Hydrogenation method capable of producing diesel oil and chemical materials flexibly

A technology for chemical raw materials and diesel oil, which is applied in the field of hydrogenation that can flexibly produce diesel oil and chemical raw materials, and can solve problems such as failure to meet the requirements of Euro IV fuel specifications, high sulfur content in diesel products, and poor flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

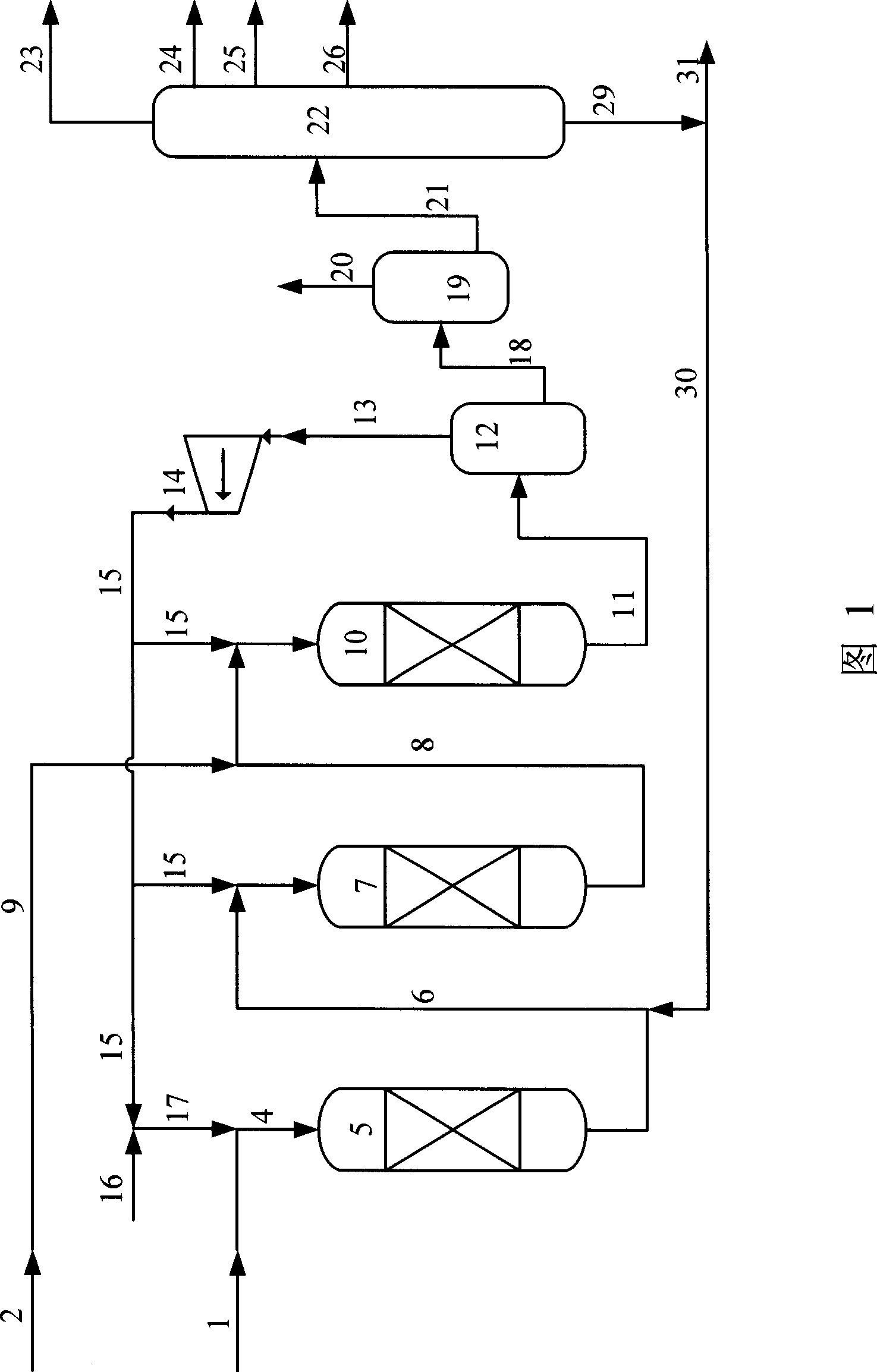

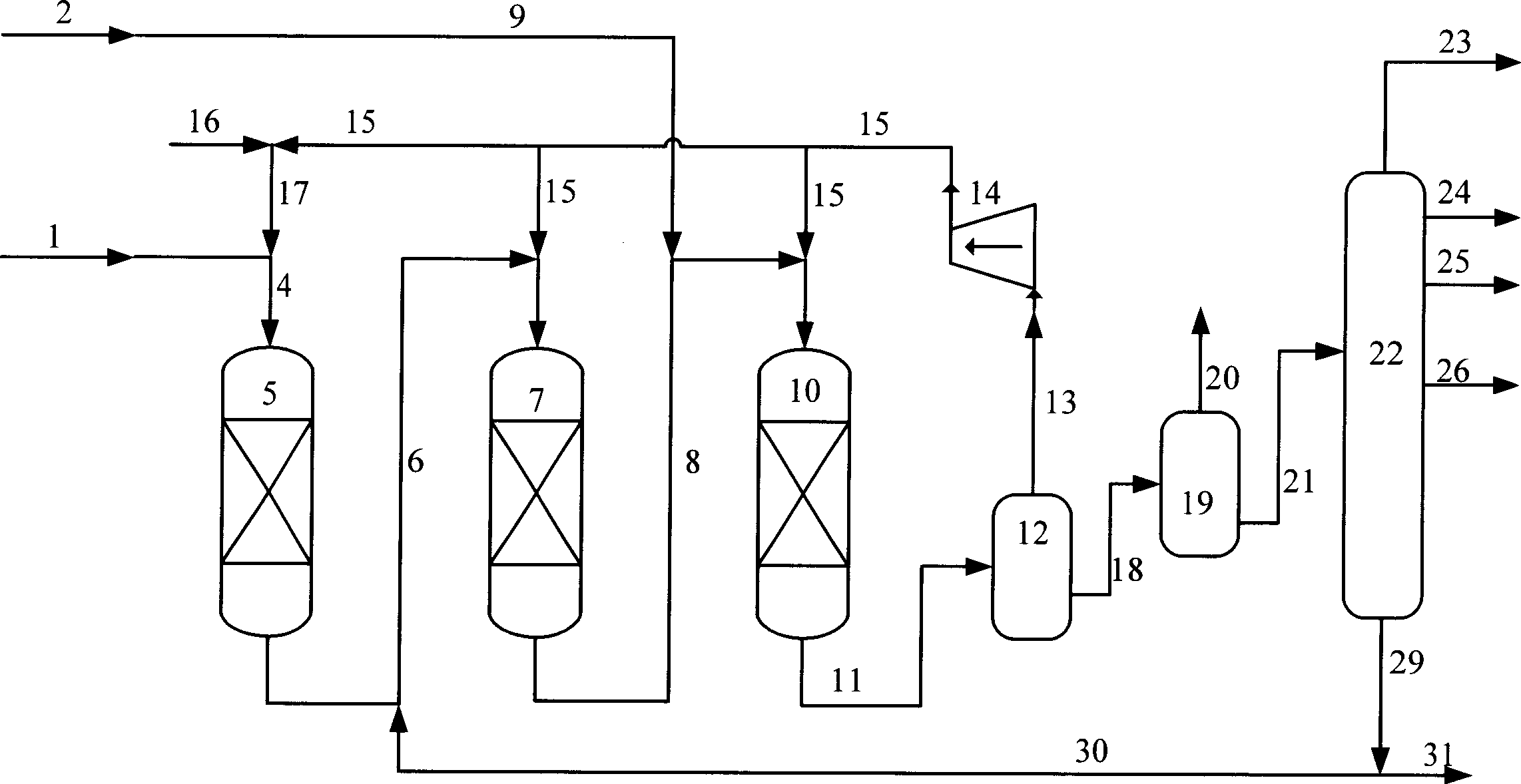

[0016] Preferred embodiment one (the embodiment that produces high-quality diesel oil in a large amount):

[0017] After the heavy raw material is mixed with hydrogen, it enters the first hydrogenation reaction zone and the second hydrogenation reaction zone successively, and reacts with the hydrotreating catalyst I and the hydrocracking catalyst respectively, and the reaction product in the second hydrogenation reaction zone does not After being separated and mixed with the light raw material, it enters the third hydrogenation reaction zone, and reacts with the hydrogenation catalyst II, wherein the weight ratio of the heavy raw material to the light raw material is preferably 1:1-9:1. The reaction product in the third hydrogenation reaction zone is cooled, separated and fractionated to obtain light naphtha fraction, heavy naphtha fraction, diesel fraction and tail oil fraction. Part or all of the tail oil fraction can be recycled to the second hydrogenation reaction zone for...

Embodiment approach 2

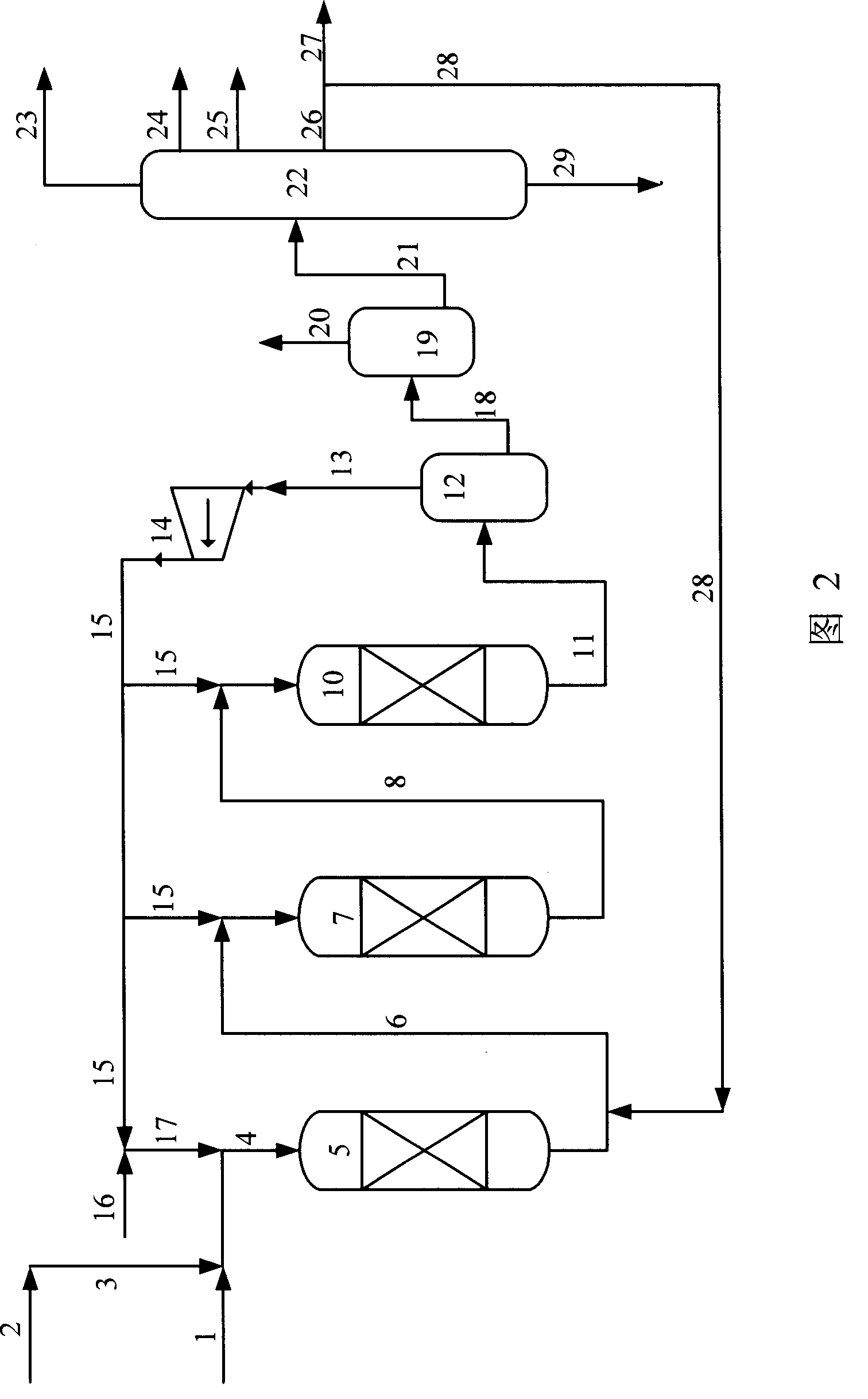

[0018] Preferred embodiment two (the embodiment that produces chemical raw material in a large amount):

[0019] Heavy raw materials and light raw materials, the weight ratio of heavy raw materials and light raw materials is preferably 1:1 to 9:1, and after being mixed with hydrogen, they enter the first hydrogenation reaction zone, the second hydrogenation reaction zone and the third hydrogenation reaction zone in turn. The hydrogenation reaction zone is respectively contacted with the hydrotreating catalyst I, the hydrocracking catalyst and the hydrotreating catalyst II to react, the intermediate reaction product is not separated, and the final reaction product is cooled, separated and fractionated to obtain light Naphtha fraction, heavy naphtha fraction, diesel fraction and tail oil fraction, wherein part or all of the diesel fraction can be recycled to the second hydrogenation reaction zone for hydrocracking reaction again to increase the yield of heavy naphtha fraction, an...

Embodiment 1

[0041] This embodiment adopts the preferred embodiment one, that is, the embodiment of the maximum production of diesel oil. After the heavy raw material is mixed with hydrogen, it passes through the first hydrogenation reaction zone and the second hydrogenation reaction zone successively, and is respectively mixed with the hydrotreating catalyst 1 and the second hydrogenation reaction zone. Hydrocracking catalyst contact reaction, the reaction effluent mixed with light raw materials enters the third hydrogenation reaction zone, and undergoes hydrogenation reaction under the action of hydrotreating catalyst II, and the reaction effluent of the third hydrogenation reaction zone passes through After cooling, separation and fractionation, light naphtha fraction, heavy naphtha fraction, diesel fraction and tail oil fraction are obtained. The weight ratio of heavy raw material to light raw material is 5:1. Based on the overall catalyst volume, the filling volume percentages of hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com