ZSM-5/MCM-48 composite molecular sieve, preparation method and application thereof

A technology of MCM-48 and composite molecular sieves, which is applied in the field of ZSM-5/MCM-48 composite molecular sieves and its preparation, can solve the problems of cumbersome catalyst preparation process, high cost, and modulation of reaction products, and improve hydrothermal stability , Improve low-temperature activity and extend the carbon chain length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

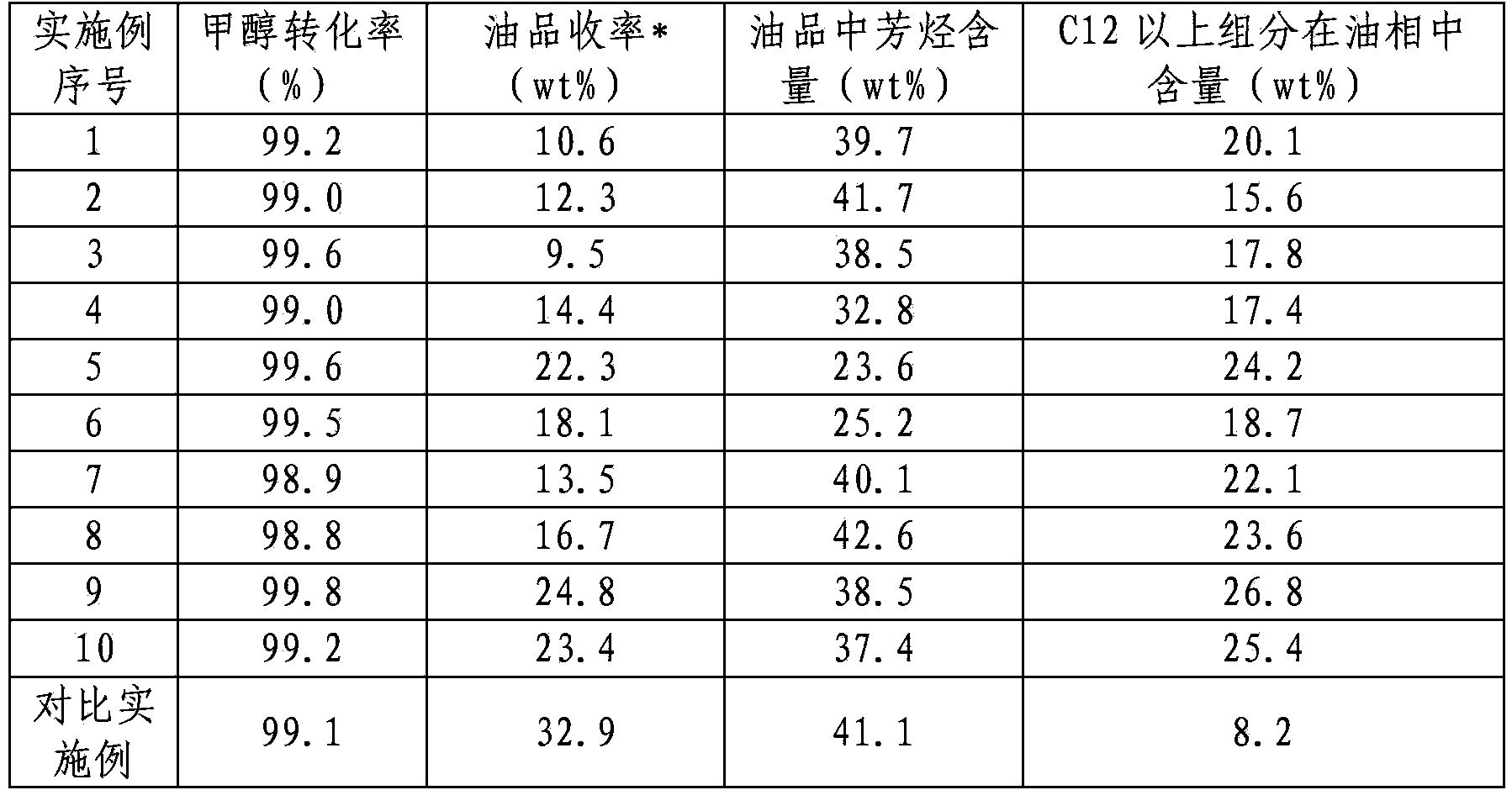

Examples

Embodiment 1

[0043] Preparation of ZSM-5 / MCM-48 composite molecular sieve:

[0044] The molar ratio of each raw material in the preparation of ZSM-5 / MCM-48 composite molecular sieve is: TEOS:CTAB:NaOH:Al:H2O=1.0:0.12:0.4:0.0125:56.

[0045] Mix 4.459g of cetyltrimethylammonium bromide (CTAB), 1.432g of sodium hydroxide and 100.89g of deionized water, add 0.26g of aluminum isopropoxide to the above solution, stir at a constant temperature of 35°C until clear, gradually Add 21.24g tetraethyl orthosilicate (TEOS) dropwise, adjust the pH to 10-11 with 50wt% acetic acid aqueous solution, and stir for 4 hours to prepare the MCM-48 precursor solution.

[0046] ZSM-5 (Si / Al=38, Nankai Catalyst Factory) was stirred in 0.5mol / L NaOH aqueous solution at 75°C for 4h, filtered, washed until the filtrate was neutral, dried at 110°C for 12h, and calcined at 550°C for 6h. Then grind it into 280-300 mesh particles, slowly add it to the precursor solution of MCM-48, stir at room temperature for 2h, crystal...

Embodiment 2

[0053] Preparation of ZSM-5 / MCM-48 composite molecular sieve:

[0054] The molar ratio of each raw material prepared by ZSM-5 / MCM-48 composite molecular sieve is: Na 2 SiO 3 :OTAC:NaOH:Al:H 2 O=0.8:0.4:0.55:0.025:120.

[0055] Mix 13.922g of octadecyltrimethylammonium chloride (OTAC), 2.212g of sodium hydroxide with 216.45g of deionized water, add 0.511g of aluminum isopropoxide to the above solution, stir at a constant temperature of 35°C until clear, gradually Add dropwise 9.765 sodium silicate (Na 2 SiO 3 ), adjust the pH=10-11 with 50wt% acetic acid aqueous solution, stir for 4h, and prepare the MCM-48 precursor solution.

[0056] ZSM-5 (Si / Al=38, Nankai Catalyst Factory) was treated in 0.3mol / L NaF aqueous solution, stirred at 60°C for 6h, filtered, the filtrate was washed until neutral, dried at 100°C for 16h, and calcined at 550°C for 6h. Then grind it into 280-300 mesh particles, slowly add it to the precursor solution of MCM-48, stir at room temperature for 2h, ...

Embodiment 3

[0060] Preparation of ZSM-5 / MCM-48 composite molecular sieve:

[0061] The molar ratio of each raw material prepared by ZSM-5 / MCM-48 composite molecular sieve is: Na 2 SiO 3 :CTAB:NaOH:Al:H 2 O=1.4:0.75:0.7:0.0355:165.

[0062] 27.333g cetyltrimethylammonium bromide (CTAB) 2.812g sodium hydroxide mixed with 297.02g deionized water, 1.215g aluminum sulfate (Al 2 (SO4) 3 ) into the above solution, stirred at a constant temperature of 35°C until clear, then added 17.088 sodium silicate (Na 2 SiO 3 ), adjust the pH=10-11 with 50wt% acetic acid aqueous solution, stir for 4h, and prepare the MCM-48 precursor solution.

[0063] ZSM-5 (Si / Al=38, Nankai Catalyst Factory) was treated in 0.7mol / L NaOH aqueous solution, stirred at 80°C for 3h, filtered, the filtrate was washed until neutral, dried at 120°C for 10h, and calcined at 550°C for 6h. Then grind it into 280-300 mesh particles, slowly add it to the precursor solution of MCM-48, stir at room temperature for 2h, crystallize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com