Patents

Literature

43results about How to "High conversion rate of methanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

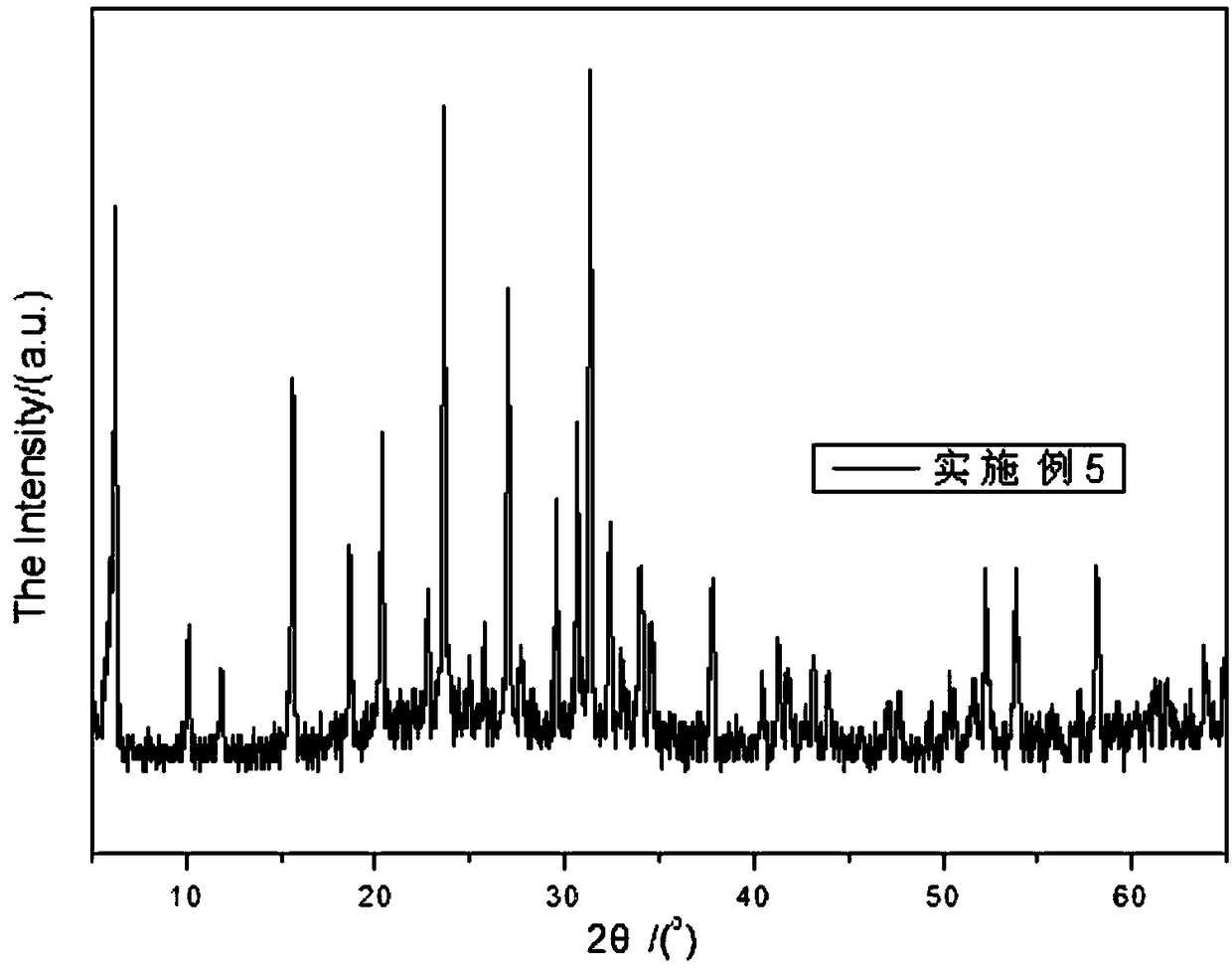

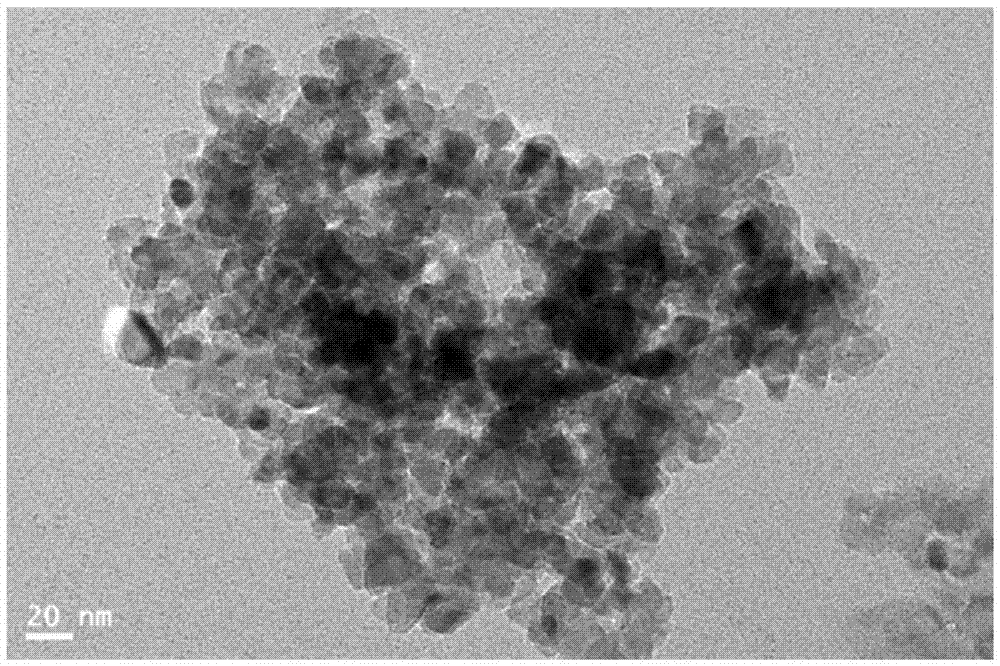

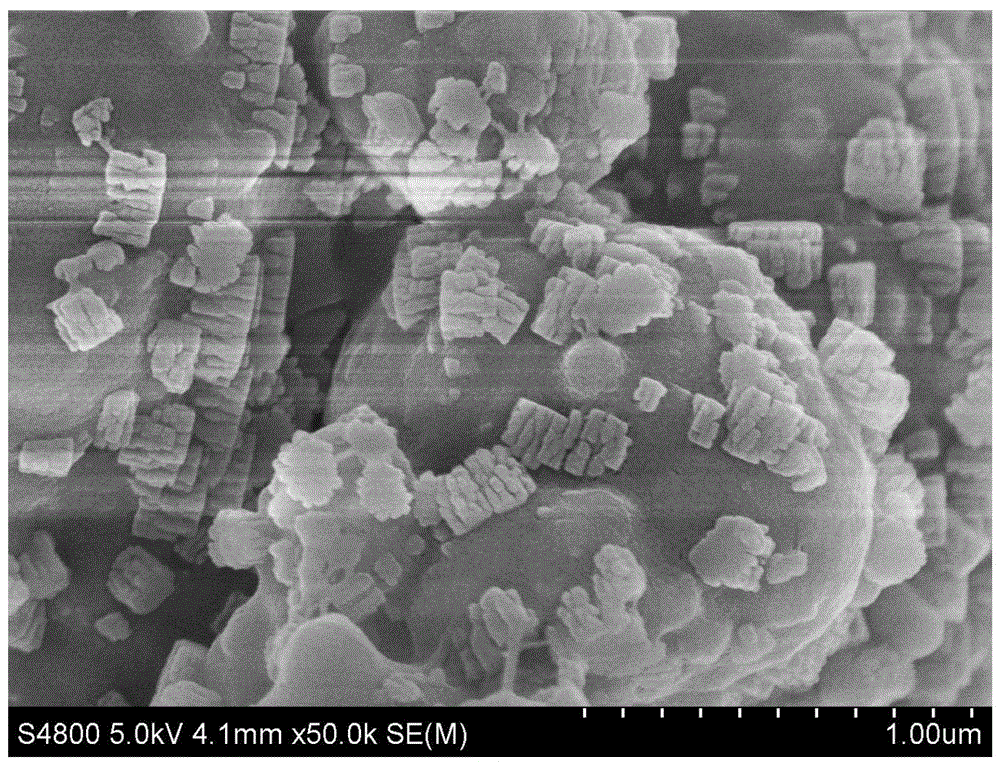

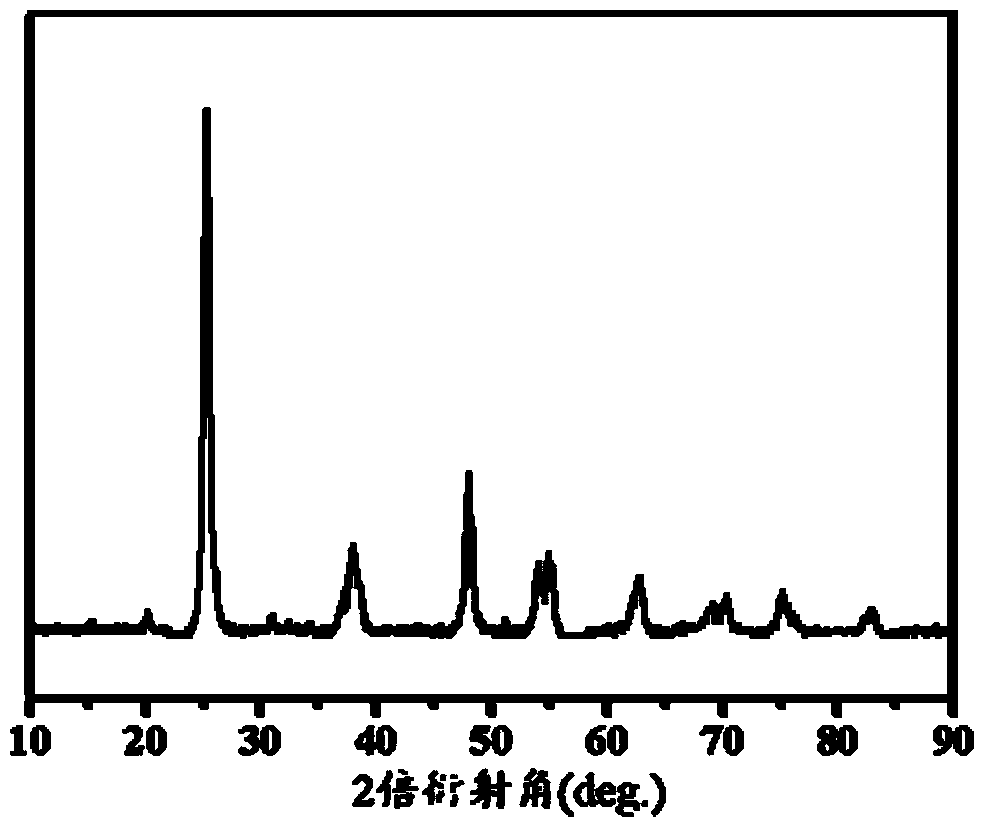

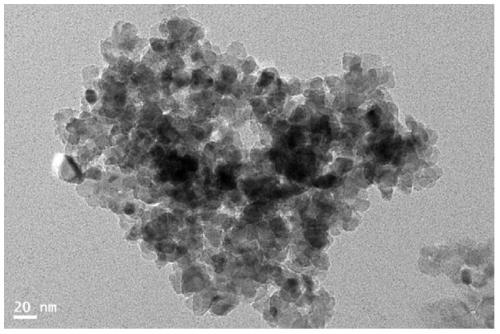

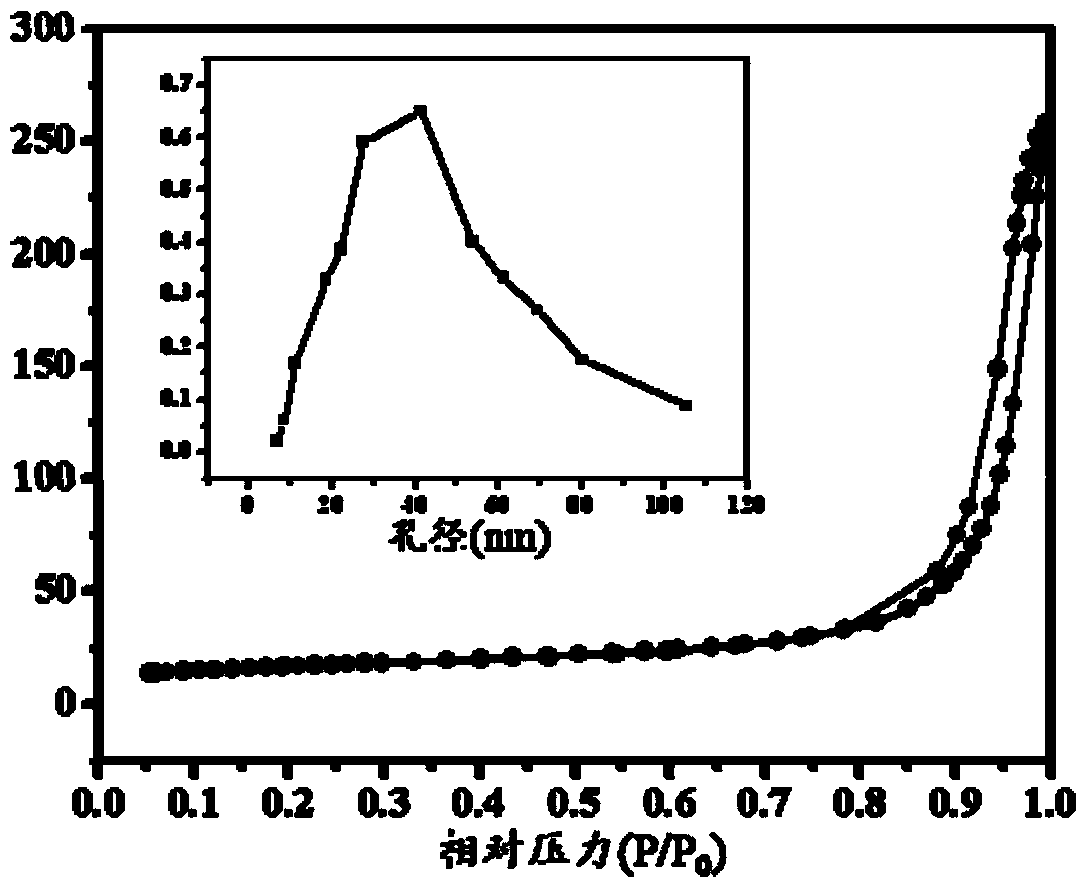

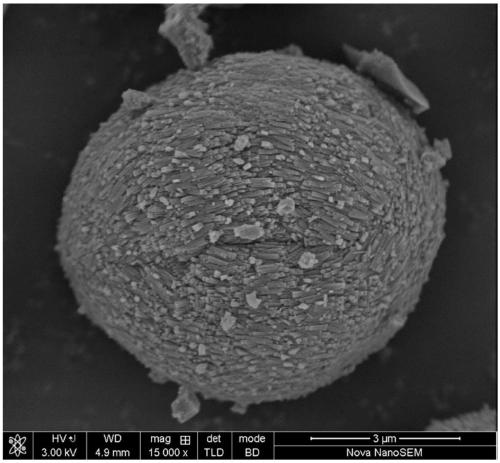

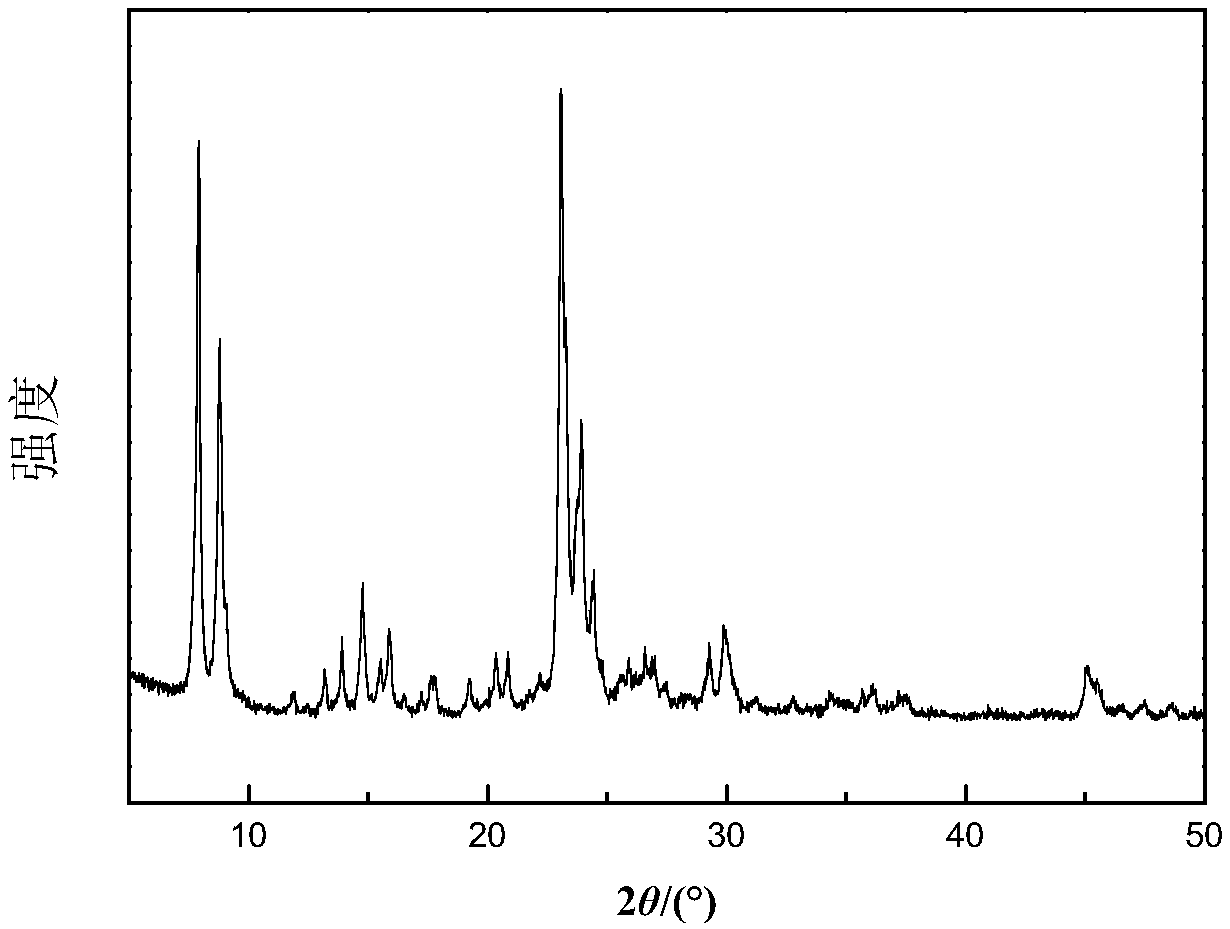

One-step synthesizing method for hollow type multilevel-hole Fe-Silicalite-1

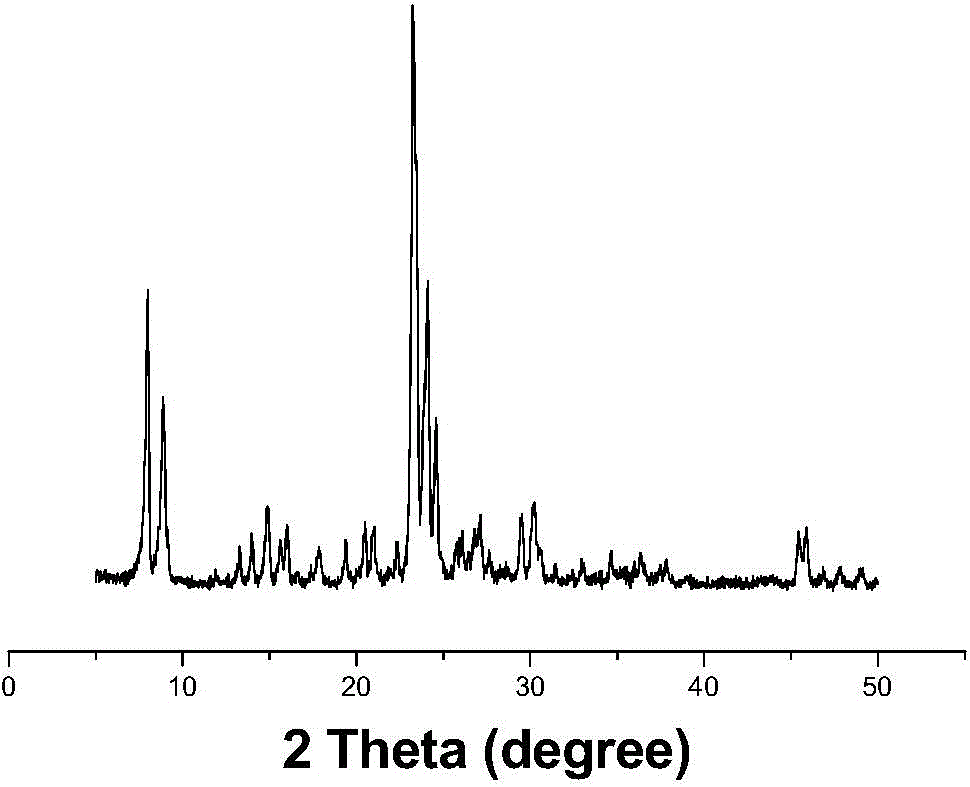

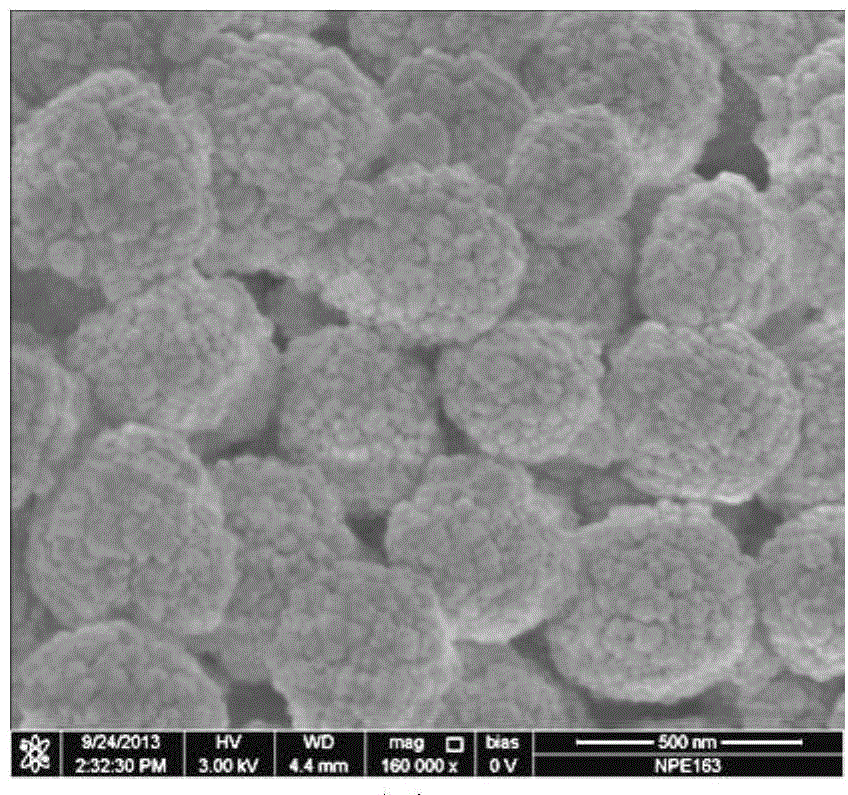

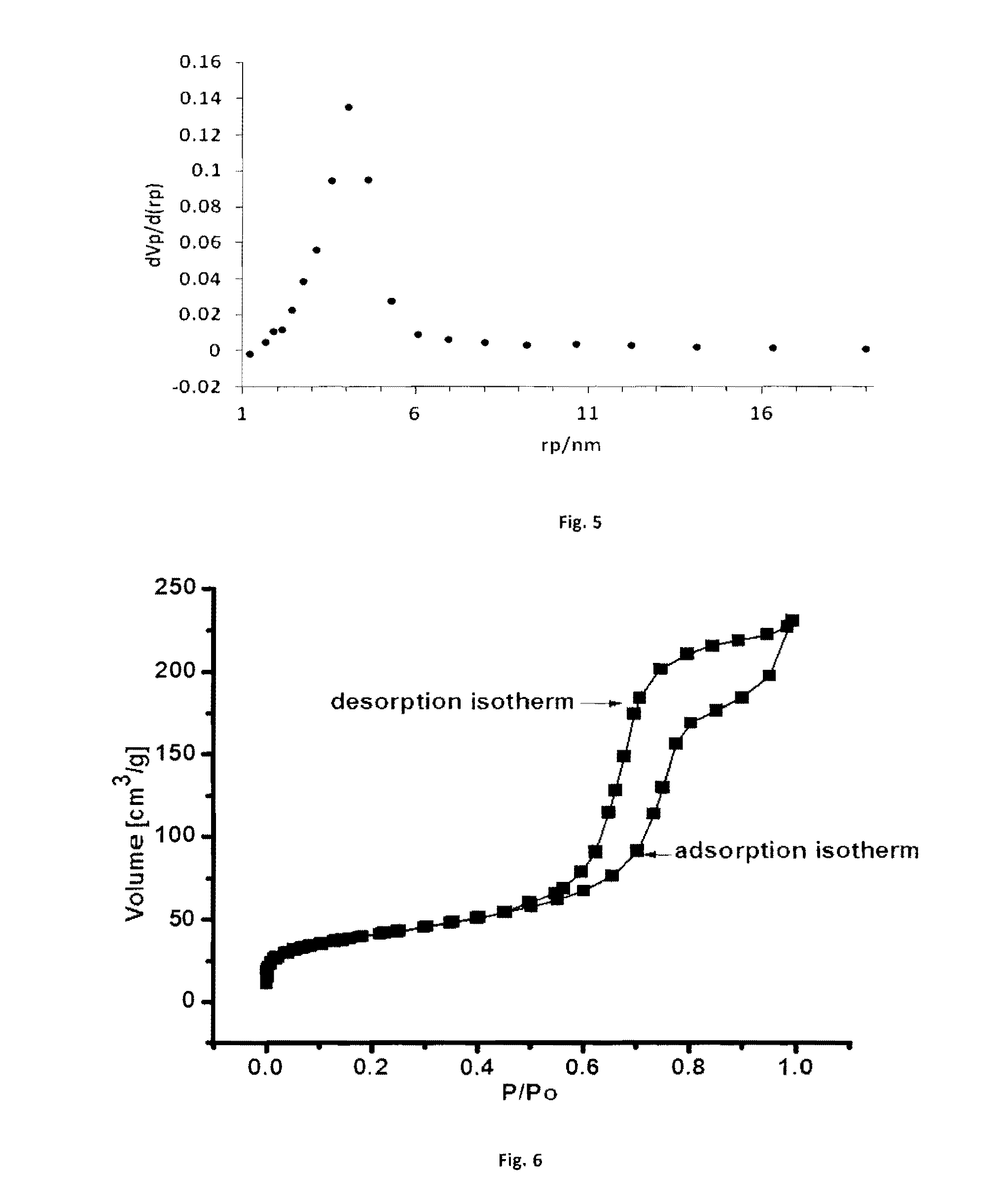

ActiveCN104098106ASmall particle sizeAvoid hydrolysisCrystalline aluminosilicate zeolitesSiliconCrystallization

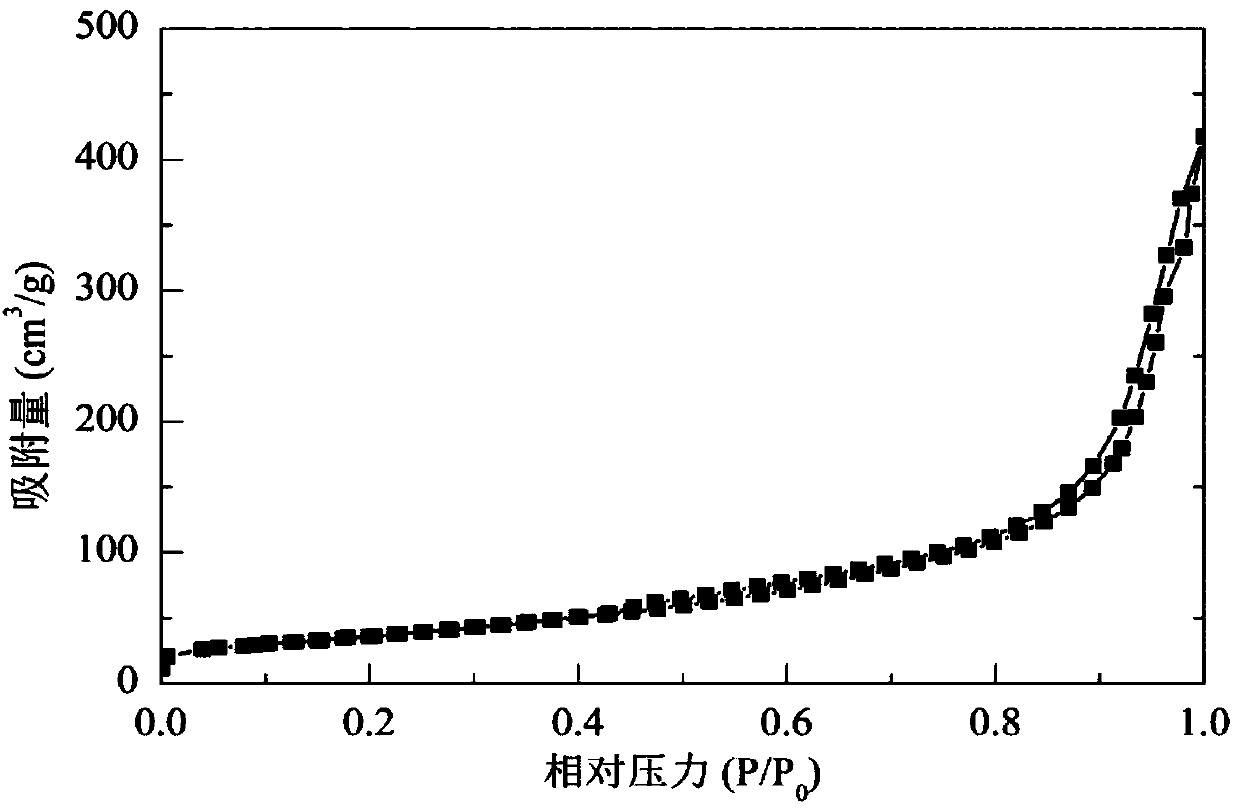

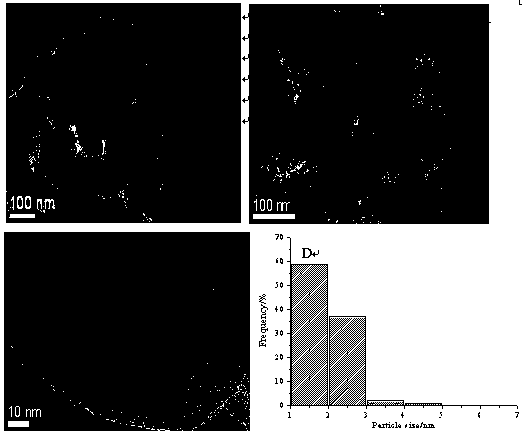

The invention provides a one-step synthesizing method for hollow type multilevel-hole Fe-Silicalite-1 zeolite and application thereof. The method adopts a silicon source, an organic iron source, an alkali source, a template agent and water as raw materials, and the raw materials are crystallized in a crystallization kettle, and then subjected to centrifugal separation, washing, drying and calcinating for preparing the hollow type Fe-Silicalite-1 zeolite with distributed micropores and mesoporouses . The synthesis technology is simple, and requires no multistep operation and no additional expensive additive; through adjusting the types of the iron source, the appearance and the pore size distribution of the Fe-Silicalite-1 zeolite are adjusted effectively; when used for catalyzing a methanol-to-propylene reaction, the Fe-Silicalite-1 zeolite synthesized through the invention is higher in propylene selectivity and methanol conversion rate, and longer in the service life of a catalyst.

Owner:CHAMBROAD CHEM IND RES INST CO LTD +1

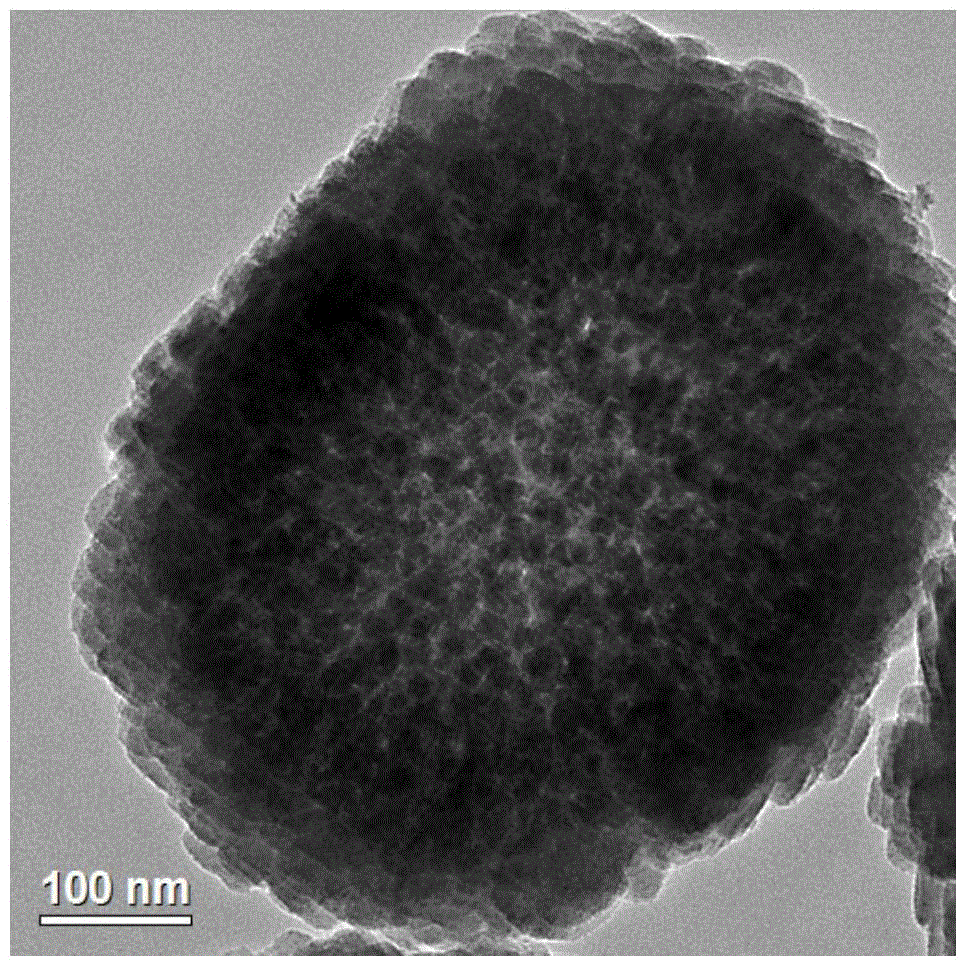

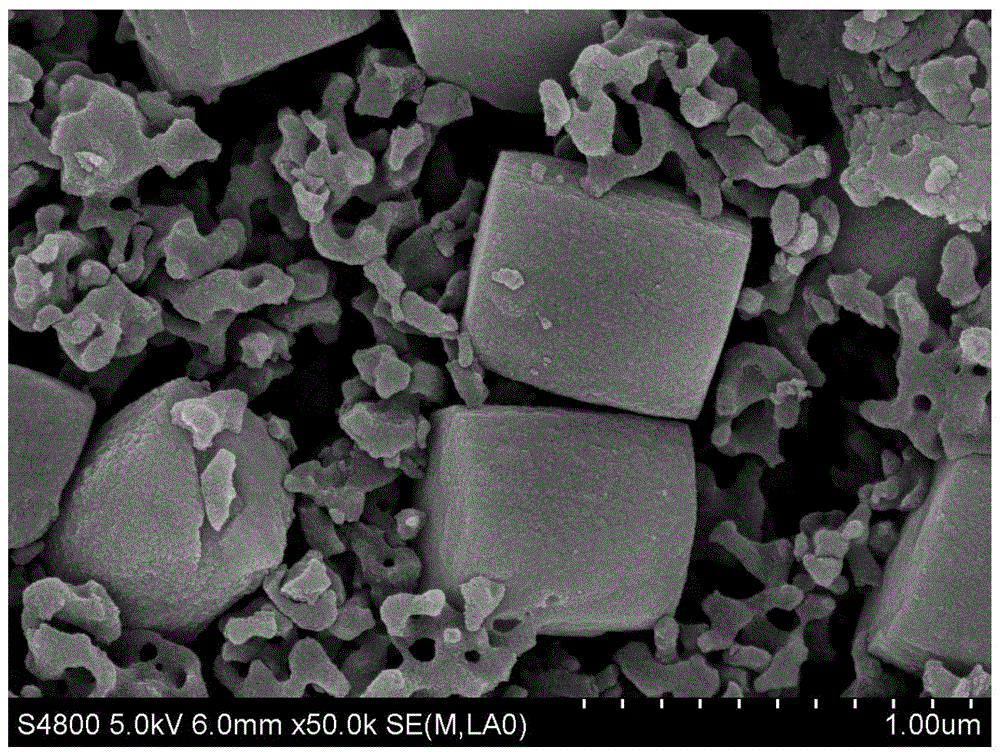

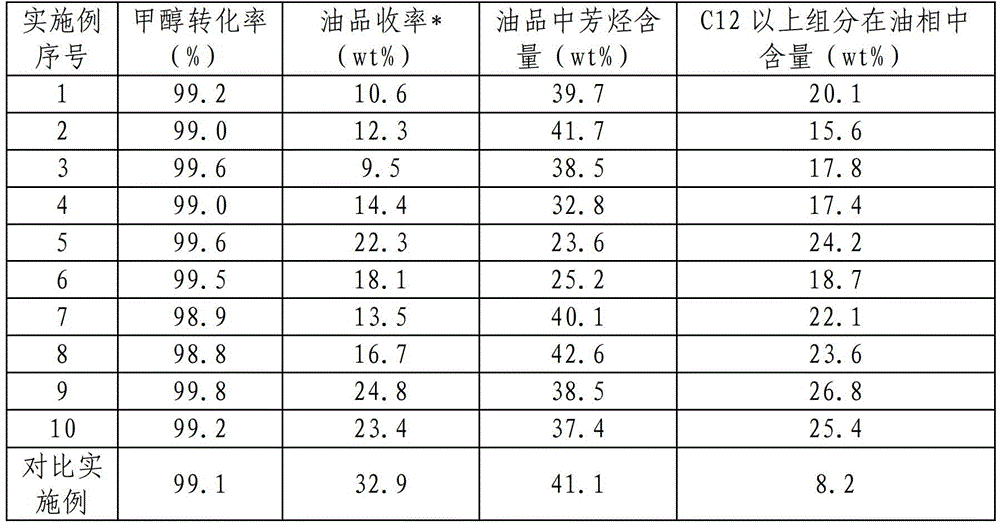

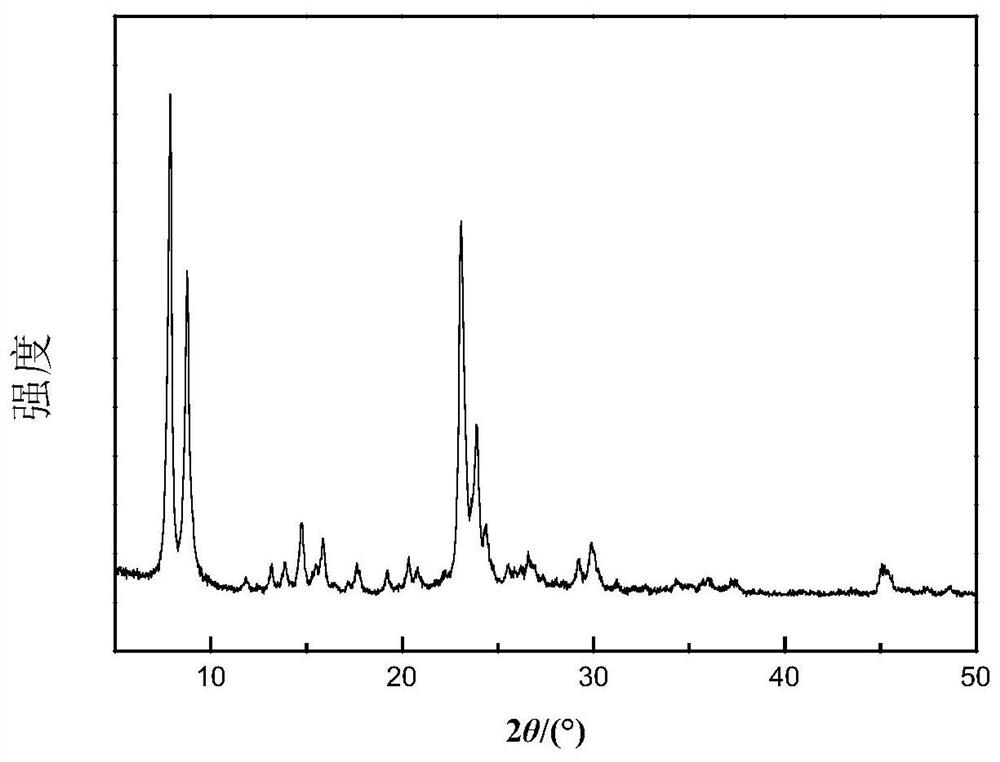

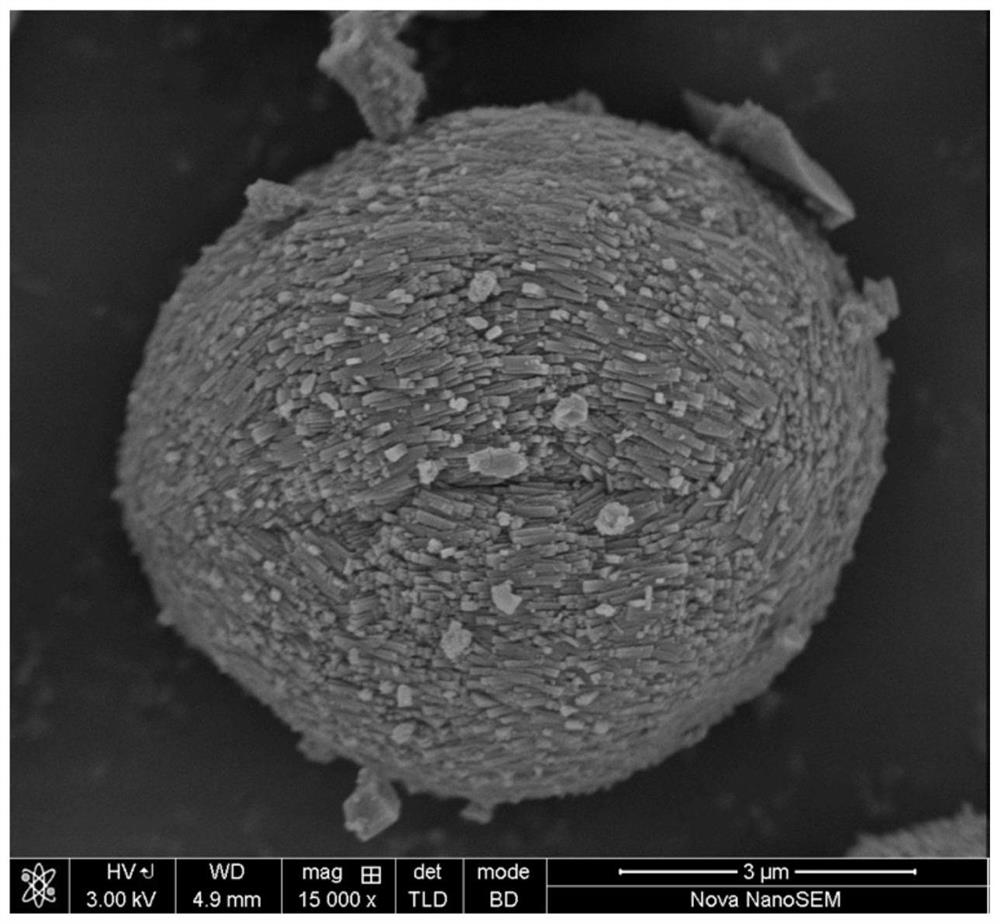

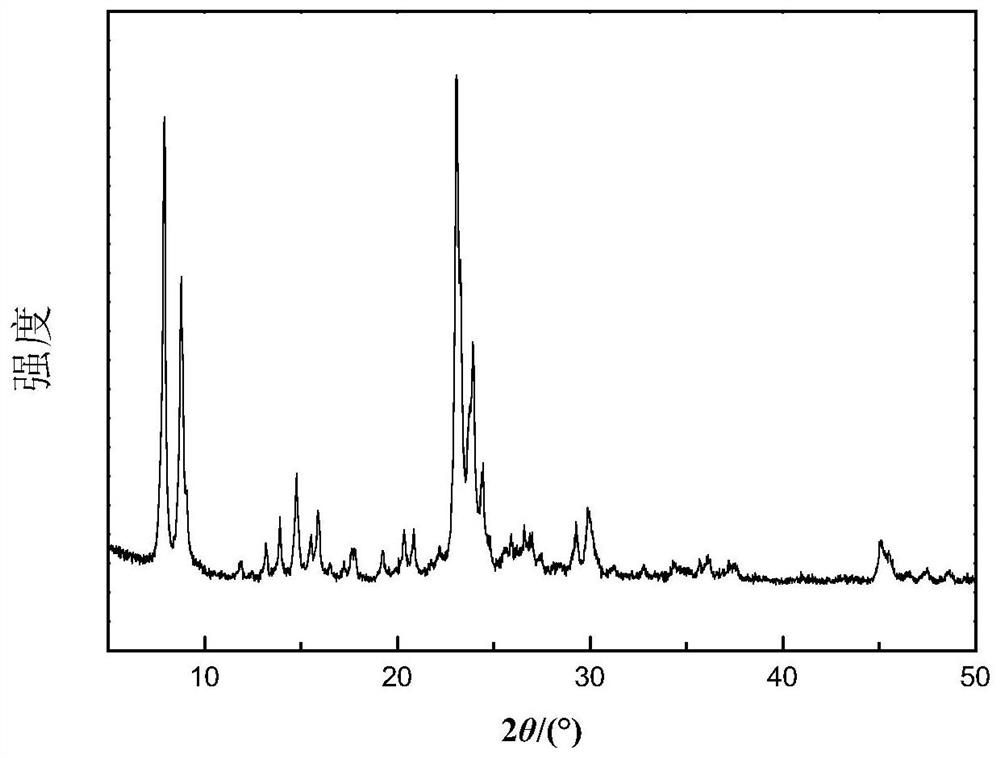

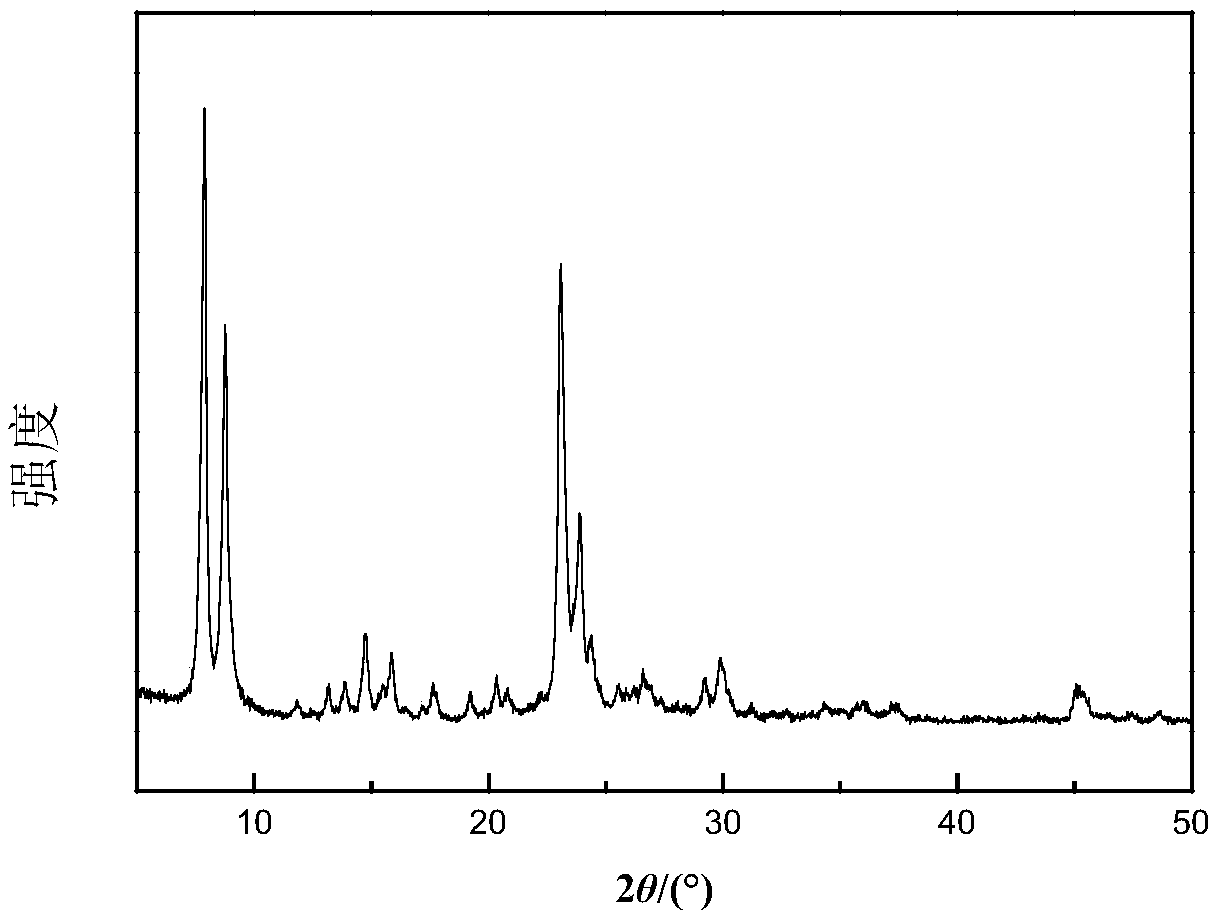

ZSM-5/MCM-48 composite molecular sieve, preparation method and application thereof

ActiveCN104043477AHigh selectivityLow aromatic contentMolecular sieve catalystsLiquid hydrocarbon mixture productionReaction temperatureGasoline

The invention relates to methanol-to-gasoline catalysts, in particular to a ZSM-5 / MCM-48 composite molecular sieve, a preparation method and application thereof. The composite molecular sieve adopts a ZSM-5 microporous molecular sieve as the seed crystal, on the surface of which a MCM-48 mesoporous structure composite molecular sieve that is chemically interlinked at a mesoporous and micropore interface is obtained by overgrowth. The composite molecular sieve undergoes acidification, and then is mixed with a binder to undergo molding and roasting, and the product is used as a catalyst for methanol-to-gasoline (MTG) reaction. The catalyst provided by the invention is used for overgrowth of the mesoporous molecular sieve on the microporous molecular sieve surface, integrates the advantages of the microporous material and the mesoporous material so as to develop the strong points and avoid the weak points and reach a synergistic effect. The catalyst shows good catalytic properties to the methanol-to-gasoline (MTG) reaction, has high selectivity to gasoline products and a low aromatic hydrocarbon content, and extends the carbon chain length. More importantly, the problems of high reaction temperature, high aromatic hydrocarbon content in oil products, and limitation of hydrocarbon compounds only to less than C11 in traditional MTG technologies are solved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

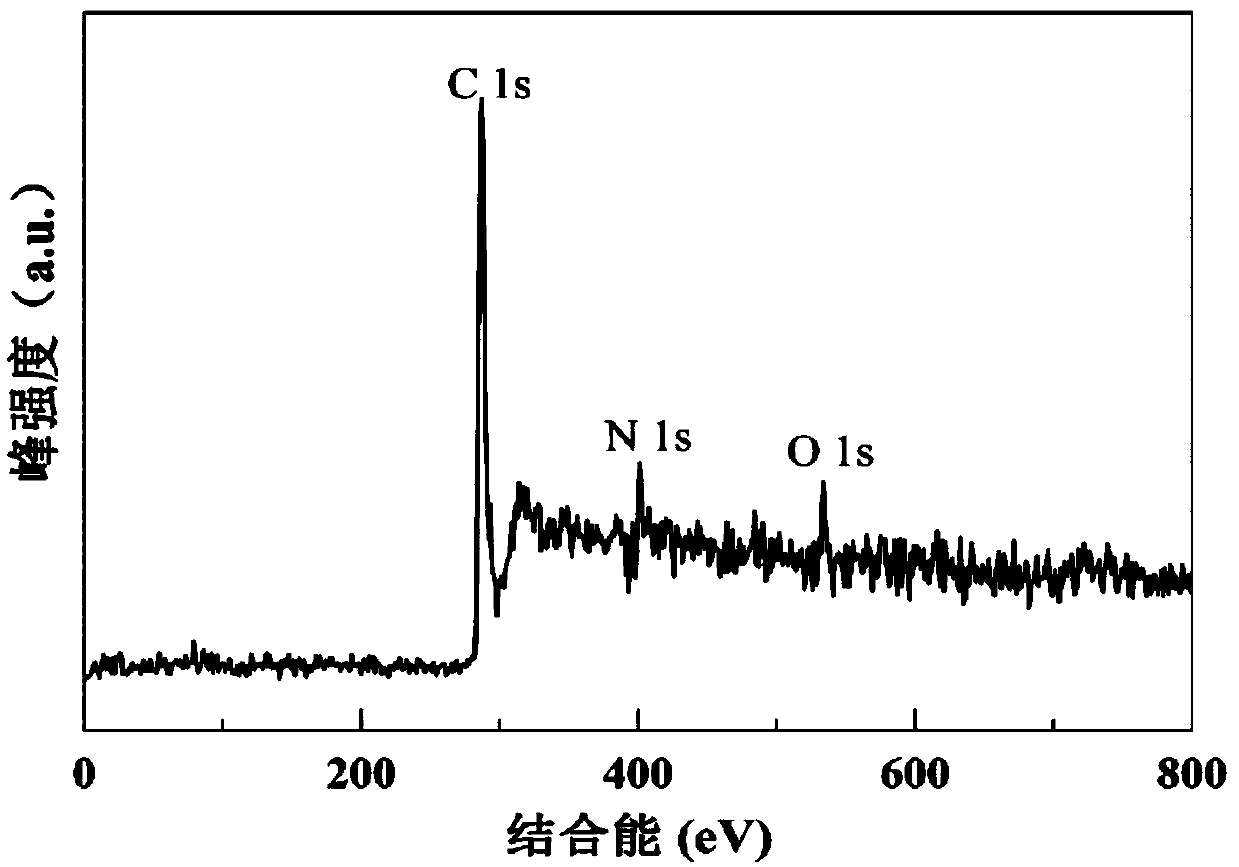

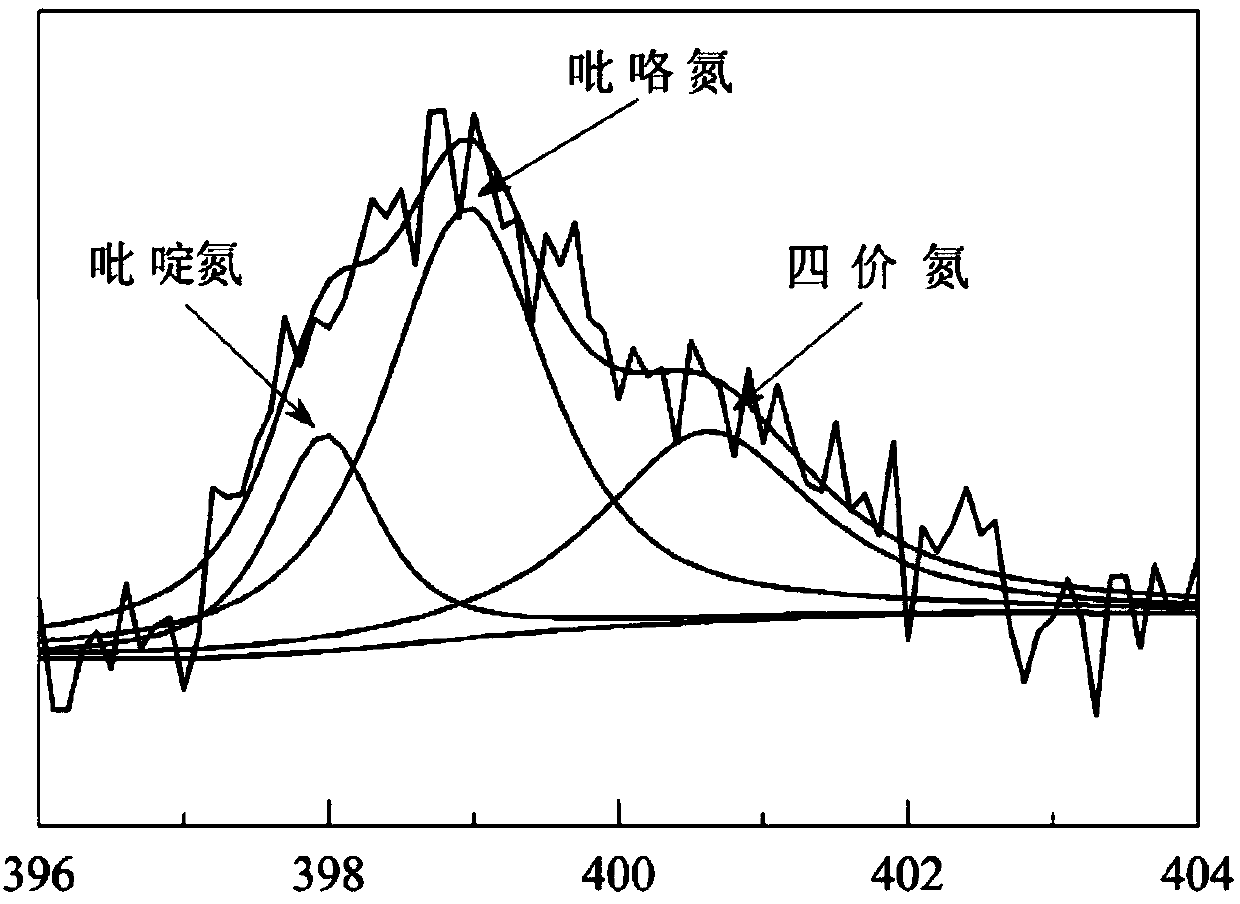

Preparation method and application of high-efficiency nitrogen-doped carbon nanotube

ActiveCN107686105ASmall particle sizeEvenly dispersedOrganic compound preparationCarbon compoundsMultiwalled carbonFiltration

The invention discloses a preparation method of a high-efficiency nitrogen-doped carbon nanotube. The preparation method comprises the following steps: adding a multiwalled carbon nanotube into a nitric acid solution; closing the solution in an autoclave; pressurizing to 0.4 to 1.0 MPa, and stirring; then heating to 120 to 200 DEG C and keeping for 1 to 4 hours; finally, cooling to room temperature by the autoclave; washing to neutral and carrying out suction filtration and drying; mixing the carbon nanotube with a melamine solid according to the mass ratio being 1 to (1 to 4), and uniformly grinding by using mortar; and carrying out high-temperature sintering in nitrogen, washing to neutral and then drying to obtain the nitrogen-doped carbon nanotube. The nitrogen doping amount of the high-efficiency nitrogen-doped carbon nanotube disclosed by the invention is 4.6 to 10.3 weight percent.

Owner:TAIYUAN UNIV OF TECH

Catalyst for synthesizing dimethyl carbonate by methanol liquid-phase oxidative carbonylation and methods

InactiveCN107694609AHigh selectivityReduce corrosionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHalogenMethyl carbonate

The invention discloses a catalyst for synthesizing dimethyl carbonate by methanol liquid-phase oxidative carbonylation and methods. The catalyst comprises a copper halide and an ionic liquid; the mass ratio of the copper halide to the ionic liquid is 1:(1-10); a cation of the ionic liquid is an imidazole cation, a quaternary ammonium salt cation or a pyridine cation; and an anion of the ionic liquid is a halogen ion. The catalyst disclosed by the invention has relatively high methanol conversion ratio and high dimethyl carbonate selectivity and has an industrial application prospect. In addition, due to the addition of the ionic liquid, corrosion to stainless steel reaction equipment can be relieved.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

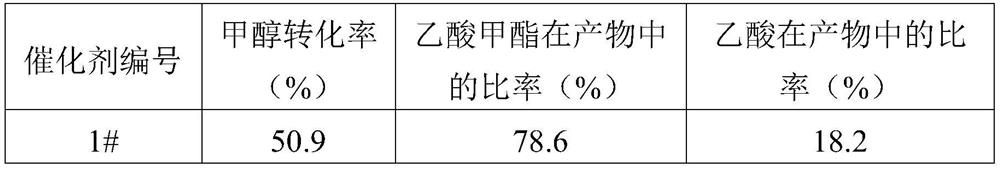

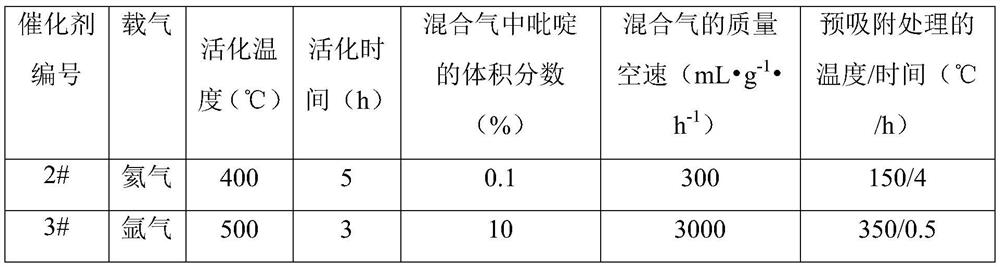

Method of using gold-supported molecular sieve catalyst to convert methanol to methyl acetate

InactiveCN108579794ASimple processing methodHigh conversion rate of methanolMolecular sieve catalystsCatalyst activation/preparationMolecular sieveStrong acids

The invention relates to a method for preparing methyl acetate through a carbonylation reaction of methanol by using a gold-supported zeolite molecular sieve catalyst. Gold can strongly interact withSi-OHin the high-silicon zeolite when the nano gold is loaded on the high-silicon zeolite. A bifunctional catalyst having a metal activity and acidity can be produced. The molecular sieve refers to atitanium-silicon zeolite molecular sieve and a high-silicon zeolite molecular sieve. Preparation of a supported gold catalyst by deposition and precipitation under negative pressure is beneficial to purifying the inner and outer surfaces and pore channels of the molecular sieve, so that the gold easily enter the pore channels of the molecular sieve, and the highly-dispersed gold-supported zeolitemolecular sieve catalyst is obtained. When the supported gold catalyst prepared by the method is used for the carbonylation reaction of the methanol, the strong acid center and the metal active centerwhich are required by the carbonylation of the methanol enable the methanol to react to generate methyl acetate and methyl formate under the double-function action of the metal and the acid.

Owner:XINJIANG UNIVERSITY

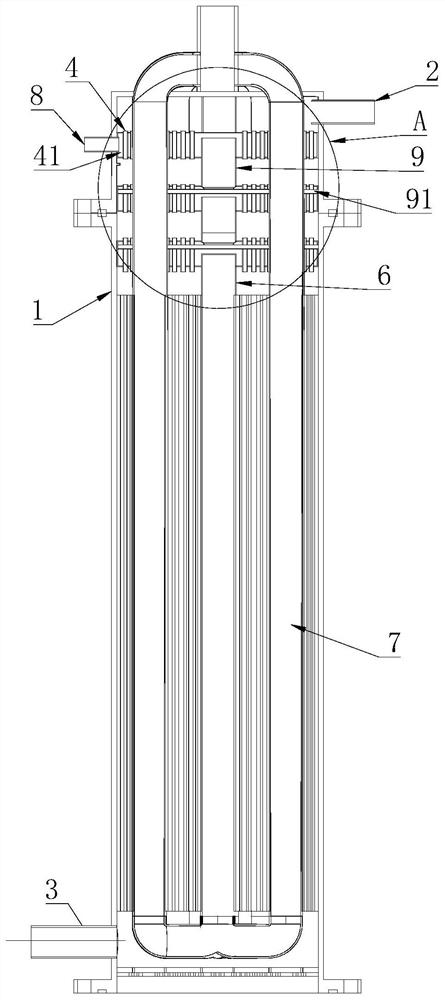

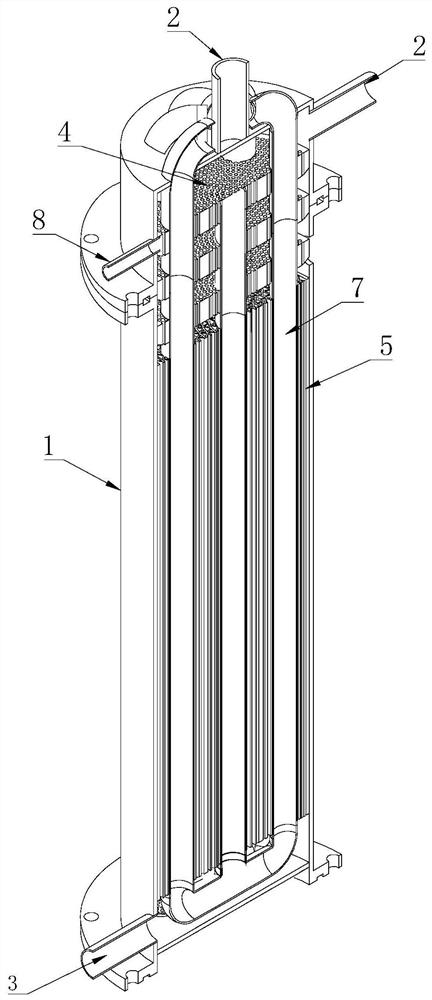

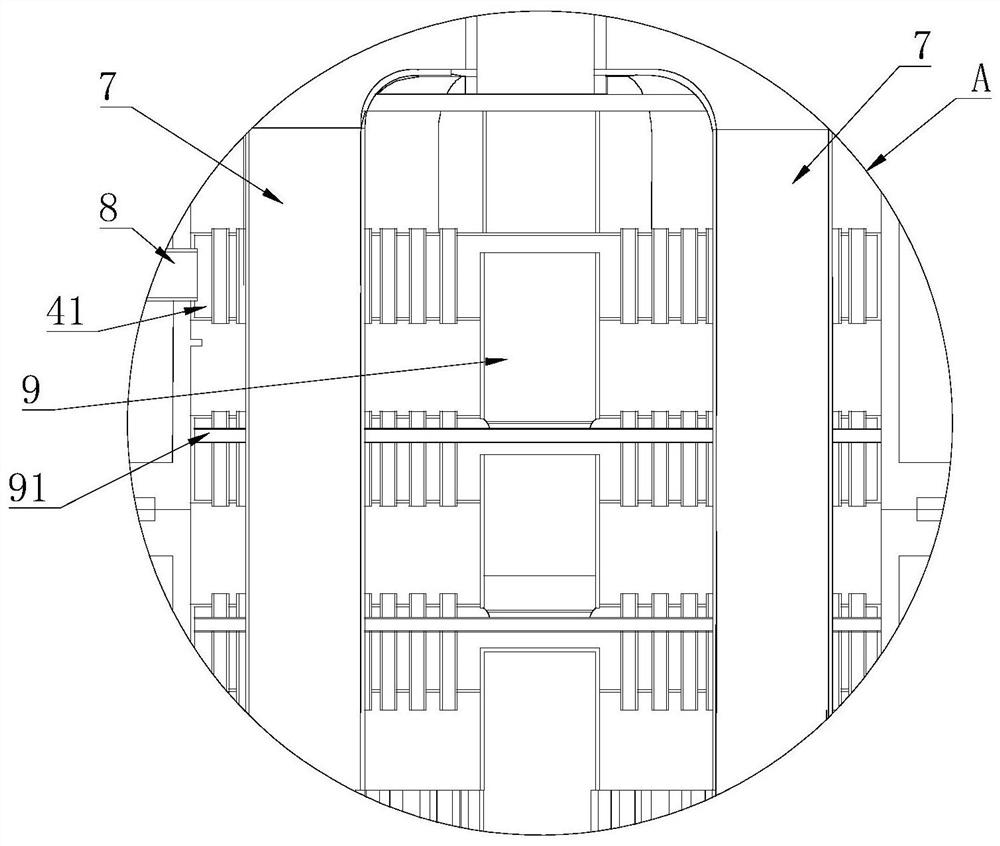

Self-heating methanol reforming hydrogen production reactor

ActiveCN112892460AImprove conversion rateHighly integratedProcess control/regulationHydrogenThermodynamicsHigh energy

The invention discloses a self-heating methanol reforming hydrogen production reactor, and aims to provide the self-heating methanol reforming hydrogen production reactor which integrates preheating, reforming reaction and catalytic combustion and has the advantages of high integration level, strong functionality and high energy utilization rate. The self-heating methanol reforming hydrogen production reactor comprises a reactor body, the reactor body is provided with a preheating cavity and a reaction cavity from top to bottom, the preheating cavity is provided with an exhaust port, and the reaction cavity is provided with a fuel inlet; the preheating cavity is provided with a first honeycomb-shaped carrier, the reaction cavity is provided with a second honeycomb-shaped carrier, the second honeycomb-shaped carrier is provided with a material guide pipe and a plurality of reforming pipes in a penetrating manner, and the material guide pipe is communicated with the bottom ends of the reforming pipes; and the upper ends of the reforming pipes penetrate through the first honeycomb-shaped carrier and extend to the outer side of the reactor body, the first honeycomb-shaped carrier is provided with a heat exchange cavity, and the heat exchange cavity is communicated with a reforming raw material inlet and a material guide pipe. The reactor is suitable for the technical field of hydrogen production devices.

Owner:NINGBO SHENJIANG TECH

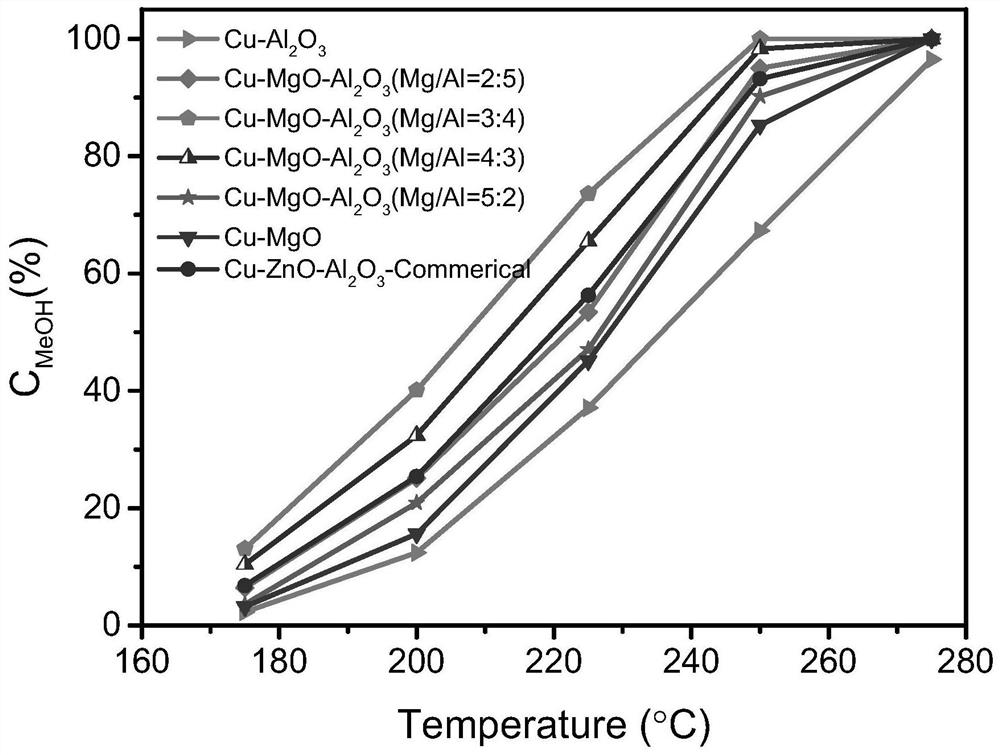

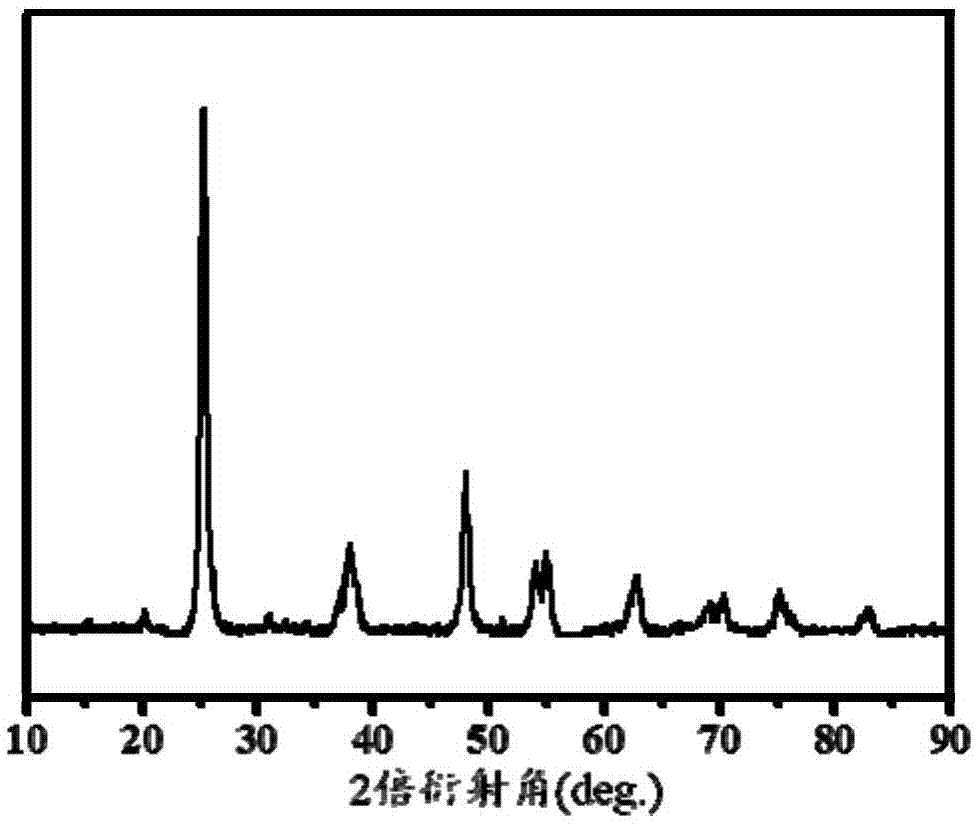

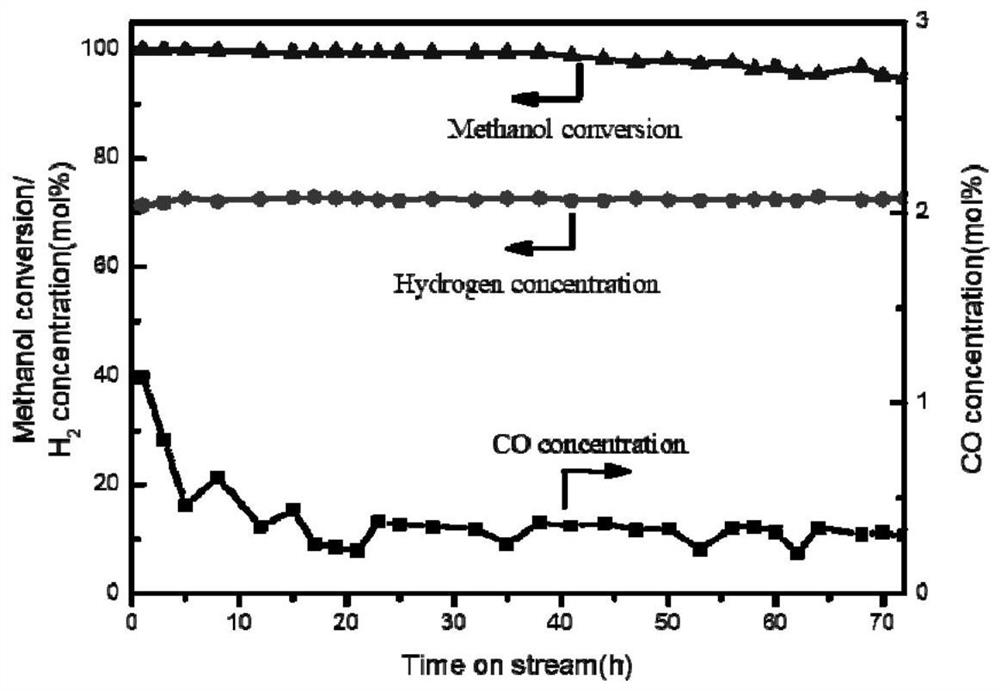

Supported copper-based catalysts for hydrogen production by methanol steam reforming as well as preparation method and application of supported copper-based catalysts

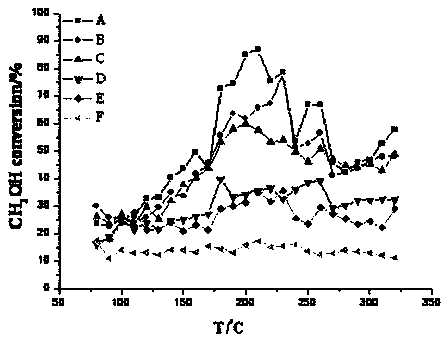

InactiveCN112108148AHigh conversion rate of methanolOvercoming Activity and Selectivity BottlenecksHydrogenHeterogenous catalyst chemical elementsChemistryComposite oxide

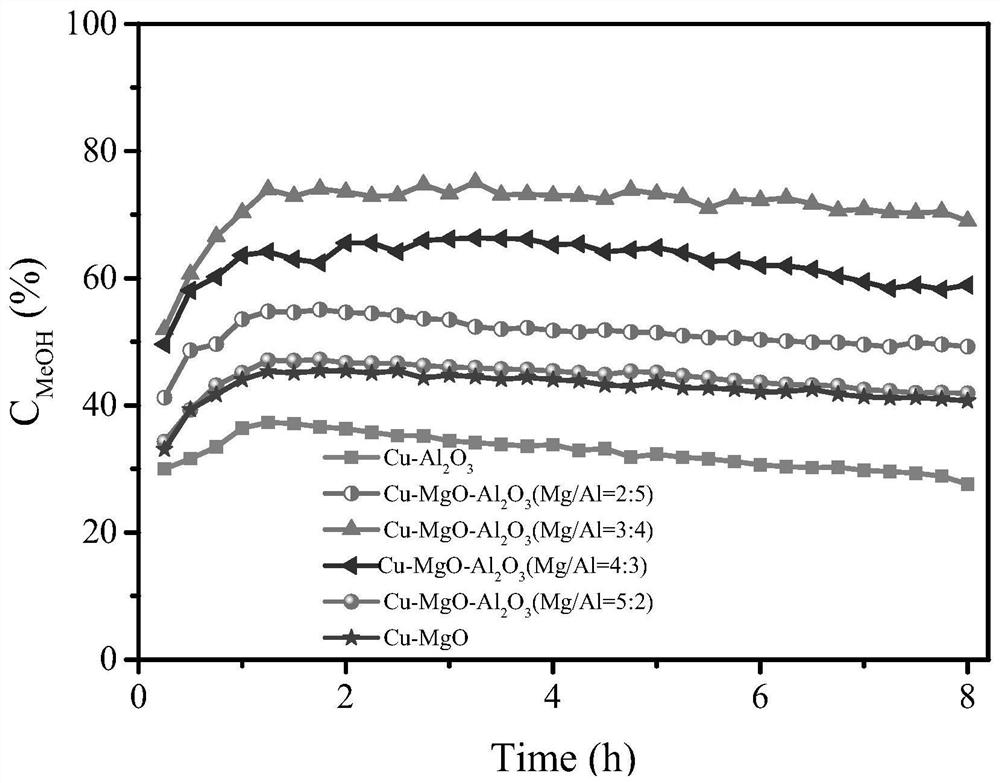

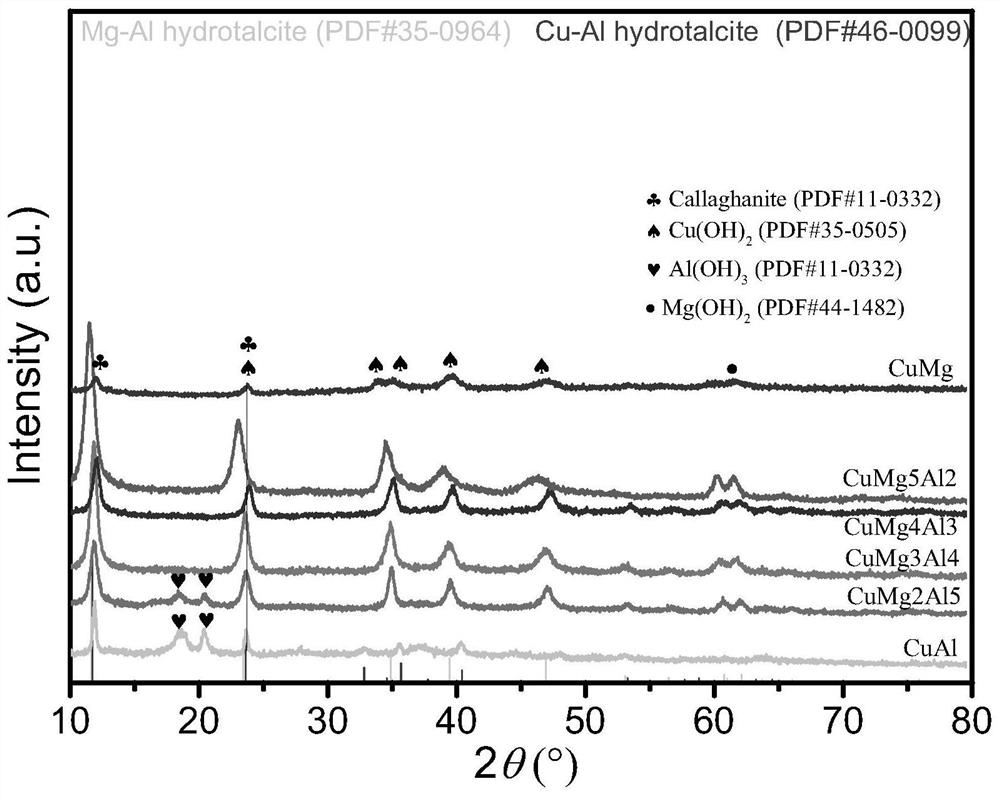

The invention relates to supported copper-based catalysts for hydrogen production by methanol steam reforming as well as a preparation method and application of the supported copper-based catalysts. According to the invention, magnesium-and-aluminum-supported copper-based catalysts with different magnesium-to-aluminum molar ratios are prepared by roasting a hydrotalcite precursor, wherein the supported copper-based catalyst is a Cu-Mg-Al composite oxide, a molar ratio of Mg to Al in the Cu-Mg-Al composite oxide is 2: 5 to 5: 2, and the mass fraction of CuO is 10%-30%. Compared with the prior art, the catalyst provided by the invention has the advantages that through doping modification of a single oxide carrier, a methanol conversion rate is greatly improved on the basis of keeping high hydrogen selectivity, and particularly, the methanol conversion rate is improved by nearly one time at a low-temperature section (225 DEG C) without generation of CO, so a basis is provided for application of the catalyst to a fuel cell; the stability of the catalyst is higher than the stability of commercial Cu / ZnO / Al2O3, and the bottleneck that the activity, selectivity and stability of an existing catalytic system cannot be obtained at the same time is overcome; and the preparation method is simple, the magnesium / aluminum ratio is adjustable, and the method is suitable for large-scale industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH

Catalyst used in process of preparing dimethyl ether from methanol on fluidized bed and preparation method thereof

ActiveCN102029184ASpeed up the flowImprove liquidityMolecular sieve catalystsEther preparation by compound dehydrationMolecular sieveMicrosphere

The invention discloses a catalyst used in the process of preparing dimethyl ether from methanol on a fluidized bed, which is prepared by a method comprising the following steps of: uniformly mixing desalted water and a silicon-containing material, adding an aluminum-containing material and silicon aluminum phosphorus molecular sieves, uniformly mixing, adding a base material, uniformly mixing toobtain slurry, adjusting a pH value to ensure that the slurry forms a gel state, continuously stirring, pelleting by spraying so as to obtain solid microspheres, roasting, acid-washing, drying and roasting to obtain the catalyst which has the abrasion index of 0.5 to 2.0 and is used in the process of preparing the dimethyl ether from the methanol on the fluidized bed. The hollow degree of the solid microspheres can be lowered by the catalyst prepared by the method, while the catalytic activity is met, the wear-resisting property of the catalyst is obviously improved, and the abrasion index ofthe catalyst is below 2.0 and can be below 1.5 by optimizing preparation parameters; and the catalyst has high stability and long service life and is characterized by low reaction temperature, high methanol conversion ratio, high selectivity of the dimethyl ether and low cost, and the large-scale production of the dimethyl ether can be realized by the catalyst.

Owner:CHINA TIANCHEN ENG +1

Method for serially producing dimethyl ether by dehydrating solid acid catalyzing methanol

ActiveCN102050706AExtend your lifeHigh conversion rate of methanolEther preparation by compound dehydrationGas phaseSolid acid

The invention discloses a method for serially producing dimethyl ether by dehydrating solid acid catalyzing methanol, comprising the steps of: filling solid acid catalysts in a reactor section by section; arranging an inert filler layer at the upper part of each catalyst bed; and contacting cold shock materials with the solid acid catalysts after the cold shock materials pass through the inert filler layers, wherein the reaction pressure is 0.2-4.0MPa, the reaction temperature is 120-400DEG C and the feeding airspeed is 0.1-20.0h<-1>. In the invention, the solid acid catalysts are filled section by section and the temperature of a gas-phase reaction catalyst bed is controlled in a set range by using the cold shock materials; and under the condition of obtaining higher methanol percent conversion, as the temperature of the catalyst beds is controlled evenly, the side reaction is reduced and the life of the catalysts is prolonged.

Owner:YANCHANG ZHONGKE (DALIAN) ENERGY TECH CO LTD

Process of catalytic ammoxidation for hydrogen cyanide production

ActiveUS7763225B2Improve performanceGood choiceHeterogenous catalyst chemical elementsCatalyst activation/preparationOxidation stateOxygen

A process for the ammoxidation of an alcohol feed, such as methanol, or a nitrile feed, such as propionitrile, or a mixture thereof, to form hydrogen cyanide uses a modified Mn—P catalyst having the following empirical formula:MnaP1AbOx where A=one or more of K, Ca, Mo, Zn, Fe or mixtures thereof; a=1 to 1.5; b=0.01 to 1.0 and x is a total number of oxygen atoms determined by the oxidation states of the other elements present.

Owner:ASCEND PERFORMACE MATERIALS OPERATIONS LLC

Composite catalyst as well as preparation method and application thereof

ActiveCN111822041AHigh conversion rate of methanolHigh selectivityMolecular sieve catalystsPreparation by carbon monoxide or formate reactionMolecular sievePtru catalyst

The invention discloses a composite catalyst, a preparation method thereof and a method for preparing methyl acetate and acetic acid through methanol carbonylation by using the composite catalyst. Thecomposite catalyst is formed by compounding a water-vapor shift catalyst and a modified H-MOR molecular sieve. The composite catalyst comprises a water vapor shift catalyst and a carbonylation catalyst; the carbonylation catalyst comprises a modified H-MOR molecular sieve; the modified H-MOR molecular sieve is an H-MOR molecular sieve subjected to organic alkali treatment. The composite catalystis used for methanol carbonylation, and the selectivity of methyl acetate exceeds 80%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Molecular sieve based catalyst and preparation method thereof as well as application to side chain alkylation reaction of methyl alcohol and methylbenzene

ActiveCN109453802AHigh conversion rate of methanolHigh styrene selectivity and yieldMolecular sieve catalystsHydrocarbonsIonIon exchange

The invention discloses a molecular sieve based catalyst and a preparation method thereof as well as application to the side chain alkylation reaction of methyl alcohol and methylbenzene. The preparation method specifically comprises the steps that a water source is added into a silicon source to dilute, then a template agent, an aluminum source and a sodium source are added sequentially and stirred uniformly after each adding is completed, and a liquid mixture is obtained; a silylating reagent is added after the liquid mixture is subjected to ageing at the room temperature and stirred uniformly, a crystallization reaction is conducted under the moderate and continuous stirring conditions after the materials are stirred uniformly, the product is washed and filtered after the reaction is ended, the obtained solid is dried and calcinated, and a molecular sieve based catalyst precursor is obtained; and the molecular sieve based catalyst precursor is placed into an alkali metal salt solution to be subjected to alkali metal ion exchanging, the obtained exchanged sample is filtered, dried and calcinated, and the molecular sieve based catalyst is obtained. The molecular sieve based catalyst is specifically applied to preparing styrene in the side chain alkylation reaction of methyl alcohol and methylbenzene. The physical and chemical features of the molecular sieve based catalyst arechanged by optimizing the preparation conditions of the molecular sieve, and the methyl alcohol conversion rate, and the selectivity and yield of styrene are finally and effectively improved.

Owner:NEIJIANG NORMAL UNIV

Catalyst for preparing methylal and methyl formate through one-step selective oxidation of methanol

ActiveCN106890652AIncreased dispersionImprove anti-sintering performancePhysical/chemical process catalystsOrganic compound preparationFormate EstersMethanol

The invention provides a catalyst for preparing methylal and methyl formate through one-step selective oxidation of methanol. The catalyst comprises the following raw material components in percentage by mass based on total mass of the raw material components of the catalyst: 10-20% of a vanadium source, 55-65% of a titanium source and 15-35% of sulfuric acid. The invention provides a catalyst for preparing methyl formate and methylal through one-step selective oxidation of methanol and a preparation method of the catalyst. The catalyst has a high methanol conversion rate, high product selectivity, long life and low-temperature fluctuation sensitivity, the product composition is easily controlled in industrial reaction, and subsequent separation is convenient.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

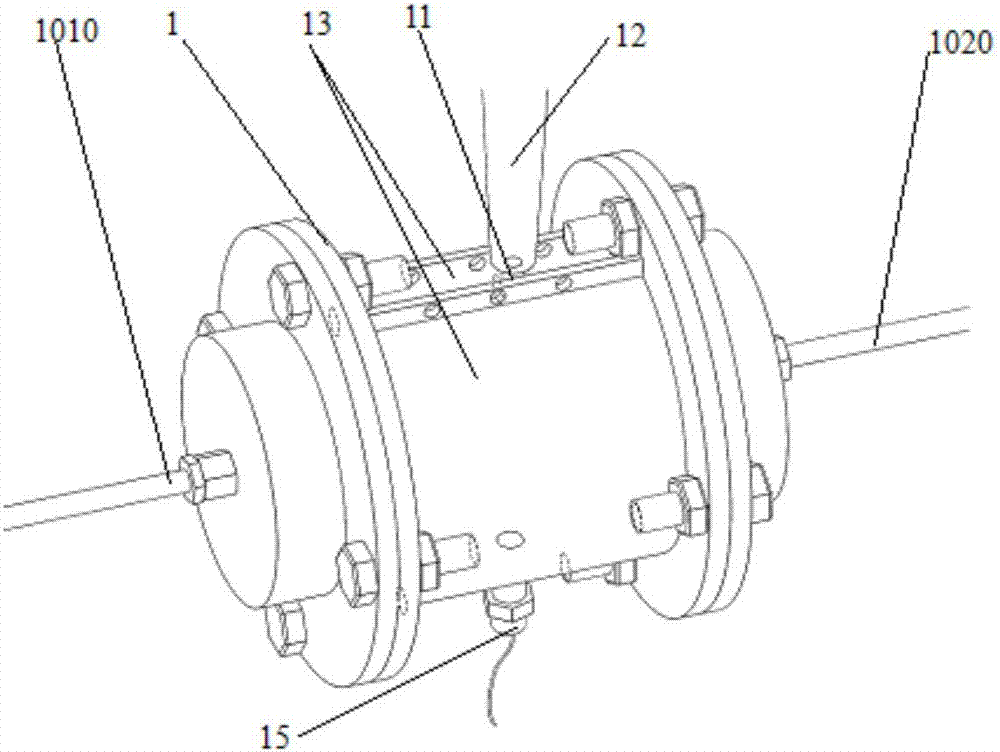

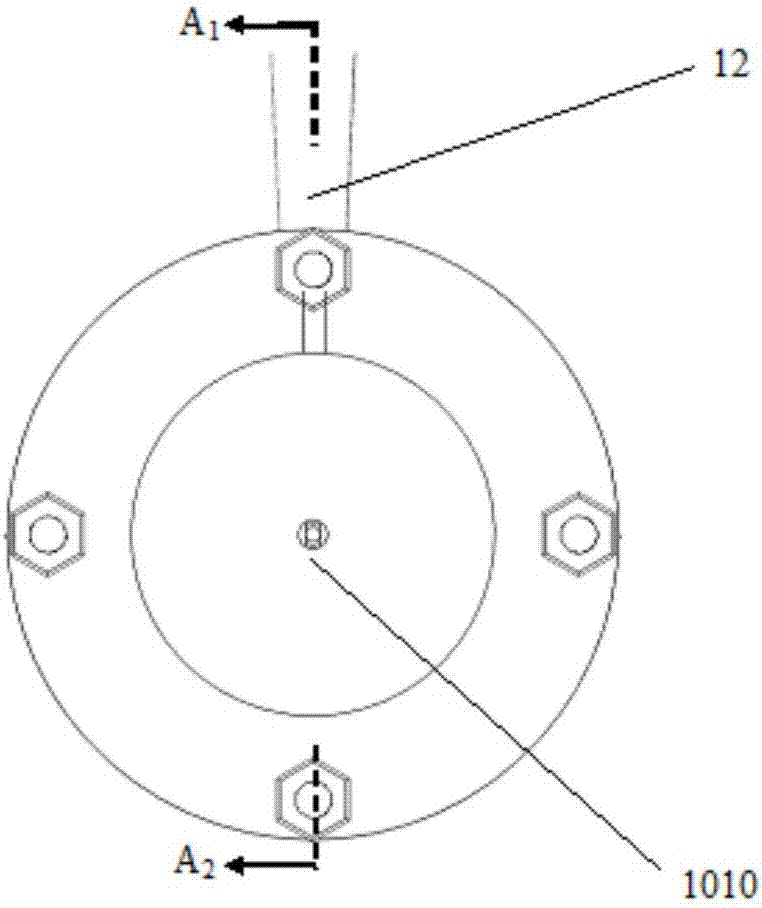

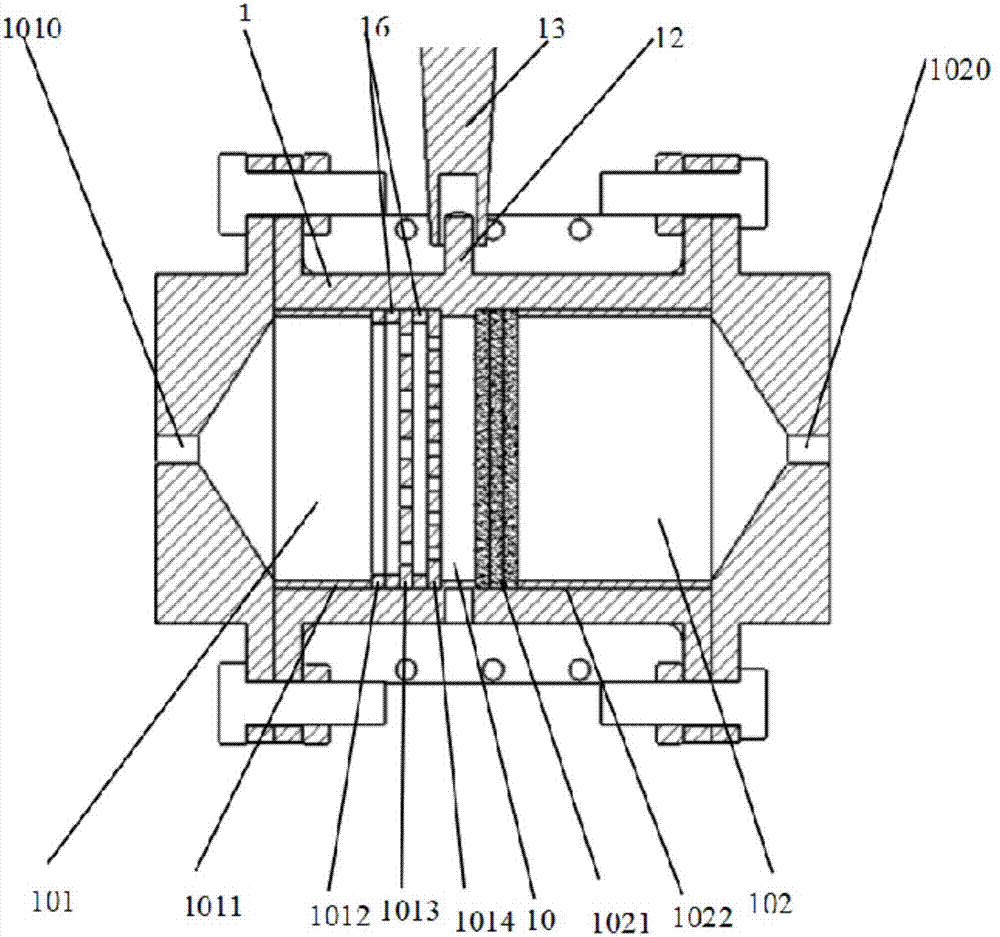

Ultrasonic-assisted methanol steam reforming hydrogen production reactor

ActiveCN108002347AHigh hydrogen production efficiency by reformingHigh conversion rate of methanolHydrogenSteam reformingUltrasonic assisted

The invention relates to the field of methanol steam reforming hydrogen production and discloses an ultrasonic-assisted methanol steam reforming hydrogen production reactor. The reactor comprises a reactor main body, an inner chamber formed from the reactor main body is used as a reaction chamber, the reactor main body is provided with an ultrasonic probe and an ultrasonic horn connected to the ultrasonic probe, and two ends of the reactor main body are provided with a material inlet for introducing a methanol aqueous solution and a material outlet for discharging hydrogen gas. Along a material flowing direction, the reaction chamber orderly comprises an evaporation zone containing an evaporation plate and a reforming zone containing a metal carrier reaction plate. The ultrasonic-assistedmethanol steam reforming hydrogen production reactor has the advantages of high reforming hydrogen production efficiency and high methanol conversion rate in hydrogen preparation from the methanol aqueous solution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing anhydrous formaldehyde by dehydrogenation of absolute methanol

InactiveCN105712857AHigh selectivityHigh conversion rate of methanolOrganic compound preparationCarbonyl compound preparationChemical industryDehydrogenation

The patent of the invention belongs to the technical field of chemical industry, and specifically relates to the preparation and application of a catalyst for preparing anhydrous formaldehyde by direct dehydrogenation of anhydrous methanol. The catalyst uses one or both of copper and zinc oxide as the active ingredient, the corresponding metal salt as the precursor, sodium carbonate, etc. as the precipitating agent, and the sample is prepared by the deposition precipitation method, and then filtered, washed, dried and The catalyst is finally prepared by roasting and other processes. The catalyst prepared by the method shows high activity, selectivity and stability in the process of catalyzing the dehydrogenation of anhydrous methanol to produce anhydrous formaldehyde. At a temperature of 400-600°C, nitrogen is used as a carrier gas, the feed ratio of methanol is in the range of 1-40 vol%, the conversion rate of methanol is 10-90%, and the selectivity of formaldehyde is as high as 60-99%. The preparation process of the catalyst is simple, the cost is low, the catalytic effect is good and the stability is high, and the catalyst has potential industrial application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

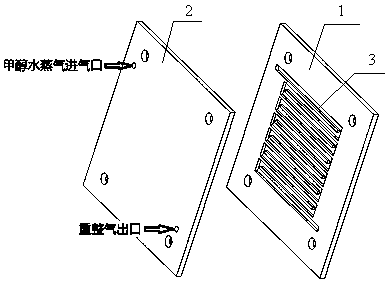

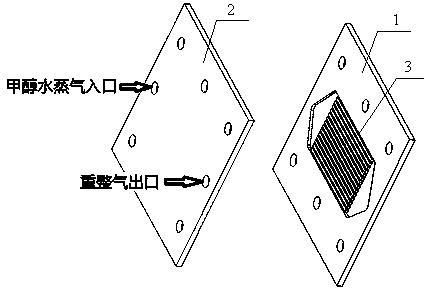

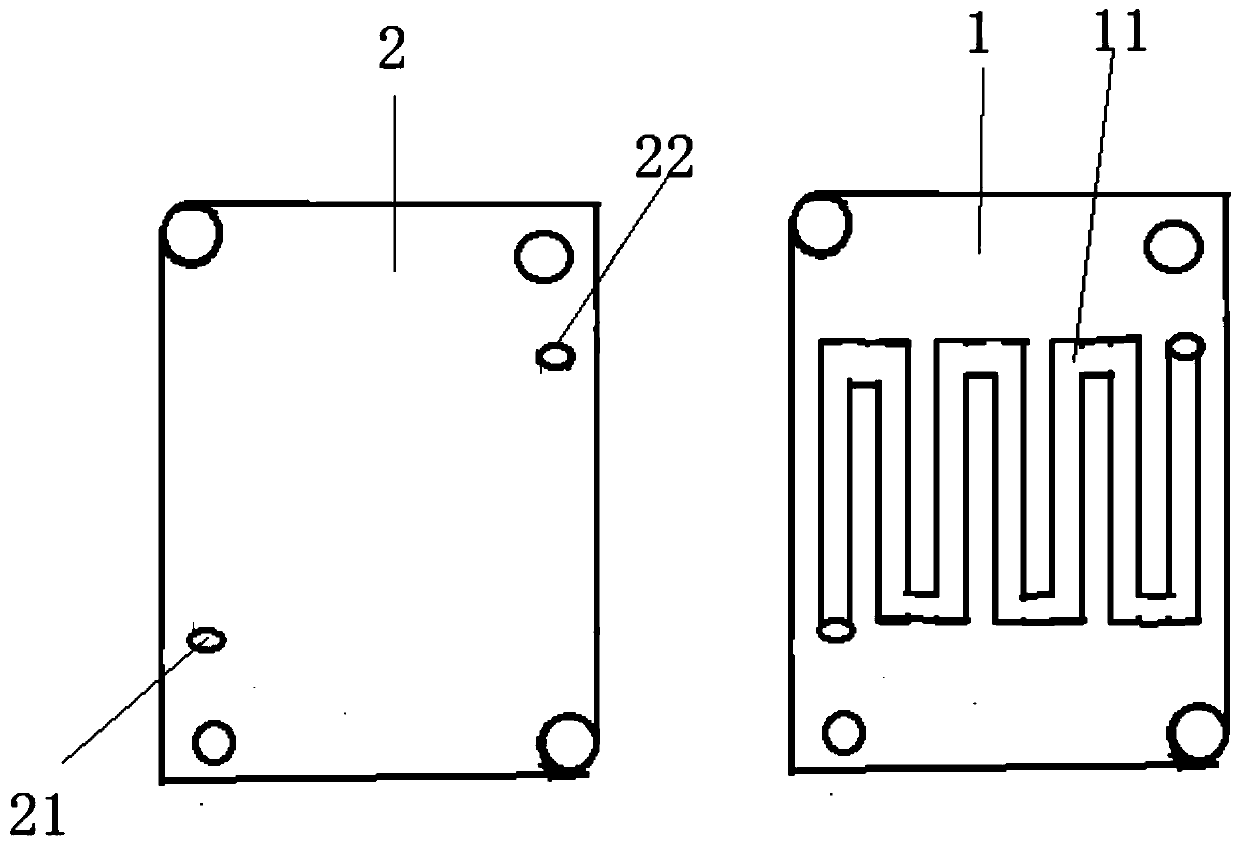

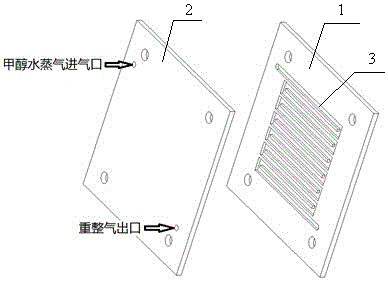

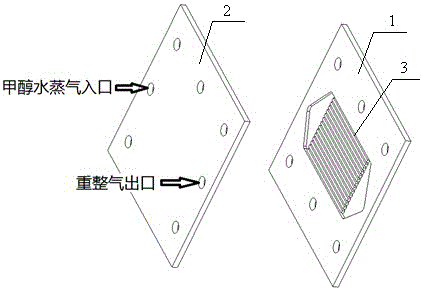

Miniature methanol and steam reforming chamber

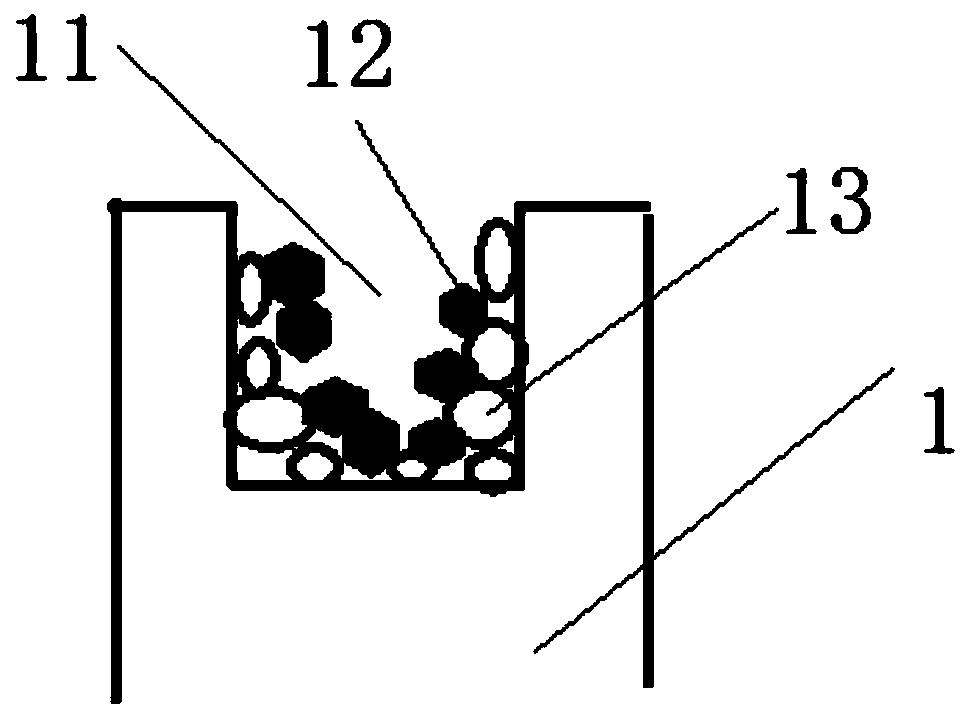

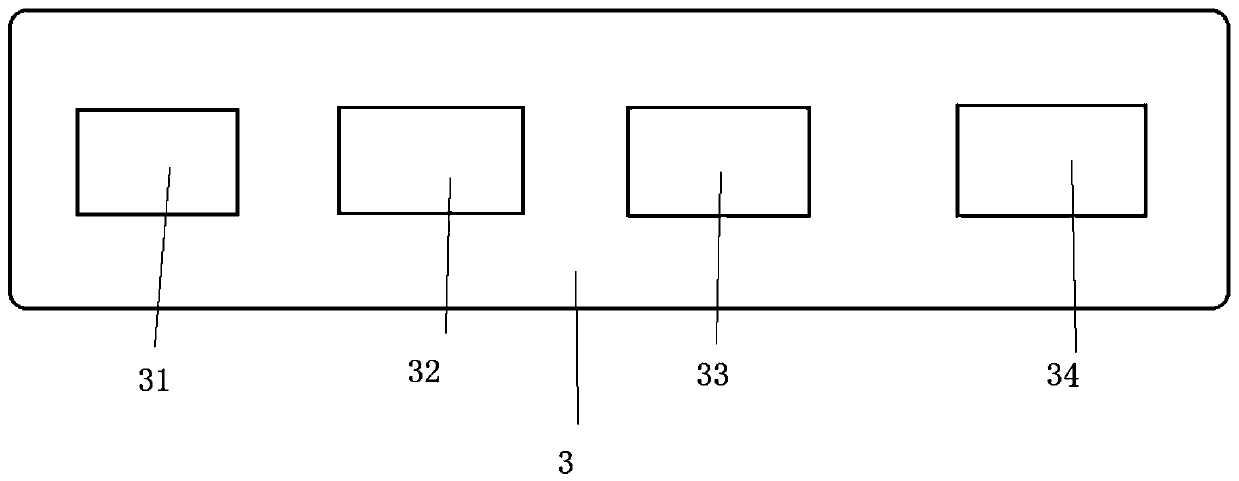

ActiveCN103956508AImprove adhesionLarge catalytic areaFuel cellsMicro arc oxidationCeramic thin films

The invention discloses a miniature methanol and steam reforming chamber which is made from an aluminum alloy material. The miniature methanol and steam reforming chamber comprises an aluminum alloy main body, an aluminum alloy packaging end plate and a miniature flow field structure, wherein the miniature flow field structure is used as a gas circulating channel in the reforming chamber, and located between the aluminum alloy main body and the aluminum alloy packaging end plate and on the surface of the aluminum alloy main body. One layer of porous ceramic thin film grows on the surface of a runner of the miniature flow field structure inside the reforming chamber through a micro-arc oxidation method, and a reforming reaction catalysis layer is formed on the ceramic thin film through a full-filling method. According to the miniature methanol and steam reforming chamber, one layer of porous oxide ceramic film is prepared inside the reforming chamber by applying a micro-arc oxidation technology, so that the adhesive capacity of the reforming catalyst in the miniature runner of the reforming chamber is improved, the contact area between a reactant and the catalyst is increased, and the efficiency of reaction between methanol and steam and the conversion rate of the methanol are increased.

Owner:HARBIN INST OF TECH

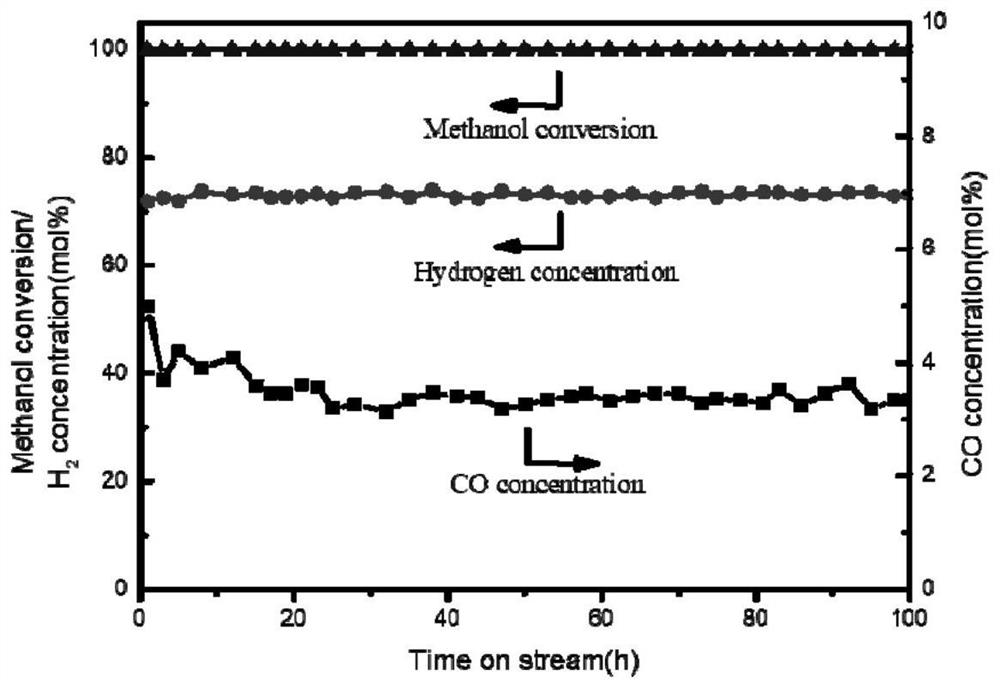

Copper-based catalyst for hydrogen production by methanol steam reforming and preparation method and application thereof

PendingCN113731429AReduce CO contentGood activity at low temperatureHydrogenHeterogenous catalyst chemical elementsSteam reformingMethanol water

The invention discloses a copper-based catalyst for hydrogen production by methanol steam reforming and a preparation method and application thereof, CuO is used as a main active component, the copper-based catalyst also comprises ZnO, Al2O3, ZrO2, CeO2 and an auxiliary agent MxOy, and MxOy is one of MgO, La2O3, CaO or MnO. The catalyst is applied to methanol steam reforming hydrogen production reaction, and has the advantages of high methanol conversion rate, low CO content in reforming tail gas, good low-temperature activity, strong thermal stability and the like. The preparation process is simple, raw materials are cheap and easy to obtain, and the method has a good industrial application prospect.

Owner:XIAMEN UNIV

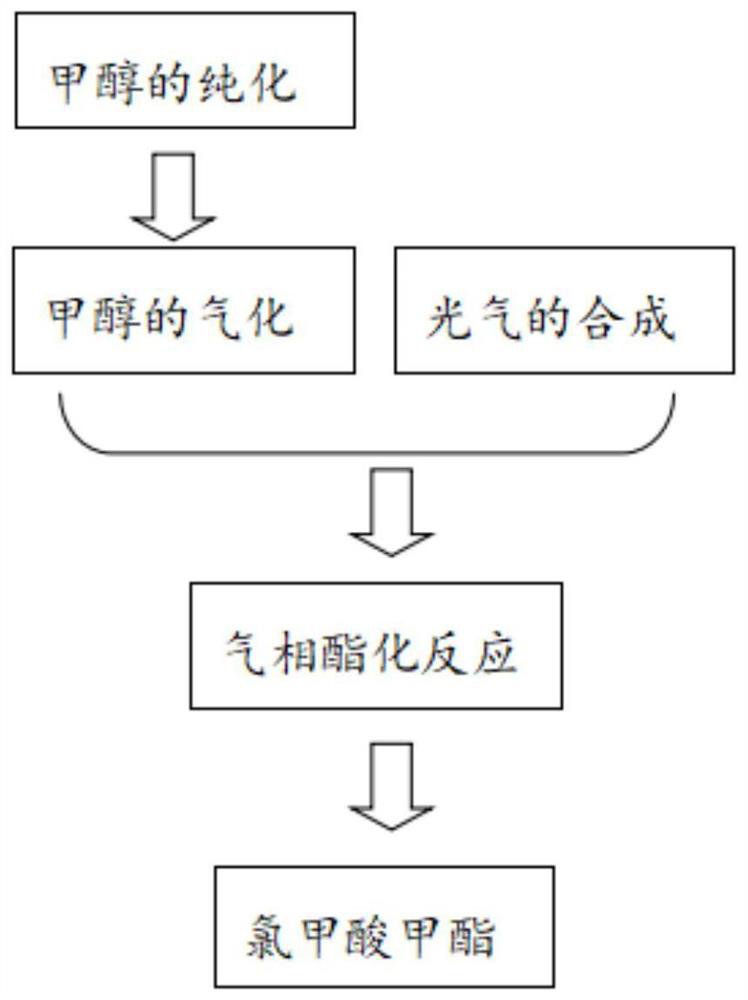

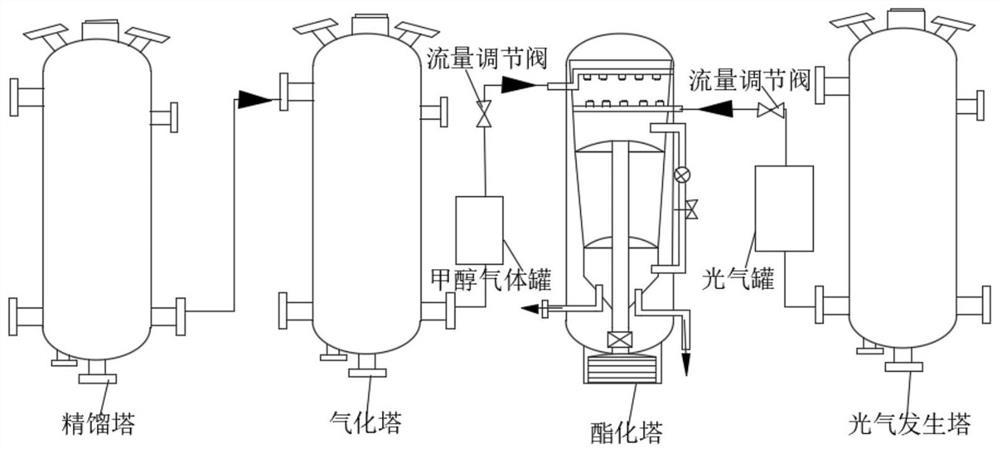

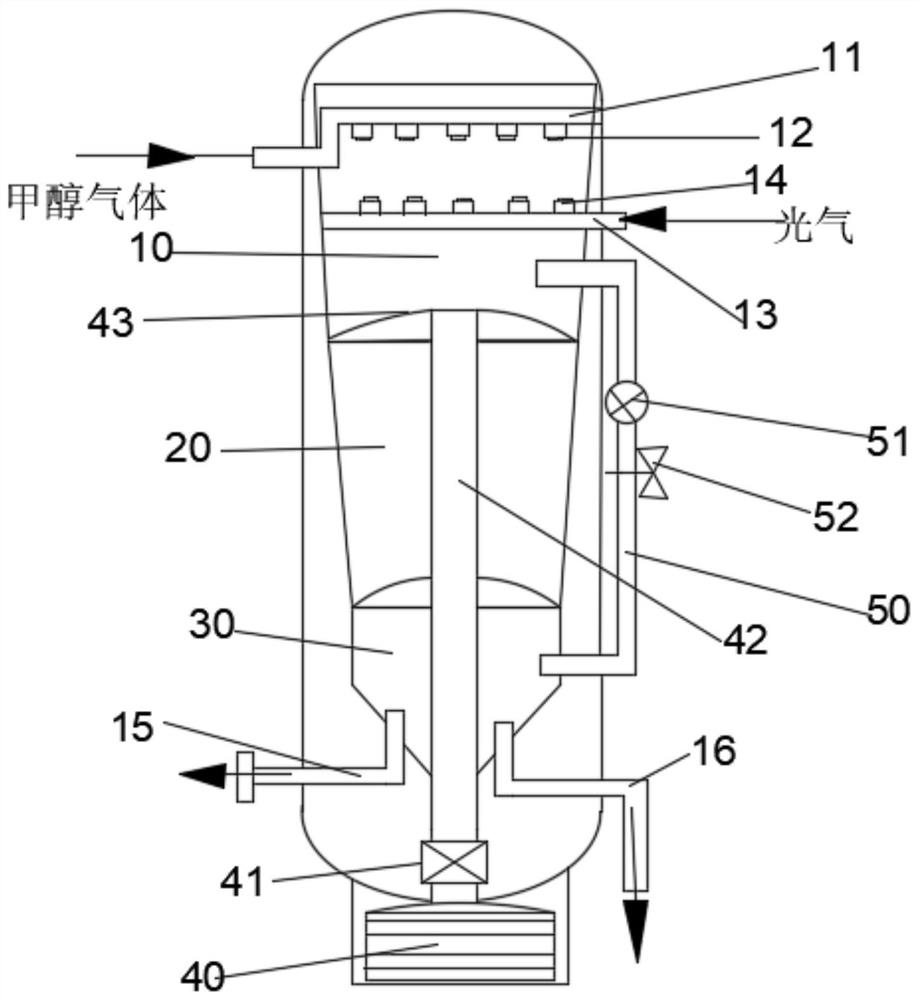

Synthesis method of methyl chloroformate

PendingCN113527102AImprove conversion rateIncrease pressurePreparation from phosgene or haloformatesGas liquid reactionPhysical chemistry

The invention discloses a synthesis method of methyl chloroformate, and belongs to the technical field of production of methyl chloroformate. The synthesis method of the methyl chloroformate comprises the following steps: step 1, purifying methanol; step 2, gasifying methanol; step 3, synthesizing phosgene; and 4, carrying out gas-phase esterification reaction. Gas-phase reaction of methanol gas and phosgene is utilized, and contact among gas-phase reaction molecules is more sufficient than contact among gas-liquid reaction molecules, so that the conversion rate of methanol is increased; through the arrangement of a circular baffle, a rotating shaft, a circulating gas pipe and a circulating pump, the mixing degree and the contact time between methanol gas and phosgene are increased, so that methanol reaction is more sufficient, side reaction of excessive methanol and methyl chloroformate is avoided, and the purity of methyl chloroformate and the conversion rate of methanol are improved; and methanol gas and phosgene are introduced by means of batch circulation, so that the phosgene is always excessive, and meanwhile, the phosgene is not excessive, and the tail gas treatment pressure is reduced.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

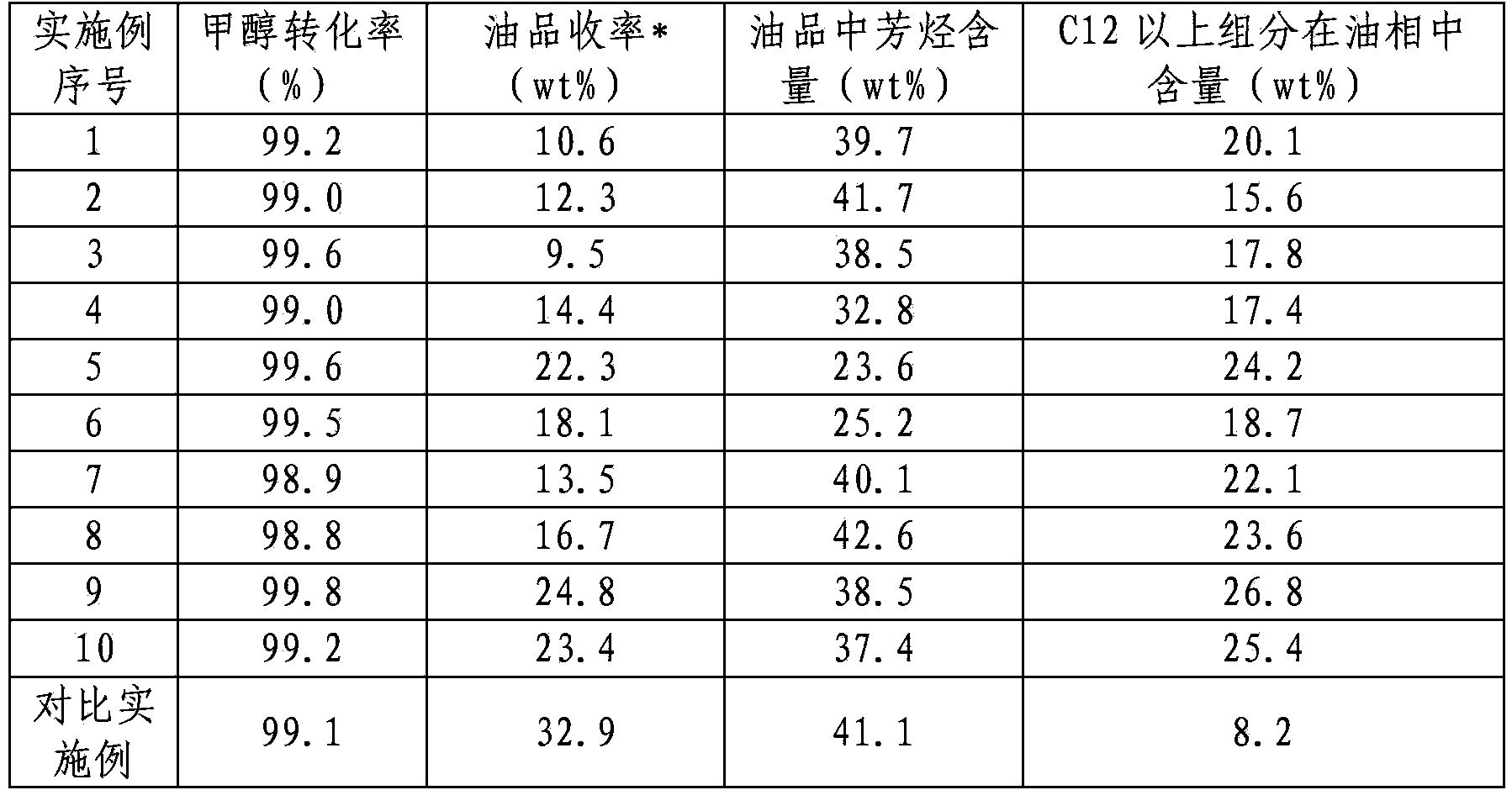

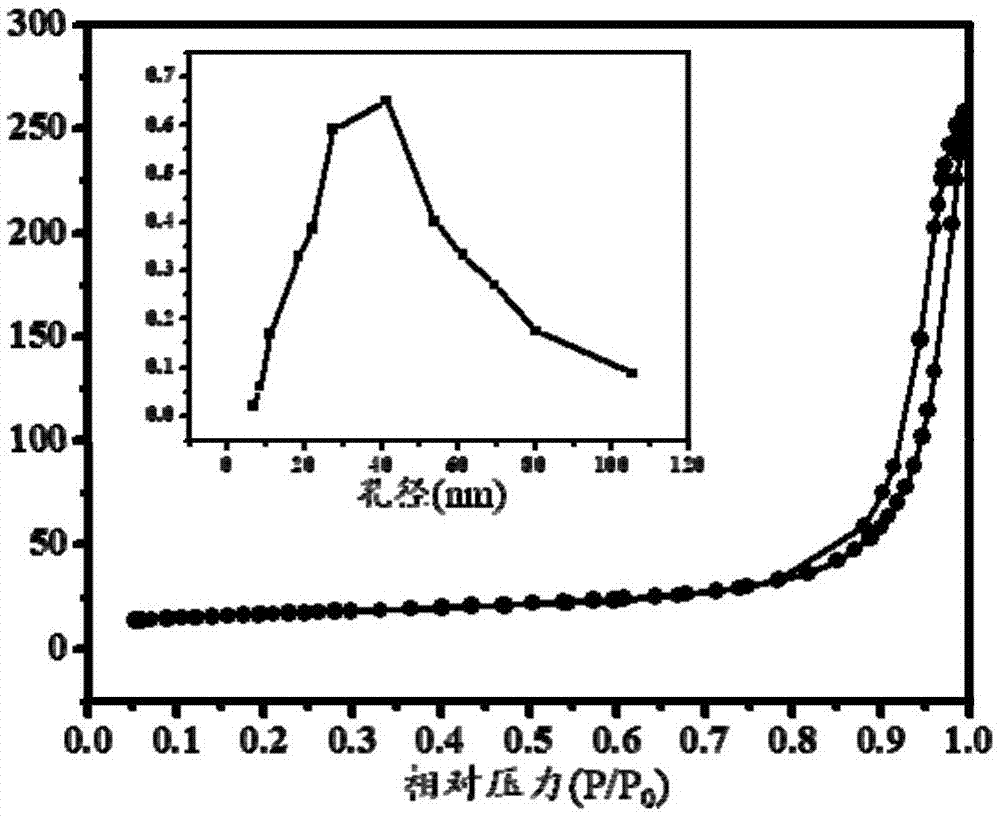

A kind of zsm-5/mcm-48 composite molecular sieve and its preparation method and application

ActiveCN104043477BHigh selectivityLow aromatic contentMolecular sieve catalystsLiquid hydrocarbon mixture productionReaction temperatureGasoline

The invention relates to methanol-to-gasoline catalysts, in particular to a ZSM-5 / MCM-48 composite molecular sieve, a preparation method and application thereof. The composite molecular sieve adopts a ZSM-5 microporous molecular sieve as the seed crystal, on the surface of which a MCM-48 mesoporous structure composite molecular sieve that is chemically interlinked at a mesoporous and micropore interface is obtained by overgrowth. The composite molecular sieve undergoes acidification, and then is mixed with a binder to undergo molding and roasting, and the product is used as a catalyst for methanol-to-gasoline (MTG) reaction. The catalyst provided by the invention is used for overgrowth of the mesoporous molecular sieve on the microporous molecular sieve surface, integrates the advantages of the microporous material and the mesoporous material so as to develop the strong points and avoid the weak points and reach a synergistic effect. The catalyst shows good catalytic properties to the methanol-to-gasoline (MTG) reaction, has high selectivity to gasoline products and a low aromatic hydrocarbon content, and extends the carbon chain length. More importantly, the problems of high reaction temperature, high aromatic hydrocarbon content in oil products, and limitation of hydrocarbon compounds only to less than C11 in traditional MTG technologies are solved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

A kind of zsm-5 and zsm-11 eutectic molecular sieve and its preparation method and application

ActiveCN111484033BEmission reductionIncrease greennessMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePhysical chemistry

Owner:PETROCHINA CO LTD

Molecular sieve catalyst, preparation method thereof, and application in methanol and toluene side chain alkylation reaction

ActiveCN109453802BHigh conversion rate of methanolHigh selectivityMolecular sieve catalystsHydrocarbonsMolecular sievePtru catalyst

The invention discloses a molecular sieve catalyst and its preparation method, and its application in the side-chain alkylation reaction of methanol and toluene. Specifically, water is added to the silicon source for dilution, and then a template agent, an aluminum source and a sodium source are added successively and each time Stir evenly after adding to obtain a liquid mixture; add a silylating agent after aging at room temperature, stir evenly and carry out a crystallization reaction under mild and constant stirring conditions, wash and filter after the reaction, and dry the obtained solid before roasting to obtain Molecular sieve catalyst precursor; the molecular sieve catalyst precursor is placed in an alkali metal salt solution for alkali metal ion exchange, and the resulting exchanged sample is filtered, dried and roasted to obtain a molecular sieve catalyst. The specific application is to use the molecular sieve catalyst on the side of methanol and toluene Styrene is produced in chain alkylation reactions. The invention changes the physical and chemical properties of the molecular sieve by optimizing the preparation conditions, and finally effectively improves the conversion rate of methanol, the selectivity and yield of styrene.

Owner:NEIJIANG NORMAL UNIV

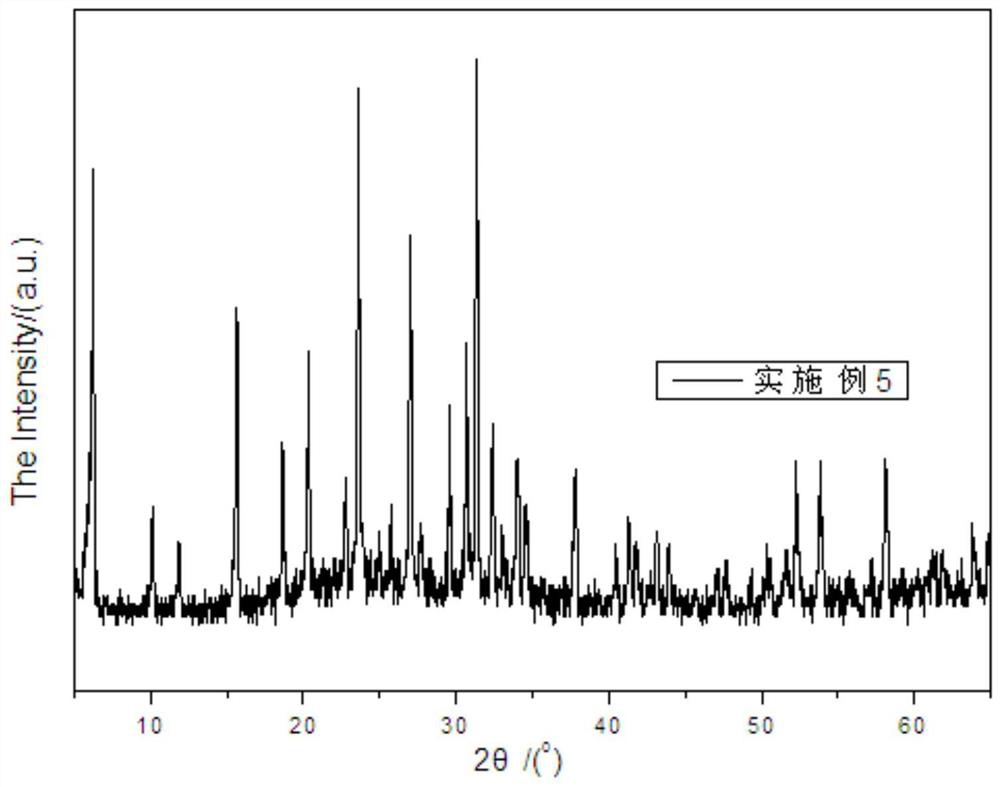

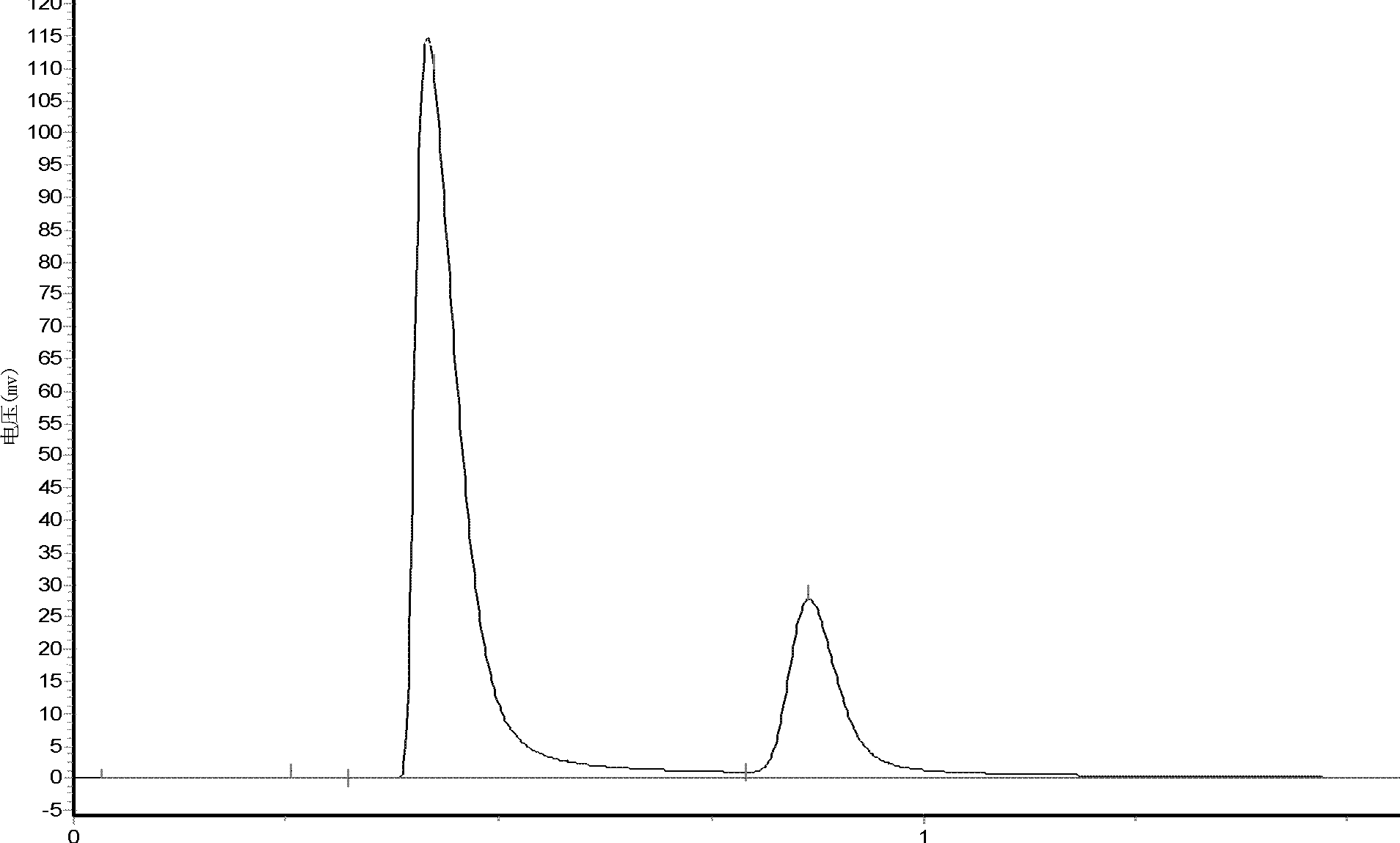

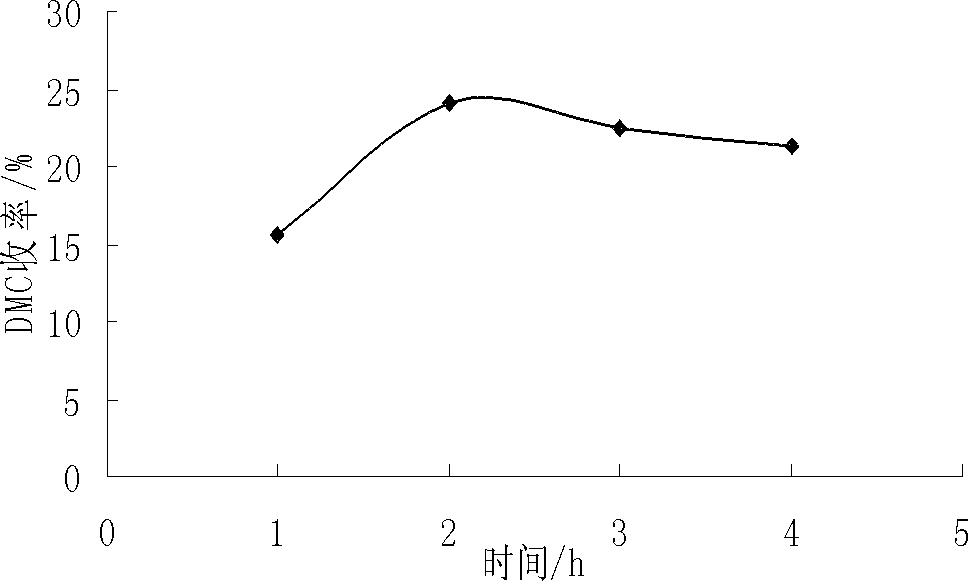

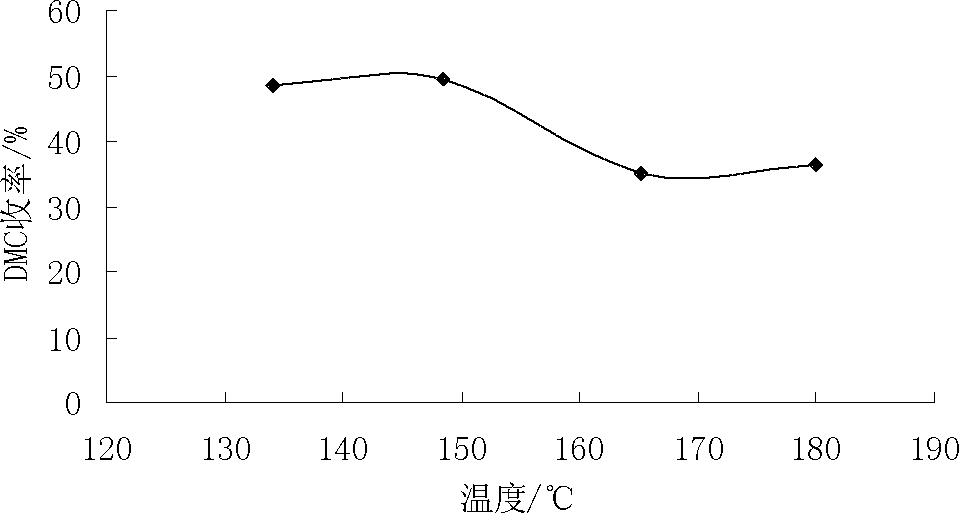

Catalyst for synthesizing dimethyl carbonate and preparation method thereof

InactiveCN102527425BHigh conversion rate of methanolHigh DMC yieldMolecular sieve catalystsOrganic compound preparationMethyl carbonatePotassium

The invention relates to a catalyst for synthesizing dimethyl carbonate from methanol through oxidization and carbonylation and a preparation method of the catalyst. The catalyst is composed of CuO-CoO as active ingredients, K2O as a cocatalyst, and a ZSM-5 molecular sieve as a carrier, wherein the molar ratio of Cu to Co to K is (1.00-1.20):(0.70-0.80):(0.02-0.04), preferably 1.00:0.75:0.03. The preparation method of the catalyst comprises the steps of: mixing soluble thermally-decomposable copper salt, cobalt salt and potassium salt at the molar ratio of Cu to Co to K being (1.00-1.20):(0.70-0.80):(0.02-0.04), preferably 1.00:0.75:0.03, then adding the ZSM-5 molecular sieve, ultrasonically dispersing, filtering, drying, calcining and aging to obtain the catalyst. The catalyst has high methanol conversion rate and good dimethyl carbonate selectivity.

Owner:TAIYUAN NORMAL UNIV

A kind of preparation method of sapo-34 molecular sieve microsphere catalyst and the application of catalyst

ActiveCN106082253BIncrease volume yieldHigh yieldMolecular sieve catalystsMolecular sieve catalystMolecular sieveMicrosphere

The invention relates to a SAPO-34 molecular sieve microsphere catalyst preparation method, which comprises: adding an aluminum source into deionized water under a room temperature stirring state, adding a phosphorus source, uniformly stirring, slowly adding a silicon source, continuously and uniformly stirring, adding a tetraethyl ammonium hydroxide solution, continuously adding one and / or a plurality of materials selected from isopropylamine, diethylamine and triethylamine after uniformly stirring to form a uniform gel, crystallizing, unloading the synthesized product mother liquor from the autoclave after completing the crystallizing, carrying out spray drying, and calcining for 1.5-2.5 h to obtain the catalyst. According to the present invention, the synthesis yield is high, the separation and the washing on the molecular sieve synthetic product are not required, and the one-time catalyst molding granulation is achieved.

Owner:岳阳慧璟新材料科技有限公司

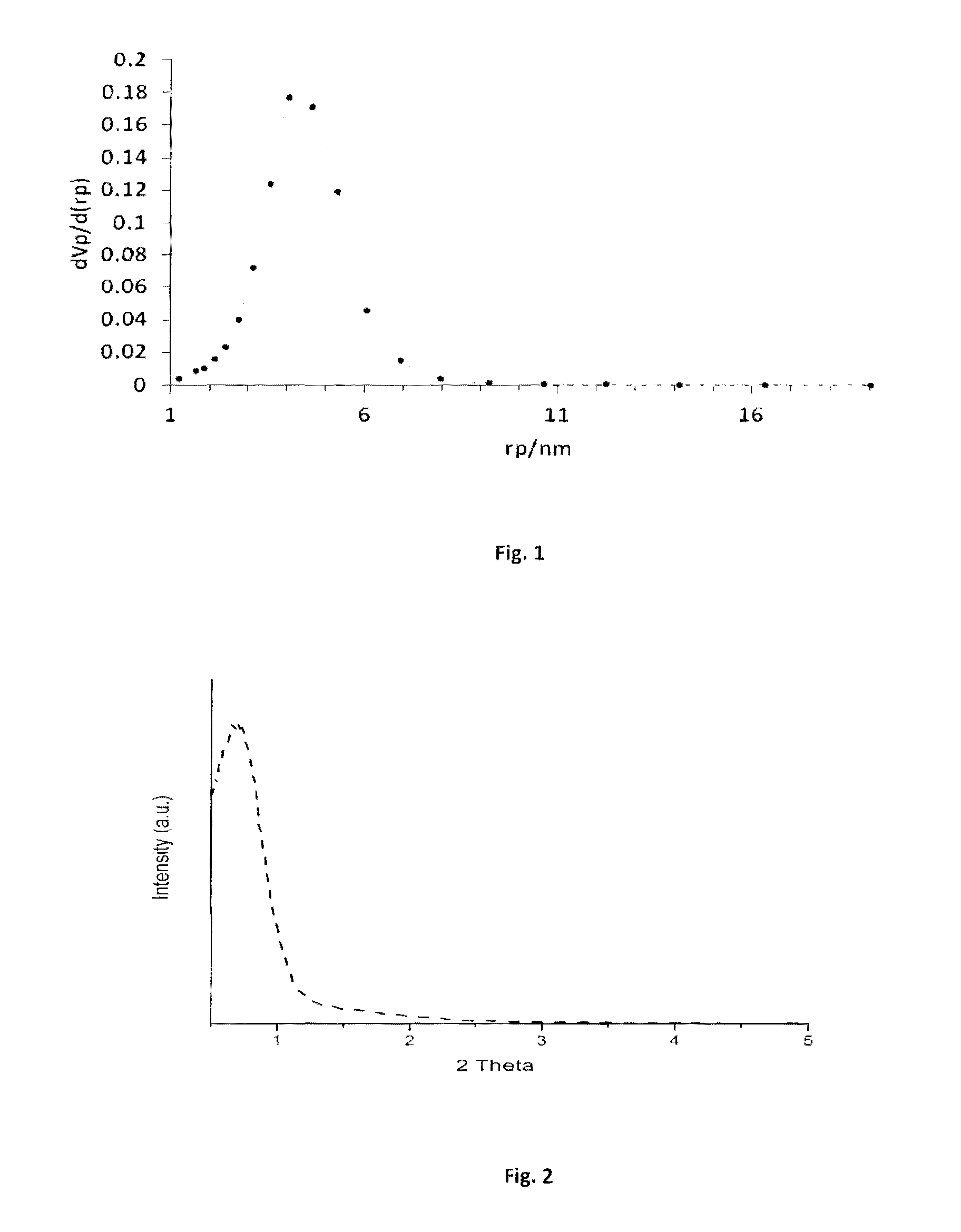

Process for the preparation of phosphorous containing mesoporous alumina catalyst for selective dehydration of methanol to dimethyl ether

ActiveUS20150336086A1Easy to handleSelective dehydration of methanolOrganic compound preparationCatalyst activation/preparationDimethyl etherDehydration

The present invention provides an improved process for the preparation of phosphorous containing mesoporous alumina catalyst for selective dehydration of methanol to dimethyl ether. The process provides a single step selective vapour phase dehydration of methanol to produce dimethyl ether over phosphorous containing mesoporous alumina (P / Al2O3) catalyst at a temperature in the range of 150-350° C. The process provides methanol conversion of 45-100% with a selectivity of the DME up to 100%.

Owner:COUNCIL OF SCI & IND RES

Catalyst used in process of preparing dimethyl ether from methanol on fluidized bed and preparation method thereof

ActiveCN102029184BSpeed up the flowImprove liquidityMolecular sieve catalystsEther preparation by compound dehydrationMolecular sieveMicrosphere

The invention discloses a catalyst used in the process of preparing dimethyl ether from methanol on a fluidized bed, which is prepared by a method comprising the following steps of: uniformly mixing desalted water and a silicon-containing material, adding an aluminum-containing material and silicon aluminum phosphorus molecular sieves, uniformly mixing, adding a base material, uniformly mixing toobtain slurry, adjusting a pH value to ensure that the slurry forms a gel state, continuously stirring, pelleting by spraying so as to obtain solid microspheres, roasting, acid-washing, drying and roasting to obtain the catalyst which has the abrasion index of 0.5 to 2.0 and is used in the process of preparing the dimethyl ether from the methanol on the fluidized bed. The hollow degree of the solid microspheres can be lowered by the catalyst prepared by the method, while the catalytic activity is met, the wear-resisting property of the catalyst is obviously improved, and the abrasion index ofthe catalyst is below 2.0 and can be below 1.5 by optimizing preparation parameters; and the catalyst has high stability and long service life and is characterized by low reaction temperature, high methanol conversion ratio, high selectivity of the dimethyl ether and low cost, and the large-scale production of the dimethyl ether can be realized by the catalyst.

Owner:CHINA TIANCHEN ENG +1

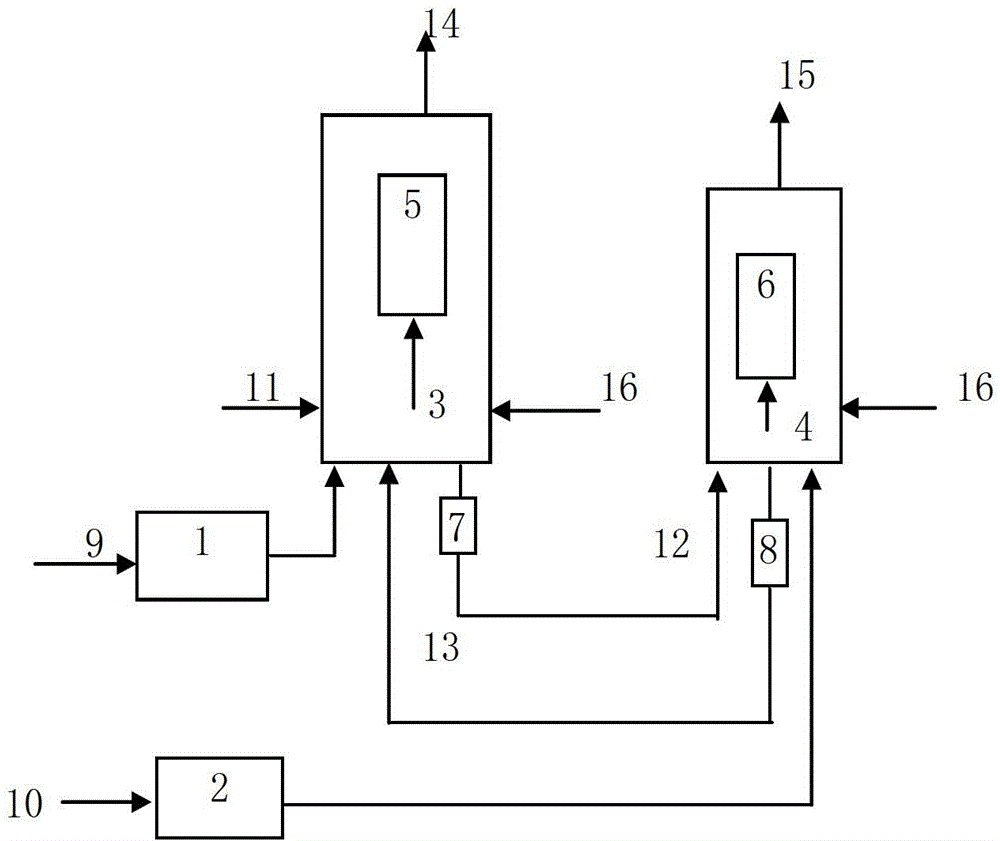

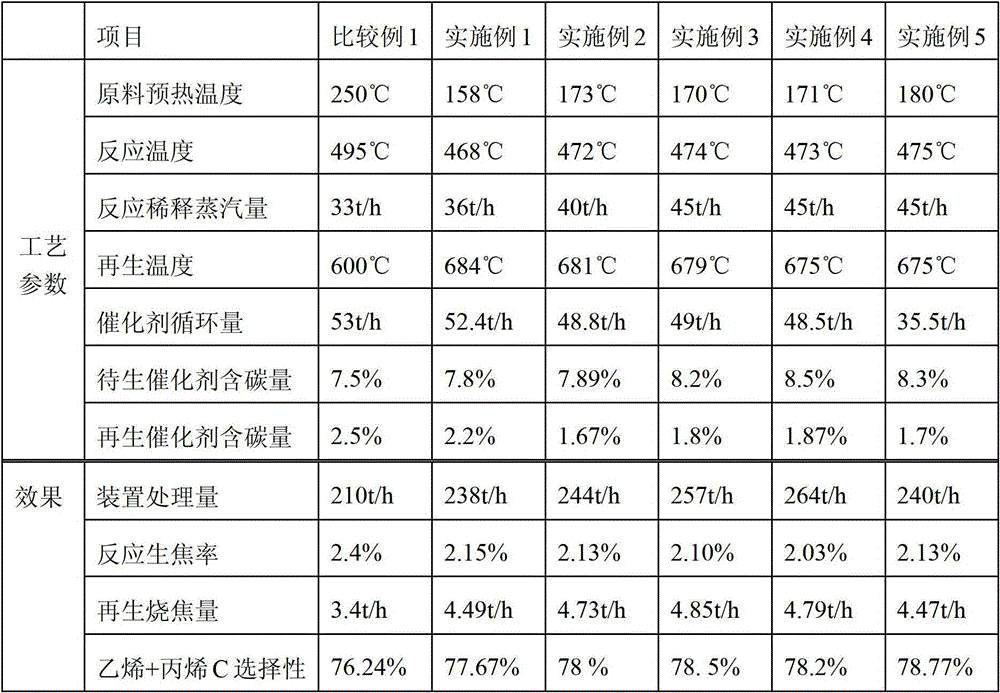

A kind of methanol-to-olefins method

ActiveCN103588605BReduce productionHigh conversion rate of methanolHydrocarbon from oxygen organic compoundsEthylene productionPtru catalystFluidized bed

The invention relates to a method for producing alkene from methanol. The method is a catalyst fluidized-bed continuous reaction regeneration technology for industrialized production of alkene from methanol, and comprises that: methanol is heated to a preheating temperature by a charging system and mixed with diluted vapor, the mixture enters a fluidized-bed reactor and contacts with a catalyst for a reaction at a reaction temperature; with the reducing of catalysit activity, the to-regenerated catalyst is controlled to enter a reactivator for regeneration at a regeneration temperature and further for generation of a regeneration catalyst; and the regeneration catalyst enters the reactor and continues to participate in the reaction, and thus the cycle of the catalyst is realized, wherein the reaction temperature is 495 DEG C. The method provided by the invention helps to guarantee relatively high methanol conversion rate at a relatively low reaction temperature, and is beneficial to reducing of generation amount of coke and reaction byproducts.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Reforming chamber for fuel cell system and fuel cell system

ActiveCN108736024BGood resistance to sulfide poisoningHigh conversion rate of methanolCell electrodesFuel cellsIndiumFuel cells

The invention discloses a reforming chamber for a fuel cell system, and a fuel cell system. The reforming chamber comprises an aluminum-magnesium alloy flow field plate and a sealed end plate; the aluminum-magnesium alloy flow field plate comprises a flow field, a composite catalyst and a composite carrier; the composite carrier is formed on the surface of the flow field; the composite carrier iscomposed of aluminum oxide and magnesium oxide; the composite catalyst is formed on the composite carrier; the composite catalyst is composed of elemental copper, copper oxide, germanium dioxide and indium sesquioxide; the composite carrier is formed through electrochemical corrosion method, and the composite catalyst is formed through reaction plasma spray-coating method and cold spray-plating method. The reforming chamber disclosed by the invention has high methanol conversion rate and low CO selectivity, and further has good capacity of resisting sulfide poisoning.

Owner:德州新动能铁塔发电有限公司

Mini Methanol Steam Reforming Chamber

ActiveCN103956508BImprove adhesionIncrease reaction rateFuel cellsSteam reformingMicro arc oxidation

Owner:HARBIN INST OF TECH

Catalyst for preparing methylal and methyl formate by one-step selective oxidation of methanol

ActiveCN106890652BHigh conversion rate of methanolHigh selectivityPhysical/chemical process catalystsOrganic compound preparationDimethoxymethaneRaw material

The invention provides a catalyst for preparing methylal and methyl formate through one-step selective oxidation of methanol. The catalyst comprises the following raw material components in percentage by mass based on total mass of the raw material components of the catalyst: 10-20% of a vanadium source, 55-65% of a titanium source and 15-35% of sulfuric acid. The invention provides a catalyst for preparing methyl formate and methylal through one-step selective oxidation of methanol and a preparation method of the catalyst. The catalyst has a high methanol conversion rate, high product selectivity, long life and low-temperature fluctuation sensitivity, the product composition is easily controlled in industrial reaction, and subsequent separation is convenient.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

ZSM-5 and ZSM-11 eutectic molecular sieve as well as preparation method and application thereof

ActiveCN111484033AEmission reductionIncrease greennessMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveSolvent

The invention provides a ZSM-5 and ZSM-11 eutectic molecular sieve as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) mixing and stirring a silicon source, an aluminum source, a first organic template agent, a second organic template agent, sodium hydroxide and a solvent to obtain mixed gel; (2) carrying out drying treatment and grinding treatment on the mixed gel to obtain gel powder; (3) performing crystallization treatment on the gel powder in a hydrothermal kettle to obtain an intermediate product, wherein in the crystallization treatment, the pressure is 0.7-1.3 Mpa, the temperature is 160-180 DEG C, the time is 24-48 hours, and the mass ratio of the water to the gel powder in the hydrothermal kettle is (1-10): 1; and (4)washing, drying and roasting the intermediate product to obtain the ZSM-5 and ZSM-11 eutectic molecular sieve. According to the preparation method disclosed by the invention, the eutectic molecular sieve with a controllable ratio of ZSM-5 to ZSM-11 is innovatively prepared by virtue of a water vapor assisted crystallization method.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com