Method for producing low-carbon olefins by cracking petroleum hydrocarbon

A technology for low-carbon olefins and petroleum hydrocarbons, which is used in hydrocarbon cracking to produce hydrocarbons, petroleum industry, cracking, etc. It can solve the problems of increased raw material consumption, loss of isoparaffin and naphthenic components, etc. Selective and comprehensive energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

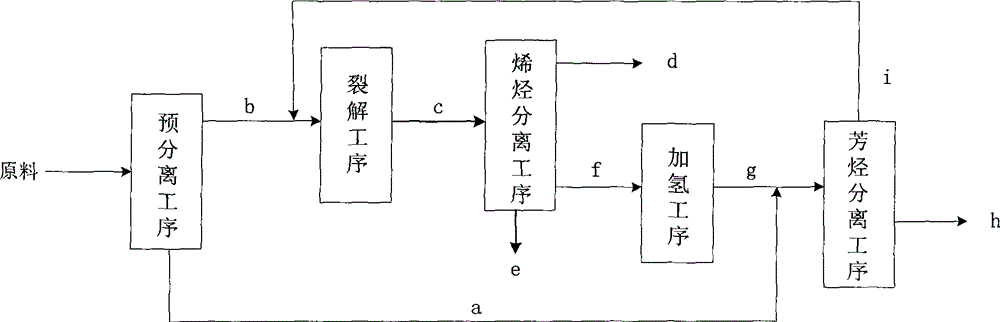

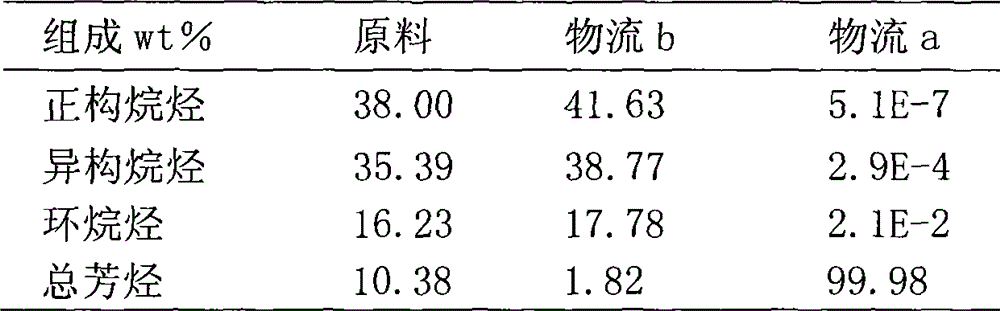

[0049] by figure 1 As an example to illustrate the method of the present invention, C 4 ~C 15 The hydrocarbon naphtha is introduced into the pre-separation process and separated by solvent extraction. Select sulfolane as the solvent, the mass ratio of the solvent to the feed is 5, the water content of the solvent is 0.8%, the pressure of the extraction tower is 0.6MPa, the temperature at the top of the tower is 70°C, and the mass ratio of the reflux to the feed is 0.1; The pressure is 0.2MPa, the temperature at the top of the tower is 112°C, and the temperature at the bottom of the tower is 170°C; the pressure of the recovery tower is 0.045MPa, the temperature at the top of the tower is 70°C, the temperature at the bottom of the tower is 165°C, and the reflux ratio is 0.5. The petroleum hydrocarbon stream a with aromatics content of 1.82% and the petroleum hydrocarbon mixture b with 99.98% aromatics content obtained after separation, the group composition and BMCI value of e...

Embodiment 2

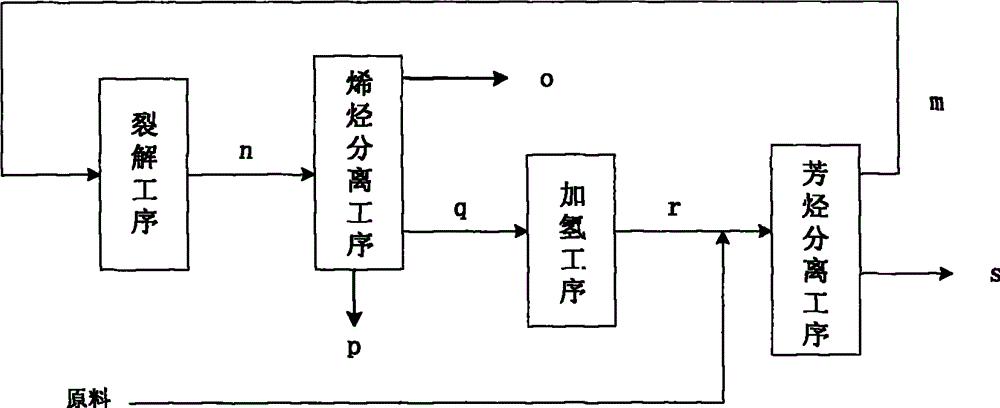

[0057] by figure 2 As an example to illustrate the method of the present invention, the C 4 ~C 15 Petroleum hydrocarbon cracking raw materials of hydrocarbons are introduced into the aromatics separation process together with pyrolysis gasoline, and separated by extractive distillation. Sulfolane is selected as the solvent, the solvent ratio is 3, the water content of the solvent is 0.8%, the pressure at the top of the extractive distillation tower is 0.12Mpa, the temperature at the top of the tower is 102°C, the temperature at the bottom of the tower is 171°C, and the reflux ratio is 0.65; The pressure is 0.04MPa, the temperature at the top of the tower is 65°C, the temperature at the bottom of the tower is 168°C, and the reflux ratio is 0.9. After separation, the petroleum hydrocarbon stream m with aromatics content of 2% and the petroleum hydrocarbon mixture s with aromatics content higher than 99.99% obtained after separation, the group composition and BMCI value of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com