Supported copper-based catalysts for hydrogen production by methanol steam reforming as well as preparation method and application of supported copper-based catalysts

A copper-based catalyst, reforming hydrogen production technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve problems such as stability to be improved, easy sintering, etc. , to overcome activity and selectivity bottlenecks, increase methanol conversion, and simplify the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

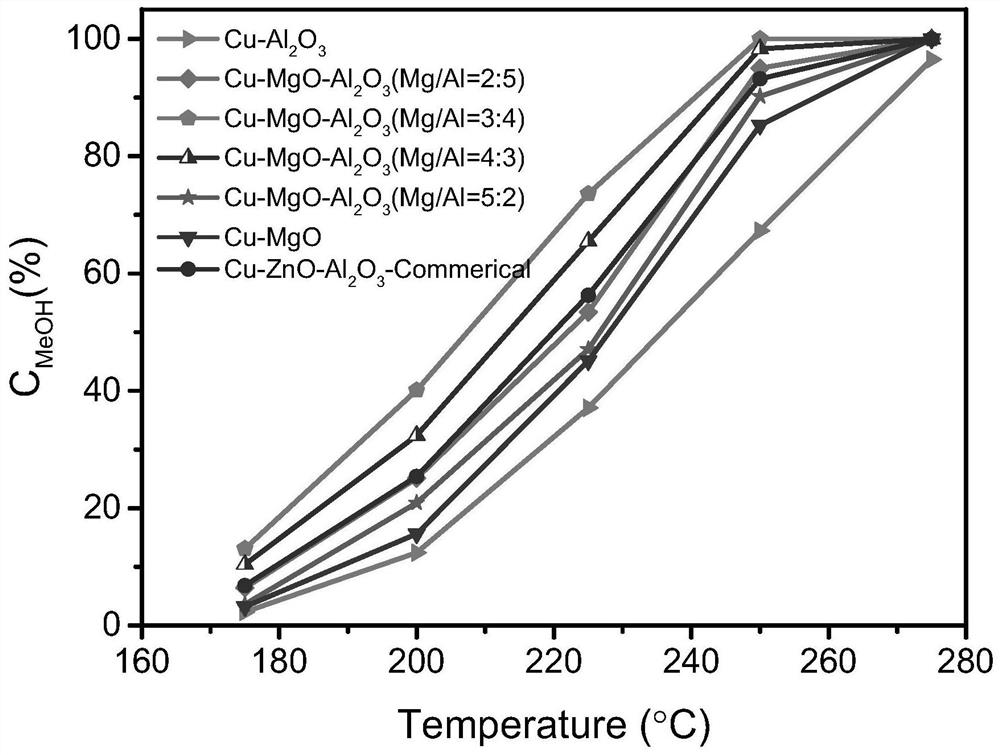

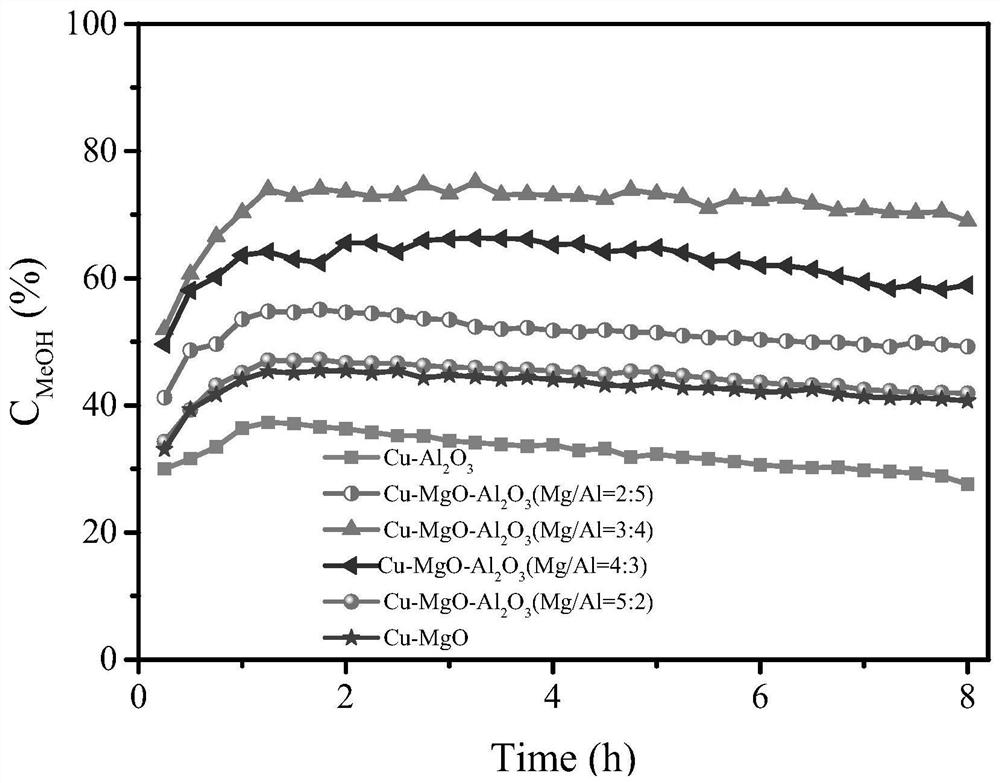

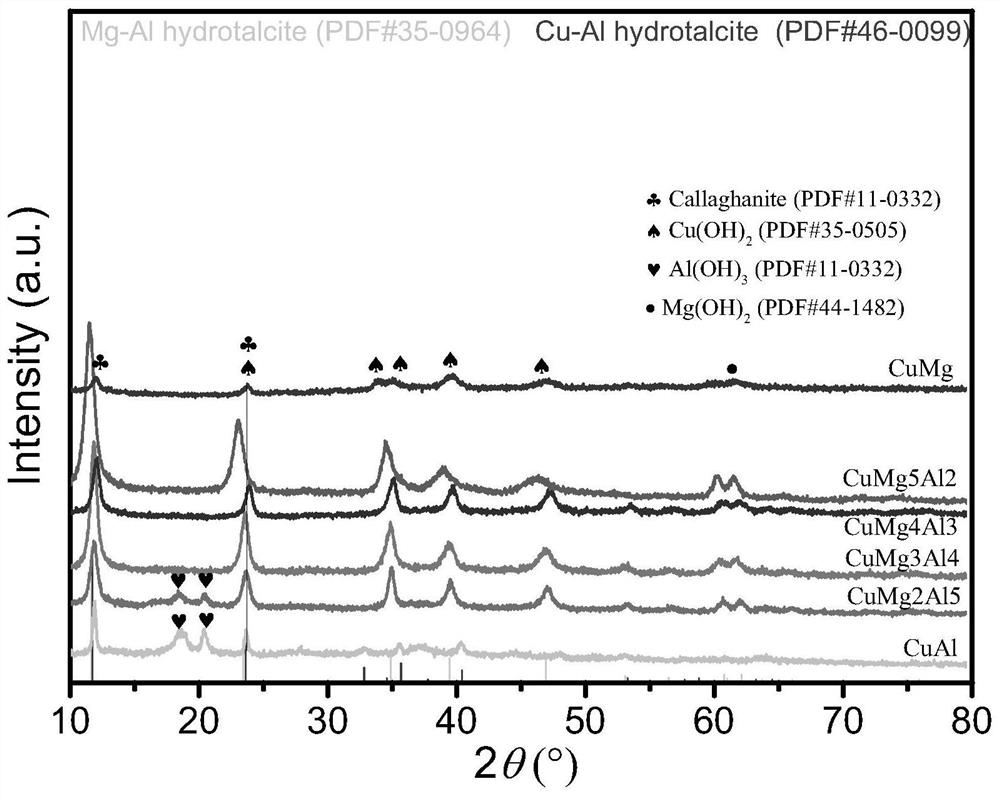

[0038] A hydrogen production catalyst for methanol steam reforming was prepared by co-precipitation method using sodium carbonate and sodium hydroxide as precipitants. A certain amount of sodium carbonate and sodium hydroxide was added to the nitrate mixed solution of copper, magnesium and aluminum at a constant rate. , aging after precipitation, and after suction filtration, drying, grinding and calcination, the catalyst was obtained. by Cu-Al 2 o 3 The addition of magnesium oxide to the catalyst improves the activity and stability of the original copper-based catalyst.

[0039] In this example, it is CuO-MgO-Al 2 o 3 Preparation of catalyst, copper oxide mass content 20wt%, molar ratio Mg:Al=2:5

[0040] making process:

[0041] S1: 1.522g Cu(NO 3 )2 ·3H 2 O, 11.254g Al(NO 3 ) 3 9H 2 O and 3.077g Mg(NO 3 ) 2 ·6H 2 Dissolve O in 100mL deionized water, and dissolve it with a magnetic stirrer;

[0042] S2: 100mL of 1.6 ([M 2+ ]+[Al 3+ ]) Sodium Hydroxide 2[Al 3...

Embodiment 2

[0056] In this example, it is CuO-MgO-Al 2 o 3 Catalyst preparation, molar ratio Mg:Al=3:4

[0057] making process:

[0058] S1: 1.468g Cu(NO 3 ) 2 ·3H 2 O, 9.003g Al(NO 3 ) 3 9H 2 O and 4.615g Mg(NO 3 ) 2 ·6H 2 Dissolve O in 100mL deionized water, and dissolve it with a magnetic stirrer;

[0059] S2: 100mL of 1.6 ([M 2+ ]+[Al 3+ ]) Sodium Hydroxide 2[Al 3+ ] The mixed solution of sodium carbonate is added to the solution obtained in step S1, and the dropping rate is 1-2mL / min;

[0060] S3: After continuing to stir the mixture obtained in step S2 for 1 hour, let it stand for 18 hours;

[0061] S4: Suction filter and wash the mixture obtained in step S3, and the washing water volume is 8L;

[0062] S5: put the solid matter obtained in step S4 into an oven for 12 hours, and set the temperature at 100°C;

[0063] S6: Grinding the solid obtained in step S5 into powder, and calcining in a muffle furnace at 400-500° C. for 3-5 hours to obtain a final product.

[00...

Embodiment 3

[0071] In this example, it is CuO-MgO-Al 2 o 3 Preparation of catalyst, CuO mass content 20wt%, molar ratio Mg:Al=4:3

[0072] making process:

[0073] S1: 1.417g Cu(NO 3 ) 2 ·3H 2 O, 6.752g Al(NO 3 ) 3 9H 2 O and 6.153g Mg(NO 3 ) 2 ·6H 2 Dissolve O in 100mL deionized water, and dissolve it with a magnetic stirrer;

[0074] S2: 100mL of 1.6 ([M 2+ ]+[Al 3+ ]) Sodium Hydroxide 2[Al 3+ ] The mixed solution of sodium carbonate is added to the solution obtained in step S1, and the dropping rate is 1-2mL / min;

[0075] S3: After continuing to stir the mixture obtained in step S2 for 1 hour, let it stand for 18 hours;

[0076] S4: Suction filter and wash the mixture obtained in step S3, and the washing water volume is 8L;

[0077] S5: put the solid matter obtained in step S4 into an oven for 12 hours, and set the temperature at 100°C;

[0078] S6: Grinding the solid obtained in step S5 into powder, and calcining in a muffle furnace at 400-500° C. for 3-5 hours to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com