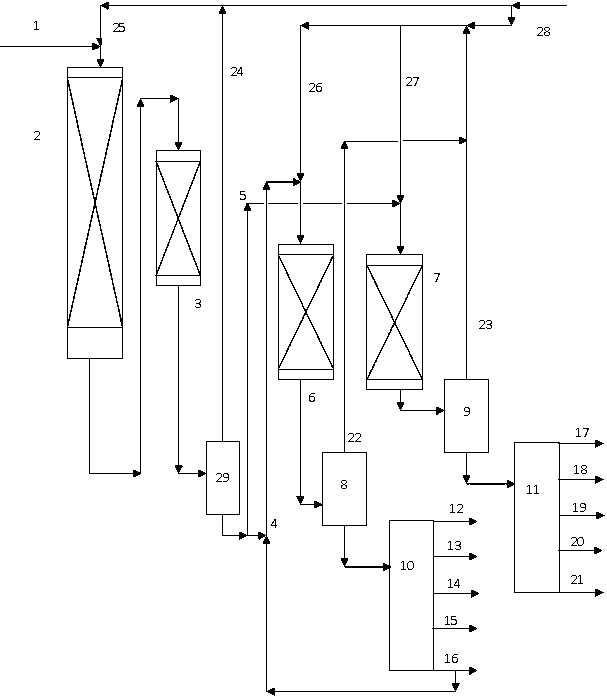

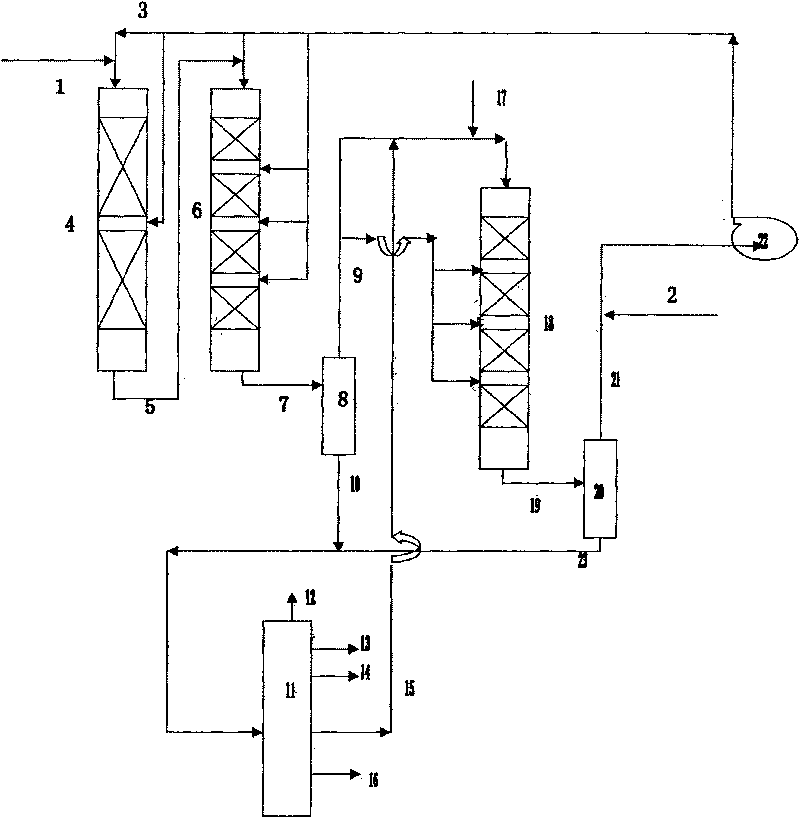

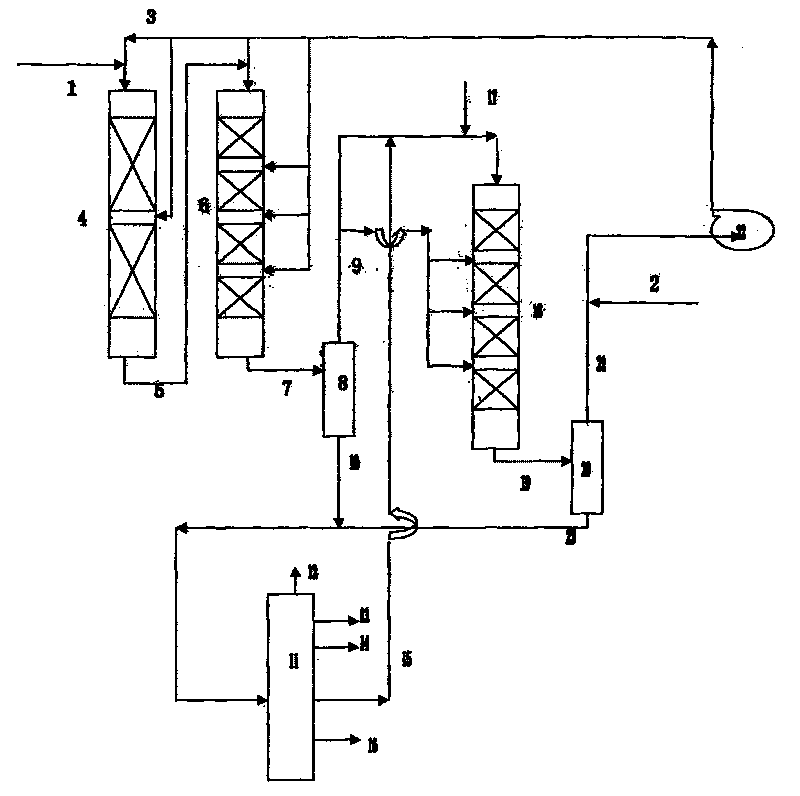

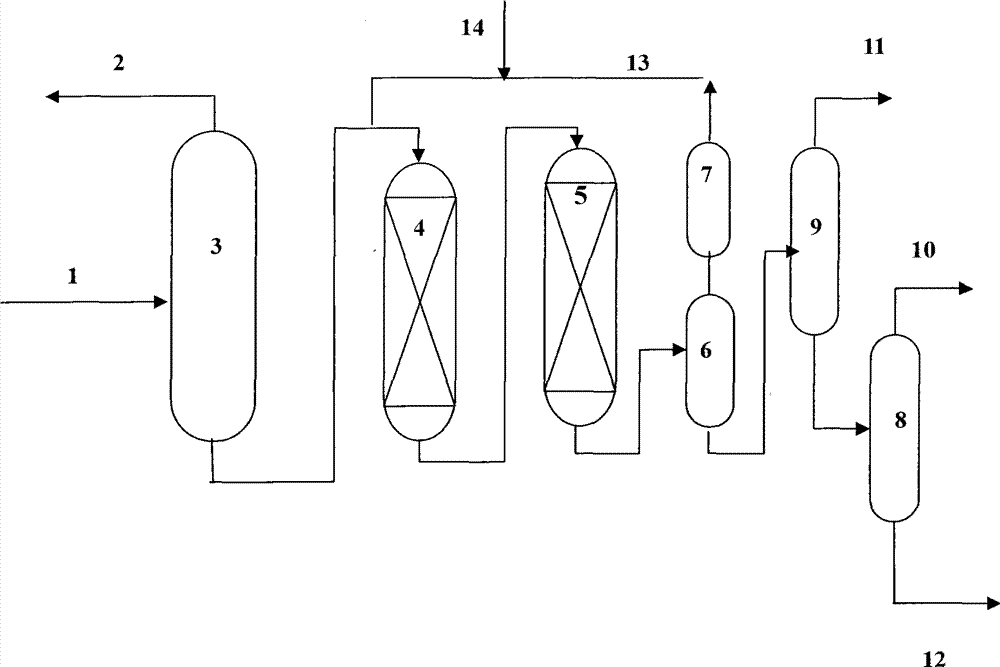

The present invention relates to a hydrogenation method for flexible production of diesel oil and chemical raw material, heavy raw material and optional light raw material mix with hydrogen, and enter into a first hydrogenation reaction area and a second hydrogenation reaction area, and contact with hydrogenation treatment catalyst I and hydrogenation cracking catalyst respectively and perform reaction. Without separation, the reactant mixes with the light raw material and enters into a third hydrogenation reaction area, under the action of hydrogenation treatment catalyst II, the mixture performs the reaction, through the reactant is cooled, separated and fractionated, the light naphtha distillate, the heavy naphtha distillate, the diesel oil distillate and the tail oil distillate can be got. The method provided by the present invention combines the hydrogenation treatment and the hydrogenation cracking organically, the heavy distillates such as decompression gas oil, etc. and the ungraded light distillate got from the second time processing are used as raw material, the operation can be adjusted flexibly according to the market demand, so as to produce high quality diesel oil or chemical raw material in the maximum volume, wherein the diesel oil can meet the requirement of Europe IV fuel specification.

Owner:CHINA PETROLEUM & CHEM CORP +1

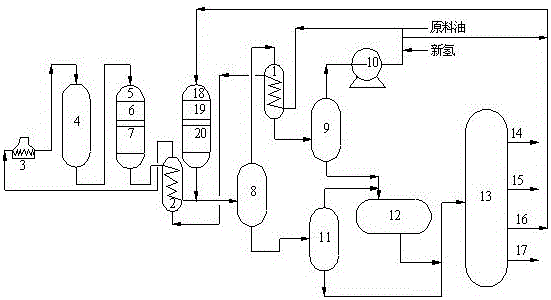

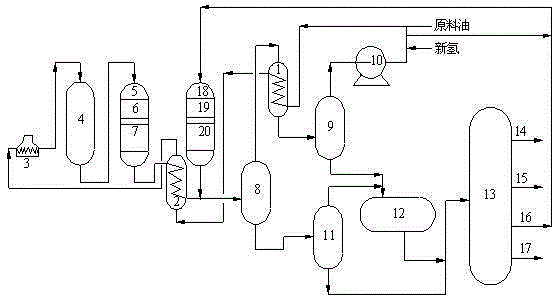

A hydrocracking method with low energy consumption and high yield of high-quality chemical raw materials

ActiveCN105018139BReduce consumptionSave engineering investmentTreatment with hydrotreatment processesMolecular sieveHydrogen

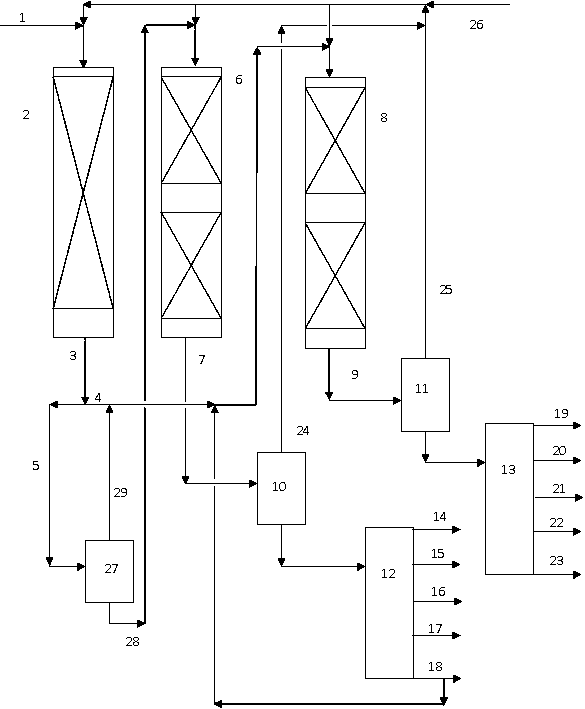

The invention discloses a hydrocracking method of low-nergy-onsumption productive high-quality chemical raw materials. After raw oil and hydrogen are mixed, the obtained mixture is subjected to heat transfer for two times and then passes through a heating furnace, the obtained object is sequentially subjected to hydrorefining and then passes through a first cracking reaction area, the obtained product is separated so as to obtain middle distillate, the middle distillate enters a second cracking reaction area to crack, wherein the first cracking reaction area is at least filled with two cracking catalysts, a catalyst I is filled in the upstream part, and a catalyst II is filled in the downstream part; and the catalyst I contains 30-70% of modified Y molecular sieve, the catalyst II contains 15-50% of modified Y molecular sieve, and the content of the modified Y molecular sieve in the catalyst I is 10-30% higher than the content of the modified Y molecular sieve in the catalyst II. In the method disclosed by the invention, a high-temperature and high-pressure countercurrent heat transfer technology and a hydrocracking catalyst grading technology are organically combined, and through the comprehensive utilization of hydrocracking reaction heat, while the selectivity of catalysts is maintained, the product quality is enhanced, and the construction investment and the energy consumption of operation are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

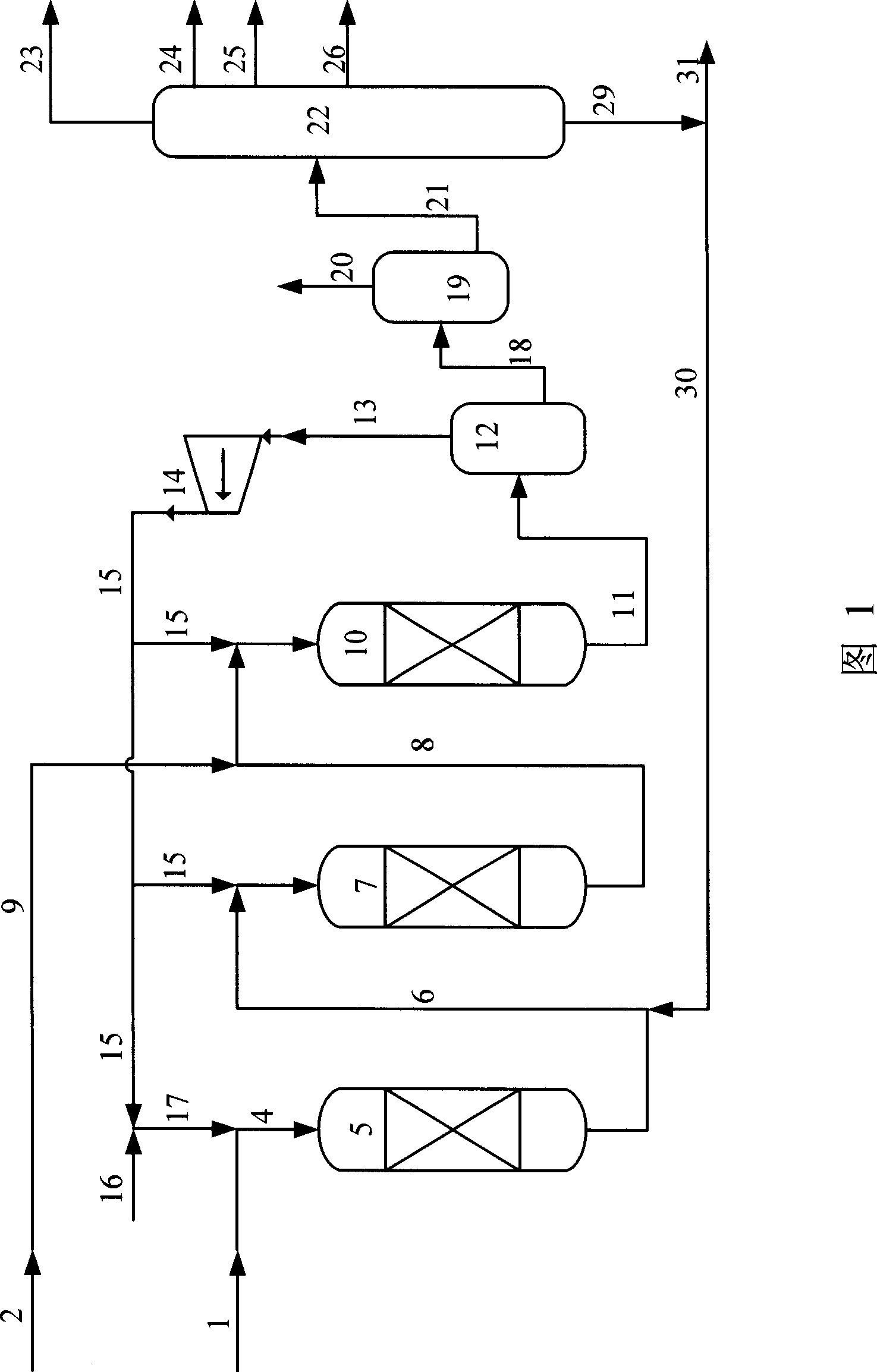

Parallel hydrocracking method

ActiveCN1955259ALow BMCIIncrease the molar ratio of silicon to aluminumTreatment with hydrotreatment processesHexadecaneCatalytic reforming

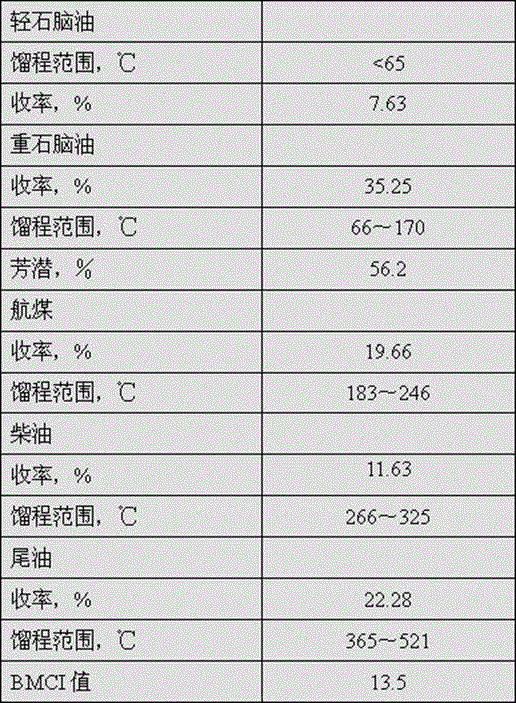

This invention discloses a hydrocracking method, and this invention is used for producing high aromatic hydrocarbon heavy naphtha and high quality end oil.It includes that heavy distillate oil and poor quality catalytic cracking diesel hydrocracks separately, and the mixture of the cracking products is conducted gas liquid separation. Light naphtha, heavy naphtha, aviation kerosene, diesel oil and end oil will be obtained by distillating the liquid phase. The density of the poor quality catalytic cracking diesel oil is above 0.9g / ml, and the aromatic hydrocarbon is over 60wt% and the value of hexadecane is under 30. It is a adequate utilization of catalytic cracking craft to produce high aromatic hydrocarbon heavy naphtha and high quality end oil with heavy distillate oil and poor quality catalytic cracking diesel, which can be separately used as catalytic reforming material and making ethylene material by steam cracking method. High aromatic hydrocarbon heavy naphtha in this invention will produce a large amount of reforming hydrogen after catalytic reforming treatment, which can be used in the process of hydrocracking to make this preparation more ecnomical and reasonable.

Owner:CHINA PETROLEUM & CHEM CORP +2

Hydrocracking method of high-yield high-quality chemical raw material

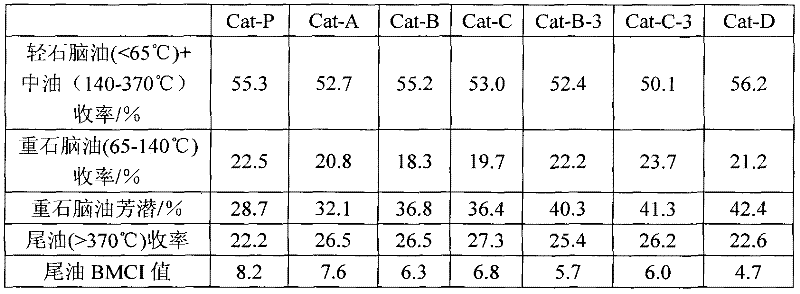

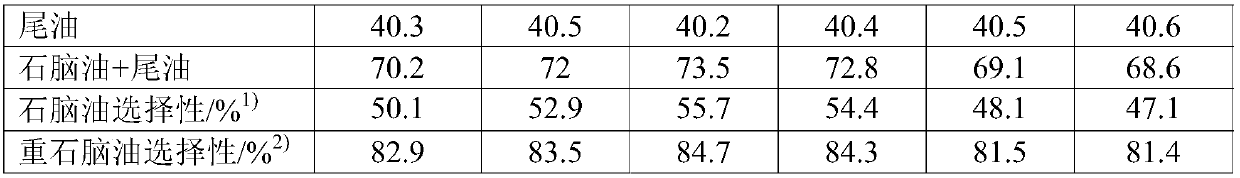

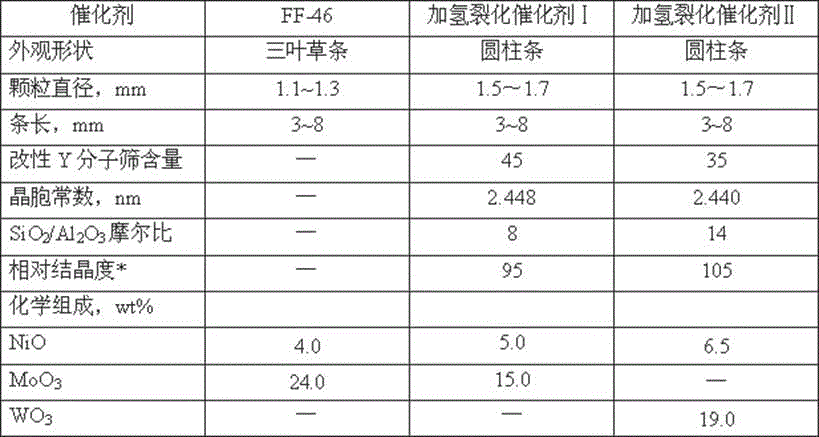

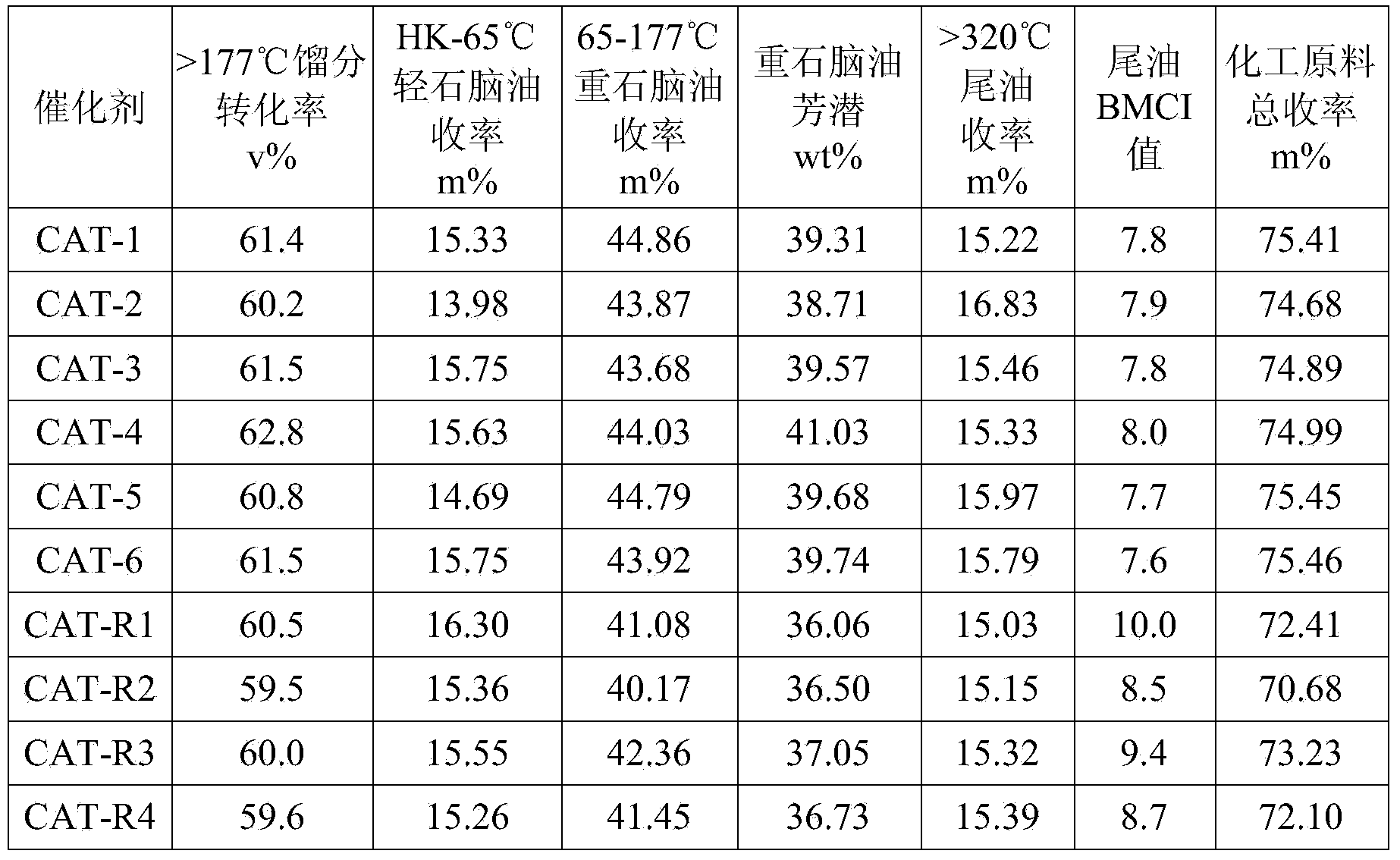

ActiveCN103773452AGood choiceFang QiangaoTreatment with hydrotreatment processesMolecular sievePetroleum naphtha

The invention discloses a hydrocracking method of a high-yield high-quality chemical raw material. According to the hydrocracking method comprises following steps: raw oil and hydrogen are subjected to hydrofinishing and are delivered through a first cracking reaction zone successively, and middle fraction oil is obtained via separation, and is delivered to a second cracking reaction zone for cracking; the first cracking reaction zone comprises two cracking catalysts, an upper zone is filled with a catalyst I, and a lower zone is filled with a catalyst II; the catalyst I comprises 30 to 70% of modified Y molecular sieve; the catalyst II comprises 15 to 50% of modified Y molecular sieve; and the content of the modified Y molecular sieve in the catalyst I is 10 to 30% higher than that in the catalyst II. Acid center of the catalyst I matches hydrogenation center, and the catalyst I possesses excellent heavy naphtha selectivity; and the catalyst II possesses excellent aromatic hydrocarbon transformative capacity, and is capable of transforming aromatic hydrocarbons in heavier components into smaller molecules so as to distribute in heavy petroleum fractions. The two catalysts are combined, so that demands of the high-yield high-quality chemical raw material are satisfied.

Owner:CHINA PETROLEUM & CHEM CORP +1

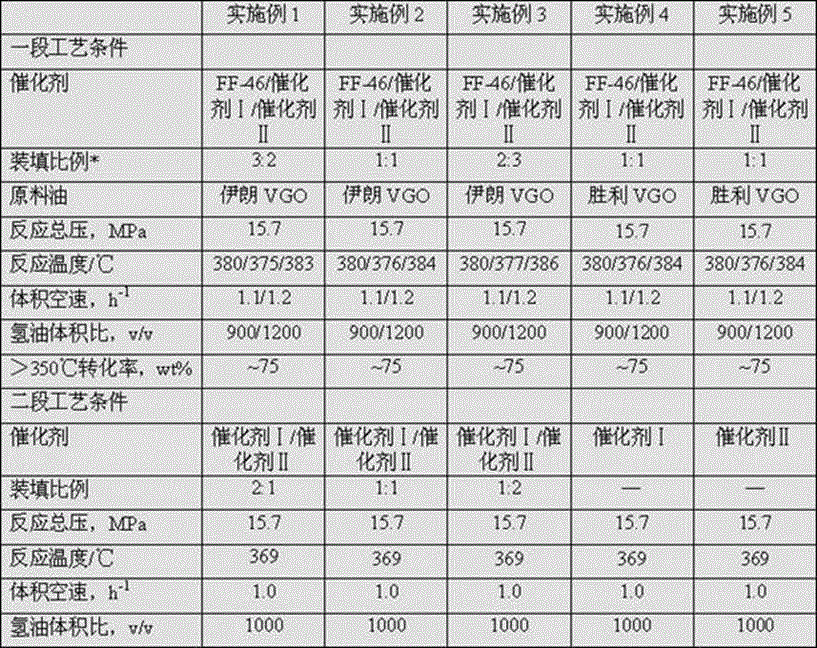

Two-stage hydrocracking method used for producing high-quality chemical raw materials

ActiveCN103773462AReduce the impactIncrease hydrogen partial pressureTreatment with hydrotreatment processesMolecular sieveLiquid product

The invention discloses a two-stage hydrocracking method used for producing high-quality chemical raw materials. The two-stage hydrocracking method comprises following steps: (1) raw material oil is mixed with hydrogen, and an obtained mixture is subjected to hydrofinishing reaction; (2) a refining reaction product is subjected to gas-liquid separation; (3) an obtained liquid product and hydrogen are subjected to hydrocracking reaction, and are contacted with a catalyst I and a catalyst II successively, wherein molecular sieve content of the catalyst I and molecular sieve content of the catalyst II are different; and (4) a hydrocracking effluent is subjected to separation and fractionation so as to obtain a plurality of hydrocracking products. The molecular sieve content of the hydrocracking catalyst I is higher, acid center of the hydrocracking catalyst I matches hydrogenation center, and the hydrocracking catalyst I possesses excellent heavy naphtha selectivity; and the catalyst II possesses excellent aromatic hydrocarbon transformative capacity, and is capable of transforming aromatic hydrocarbons in heavier components of the raw material oil into smaller molecules so as to distribute in heavy petroleum fractions. The two hydrocracking catalysts with different molecular sieve contents are combined, so that aromatic hydrocarbon potential content of heavy naphtha is increased, and tail oil BMCI value is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking technology for increase production of low solidifying point diesel oil and ethylene producing raw material

InactiveCN1493664AImprove overall utilizationLow BMCIHydrocarbon oil crackingTreatment with hydrotreatment processesPetroleumEthylene

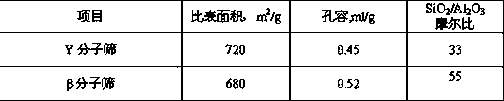

A hydrocracking process for increasing the output of low-setting-point diesel oil and the raw material used to prepare ethylene features that the Y-zeolite hydrocracking catalyst for bearing the cracking load of 50-90 wt% of petroleum hydrocarbon and the beta-zeolite one for bearing that of 10-50 wt% of petroleum hydrocarbon are hierarchically filled.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for selective hydrocracking of light oil

ActiveCN102533316AIncrease the potential content of aromaticsEnhance aromatizationMolecular sieve catalystsHydrocarbon oil crackingTreatment systemOxide

The invention relates to a method for selective hydrocracking of light oil. A catalyst used in the method comprises an acidic carrier and metal oxides NiO and WO3, wherein the acidic carrier comprises two porous beta / Y composite molecular sieves and a mesoporous amorphous silicon / aluminum, and the metal oxides are loaded on the acidic carrier; the two porous beta / Y composite molecular sieves are used for ammonium exchange and organic acid pretreatment, and the two treatment methods are carried out in one process; ammonium salt used in the ammonium exchange is NH4NO3 or NH4HCO3, and the mass ratio of the beta / Y composite molecular sieves and the ammonium salt solution is (1-10):1; the solution of one or mixture of any of citric acid, tartaric acid, acetic acid, malic acid and oxalic acid is used for treatment of the beta / Y composite molecular sieves, and the concentration of the organic acid in the treatment system is 0.5-2.0 mol.L-1; the potential content of aromatic hydrocarbon in heavy naphtha in products obtained in cracking is high, and the exhaust oil has a lower BMCI (Bureau of Mines Correlation Index) value.

Owner:PETROCHINA CO LTD +1

Hydrogenation cracking method to produce more raw material for making ethylene

ActiveCN1903993AQuality assuranceLow BMCIHydrocarbon oil crackingHydrocarbon by hydrocarbon crackingHydrogenNaphtha

The present invention relates to a hydrocracking method for producing high-grade raw material for making ethylene. It is characterized by that it adopts single-stage series-connected once-through process, the heated raw material and hydrogen gas are fed into hydrogenation treatment reactor, in the presence of optimized hydrofining catalyst they are reacted, the reaction effluent is not undergone the process of separation and is directly fed into hydrocracking reactor, in the presence of optimized hydrocracking catalyst they are reacted, the reaction effluent can be undergone the process of oil-gas separation so as to obtain hydrogen-rich gas and liquid, the hydrogen-rich gas can be circularly used after it is compressed, and the liquid can be fractionated so as to obtain naphtha fraction, diesel oil fraction and tail oil fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method for producing chemical industry raw material

ActiveCN110835550ALess investmentTaking into account productionTreatment with hydrotreatment processesChemical industryNaphtha

The invention relates to the field of hydrocracking, and discloses a hydrocracking method for producing a chemical industry raw material. The method comprises: sequentially introducing a hydrocrackingraw material into a hydrogenation pretreatment reaction zone and a hydrocracking reaction zone, and carrying out a hydrogenation reaction to obtain a hydrocracking effluent; fractionating the hydrocracking effluent, wherein the hydrocracking raw material contains a VGO distillate and a DAO distillate, the DAO distillate accounts for 10-30 wt% of the total amount of the hydrocracking raw material,and the hydrogen partial pressure in the hydrocracking reaction zone is 20-80% of the hydrogen partial pressure in the hydrogenation pretreatment reaction zone. According to the invention, by adopting the method, the heavy naphtha yield of the hydrocracking device can be greatly increased while the high-quality DCC feed can be produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method of low-nergy-onsumption productive high-quality chemical raw materials

ActiveCN105018139AReduce consumptionSave engineering investmentTreatment with hydrotreatment processesMolecular sieveHydrogen

The invention discloses a hydrocracking method of low-nergy-onsumption productive high-quality chemical raw materials. After raw oil and hydrogen are mixed, the obtained mixture is subjected to heat transfer for two times and then passes through a heating furnace, the obtained object is sequentially subjected to hydrorefining and then passes through a first cracking reaction area, the obtained product is separated so as to obtain middle distillate, the middle distillate enters a second cracking reaction area to crack, wherein the first cracking reaction area is at least filled with two cracking catalysts, a catalyst I is filled in the upstream part, and a catalyst II is filled in the downstream part; and the catalyst I contains 30-70% of modified Y molecular sieve, the catalyst II contains 15-50% of modified Y molecular sieve, and the content of the modified Y molecular sieve in the catalyst I is 10-30% higher than the content of the modified Y molecular sieve in the catalyst II. In the method disclosed by the invention, a high-temperature and high-pressure countercurrent heat transfer technology and a hydrocracking catalyst grading technology are organically combined, and through the comprehensive utilization of hydrocracking reaction heat, while the selectivity of catalysts is maintained, the product quality is enhanced, and the construction investment and the energy consumption of operation are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

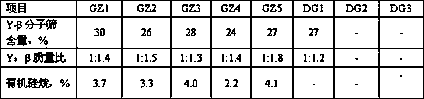

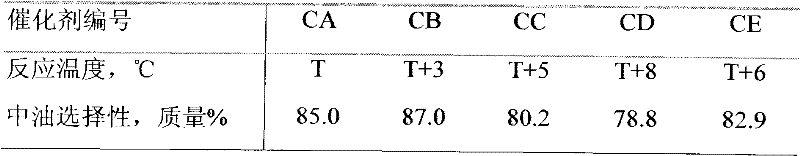

Method for hydrogen cracking

The present invention provides a kind of hydrogen cracking method of raising middle oil selectivity and product quality simultaneously. Catalyst containing Y-type molecular sieve and catalyst containing beta-type molecular sieve are filled inside the reactor separately in different layers. Catalyst containing Y-type molecular sieve and catalyst containing beta-type molecular sieve are filled in the upper part and the lower part of the reactor separately; or, catalyst containing Y-type molecular sieve and catalyst containing beta-type molecular sieve are filled in the lower part and the upper part of the reactor separately, so at to make them give their play to raise the quality of oil product.

Owner:CHINA PETROLEUM & CHEM CORP +1

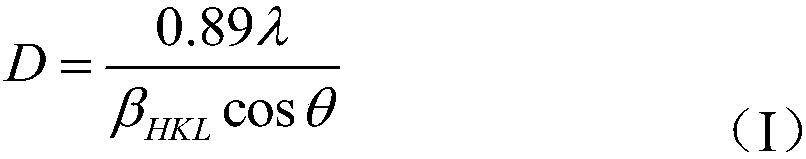

Porous carrier for hydrogenation catalyst, preparation method, hydrocracking catalyst and hydrocracking method

PendingCN107715907ALow BMCIHigh selectivityCatalyst carriersMolecular sieve catalystsMolecular sieveMetal

The present invention provides a porous carrier for a hydrogenation catalyst and a preparation method for the porous carrier. The porous carrier contains silica-alumina and a Y-type molecular sieve, based on the total amount of the porous carrier, the content of silica-alumina is 20-98 wt%, and the weight ratio of the Y-type molecular sieve to the silica-alumina is (0.02-0.2):1. The present invention also provides a hydrocracking catalyst and a hydrocracking method. The catalyst comprises the porous carrier, and a Group VIB metal element and a Group VIII metal element which are loaded into theporous carrier, wherein the porous carrier is the porous carrier provided by the present invention. When the catalyst prepared by using the porous carrier of the present invention is used in hydrocracking of hydrocarbon oils, tail oils having a low BMCI value even at low catalytically active metal content can be obtained while also a higher middle distillate selectivity can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Porous support used for hydrogenation catalyst, preparation method of porous support and hydrocracking catalyst and hydrocracking catalysis method

InactiveCN104069895ALow BMCIHigh selectivityCatalyst carriersMolecular sieve catalystsMolecular sieveSilicon oxide

The invention provides a porous support used for a hydrogenation catalyst and a preparation method of the porous support. The porous support contains silicon oxide-aluminium oxide and Y type molecular sieves, wherein based on the total quantity of the porous support, the content of silicon oxide-aluminium oxide is 20-98wt%; the weight ratio of Y type molecular sieves to silicon oxide-aluminium oxide is (0.02-0.2) to 1. The invention also provides a hydrocracking catalyst and a hydrocracking catalysis method. The catalyst contains the porous support and group VIB and VIII metallic elements loaded on the porous support, wherein the porous support is provided by the invention. The catalyst prepared by adopting the porous support can obtain tail oil with low BMCI (bureau of mines correlation index) value even under the condition of low content of metals with catalytic activities and simultaneously can obtain higher middle distillate selectivity when being used for hydrocracking of hydrocarbon oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

A hydrocracking process for flexibly producing diesel oil

ActiveCN109988648ALower freezing pointHigh viscosity indexTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxChemistry

The invention discloses a hydrocracking process for flexibly producing diesel oil. A wax oil raw material is subjected to hydrogenation pretreatment and then enters a hydrocracking reactor, and a hydrocracked material passing through a hydrocracking catalyst bed layer is divided into two streams; one stream of the hydrocracked material is subjected to gas-liquid separation and fractionation to obtain naphtha, aviation kerosene, diesel oil and tail oil; and the other stream of the hydrocracked material is mixed with a part or all of hydrocracking tail oil, and the mixture is fed into a hydrogenation isomerization cracking reactor and subjected to isomerization cracking; and a hydrogenation isomerization cracking product is subjected to gas-liquid separation and fractionation to obtain naphtha, aviation kerosene, diesel oil and tail oil. The invention provides the process for simultaneously producing more than two types of aviation kerosene, diesel oil and tail oil products with different specifications on one set of hydrogenation process equipment, especially diesel oil products with different condensation points, heat carried by a part of cracked materials can be fully utilized, and coupling operation of the hydrocracking reactor and the hydrogenation isomerization cracking reactor can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst containing Ti-P-Y molecular sieve and preparation method of hydrocracking catalyst

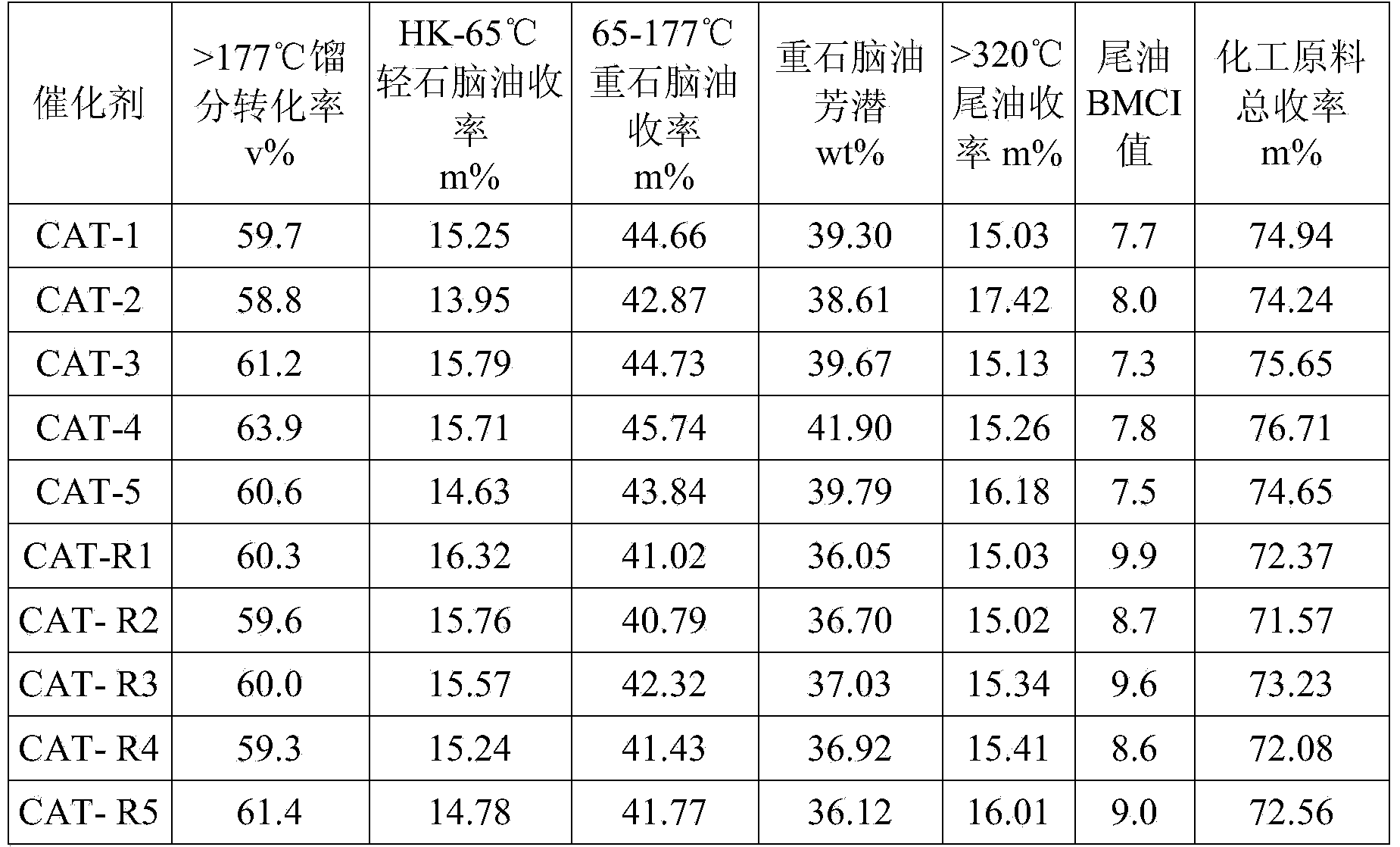

ActiveCN103521255AImprove quality and yieldPromote sulfur reductionMolecular sieve catalystsCatalyst activation/preparationMolecular sieveHigh potential

The invention provides a hydrocracking catalyst containing a Ti-P-Y molecular sieve and a preparation method of the hydrocracking catalyst. The preparation method comprises the following steps: mixing and forming amorphous silica and alumina, a Beta molecular sieve and a tungsten-loaded Ti-P-Y molecular sieve prepared by the method, thus obtaining a catalyst carrier, wherein the weight percents of the amorphous silica and alumina, the Beta molecular sieve and the tungsten-loaded Ti-P-Y molecular sieve are respectively 30-70%, 5-15% and 10-30%; loading tungsten and nickel on the catalyst carrier, thus obtaining the hydrocracking catalyst, wherein the weight percents of NiO and WO3 are respectively 1-10% and 10-29%. The hydrocracking catalyst is prepared by the preparation method provided by the invention. The catalyst has relatively high hydrocracking activity and stability, can be used for preparing heavy naphtha with high potential aromatic content and tail oil with low BMCI (Bureau of Mines Correlation Index) and has relatively high chemical material total recovery.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

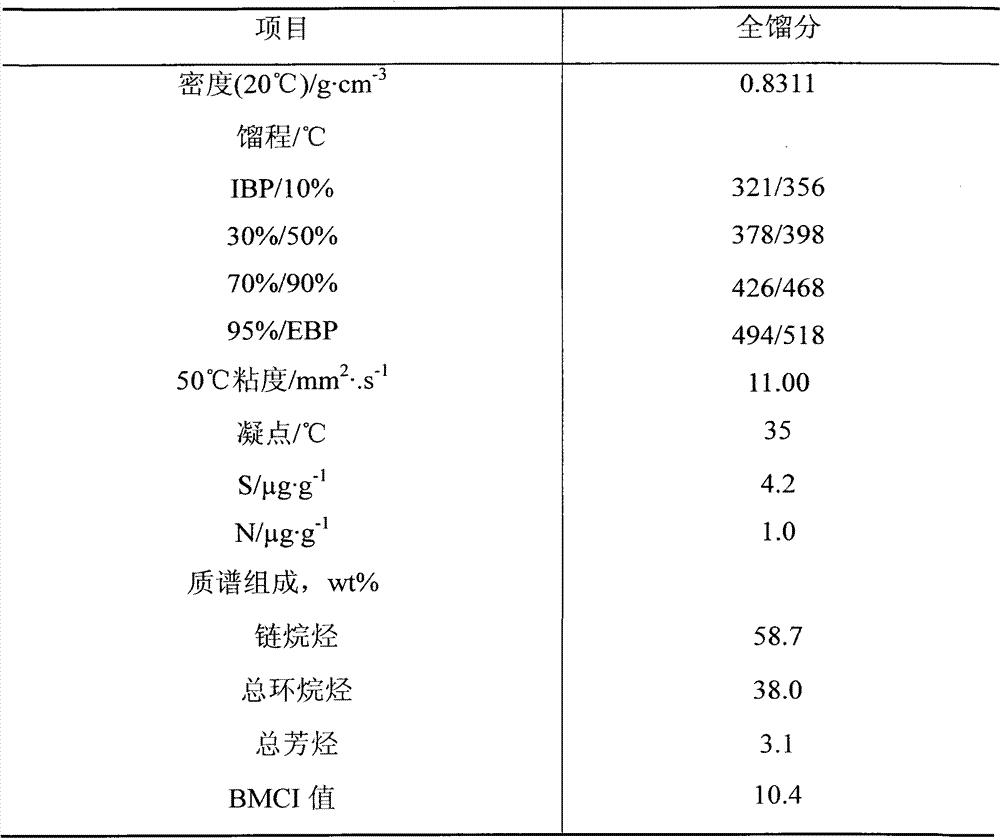

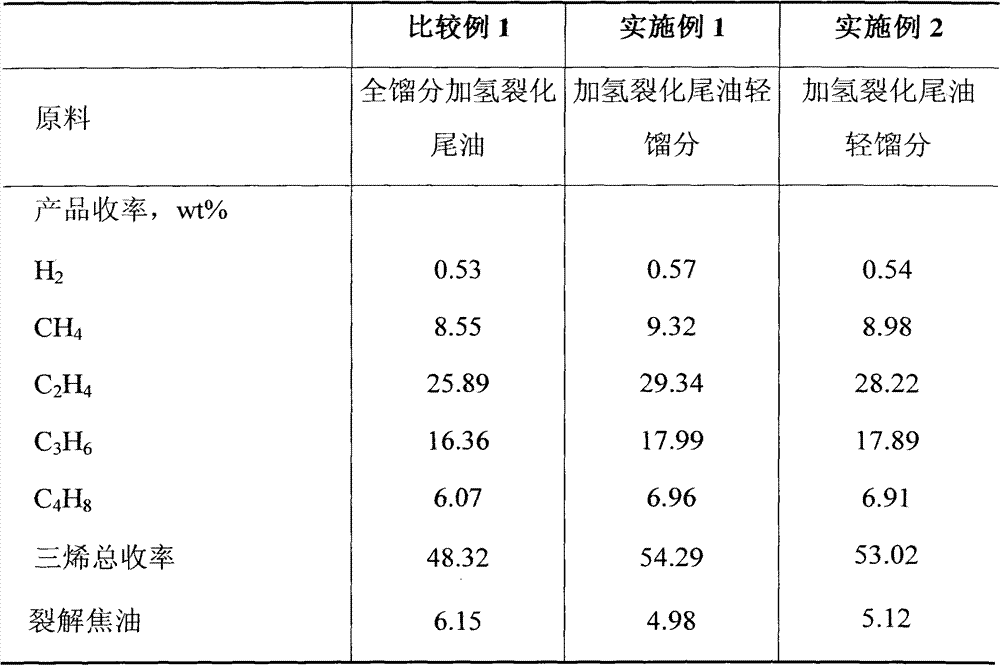

Method for producing low-carbon olefins by cracking petroleum hydrocarbon

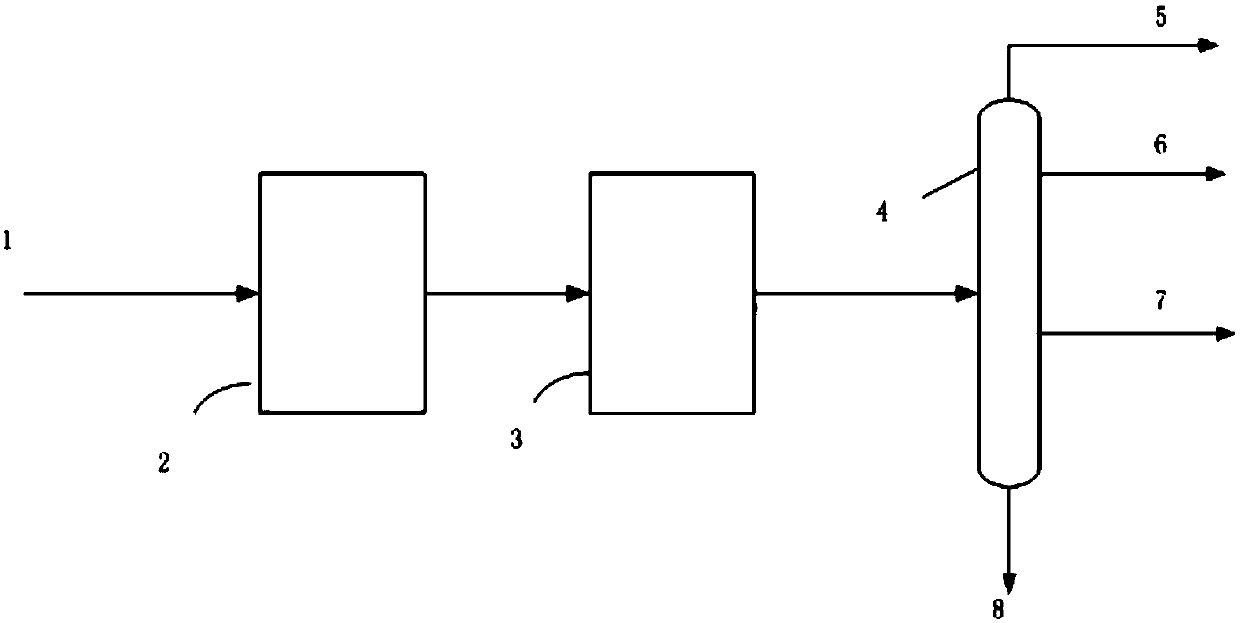

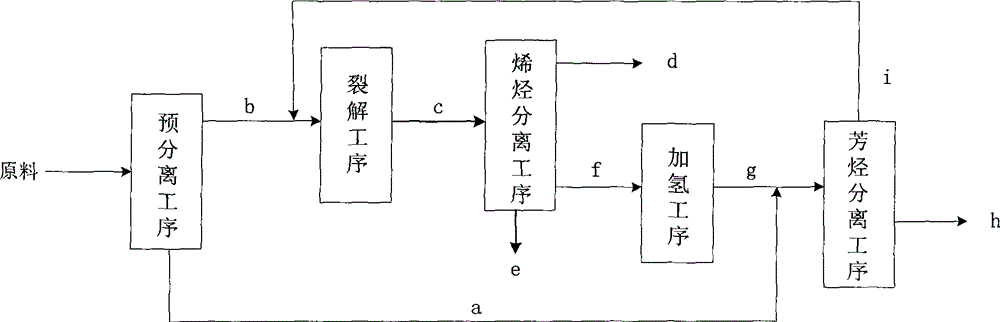

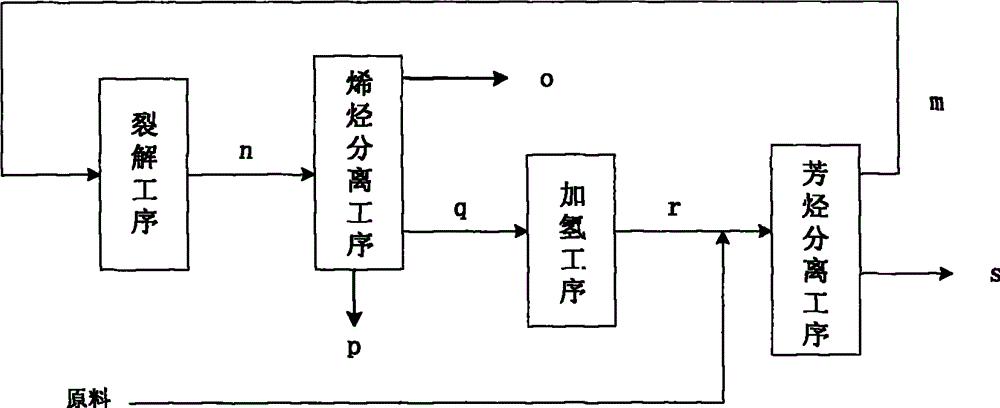

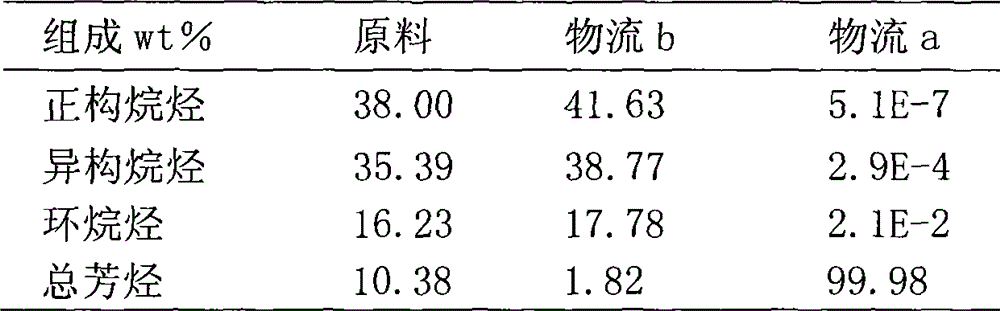

ActiveCN101684057BLow aromatic contentLow BMCIThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingHydrocarbon mixturesAromatic hydrocarbon

The invention discloses a method for producing low-carbon olefins by cracking petroleum hydrocarbon, which comprises the steps of: taking a hydrocarbon mixture with carbon atom number less than or equal to that of C35 hydrocarbon as a cracking raw material, and introducing the hydrocarbon mixture into a pre-separation working procedure to obtain a material flow rich in aromatic hydrocarbon and a petroleum hydrocarbon material flow poor in the aromatic hydrocarbon; then introducing the petroleum hydrocarbon material flow poor in the aromatic hydrocarbon into a cracking working procedure for a cracking reaction to obtain a hydrocarbon mixture containing H2 and C2-C4 olefins; and then separating the material flow rich in the aromatic hydrocarbon to obtain an aromatic hydrocarbon product. Themethod not only can improve the yield of total aromatic hydrocarbon while effectively improving the yield of the low-carbon olefins, but also effectively reduces the energy consumption, operation cost, equipment investment and the like of ethylene production devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydro-upgrading catalyst carrier as well as preparation method and application thereof

InactiveCN111318312AMatching functionEasy to useCatalyst carriersMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a hydro-upgrading catalyst carrier as well as a preparation method and application thereof. The catalyst carrier comprises a molecular sieve and organic silane loaded on the molecular sieve; wherein the weight content of the molecular sieve in the catalyst carrier is 5-35%, the weight content of organic silane is 1-5%, the molecular sieve is a Y-beta composite molecular sieve, and the mass ratio of the Y molecular sieve to the beta molecular sieve in the Y-beta composite molecular sieve is 1: 1-1: 3. The preparation method of the carrier comprises the following steps: (1) mixing and kneading a Y molecular sieve, a beta molecular sieve and macroporous alumina dry glue powder, molding, and drying and roasting after molding; and (2) introducing organic silane into thematerial roasted in the step (1), and drying to obtain the hydro-upgrading catalyst carrier. According to the catalyst prepared from the carrier, impurities in diesel oil are effectively removed and the comprehensive performance of the diesel oil is improved under the condition that the yield of the diesel oil is kept high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking process

InactiveCN1706918AHigh selectivityFang QiangaoHydrocarbon oil crackingMolecular sieveOrganic chemistry

The present invention provides one kind of hydrocracking process with simultaneously raised medium oil selectivity and product quality. By means of laminated filling of type-Y molecular sieve catalyst and type-beta molecular sieve catalyst, that is, filling the type-Y molecular sieve catalyst in the lower part of the reactor and filling the type-beta molecular sieve catalyst in the upper part of the reactor, two different kinds of molecular sieve catalyst have their characteristics utilized fully in raising medium oil selectivity and product quality simultaneously.

Owner:CHINA PETROLEUM & CHEM CORP +1

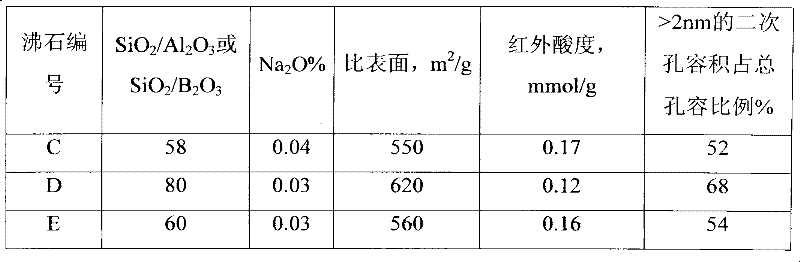

Hydrocracking catalyst, preparation method and application thereof

ActiveCN102441428AFlexibleHas a BMCI valueMolecular sieve catalystsHydrocarbon oil crackingAmorphous siliconPore diameter

The invention discloses a hydrocracking catalyst, a preparation method and application thereof. The hydrocracking catalyst comprises 1-50 percent of modified silicon-boron-oxygen crystallization material, 1-50 percent of Y zeolite, 10-60 percent of amorphous silicon aluminum, 10-40 percent of VIB-family metal oxide and 1-10 percent of VIII-family metal oxide, wherein the mol ratio of SiO2 / B2O3 ofthe modified silicon-boron-oxygen crystallization material is 20-150, the volume of a secondary pore with pore diameter of more than 2nm is above 40 percent of the total volume, the specific surface is 500-750m<2> / g, and infrared acidity is 0.05-0.50mmol / g. The catalyst has excellent hydrocracking performance and hydrodewaxing performance, good activity and high middle-oil selectivity, is suitable for a hydrocracking process of producing jet fuel and clean diesel, and is especially suitable for producing low-condensation point diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible two-stage hydrocracking method

ActiveCN109988610AHigh normal hydrocarbon contentLow aromatic contentTreatment with hydrotreatment processesFractionationCracking reaction

The invention discloses a flexible two-stage hydrocracking method. A wax oil raw material enters a separation system after hydrogenation pretreatment and mild hydrocracking; a separated liquid phase without impurities is divided into two parts; one part of the liquid phase enters a hydrocracking reactor using a reduction state hydrocracking catalyst; the other part of the liquid phase and hydrocracking tail oil are mixed and enter a hydroisomerization cracking reactor using a reduction state hydroisomerization cracking catalyst; an obtained hydrocracking reaction material and an obtained hydroisomerization cracking reaction material are subjected to gas-liquid separation and fractionation respectively to obtain naphtha, aviation kerosene, diesel oil and tail oil products of different specifications. The invention provides the two-stage hydrocracking process for simultaneously producing more than two types of light naphtha, heavy naphtha, aviation kerosene, diesel oil and tail oil products with different specifications on one set of hydrogenation process equipment for the first time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method used for producing high-quality chemical raw materials

ActiveCN103773482AGood choiceFang QiangaoTreatment with hydrotreatment processesMolecular sieveHydrogen

The invention discloses a hydrocracking method used for producing high-quality chemical raw materials. According to the hydrocracking method, raw material oil and hydrogen are delivered through a hydrofinishing reaction zone and a hydrocracking reaction zone successively; the hydrocracking reaction zone comprises at least two hydrocracking catalysts, the upper part of the hydrocracking reaction zone is filled with a hydrocracking catalyst I, and a lower part of the hydrocracking reaction zone is filled with a hydrocracking catalyst II; the hydrocracking catalyst I comprises 30 to 70wt% of modified Y molecular sieve; the hydrocracking catalyst II comprises 15 to 50wt% of modified Y molecular sieve; and the content of modified Y molecular sieve of the hydrocracking catalyst I is 10 to 30wt% higher than that of the hydrocracking catalyst II. Acid center of the hydrocracking catalyst I matches hydrogenation center, and the hydrocracking catalyst I possesses excellent heavy naphtha selectivity; and the catalyst II possesses excellent aromatic hydrocarbon transformative capacity, and is capable of transforming aromatic hydrocarbons in heavier components into smaller molecules so as to distribute in heavy petroleum fractions. The two catalysts are combined, so that product quality is improved obviously, aromatic hydrocarbon potential content of heavy naphtha is increased 3 to 10%, and tail oil BMCI value reduces 3 to 5 units.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible hydrocracking process for producing lubricant base oil

ActiveCN109988620AFlexible Hydrocracking ProcessFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsIsomerizationGas phase

The invention discloses a flexible hydrocracking process for producing lubricant base oil. A material obtained after a wax oil raw material is subjected to hydrogenation pretreatment is divided into two parts; a part of the material is separated by a hot high-pressure separator to obtain a liquid phase, and the liquid phase is mixed with hydrogen and then passes through a hydrocracking catalyst bed layer containing a Y-type molecular sieve; the other part of the material is mixed with a gas phase obtained by hot high-pressure separation and hydrocracking tail oil and then passes through a hydroisomerization cracking catalyst bed layer containing an isomerization cracking type molecular sieve; a hydrocracking reaction product and a hydroisomerization cracking reaction product are subjectedto gas-liquid separation and fractionation separately to obtain distillate oil and tail oil products with different specifications; and the hydrocracking tail oil is partially or completely circulatedinto the isomerization cracking reactor. The process provided by the invention can be used for simultaneously producing more than two kinds of naphtha, aviation kerosene, diesel oil and tail oil products with different specifications on one set of hydrogenation process equipment, especially producing high-quality lubricant base oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

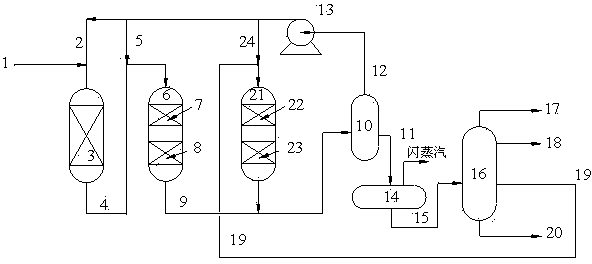

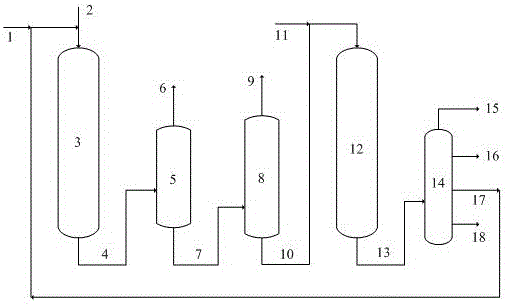

Two-stage hydrogenation cracking method for producing industrial chemicals

ActiveCN101173189BReduce loadSimple processTreatment with hydrotreatment processesNaphthaHydrogenation process

The invention discloses a hydrocracking method for manufacturing industrial chemicals, which is characterized in that: the weighty raw oil and the hydrogen are mixed and then enter the first hydrogenation process region; the hydrogen-rich gas obtained by separating the outflow from the first region enters directly the second hydrocracking reaction region and the liquid enters a fractionator to fractionate; the obtained gas, the naphtha and the tail oil are used as the industrial chemicals and go out of the system and the middle distillate oil single or mixing with other bad distillate oil enters the second hydrogenation process region to crack, and the gas obtained from the second region can be recycled and the liquid enters the fractionator. Compared with the prior art, the invention hasthe advantages of adopting two reaction regions to share a circular hydrogen system, and enabling to transform two or more bad materials into products with high added value.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method capable of producing diesel oil and chemical materials flexibly

ActiveCN101117596BFlexible adjustment of yieldReduce total usageTreatment with hydrotreatment processesNaphthaHydrogenation reaction

The present invention relates to a hydrogenation method for flexible production of diesel oil and chemical raw material, heavy raw material and optional light raw material mix with hydrogen, and enter into a first hydrogenation reaction area and a second hydrogenation reaction area, and contact with hydrogenation treatment catalyst I and hydrogenation cracking catalyst respectively and perform reaction. Without separation, the reactant mixes with the light raw material and enters into a third hydrogenation reaction area, under the action of hydrogenation treatment catalyst II, the mixture performs the reaction, through the reactant is cooled, separated and fractionated, the light naphtha distillate, the heavy naphtha distillate, the diesel oil distillate and the tail oil distillate can begot. The method provided by the present invention combines the hydrogenation treatment and the hydrogenation cracking organically, the heavy distillates such as decompression gas oil, etc. and the ungraded light distillate got from the second time processing are used as raw material, the operation can be adjusted flexibly according to the market demand, so as to produce high quality diesel oil orchemical raw material in the maximum volume, wherein the diesel oil can meet the requirement of Europe IV fuel specification.

Owner:CHINA PETROLEUM & CHEM CORP +1

A combined process method for processing low-quality diesel oil

ActiveCN103805247BReduce sulfur contentOctane RatingTreatment with hydrotreatment processesOil processingFractionation

The invention discloses a combination method used for processing inferior diesel oil. According to the combination method used for processing inferior diesel oil, secondary processing of inferior diesel fractions comprises following steps: hydro-upgrading reaction is carried out firstly, and aromatic hydrocarbon selective ring-opening reaction is carried out; a reaction effluent is separated so as to obtain a liquid material, and the liquid material is extracted; aromatic hydrocarbon components are taken as catalytic cracking raw materials and are subjected to catalytic cracking reaction, and a gas material, catalytic gasoline and catalytic diesel oil are obtained via separation and fractionation; and catalytic diesel oil can be recycled back to a hydro-upgrading reactor. The combination method is capable of converting inferior diesel oil into catalytic gasoline products with high octane value as much as possible, increasing gasoline yield and octane value of a catalytic unit as far as possible, and providing an economical feasible technical route for inferior diesel oil processing.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking technology for increase production of low solidifying point diesel oil and ethylene producing raw material

InactiveCN1188493CImprove overall utilizationLow BMCIHydrocarbon oil crackingTreatment with hydrotreatment processesPetroleumEthylene

A hydrocracking process for increasing the output of low-setting-point diesel oil and the raw material used to prepare ethylene features that the Y-zeolite hydrocracking catalyst for bearing the cracking load of 50-90 wt% of petroleum hydrocarbon and the beta-zeolite one for bearing that of 10-50 wt% of petroleum hydrocarbon are hierarchically filled.

Owner:CHINA PETROLEUM & CHEM CORP +1

Comprehensive utilization method of hydrocracking tail oil

ActiveCN102041029BHigh in paraffinsLow aromatic contentThermal non-catalytic crackingOrganic chemistryEngineeringBase oil

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst containing Ti-P-Beta molecular sieve and preparation method of hydrocracking catalyst

ActiveCN103521260AImprove quality and yieldPromote sulfur reductionMolecular sieve catalystsHydrocarbon oil crackingHigh potentialChemistry

The invention provides a hydrocracking catalyst containing a Ti-P-Beta molecular sieve and a preparation method of the hydrocracking catalyst. The preparation method comprises the following steps: mixing and forming amorphous silica and alumina, a modified Y type molecular sieve prepared by the method and a tungsten-loaded Ti-P-Beta molecular sieve prepared by the method, thus obtaining a catalyst carrier, wherein the weight percents of the amorphous silica and alumina, the modified Y type molecular sieve and the tungsten-loaded Ti-P-Beta molecular sieve are respectively 30-70%, 10-30% and 5-15%; loading tungsten and nickel on the catalyst carrier, thus obtaining the hydrocracking catalyst, wherein the weight percents of NiO and WO3 are respectively 1-10% and 10-29%. The hydrocracking catalyst is prepared by the preparation method provided by the invention. The catalyst has relatively high hydrocracking activity and stability, can be used for preparing heavy naphtha with high potential aromatic content and tail oil with low BMCI (Bureau of Mines Correlation Index) and has relatively high chemical material total recovery.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com