Hydro-upgrading catalyst carrier as well as preparation method and application thereof

A technology of catalyst support and hydrogenation modification, which is applied in the direction of catalyst support, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of large steric hindrance, lower diesel yield, difficult removal, etc., and achieve improved dispersion, The effect of high aromatic latent content and high acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

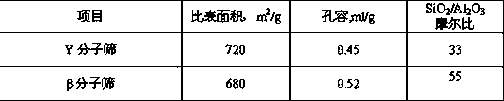

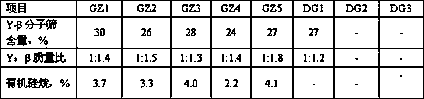

[0031] 21 grams of β molecular sieve, 15gY molecular sieve, 85 grams of macroporous alumina (pore volume 0.9mLg, specific surface area 355m 2 / g, hereinafter the same), 4g microcrystalline cellulose, and the mixed aqueous solution containing 4g guar gum and dilute nitric acid (wherein the mass concentration of nitric acid is 2.5%, and the mass concentration of guar gum is 0.5%) is put into rolling machine Mix and grind, roll into a paste, extrude, and dry the extruded strip at 120°C for 4 hours, and then bake at 530°C for 4 hours to obtain carrier Z1.

[0032]Weigh 4.5 g of 3-aminopropyltrimethoxysilane, add it into an aqueous solution containing 2 wt % ethanolamine and dissolve it to make the volume 80 mL, and obtain solution R1.

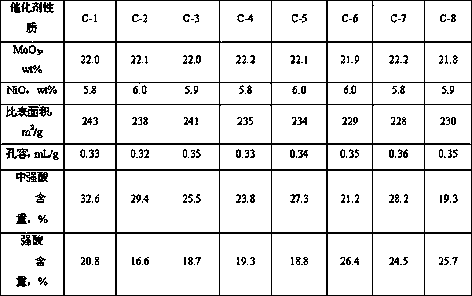

[0033] Weigh 100g of Z1, spray the solution R1 evenly on the carrier Z1, and after curing for 8 hours, dry it at 120°C for 2 hours to obtain the carrier GZ1. The composition and properties of the carrier are shown in Table 1 and Table 2.

[0034] ...

Embodiment 2

[0036] With 18 grams of β molecular sieves, 12gY molecular sieves, 85 grams of macroporous alumina, 3g microcrystalline cellulose, and containing 4g guar gum and dilute nitric acid (wherein the concentration of nitric acid is 2.5wt%, and the concentration of guar gum is 0.6wt%) The mixed aqueous solution was put into a roller compactor for mixing and grinding, and then rolled into a paste, extruded, dried at 120°C for 4 hours, and then calcined at 550°C for 4 hours to obtain carrier Z2.

[0037] Weigh 3.8 g of vinyltriethoxysilane, add it into an aqueous solution containing 1.5 wt % dimethyl sulfoxide, and dissolve it to make the volume 82 mL, and obtain a solution R2.

[0038] Weigh 100g of carrier Z2, spray the solution R2 evenly on the carrier Z2, after curing for 8 hours, dry at 110°C for 2 hours to obtain the modified carrier GZ2, the composition and properties of the carrier are shown in Table 1 and Table 2.

[0039] Carrier GZ2 was calcined at 290°C for 2.5 hours, impre...

Embodiment 3

[0041] With 15 grams of Y molecular sieves, 20 grams of β molecular sieves, 90 grams of macroporous alumina, 3g microcrystalline cellulose, and containing 2g guar gum and dilute nitric acid (wherein the concentration of nitric acid is 2.3wt%, and the concentration of guar gum is 0.8wt% %) of the mixed acidic aqueous solution was put into a roller compactor for mixing and grinding, and rolled into a paste, extruded, and the extruded strips were dried at 120°C for 4 hours, and then calcined at 520°C for 4 hours to obtain the carrier Z3.

[0042] Weigh 5 g of N-aminoethyl-3-aminopropylmethyldimethoxysilane, add it into an aqueous solution containing 2 wt % citric acid and dissolve it to make the volume 80 mL, and obtain solution R3.

[0043] Weigh 100g of hydrogenation modification catalyst support Z3, spray the solution R3 evenly on the support Z3, after curing for 6 hours, dry at 110°C for 2 hours to obtain the modified support GZ3, the composition and properties of the support ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com