Method for producing high-quality low-freezing diesel oil

A diesel and low-condensation technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of small freezing point depression and low cetane number of diesel oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

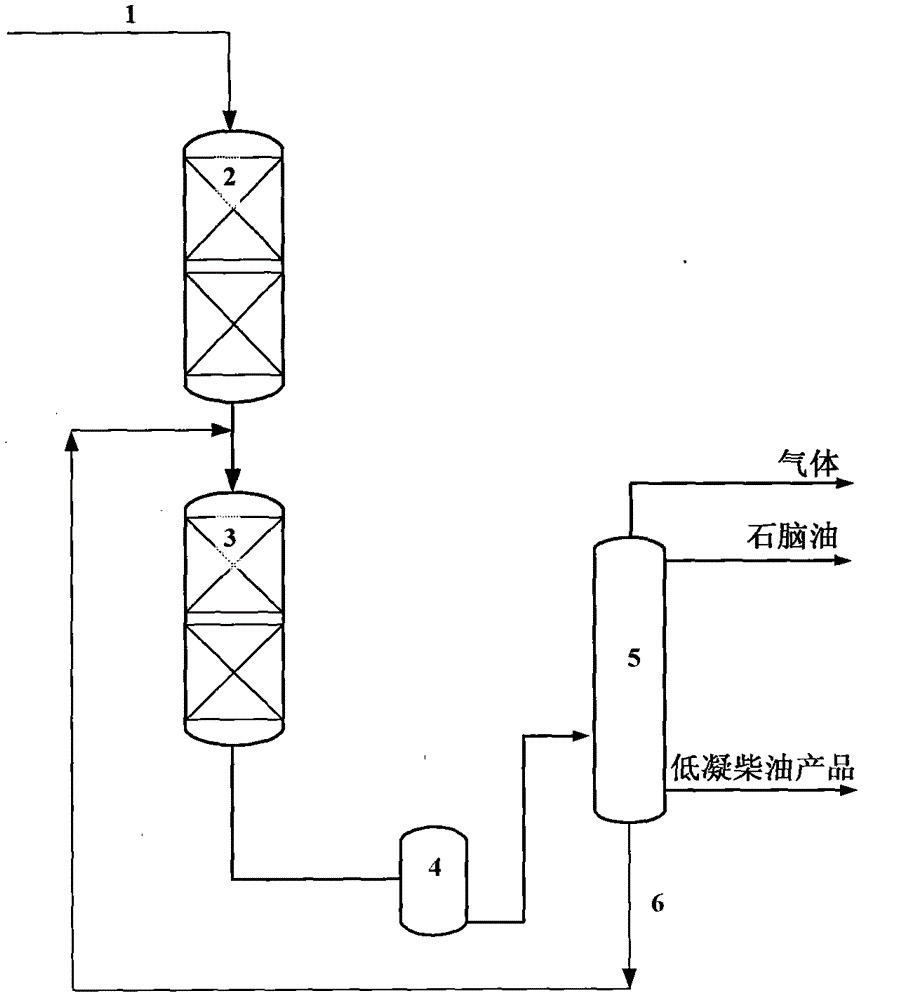

Image

Examples

Embodiment 1

[0061] Using a kind of coking gasoline and diesel mixed oil ① as the raw material, the raw material ① is firstly subjected to whole-distillate hydrotreating in the first reaction zone, and the reaction effluent directly enters the second hydrogenation reaction zone without separation, and in the second hydrogenation reaction zone In the second reaction zone, the hydrogenation upgrading and depressing catalyst and the hydrofining catalyst II are used for upgrading and depressing and supplementary refining reactions, and the product in the second reaction zone enters the separation and fractionation system to cut out low-point-point product diesel oil. All diesel fractions are recycled to the inlet of the second reaction zone to undergo isomerization and cracking reactions to further lower the freezing point. The hydrorefining catalyst I loaded in the first reaction zone is RS-1000, the second reaction zone is filled with hydrogenation upgrading and pour point depressing catalyst...

Embodiment 2

[0067] Using coking gasoline and diesel mixed oil ① as raw material, the method provided by the invention is used for depressing, and 30% by weight of the heavy diesel fraction at 340-360°C is recycled to the entrance of the second reaction zone. The catalysts used are RS-1000, plus For the hydrogen-modified and pour-point depressing catalyst B and the RS-1000 catalyst, the three-part catalyst loading ratio is 45:45:10. The properties of raw oil are listed in Table 1, and the reaction conditions and product properties are listed in Table 2.

[0068] It can be seen from the data in Table 2 that the freezing point of the diesel product was reduced to -26°C, the cold filter point was reduced to -14°C, the yield reached 93.2%, the cetane number increased to 48.5, and the sulfur content was greatly reduced.

Embodiment 3

[0070] Diesel oil ② is used as raw material, and the method provided by the present invention is used for depressing, and 80% by weight of the heavy diesel fraction at 300-380°C is recycled to the entrance of the second reaction zone. The catalysts used are RS-1000, hydrogenation, upgrading Condensed catalyst B and RS-1000 catalyst, the three-part catalyst loading ratio is 40:50:10. The properties of raw oil are listed in Table 1, and the reaction conditions and product properties are listed in Table 3.

[0071] It can be seen from the data in Table 2 that the freezing point of the diesel product is reduced to -45°C, the cold filter point is reduced to -32°C, the yield reaches 88.2%, the cetane number increases to 43.0, and the sulfur content is greatly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com