Reforming chamber for fuel cell system and fuel cell system

A technology for fuel cell systems and reforming chambers, applied in fuel cells, battery electrodes, circuits, etc., can solve problems such as poor resistance to sulfide poisoning, and achieve good effects of resistance to sulfide poisoning and high methanol conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

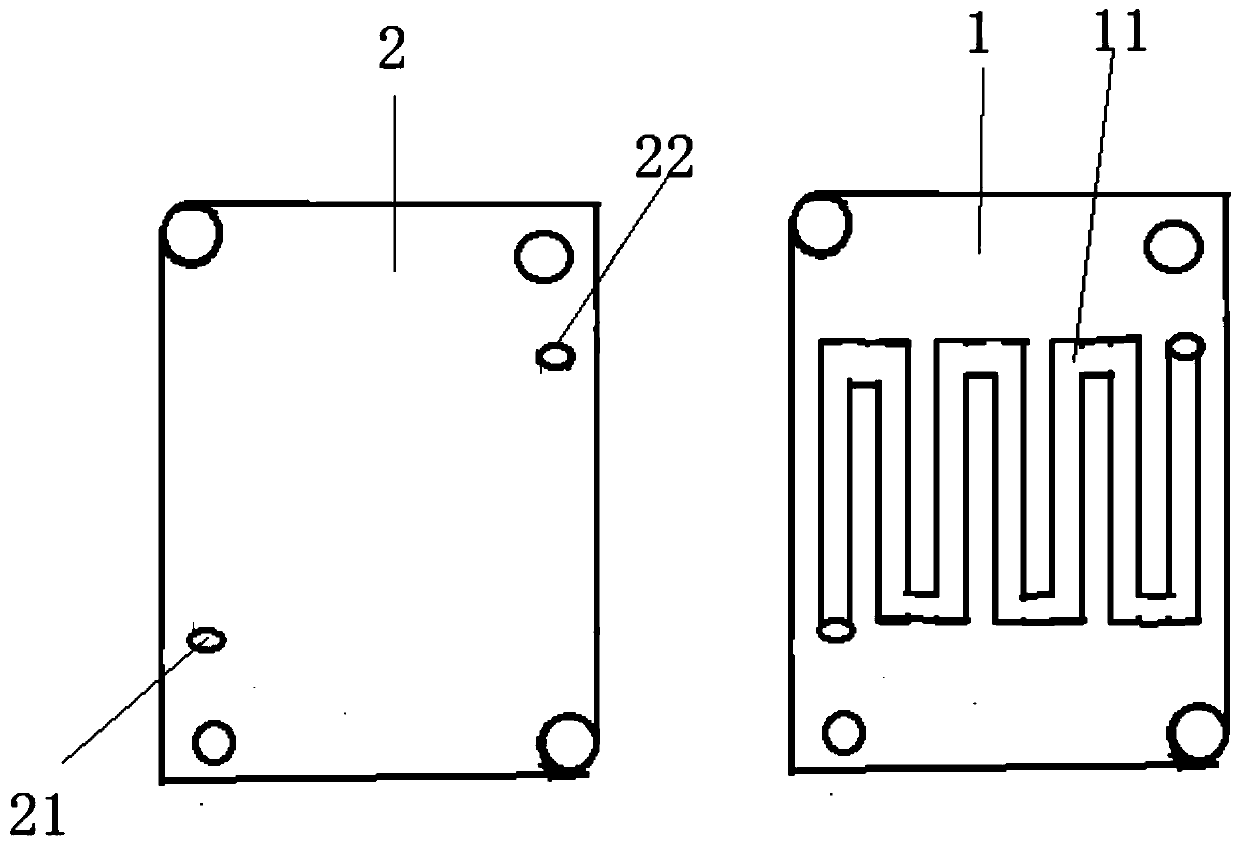

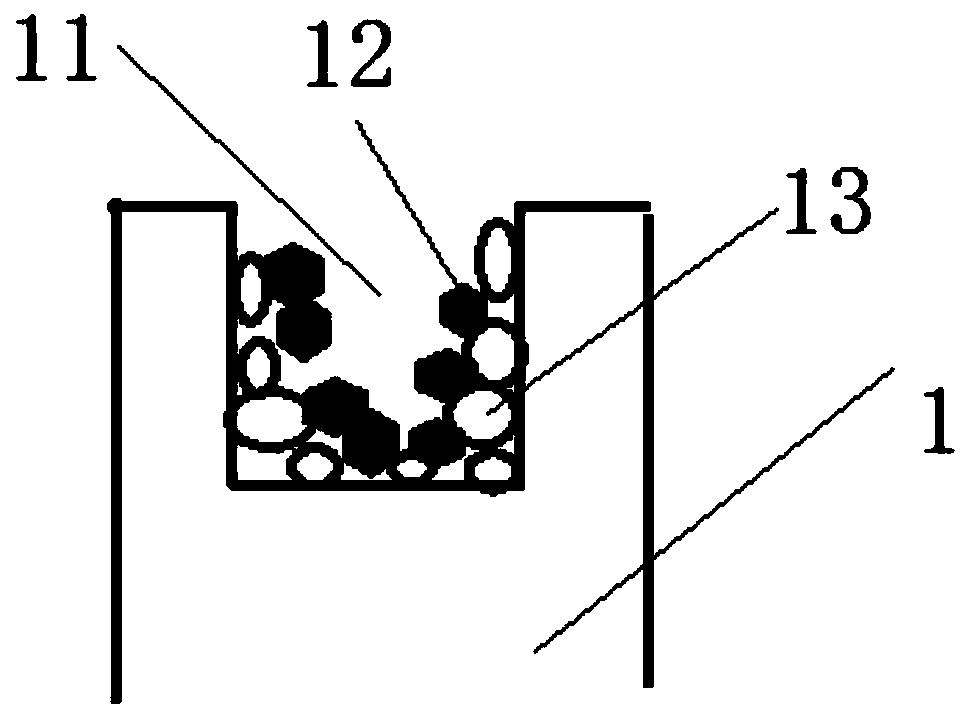

[0033] An 8wt% aluminum-magnesium alloy plate with a flow field of 30cm×50cm×10cm is selected, the flow channel is 1cm deep, 1cm wide, and the ridge width is 1cm. After cleaning the aluminum-magnesium alloy plate, ultrasonically oscillate with ethanol and deionized water for 5 minutes in sequence, then configure 0.1mol / L sodium chloride solution as the electrolyte solution, use graphite as the cathode, and the aluminum-magnesium alloy plate as the anode, apply at room temperature Direct current, the current density is 100A / m 2 , The voltage is 200V, and the electrochemical corrosion time is 120mins. The corroded aluminum-magnesium alloy plate was washed with ethanol and deionized water three times in sequence. Put it into an oven for vacuum drying at a temperature of 60° C. for 3 hours.

[0034] Mix copper powder, indium powder, and germanium powder at a mass ratio of 1:1:1 for 2 hours to obtain a mixed powder, and put it into the powder feeder of the plasma spraying equipme...

Embodiment 2

[0039] A 10wt% aluminum-magnesium alloy plate with a flow field of 30cm×50cm×10cm is selected, the flow channel is 1cm deep, 1cm wide, and the ridge width is 1cm. After cleaning the aluminum-magnesium alloy plate, ultrasonically oscillate with ethanol and deionized water for 5 minutes in sequence, then configure 0.1mol / L sodium chloride solution as the electrolyte solution, use graphite as the cathode, and the aluminum-magnesium alloy plate as the anode, apply at room temperature Direct current, the current density is 200A / m 2 , The voltage is 250V, and the electrochemical corrosion time is 60mins. The corroded aluminum-magnesium alloy plate was washed with ethanol and deionized water three times in sequence. Put it into an oven for vacuum drying at a temperature of 70° C. for 2 hours.

[0040] Mix copper powder, indium powder and germanium powder at a mass ratio of 1:2:2 for 6 hours to obtain a mixed powder, which is put into the powder feeder of the plasma spraying equipme...

Embodiment 3

[0045] A 12wt% aluminum-magnesium alloy plate with a flow field of 30cm×50cm×10cm is selected, the flow channel is 1cm deep, 1cm wide, and the ridge width is 1cm. After cleaning the aluminum-magnesium alloy plate, ultrasonically oscillate with ethanol and deionized water for 5 minutes in sequence, then configure 0.1mol / L sodium chloride solution as the electrolyte solution, use graphite as the cathode, and the aluminum-magnesium alloy plate as the anode, apply at room temperature Direct current, the current density is 300A / m 2 , The voltage is 300V, and the electrochemical corrosion time is 10mins. The corroded aluminum-magnesium alloy plate was washed with ethanol and deionized water three times in sequence. Put it into an oven for vacuum drying at a temperature of 80° C. for 1 h.

[0046] Mix copper powder, indium powder, and germanium powder at a mass ratio of 1:3:3 for 8 hours to obtain a mixed powder, and put it into the powder feeder of the plasma spraying equipment. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com