Patents

Literature

53results about How to "Large catalytic area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

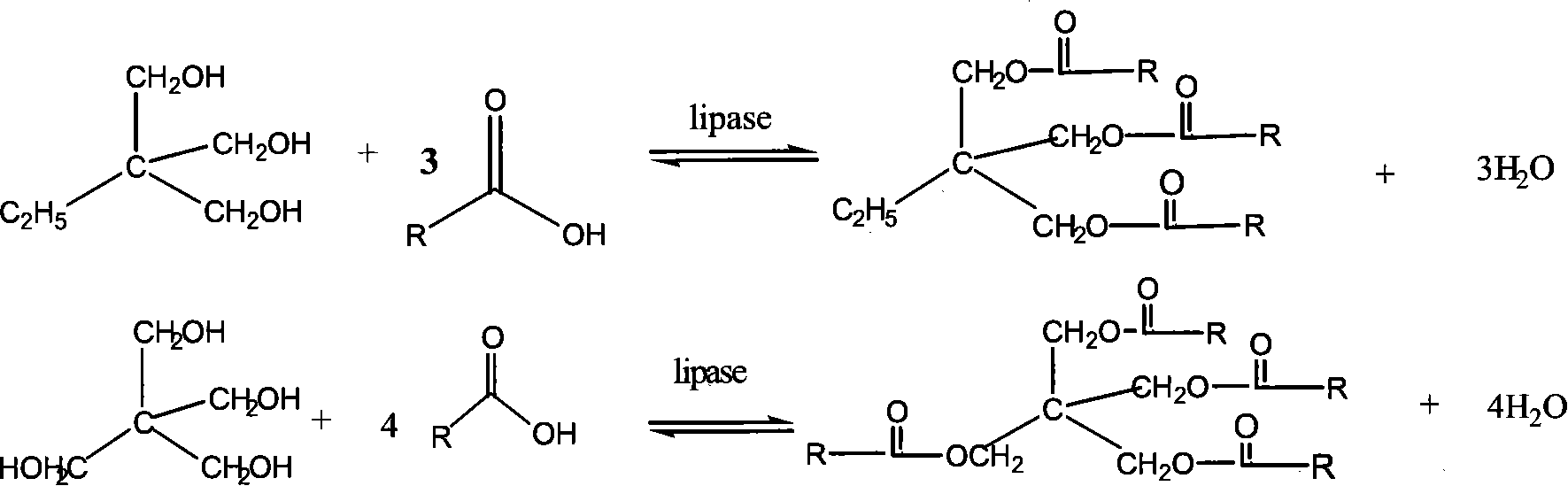

Method for catalyzing and synthesizing polyalcohol ester by immobilized lipase

InactiveCN101130796AIncrease the area of actionReduce dosageFermentationBase-materialsAlcoholBase oil

The present invention relates to a preparation method of polyhydric alcohol ester. Said method includes the steps of adopting immobilized lipolase and utilizing monobasic fatty acid and polyhydric alcohol to catalyze synthesis of polyhydric alcohol ester. Said invention also relates to a polyhydric alcohol ester preparation prepared by adopting the invented method and its application as basic oil of lubricating oil.

Owner:BEIJING UNIV OF CHEM TECH

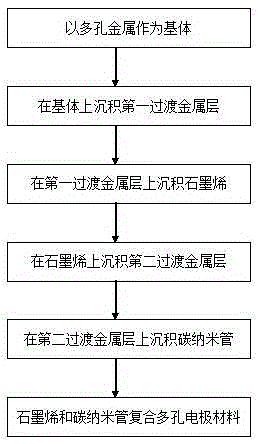

Preparing method for graphene and carbon nano tube composite porous electrode material

InactiveCN105256312ALarge specific surface areaImprove conductivitySuperimposed coating processMetal catalystCarbon nanotube

The invention discloses a preparing method for a graphene and carbon nano tube composite porous electrode material. A layer of metal catalyst is deposited on the surface of a porous metal matrix to grow graphene, then a layer of metal catalyst is deposited on the surface of the graphene to grow a carbon nano tube, and the electrode material compounding the graphene, the carbon nano tube and porous metal is obtained. The electrode material has the beneficial effects of being low in weight, high in specific area and conductivity, good in stability and long in service life, good electrochemical performance is shown, and very good application value is achieved on the aspect of electrode application.

Owner:WUZHOU HGP ADVANCED MATERIALS TECH CORP

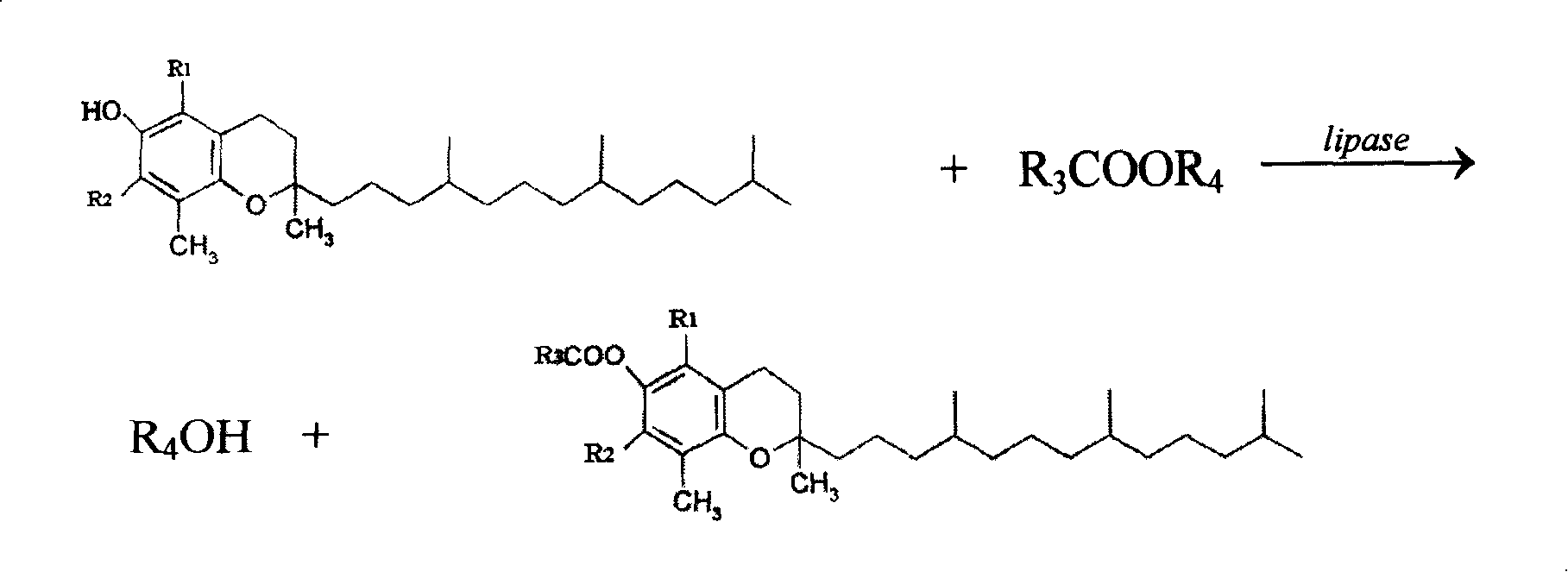

Method for catalytic synthesis of vitamin A fatty acid ester using immobilized lipase

The method of catalytically synthesizing vitamin A fatty ester with immobilized lipase includes mixing substrate vitamin An acetate and C10-C18 fatty acid or fatty ester in the molar ratio of 1 to 1-7 as well as organic solvent and immobilized lipase in the amount of 0.2-5 times weight of vitamin An acetate for reaction under 20-50 deg.c for 9-50 hr; taking out the immobilized lipase; filtering the reacted liquid and crystallizing to obtain vitamin A fatty ester. The organic solvent is C6-C10 saturated alkane containing water in 0-1 %; and the immobilized lipase is yeast type lipase on carrier of diatomite, resin or fabric membrane. The immobilized lipase of the present invention has the features of great catalysis area, high catalysis efficiency, high stability, capacity of being reused, etc. The reaction solvent has no toxicity, and the product is light in color and high in quality.

Owner:BEIJING UNIV OF CHEM TECH

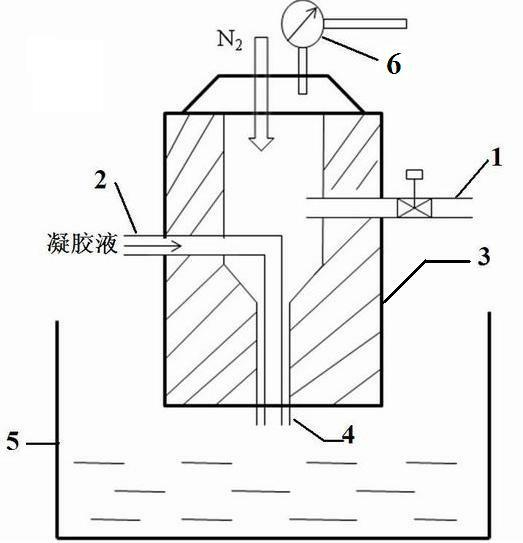

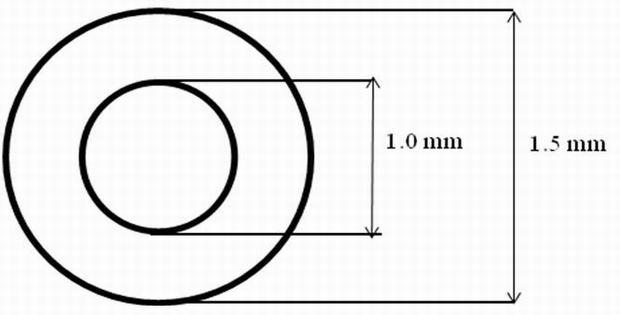

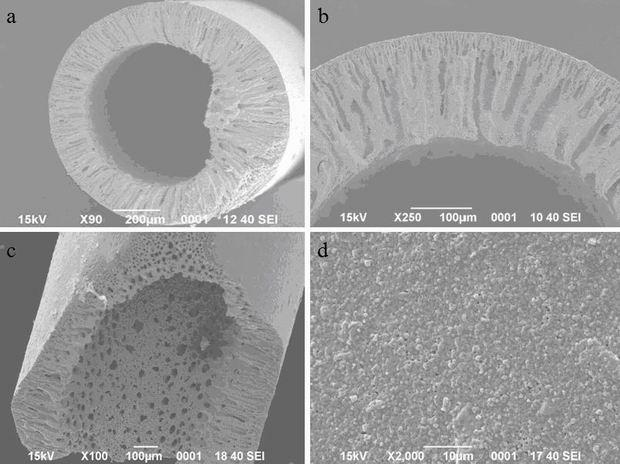

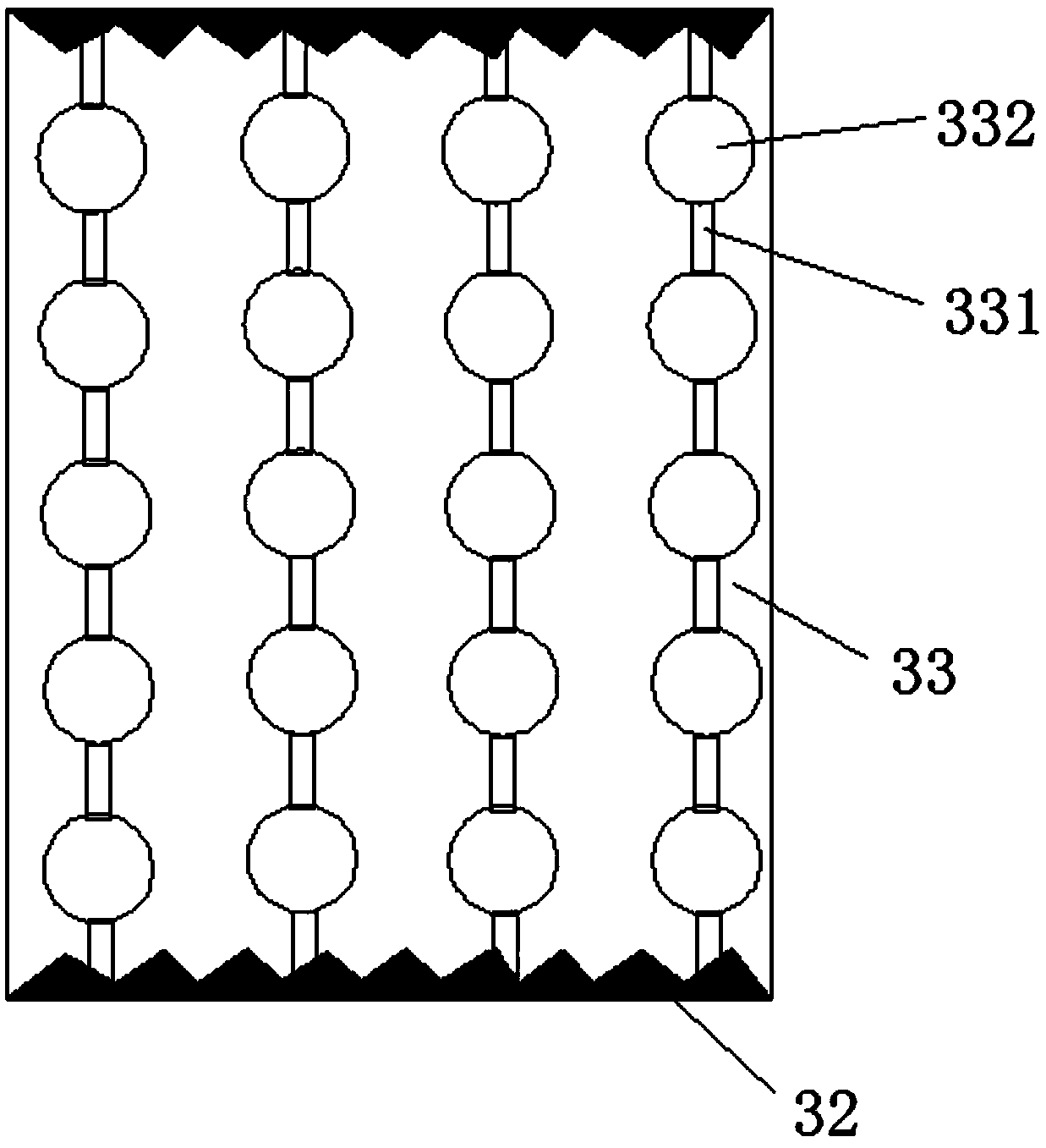

Preparation method for asymmetric hollow fiber type solid oxide fuel cell

InactiveCN102332592ASimple processLow costFinal product manufactureCell electrodesHollow fibreTextile technology

The invention discloses a preparation method for an asymmetric hollow fiber type solid oxide fuel cell. The method comprises the following steps of: preparing an anode blank of the asymmetric hollow fiber type solid oxide fuel cell through a phase inversion textile technology; performing suspended sintering on the anode blank to form an anode support with superior mechanical performance; dip-coating the anode support in electrolyte slurry through a dip-coating process to prepare an electrolyte layer; and sequentially preparing cathode brushing solution and cathode afflux solution into the asymmetric hollow fiber type solid oxide fuel cell through a brushing process. The preparation method has the advantages of simple and feasible process, low cost, no need of any spray-coating equipment, easiness in industrial large-scale production and the like; the anode and cathode three-phase region of the obtained asymmetric hollow fiber type solid oxide fuel cell is more ideal; the electrolyte layer is extremely thin and has high compactness; and thus, the electrochemical comprehensive performance of the solid oxide fuel cell is improved.

Owner:SOUTH CHINA UNIV OF TECH

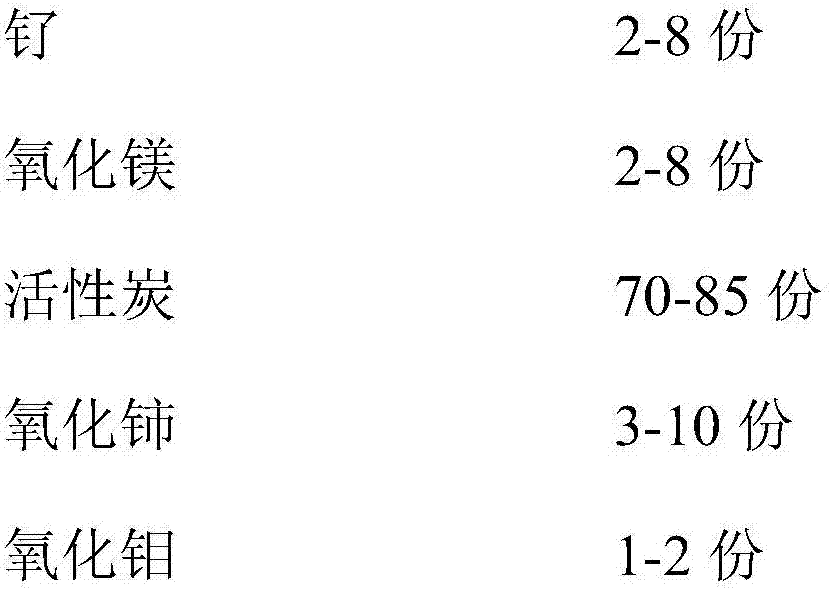

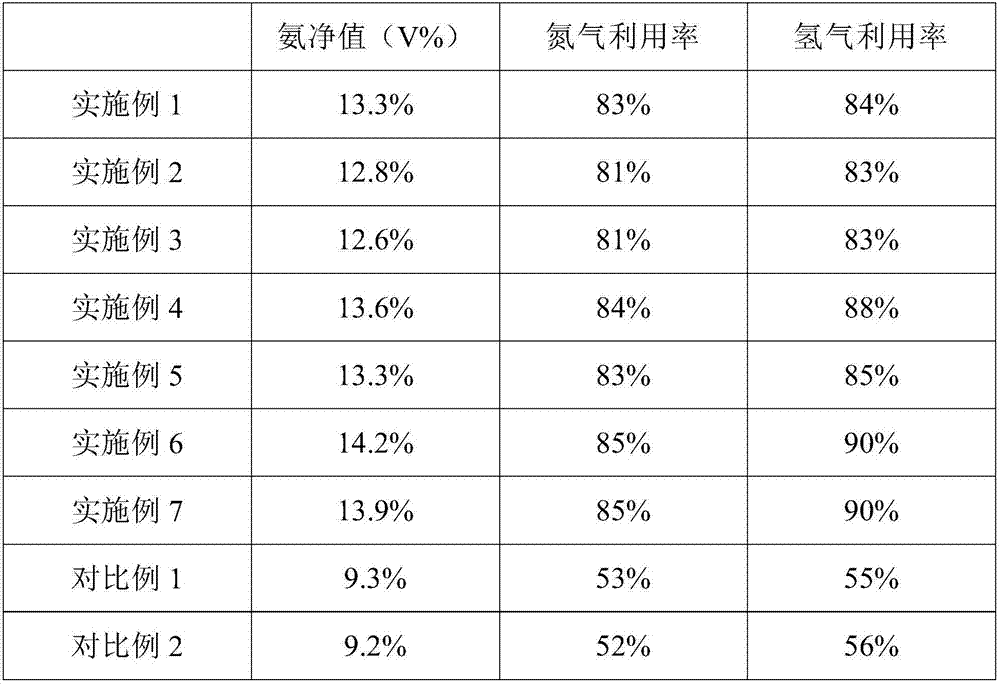

Low-pressure ammonia synthesis process

ActiveCN107117628AGuaranteed uptimeProcess operation is stableMetal/metal-oxides/metal-hydroxide catalystsAmmonia preparation/separationElectrolysisNitrogen gas

The invention provides a low-pressure ammonia synthesis process which comprises the following steps: 1) performing deep cooling air separation on air so as to obtain nitrogen and oxygen, and performing pure oxygen self-heat conversion on the oxygen with a natural gas so as to obtain a mixed gas with CO and H2; ) performing electrolysis water separation so as to obtain hydrogen; 3) mixing the hydrogen with the nitrogen so as to obtain an ammonia synthesis raw material gas, and performing primary ammonia synthesis in a first ammonia synthesis tower filled with an iron-based catalyst, wherein the synthesis pressure is 5-7MPa; 4) feeding the mixed gas discharged from the first ammonia synthesis tower into a second ammonia synthesis tower filled with a ruthenium-based catalyst, and performing secondary ammonia synthesis, wherein the synthesis pressure is 4-6MPa. By adopting the process, the ammonia synthesis process is divided into two sections which are implemented at specific pressure in the presence of specific types of catalysts and raw material gases of specific hydrogen to nitrogen ratios, ammonia synthesis process requirements are met, stable process operation is ensured, and the net value of ammonia at the outlets of the ammonia synthesis towers and the utilization rates of nitrogen and hydrogen are increased.

Owner:绿氨(北京)技术有限公司

Method for synthesizing natural tocopherol ester catalyzed by lipase

The invention discloses a method for catalyzing and synthesizing savageness tocofecol ester by lipase. savageness tocofecol and a unsaturated carboxylic ether in ratio range of 1:1-1:5 are added into reaction media organic solvent and lipase is used as energizing agent. The esterification rate of savageness tocofecol can be up to 9525023440n condition of 20-60 0.000000or 48-72 hours. The dosage of lipase is 0.5 times of the quantity of tocofecol and the carrier of lipase is textile fabric or colophony. Comparing with the present method in chemical catalyst, the invention has advantages such as gentle reaction condition, low energy consumption, simple product separation and less poison accessory substances.

Owner:BEIJING UNIV OF CHEM TECH

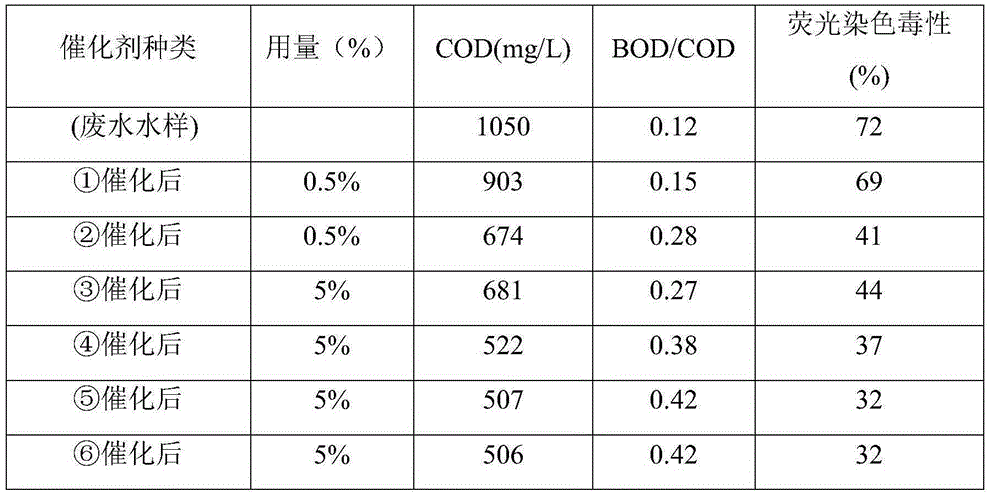

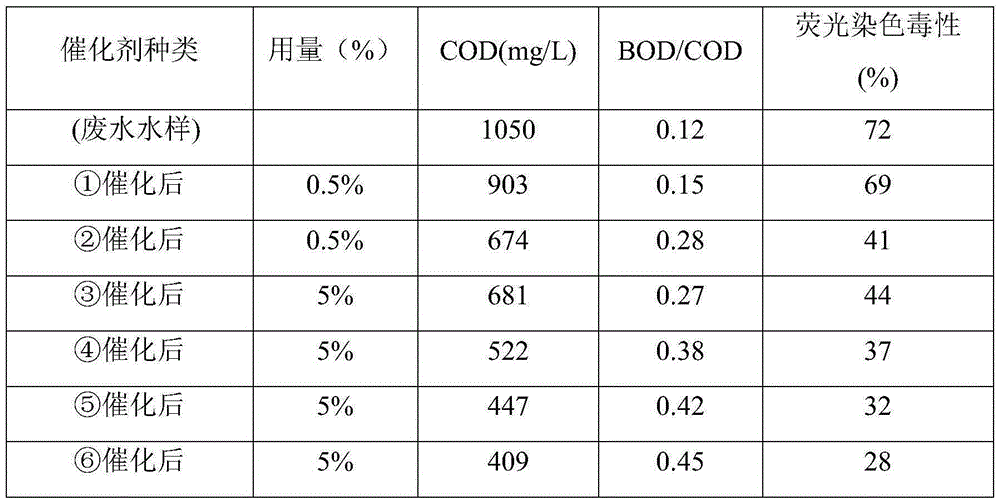

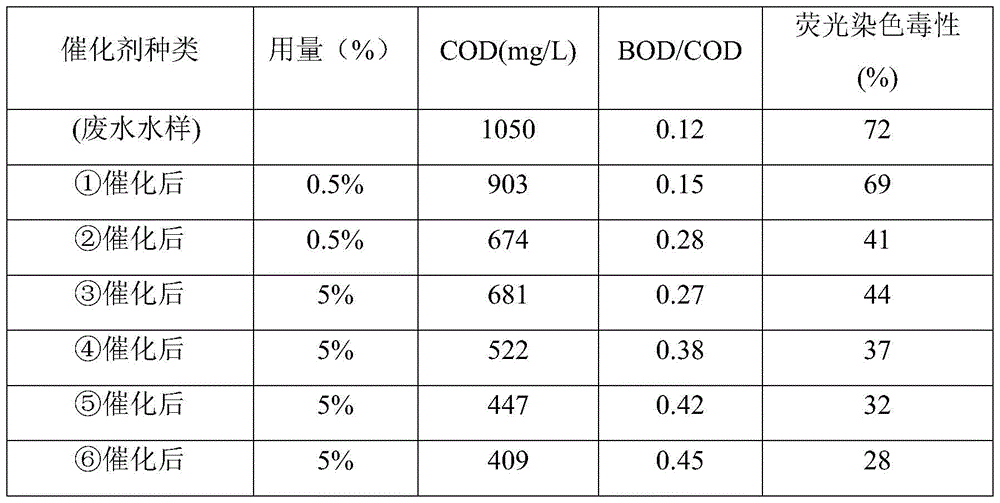

Catalyst for degrading organic wastewater and preparation method thereof

InactiveCN105413690ALow costReduce manufacturing difficultyWater/sewage treatment by irradiationEnergy based wastewater treatmentWastewaterCatalytic effect

The invention discloses a catalyst for degrading organic wastewater and a preparation method thereof. The catalyst is prepared by coating a cobalt-titanium dioxide composite material layer on a granular carrier. The thickness of the cobalt-titanium dioxide composite material layer is 100-240 nm. The molar ratio of cobalt to titanium dioxide in the cobalt-titanium dioxide composite material layer is 1: (50-200). The catalyst is good in catalytic effect and long in service life.

Owner:HUNAN YONKER ENVIRONMENTAL PROTECTION RES INST

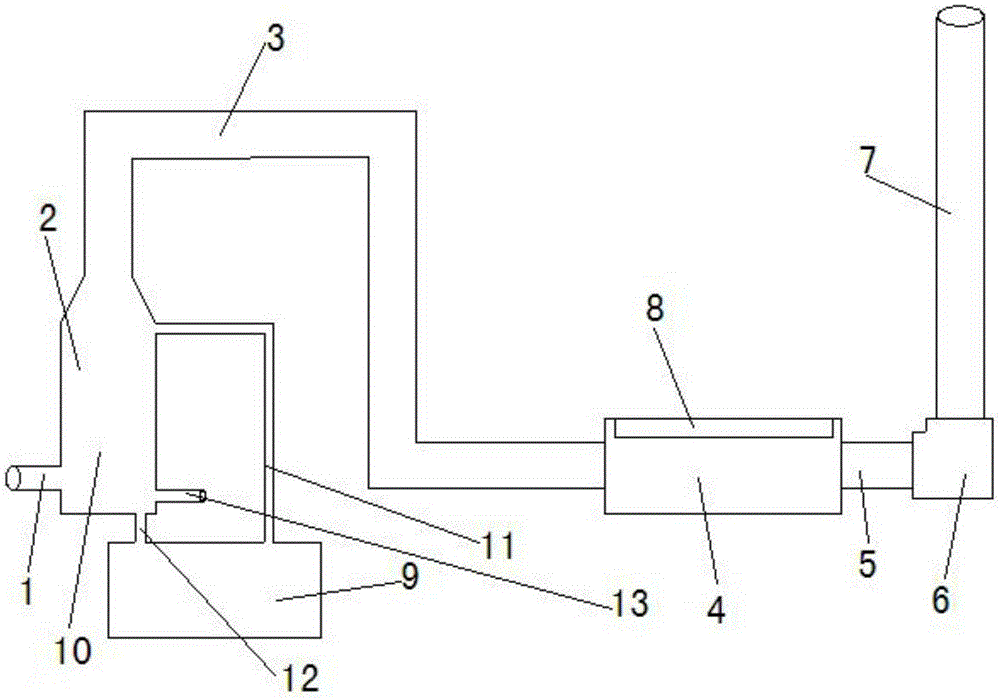

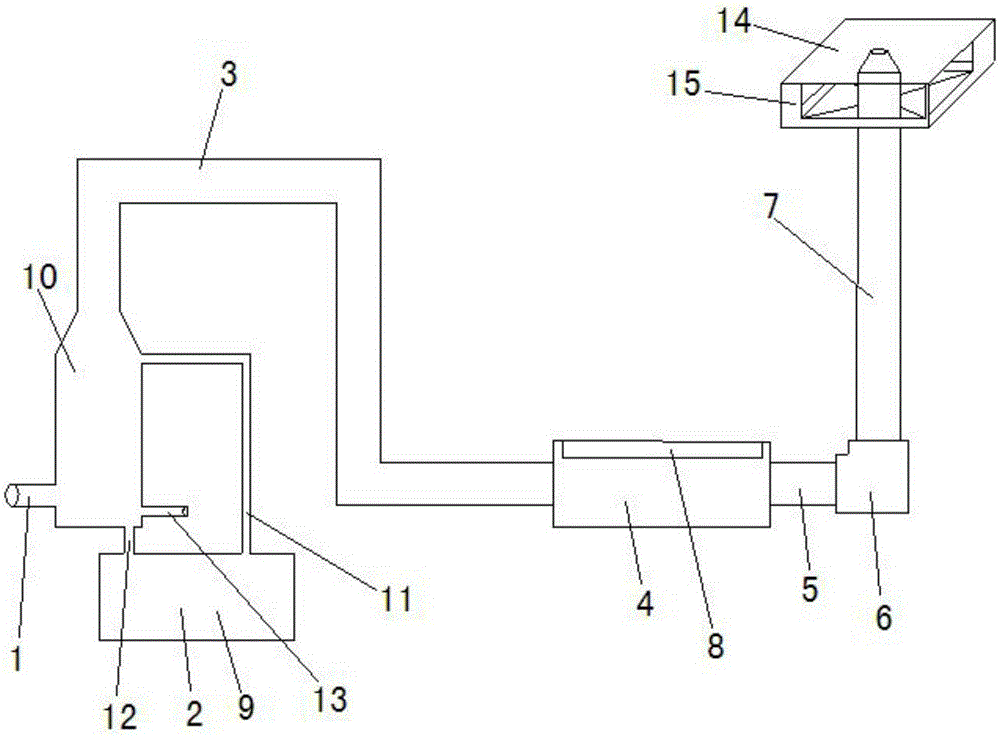

Photo oxidation and catalysis deodorization waste gas treatment device

InactiveCN105311899AQuick breakdownEfficient removalUsing liquid separation agentParticulatesOzone generator

The invention discloses a photo oxidation and catalysis deodorization waste gas treatment device which is characterized by comprising a spraying unit (2) connected with a flue gas inlet (1), wherein the top end of the spraying unit (2) is connected with a gas inlet of a photo oxidation and catalysis deodorization unit (4) through a first gas passage (3); the gas outlet of the photo oxidation and catalysis deodorization unit (4) is connected with the gas inlet of a fan (6) through a second gas passage (5); the gas outlet of the fan (6) is connected with a third vertical gas passage (7); the photo oxidation and catalysis deodorization unit (4) comprises a housing and a high-energy electron generator (8) arranged in the housing; a catalyst net plate and an ultraviolet lamp are arranged in the housing; the photo oxidation and catalysis deodorization unit (4) is connected with an ozone generator. The photo oxidation and catalysis deodorization waste gas treatment device provided by the invention can efficiently remove particles and organic matters in the waste gas, is simple in structure, low in cost, easy to maintain, and stable and reliable in running.

Owner:SUZHOU RHYMEBLUE ENVIRONMENTAL TECH CO

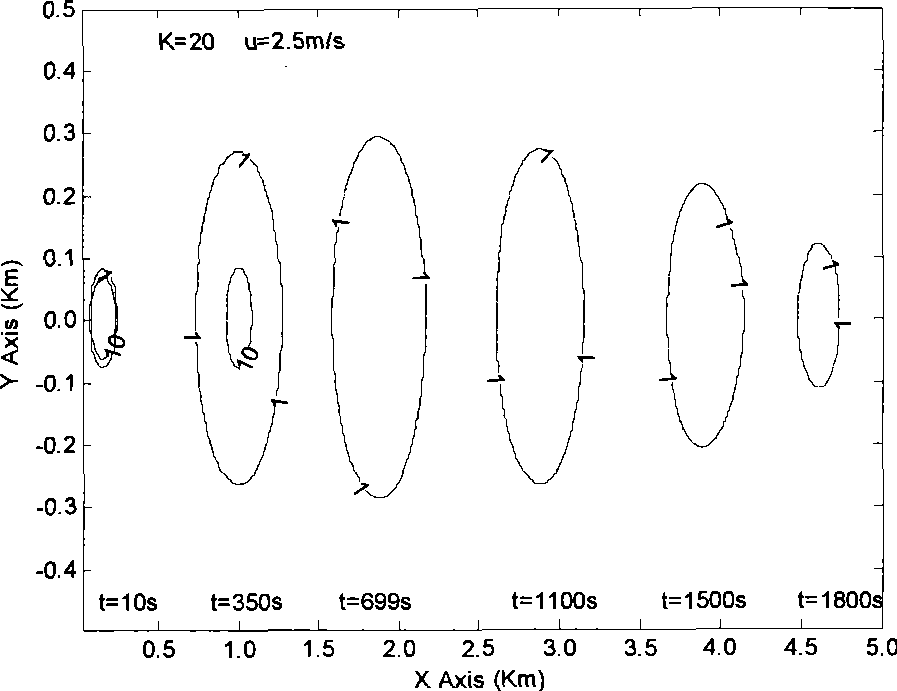

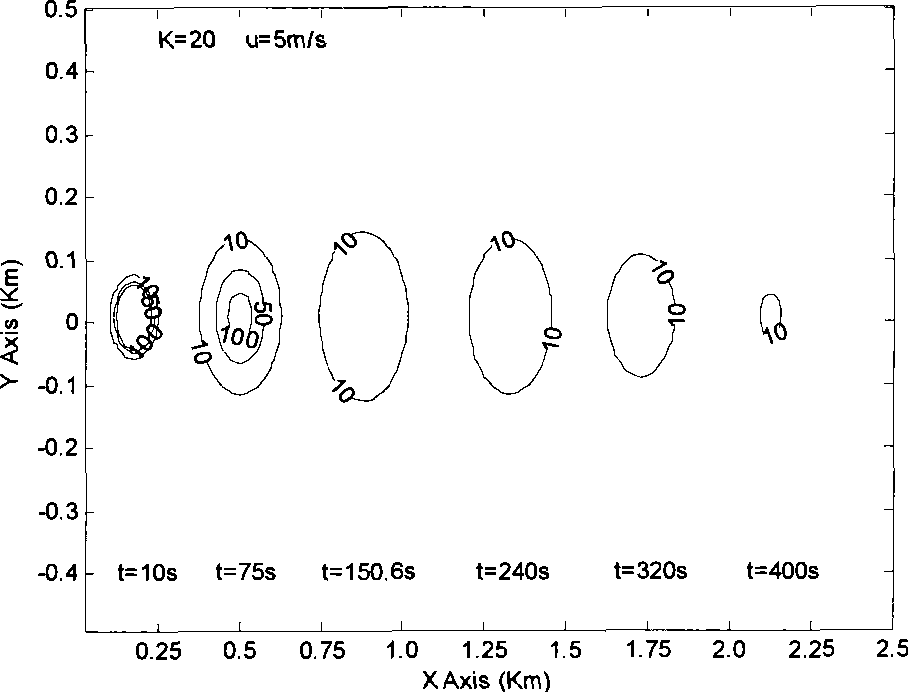

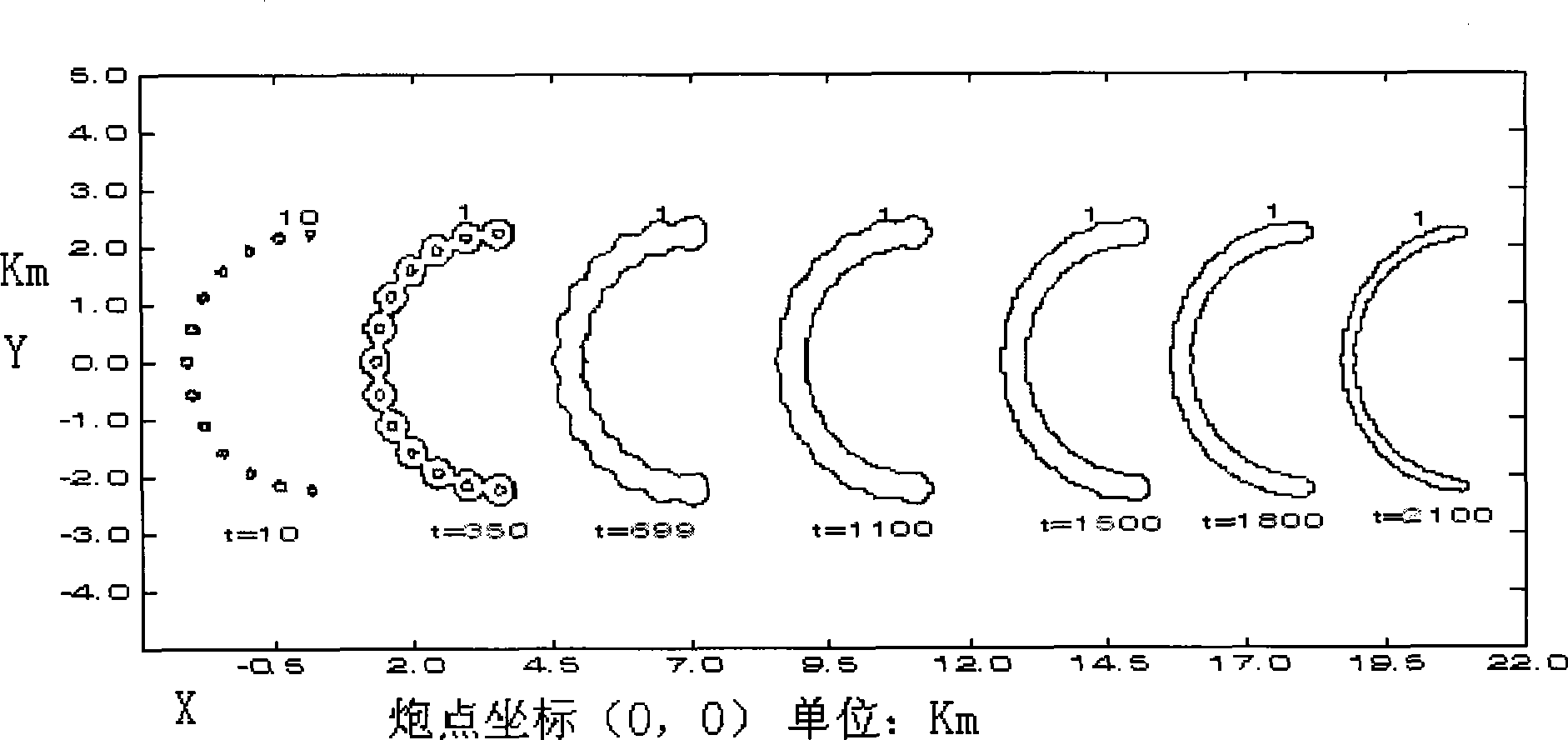

Antiaircraft gun artificial rain-increasing multi-round working method

InactiveCN101473766AEasy to masterUse less ammunitionWeather influencing devicesEngineeringDiffusion

The invention discloses a cannon artificial precipitation enhancement operation scheme, in particular a cannon artificial precipitation enhancement multi-operation method. The operation scheme is as follows: the multi-operation method comprises forming a catalyst diffusion zone for a plurality of combined cannons and performing a numerical simulation according to a point source diffusion equation of a cold cloud cannon catalyst, wherein, the operating cannons are downstream of the wind direction, the cannons are shot in a semicircle perpendicular to the wind direction, and angles among various cannons are the same. The scheme is the optimal cannon artificial precipitation enhancement operation scheme and can help achieve the widest diffusion zone and optimal operation effect with the fewest cannons. In the scheme, two operation scheme parameters are provided respectively by taking AgI particle concentration of 1 / L and the AgI particle concentration of 10 / L as thresholds.

Owner:山东省气象科学研究所

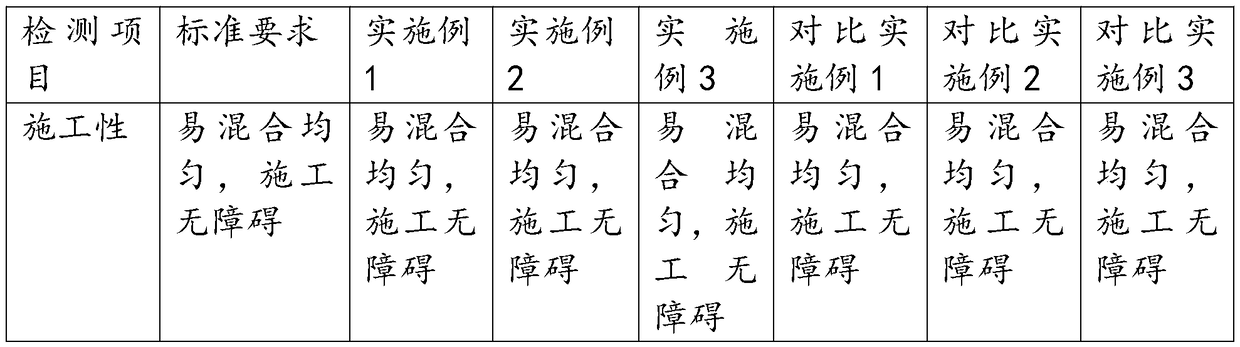

Diatom ooze coating for indoor decoration

ActiveCN109021750AFlat surfaceImprove surface smoothnessFireproof paintsSodium BentoniteMaterials science

Diatom ooze coating for indoor decoration is disclosed. Raw materials include, by weight, 5-15% of diatomite, 3-6% of bentonite, 15-20% of pure acrylic emulsion, 15-25% of precipitated calcium carbonate, 4-8% of hydroxyethyl cellulose, 5-8% of a composite photocatalyst, 6-9% of starch ether, 1-3% of waterborne silicone oil, 0.5-2% of a surfactant, 1-3% of a dispersant, and 0.3-1% of a thickener, with the balance being deionized water. BiNbO4 is doped with Ru through a hydrothermal method for modification to increase the visible light range of the BiNbO4, to reduce photoproduced electron-hole combination, and to greatly increase photocatalytic performance; and then activated diatomite is loaded with the composite photocatalyst Ru-BiNbO4, thus increasing the catalytic area of the photocatalyst, and greatly improving the formaldehyde degradation efficiency of the composite photocatalyst Ru-BiNbO4. The prepared coating is high in practicability, has excellent properties and high application value and allows a decorated surface to be smoother.

Owner:蔡盼

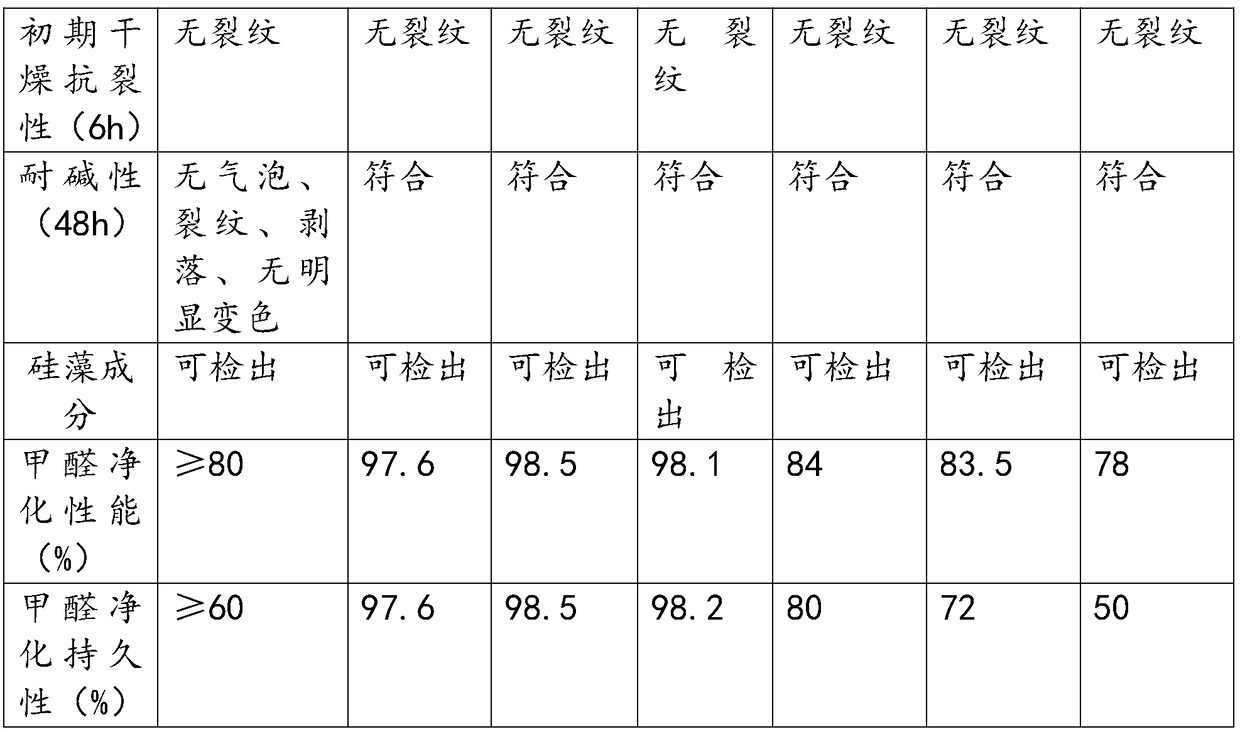

Mesoporous silicon, preparation method of same, and method of photolyzing water to produce hydrogen

ActiveCN105905909AHigh crystallinitySmall scalePhysical/chemical process catalystsHydrogen productionMesoporous silicaSilicon dioxide

The invention provides mesoporous silicon, a preparation method of same, and a method of photolyzing water to produce hydrogen. The preparation method includes the steps of: 1) mixing colloidal silicon dioxide with low-temperature eutectic salt in water, and atomizing the mixture to prepare atomized small drops; 2) performing thermal-treatment to obtain mesoporous silicon dioxide; and 3) mixing the mesoporous silicon dioxide with magenisum powder, and calcining the mixture in vacuum atmosphere or a protective atmosphere, and soaking the calcined mixture in an acid solution to prepare the mesoporous silicon. The mesoporous silicon has small size, good dispersion property, large specific area, good crystallization performance and less defects. The mesoporous silicon is increased in catalytic area, is increased in visible light absorption rate, is enhanced in charge separation and has good charge transfer property. The mesoporous silicon, within the visible light range, has excellent performance of photolyzing water to produce hydrogen. The method is simple, is low in cost and avoids environment pollution.

Owner:UNIV OF SCI & TECH OF CHINA

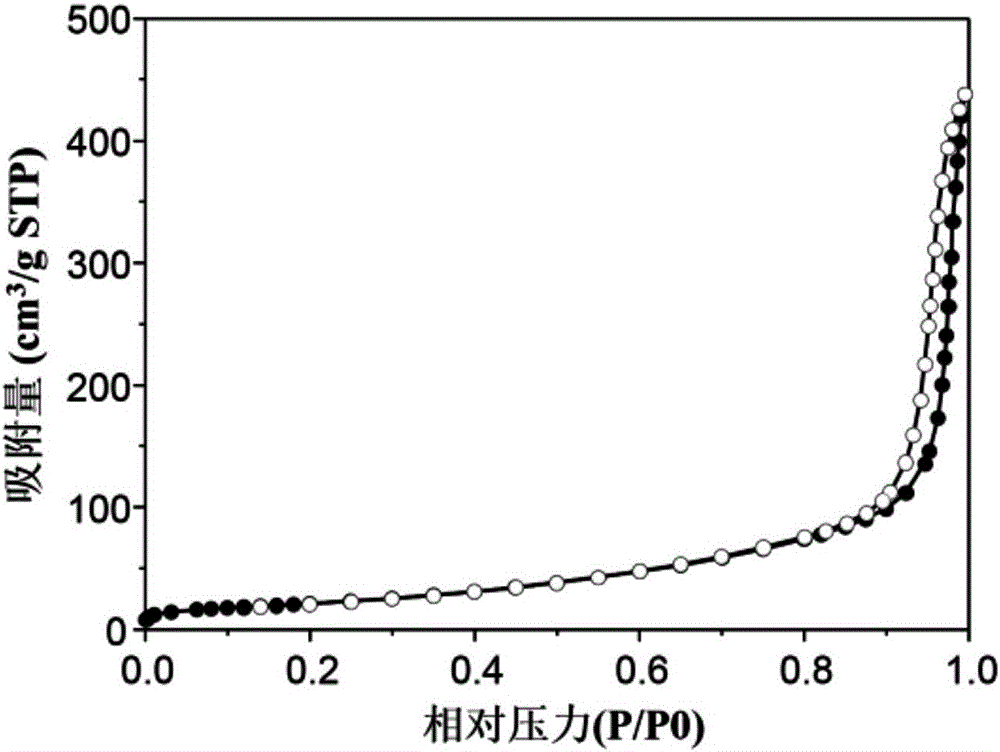

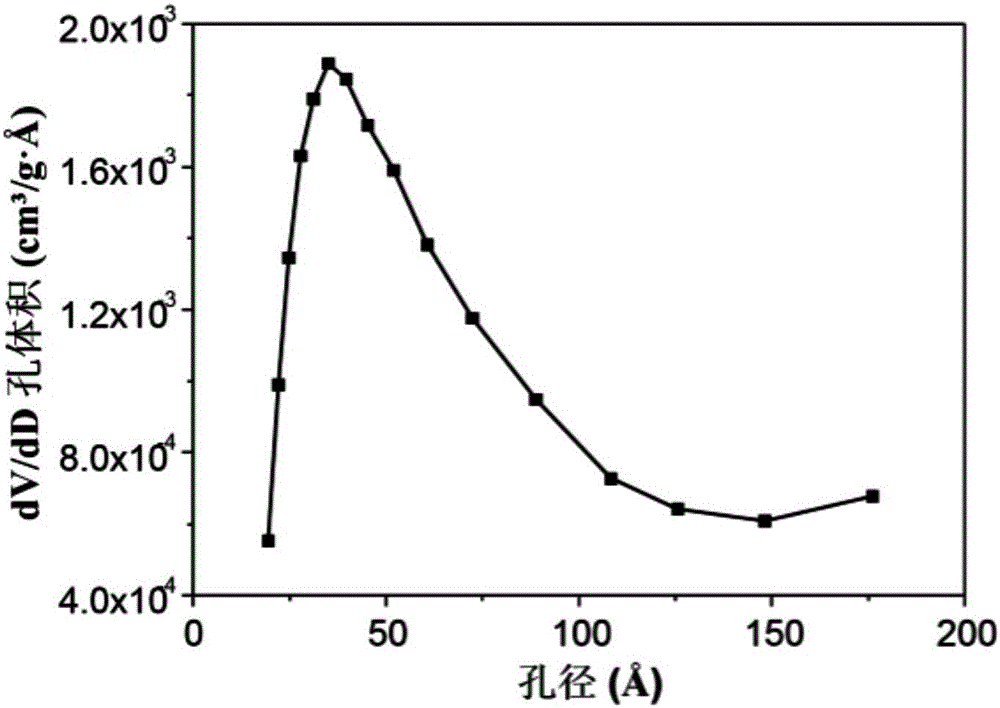

Catalyst for organic wastewater treatment and preparation method thereof

ActiveCN105413691ALow costReduce manufacturing difficultyWater/sewage treatment by irradiationEnergy based wastewater treatmentWastewaterCatalytic effect

The invention discloses a catalyst for organic wastewater treatment and a preparation method thereof. The catalyst is prepared by coating a cobalt-doped composite material layer on a granular silicon-containing carrier. The thickness of the cobalt-doped composite material layer is 100-240 nm. The cobalt-doped composite material layer takes a silicon oxide-titanium oxide composite layer as a base body and cobalt as an enhancer. The molar ratio of the enhancer to the base body in the cobalt-doped composite material layer is 1: (50-200). The molar ratio of silicon oxide to titanium oxide in the silicon oxide-titanium oxide composite layer is 1: (1-3). The catalyst is good in catalytic effect and long in service life.

Owner:HUNAN YONKER ENVIRONMENTAL PROTECTION RES INST

Preparation method of 3DOM bulk hydrogenation catalyst

PendingCN112958106ALarge loading capacityReduce mass transfer resistanceMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentPtru catalystMicrosphere

The invention discloses a preparation method of a 3DOM bulk hydrogenation catalyst, belonging to the technical field of catalysts. The preparation method comprises the following specific steps: (1) dissolving an emulsifier in water under the protection of inert gas, conducting heating to 70-75 DEG C, then adding methyl methacrylate, keeping the temperature for 15-20 minutes, then adding an initiator, conducting reacting for 1-1.5 hours, performing cooling to room temperature, and successively carrying out centrifugal assembling and drying to obtain a a PMMA microsphere template; (2) sequentially dissolving an active component precursor and an auxiliary agent into an alcohol solution to obtain a precursor solution; and (3) adding a PMMA microsphere template into the precursor solution, carrying out dipping and drying, repeating the dipping and drying steps 1-2 times, and finally, carrying out roasting for 5 hours under the condition of 400-600 DEG C to obtain the 3DOM bulk hydrogenation catalyst. The 3DOM bulk hydrogenation catalyst prepared by the invention has a large and ordered pore structure, and sulfur-containing macromolecules can enter internal pores, so the desulfurization activity of the catalyst is greatly improved.

Owner:QINGDAO UNIV OF SCI & TECH

Waterproof light-oxygen catalyzing deodorizing type waste gas treatment device

InactiveCN105233684AWith rain protection functionWatertightUsing liquid separation agentSelf weightSmoke

The invention discloses a waterproof light-oxygen catalyzing deodorizing type waste gas treatment device. The waterproof waste gas treatment device is characterized by comprising a spraying unit (2) connected with a smoke inlet (1), wherein the top end of the spraying unit (2) is connected with an air inlet of a light-oxygen catalyzing deodorizing unit (4) by a first air duct (3); an air outlet of the light-oxygen catalyzing deodorizing unit (4) is connected with an air inlet of a fan (6) by a second air duct (5); an air outlet of the fan (6) is connected with a vertical third air duct (7); and a rain shielding plate (14) is arranged at the top end of an air outlet of the third air duct (7) and is formed in a manner that a light bracket (15) is fixed on the side wall of the third air duct (7). The waterproof light-oxygen catalyzing deodorizing type waste gas treatment device provided by the invention has a rain shielding function to protect the fan from water entering, the rain shielding plate is fixed on the side wall of the third air duct, grounded surface support is not required, the self weight is light, materials are saved, and the cost is low.

Owner:SUZHOU RHYMEBLUE ENVIRONMENTAL TECH CO

Sectional isobaric ammonia synthesis process

ActiveCN107200335AImprove ammonia net valueIncrease profitCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrogenNitrogen

The invention provides a sectional isobaric ammonia synthesis process. The sectional isobaric ammonia synthesis process comprises the following steps: (1) primary ammonia synthesis is performed on feed gases of synthetic ammonia in a first ammonia synthesis tower filled with an iron-based catalyst,wherein the synthetic pressure of the primary ammonia synthesis is 5-7 MPa, and the molar ratio of hydrogen to nitrogen in the feed gases of synthetic ammonia is (1.5-2.5):1; and (2) a mixed gas getting out of the first ammonia synthesis tower enters a second ammonia synthesis tower filled with a ruthenium-based catalyst to perform secondary ammonia synthesis, wherein the synthetic pressure of the secondary ammonia synthesis is 4-6 MPa. According to the sectional isobaric ammonia synthesis process, as the ammonia synthesis process is divided into two stages and performed under the specific pressures, specific catalysts and the specific hydrogen-to-nitrogen ratio, not only are technological requirements of synthetic ammonia satisfied and is stable technological operation guaranteed, but also the net value of ammonia at the outlets of the ammonia synthesis towers and the nitrogen and hydrogen utilization ratios are improved; and besides, each stage of synthesis is performed at low pressure, so that the energy consumption of the ammonia synthesis process is greatly reduced.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

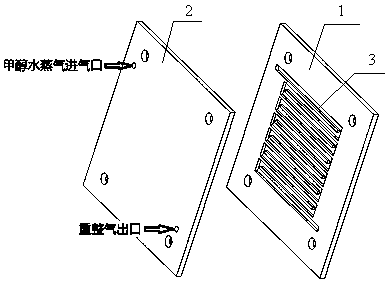

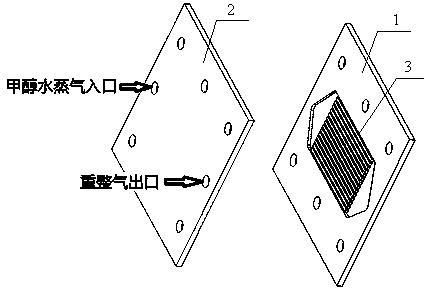

Miniature methanol and steam reforming chamber

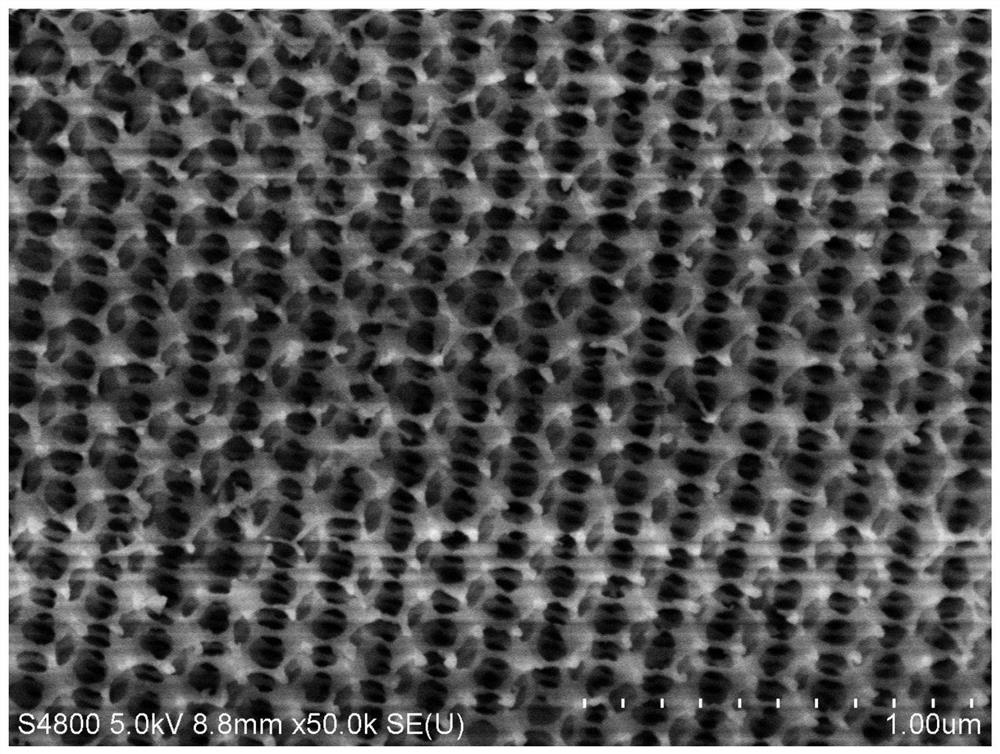

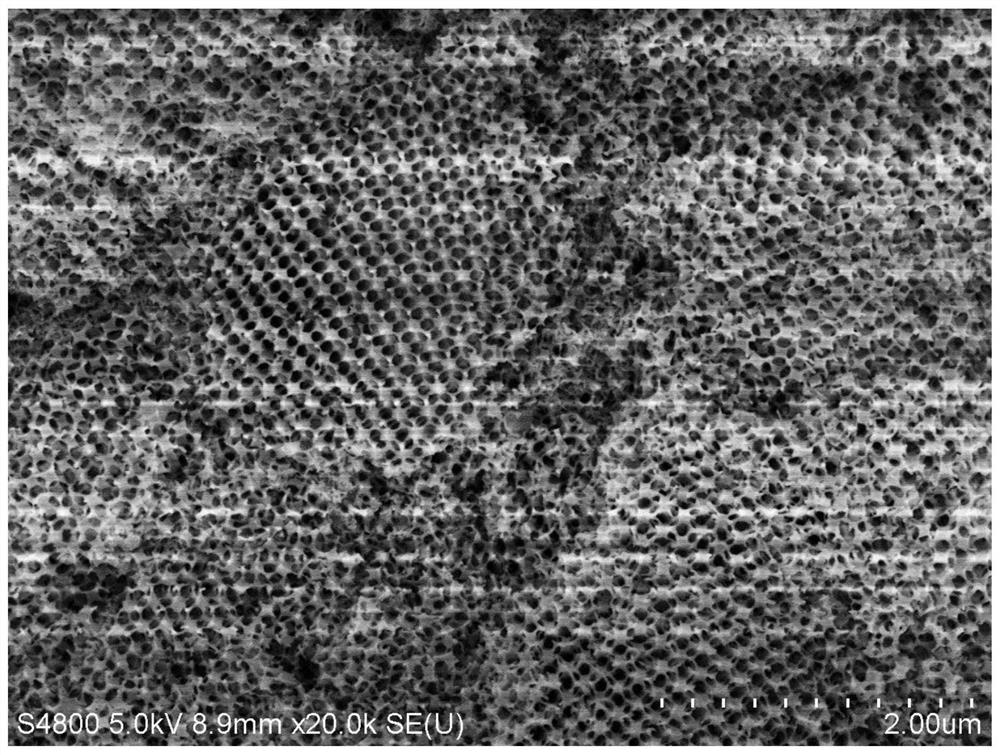

ActiveCN103956508AImprove adhesionLarge catalytic areaFuel cellsMicro arc oxidationCeramic thin films

The invention discloses a miniature methanol and steam reforming chamber which is made from an aluminum alloy material. The miniature methanol and steam reforming chamber comprises an aluminum alloy main body, an aluminum alloy packaging end plate and a miniature flow field structure, wherein the miniature flow field structure is used as a gas circulating channel in the reforming chamber, and located between the aluminum alloy main body and the aluminum alloy packaging end plate and on the surface of the aluminum alloy main body. One layer of porous ceramic thin film grows on the surface of a runner of the miniature flow field structure inside the reforming chamber through a micro-arc oxidation method, and a reforming reaction catalysis layer is formed on the ceramic thin film through a full-filling method. According to the miniature methanol and steam reforming chamber, one layer of porous oxide ceramic film is prepared inside the reforming chamber by applying a micro-arc oxidation technology, so that the adhesive capacity of the reforming catalyst in the miniature runner of the reforming chamber is improved, the contact area between a reactant and the catalyst is increased, and the efficiency of reaction between methanol and steam and the conversion rate of the methanol are increased.

Owner:HARBIN INST OF TECH

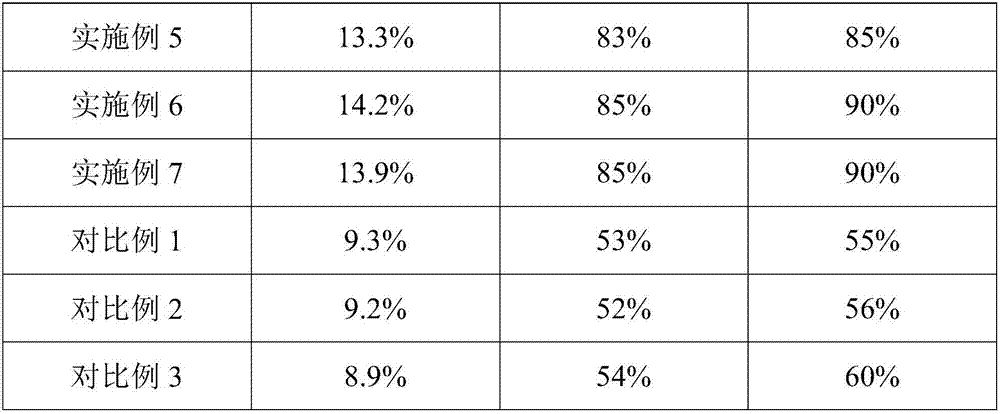

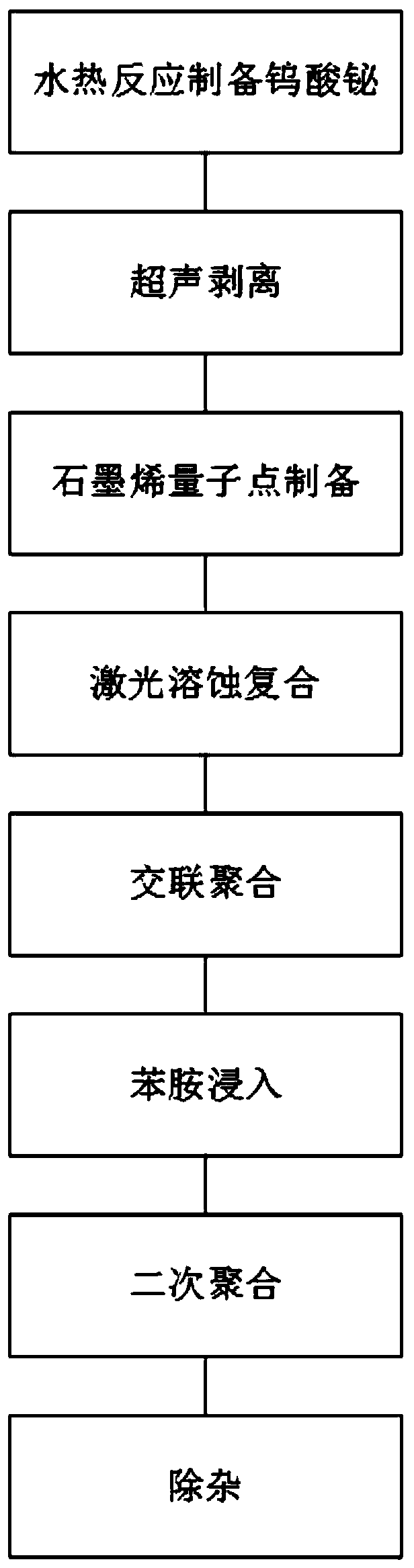

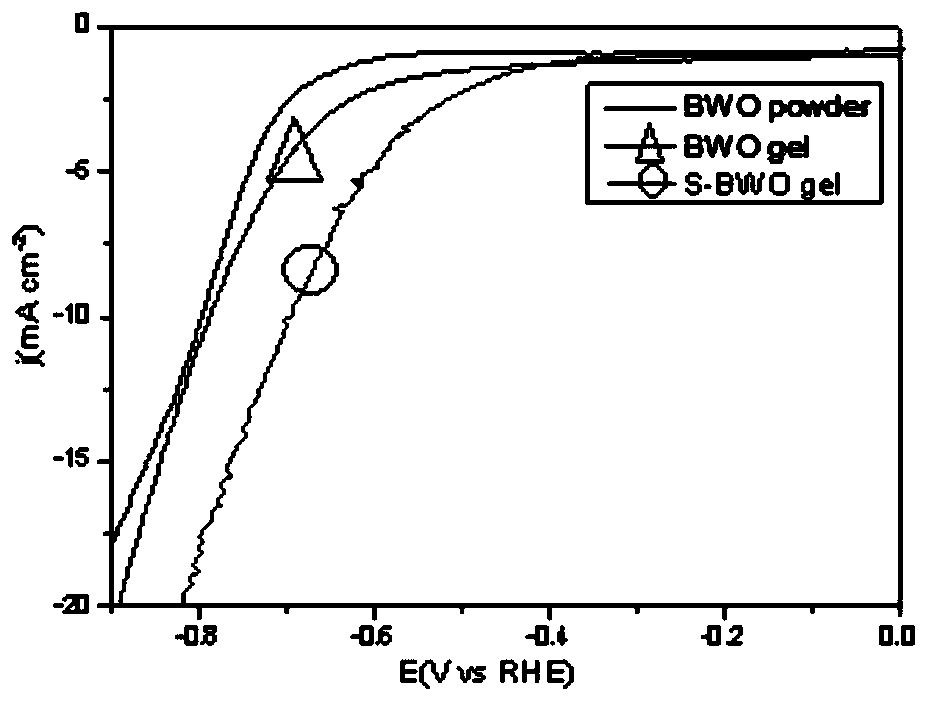

Preparation method and application of bismuth tungstate-graphene-conductive hydrogel

ActiveCN111471192AIncrease the active siteEasy to recycleOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention belongs to the technical field of research and development of electrolytic catalysts, and particularly relates to a preparation method and application of bismuth tungstate-graphene-conductive hydrogel. The invention provides a preparation method of bismuth tungstate-graphene-conductive hydrogel. The preparation method comprises the following steps: preparing bismuth tungstate througha hydrothermal reaction, performing ultrasonic stripping, preparing graphene quantum dots, performing laser corrosion compounding, performing crosslinking polymerization, performing aniline leaching,and performing secondary polymerization. The invention also provides an application of the product obtained by the preparation method in an electrolytic catalyst. By introducing the graphene quantumdots, the active sites of bismuth tungstate are increased so as to improve the electro-catalytic performance; furthermore, the bismuth tungstate-graphene composite material is combined with conductivegel, so that bismuth tungstate-graphene is further uniformly dispersed, the catalyst agglomeration is prevented, the catalytic area of the catalyst is increased, and the gel is convenient to recoverafter the catalysis is completed. The technical defects that in the prior art, a catalyst for photoelectric degradation or water electrolysis cathode hydrogen evolution reaction is poor in catalytic performance and cannot be recycled are overcome.

Owner:SUN YAT SEN UNIV

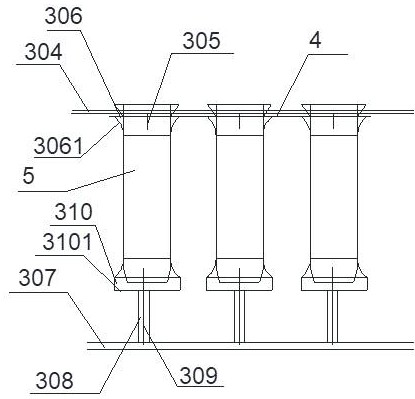

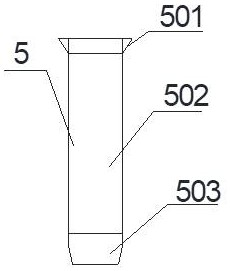

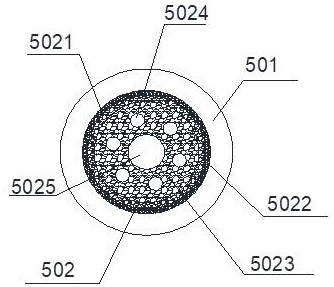

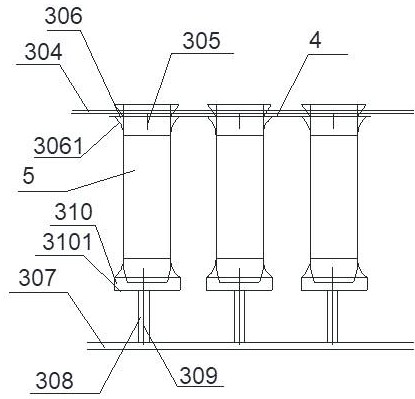

Desulfurization, denitrification and dust removal integrated device and process for flue gas from glass kiln

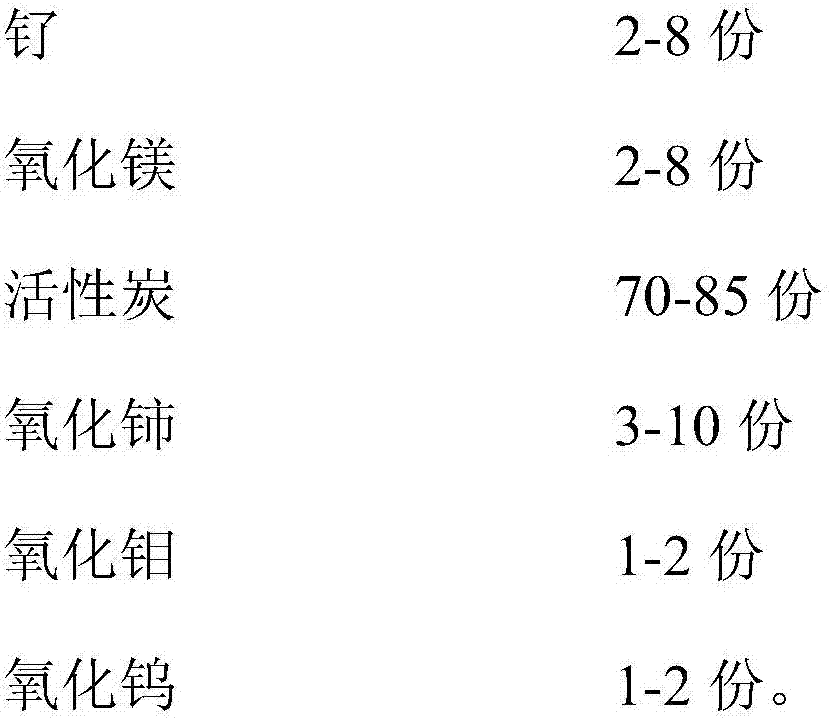

ActiveCN113577913ALarge catalytic areaHigh catalytic activityHuman health protectionGas treatmentFlue gasDust control

The invention discloses a desulfurization, denitrification and dust removal integrated device and process for flue gas from a glass kiln. The integrated device comprises a desulfurization and denitrification agent storage tank, a desulfurization and denitrification reactor, a blowing system, a tubesheet, a catalytic ceramic membrane, a transition bin and an ash conveying pipe, wherein the desulfurization and denitrification reactor comprises an upper box body, a middle box body and a lower box body, the tubesheet is located between the upper box body and the middle box body, the tubesheet is provided with tubesheet holes, the catalytic ceramic membrane comprises an expansion section, a catalytic main body and a supporting bottom, the catalytic main body comprises a filtering layer, a filtering catalytic layer, a main catalytic layer and a main clean gas channel from outside to inside, the thickness of the main catalytic layer is 3-10 cm, and auxiliary clean gas channels are distributed in the main catalytic layer. According to the desulfurization, denitrification and dust removal integrated device and process for the flue gas from the glass kiln, dust removal, desulfurization and denitrification can be completed in one device, the volume of glass kiln flue gas treatment equipment is greatly reduced, equipment investment is lowered, and desulfurization, denitrification and dust removal efficiency is improved.

Owner:山东蓝繁环保科技有限公司

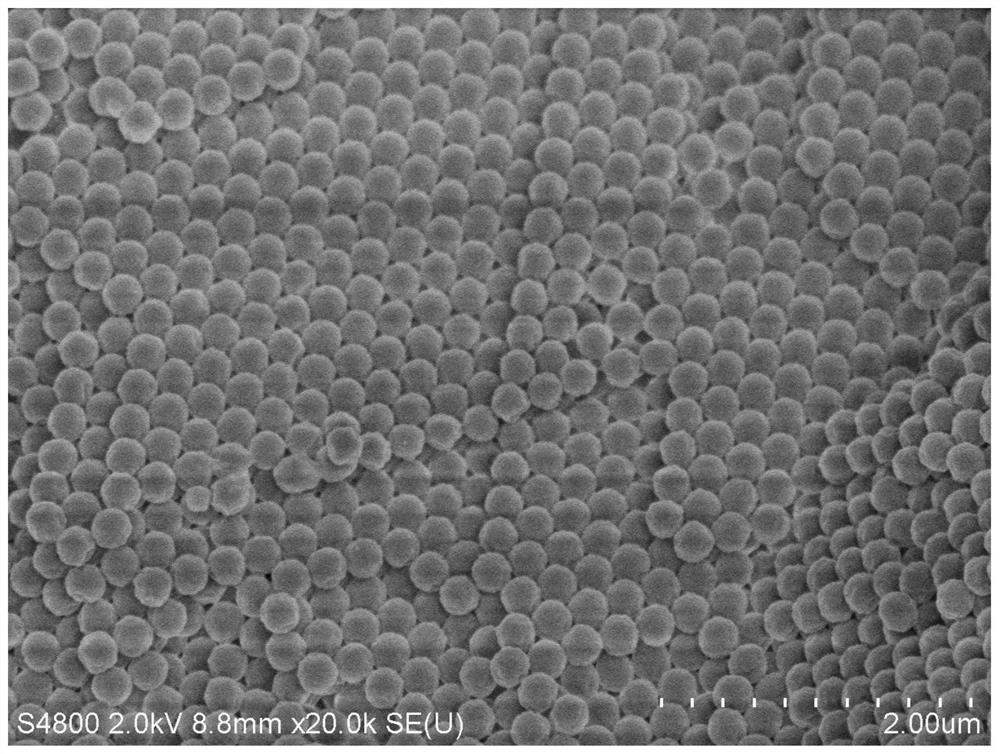

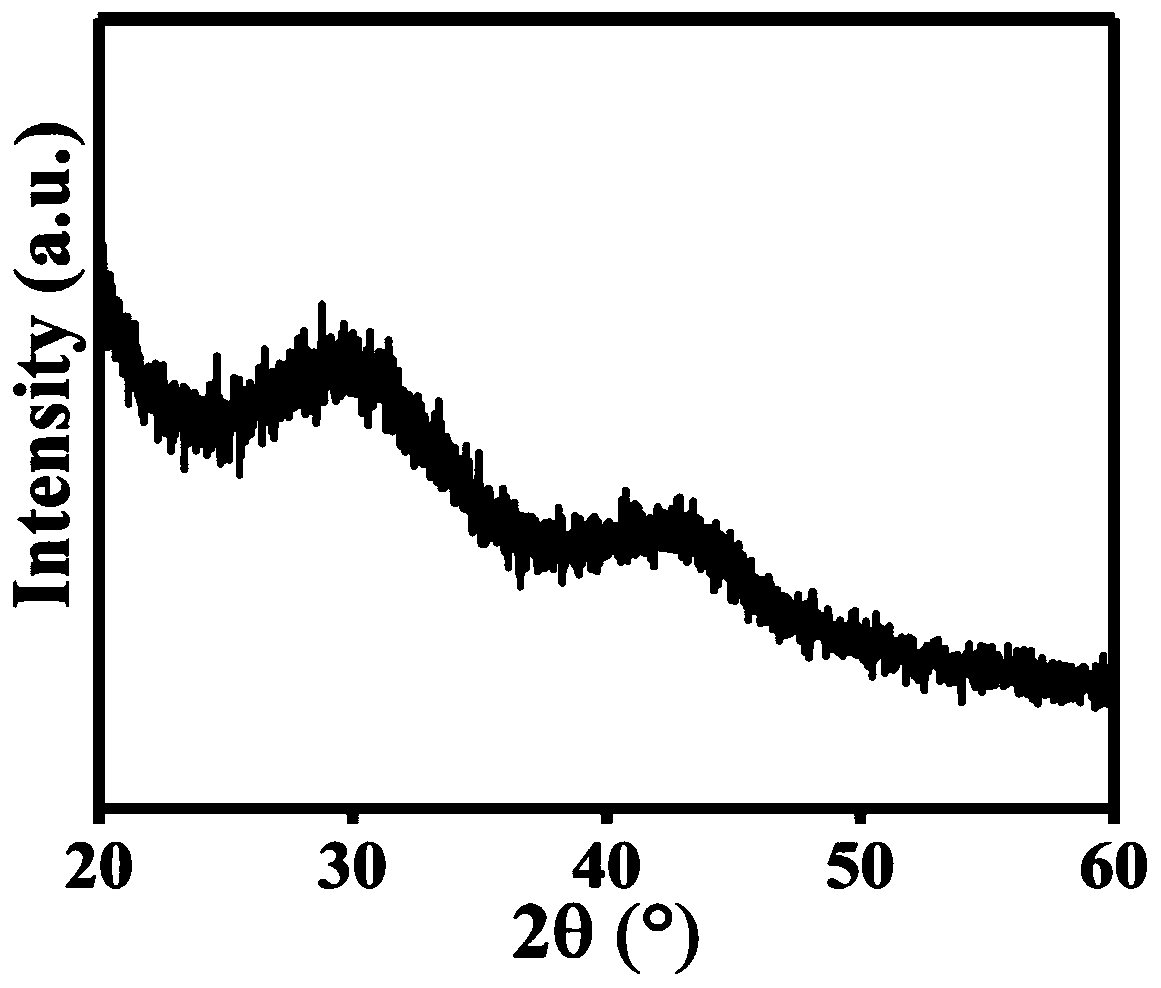

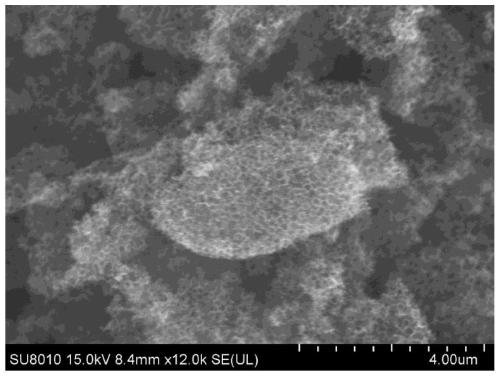

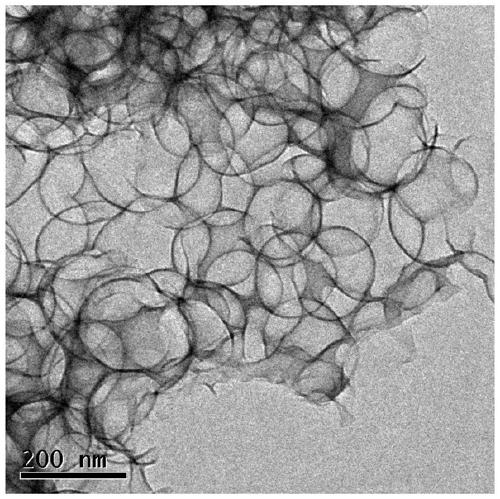

Bimetallic atom hollow carbon nanosphere catalyst and preparation method thereof

ActiveCN111313044AImprove performanceEasy to prepareMaterial nanotechnologyCell electrodesPtru catalystPhysical chemistry

The invention provides a FeCu-N-HC nanosphere catalyst and a preparation method thereof, and belongs to the field of air battery catalytic materials. The preparation method comprises: firstly formingFeCu-N coordination, physically mixing NaCl and SiO2 nanosphere templates, then preparing the FeCu-N6-containing hollow carbon nanospheres through carbonization, and the BET specific surface area being 610 m<2> g<-1>. Due to the fact that the Fe-Cu synergistic coordination ligand is formed firstly, when oxygen reduction catalysis is conducted on the finally-prepared FeCu-N6, the catalysis steps can be effectively shortened, and the catalysis rate of active sites is increased. The FeCu-N-HC hollow carbon nanosphere prepared by the method is used as an oxygen reduction catalyst, and the catalytic performance and the stability of the FeCu-N-HC hollow carbon nanosphere are superior to those of a current commercial 20% Pt / C catalyst.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A glass kiln flue gas desulfurization, denitrification and dust removal integrated device and process

ActiveCN113577913BLarge catalytic areaHigh catalytic activityHuman health protectionGas treatmentGlass furnaceFlue gas

The invention discloses an integrated device for desulfurization, denitrification and dust removal of glass kiln flue gas, which comprises a desulfurization and denitration agent storage tank, a desulfurization and denitration reactor, an injection system, a flower plate, a catalytic ceramic membrane, a transition chamber, and an ash conveying pipe. The desulfurization and denitrification reactor includes an upper box, a middle box, and a lower box. The flower plate is located between the upper box and the middle box. The flower plate has a flower plate hole; the catalytic ceramic membrane includes an enlarged section , a catalytic body and a supporting bottom, the catalytic body includes a filter layer, a filter catalytic layer, a main catalytic layer and a main clean gas channel from the outside to the inside, the main catalytic layer is 3-10cm thick, and there are auxiliary clean gas channels distributed inside . The invention discloses a glass kiln flue gas desulfurization, denitrification and dust removal integrated device and process, which can complete dust removal, desulfurization, and denitrification in one device, and greatly reduce glass kiln flue gas treatment equipment while improving the efficiency of desulfurization, denitrification and dust removal Volume, reduce equipment investment.

Owner:山东蓝繁环保科技有限公司

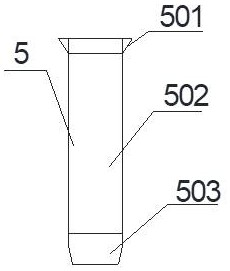

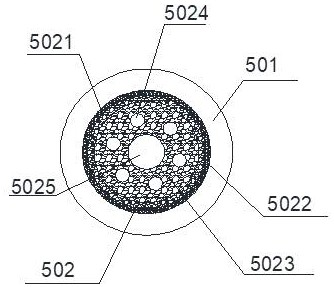

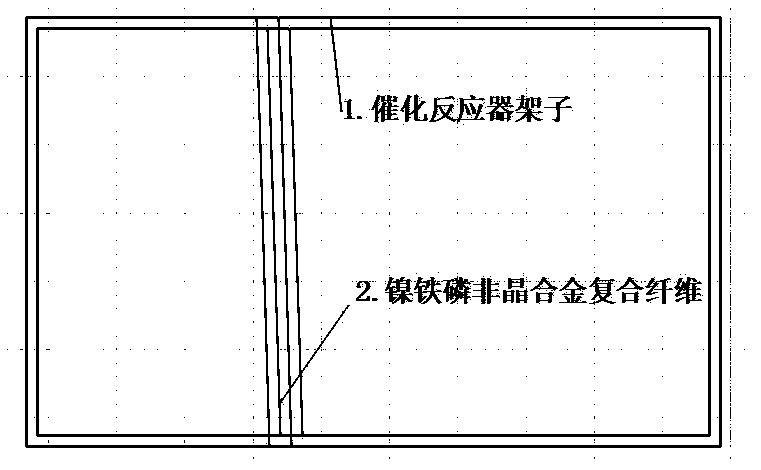

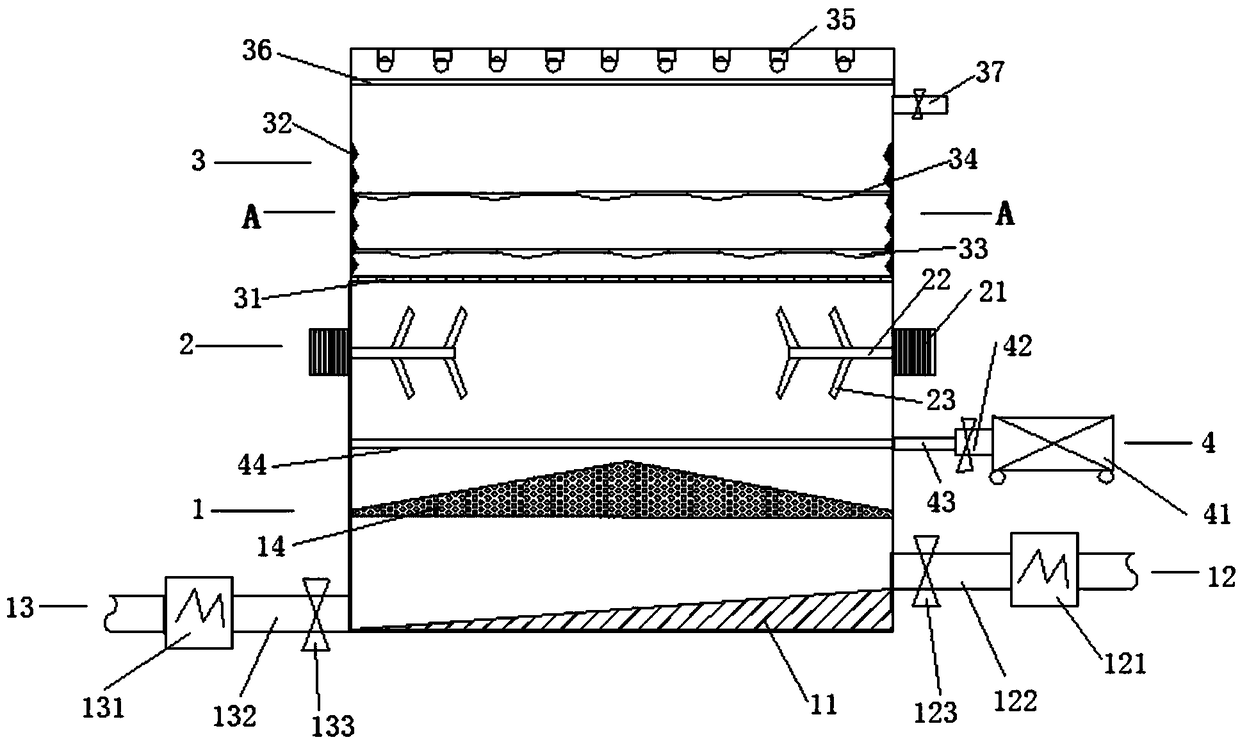

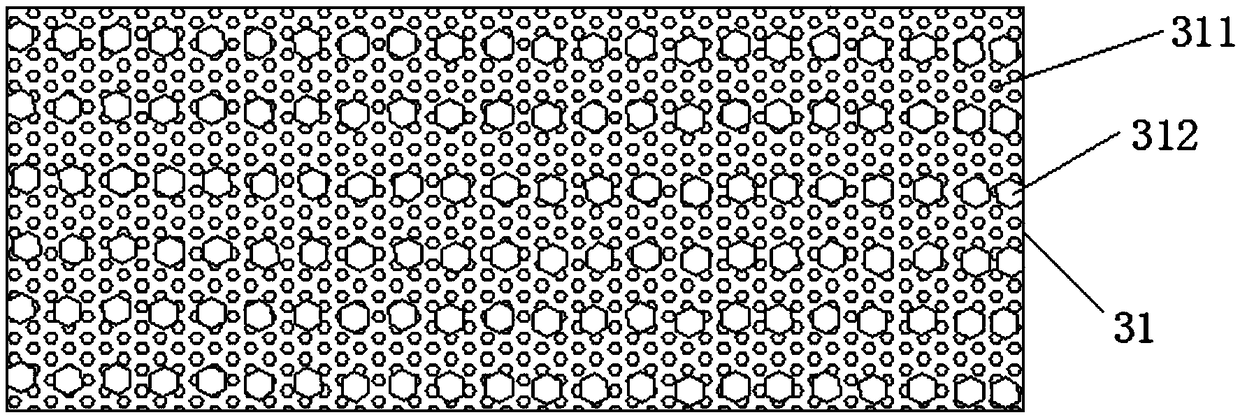

Production method of nickel-iron-phosphorus amorphous alloy catalytic reactor

InactiveCN109126656AApplicable catalytic reactionIncrease the usable areaLiquid/solution decomposition chemical coatingChemical/physical/physico-chemical processesFiberYarn

The invention provides a nickel-iron-phosphorus amorphous alloy composite fiber. The length of the composite fiber can be continuous, the cross section of the composite fiber can be circular, special-shaped and the like, the external diameter of the composite fiber is 0.01-0.2 millimeter, and the diameter of core yarn of the composite fiber is 0.005-0.08 millimeter; a coating layer of the composite fiber is nickel-iron-phosphorus amorphous alloy, the nickel-iron-phosphorus amorphous alloy is prepared from 40-85% of nickel, 10-20% of ferrum and 6-20% of phosphorus, and the core yarn of the composite fiber is made from a polymer. A preparation method of the composite fiber comprises the steps that (1) a polymer fiber is degreased; (2) the fiber surface is coarsened; (3) the fiber is sensitized; (4) the fiber surface is activated; (5) chemical nickel-iron-phosphorus plating is carried out on the fiber; (6) the nickel-iron-phosphorus amorphous alloy is plated on a fiber electric brush.

Owner:罗奕兵

Environmentally-friendly nano-ceramic material

InactiveCN109019964AIncreased visible light rangeIncreased degradation rateWater/sewage treatment by irradiationWater treatment compoundsSewageOrganic matter

The invention discloses an environmentally-friendly nano-ceramic material. The nano-ceramic material comprises 30-50 wt% of diatomite, 10-15 wt% of seashell nano-powder, 5-10 wt% of a composite photocatalyst, 1-3 wt% of a surfactant, 0.5-2 wt% of a dispersant and 20-35 wt% of deionized water. The nano-ceramic material is used in an energy-saving and environmentally-friendly sewage treatment device, the energy-saving and environmentally-friendly sewage treatment device includes a precipitation tank, an oxygen supply tank and a photocatalytic tank, the photocatalytic tank comprises a filter, a triple prism and a photocatalytic system, the photocatalytic system comprises a first photocatalytic mechanism, a second photocatalytic mechanism and a light source, each of the first photocatalytic mechanism and the second photocatalytic mechanism is composed of a connecting rod and a photocatalytic net, and the photocatalytic net is made from the porous nano-ceramic material. The composite photocatalyst Zr-BiVO4 is loaded onto activated diatomite and the seashell nano-powder to increase the catalytic area of the photocatalyst, so the degradation rate of organic matters in the sewage by thecomposite photocatalyst Zr-BiVO4 is greatly improved.

Owner:SHENGSHIYAOLAN SHENZHEN TECH CO LTD

Fixed lipase catalyzed synthesis of fatty acid low carbon alcohol ester

InactiveCN1279174CIncrease the area of actionReduce dosageFermentationEnzymatic synthesisHigh pressure

The invention uses immobilized microbial lipase to catalyze the synthesis of fatty acid lower alcohol esters in a non-aqueous phase system. Lipase is immobilized on an inert carrier film or textile, and the immobilized carrier can be combined with a wire mesh to form a new type of reactor, which catalyzes the esterification reaction of fatty acids and alcohols in the organic phase within the range of 20-60 ° C, 14 -24hr esterification rate can reach 90-97%. Compared with the current industrial process of esterification using chemical catalysts under high temperature and high pressure, this method has the advantages of mild reaction conditions, low energy consumption, strong reaction specificity and less by-products. Compared with similar enzymatic synthesis processes, the method has the characteristics of easy separation of the product from the immobilized enzyme, which is beneficial to continuous production and easy recovery and repeated use of the immobilized enzyme. At the same time, adding a water-absorbing agent during the reaction can shorten the reaction time and increase the esterification rate. The product transformed by the method has light color and high quality, and has important applications in the fields of energy, agriculture, textile, plastics, food, cosmetics and the like.

Owner:BEIJING UNIV OF CHEM TECH

A kind of preparation method of carbon-supported porous hollow platinum-iridium alloy nanoparticle catalyst

The invention belongs to the technical field of inorganic chemistry, and specifically relates to a method for preparing a carbon-supported porous hollow platinum-iridium alloy nanoparticle catalyst, including the preparation of Au@PtIr alloy nanoparticle colloidal solution, the preparation of modified multi-walled carbon nanotubes, and the preparation of Au@PtIr alloy nanoparticles. PtPd alloy nanoparticles, hydrogen heat treatment, nucleation and other processes. The catalyst prepared by the invention has a special structure, increases the catalytic area, enhances the effect of synergistic catalysis and crystal lattice distortion, and improves the catalytic performance.

Owner:深圳仁旺科技有限公司

Preparation method of VOCs catalytic oxidation catalyst and obtained catalyst

PendingCN114849728ALarge catalytic areaUniform distribution of poresGas treatmentHeterogenous catalyst chemical elementsRoastingMaterials science

The invention provides a preparation method of a VOCs catalytic oxidation catalyst. The preparation method comprises the following steps: acid etching: carrying out acid etching on a carrier; performing drying; an acid etching carrier is obtained; wherein the pH value of the acid is 4-6, the acid etching time is 0.5-4 hours, and the acid etching temperature is 20-80 DEG C; the drying time is 6-12 hours and the drying temperature is 80-120 DEG C; coating roasting: coating the surface of the acid etching carrier with a coating material; roasting after drying to obtain a coating carrier; roasting the precursor: dip-coating the precursor solution on the surface of the coating carrier; and drying and roasting to obtain the catalyst. The obtained catalyst has the advantages of being high in catalytic capacity, low in cost and long in service life.

Owner:湖南立泰环境工程有限公司

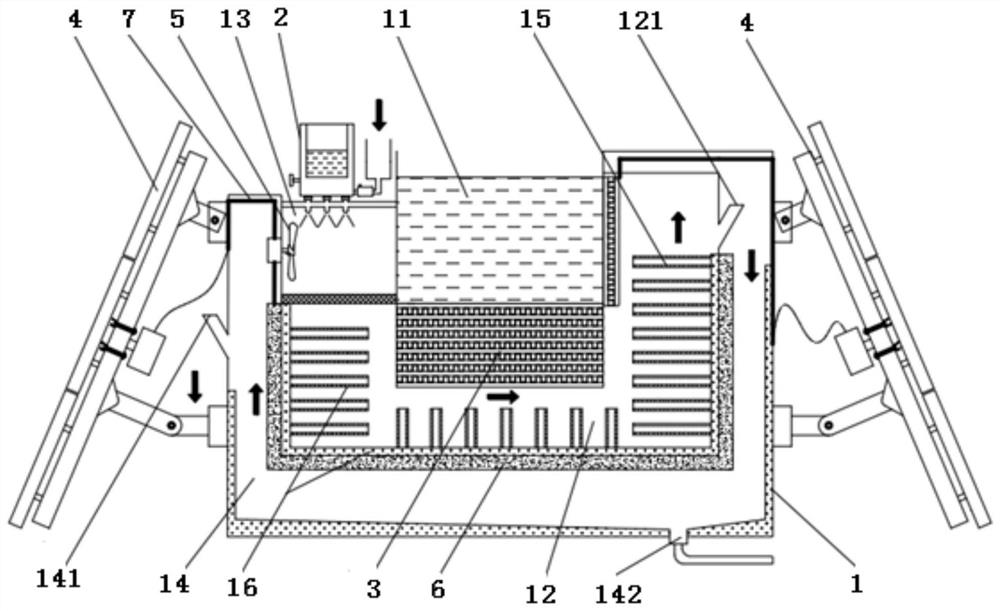

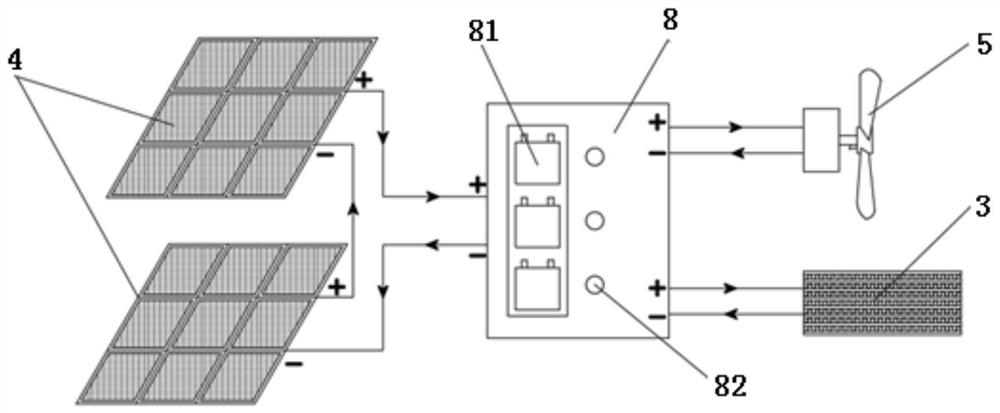

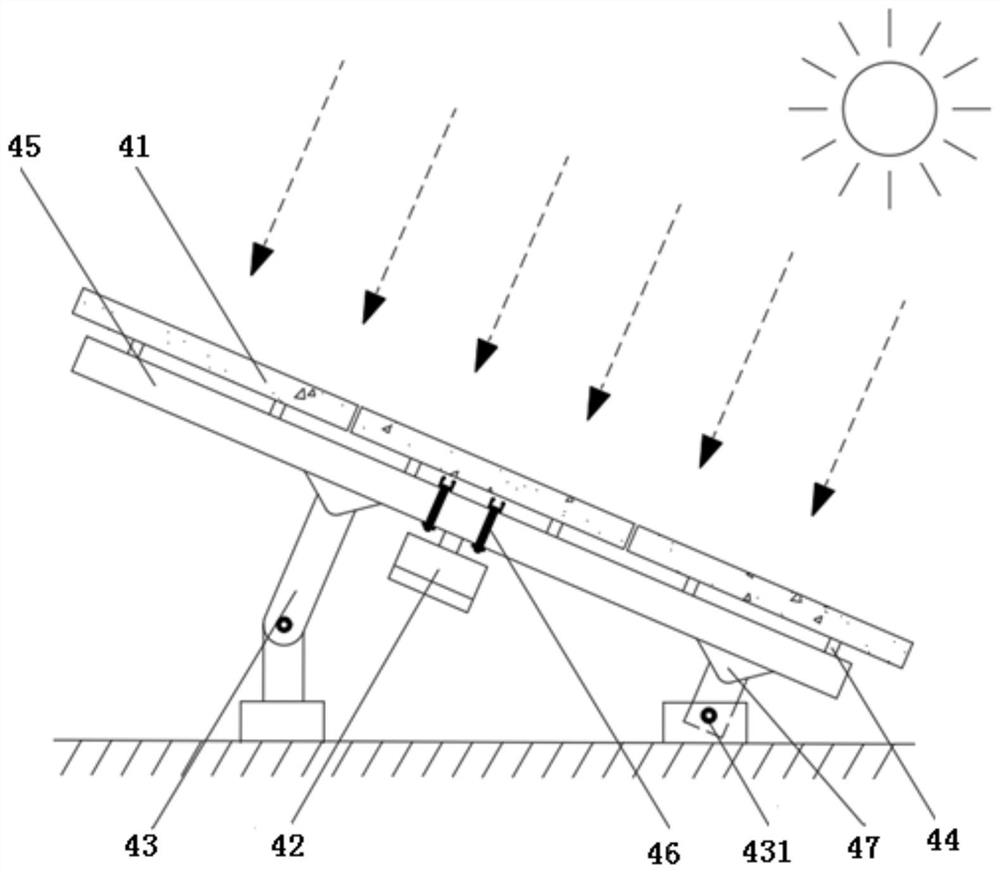

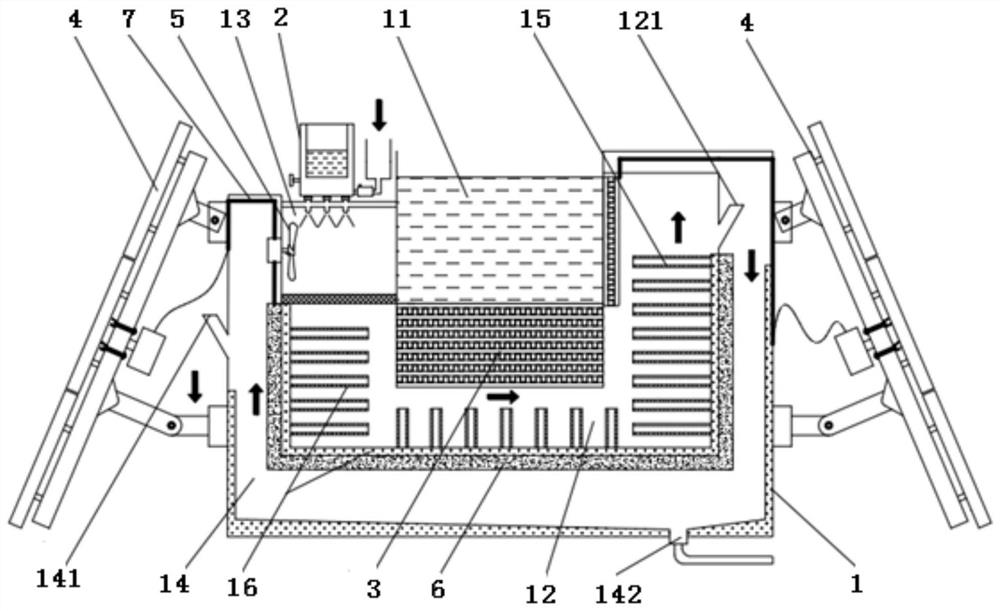

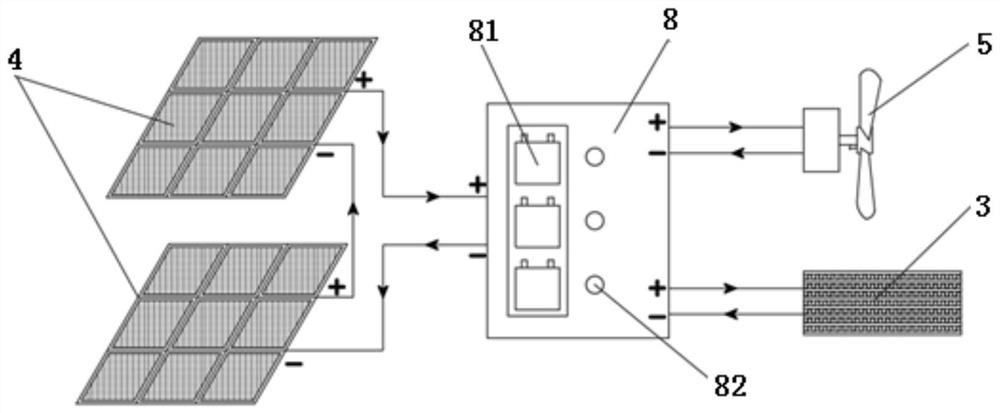

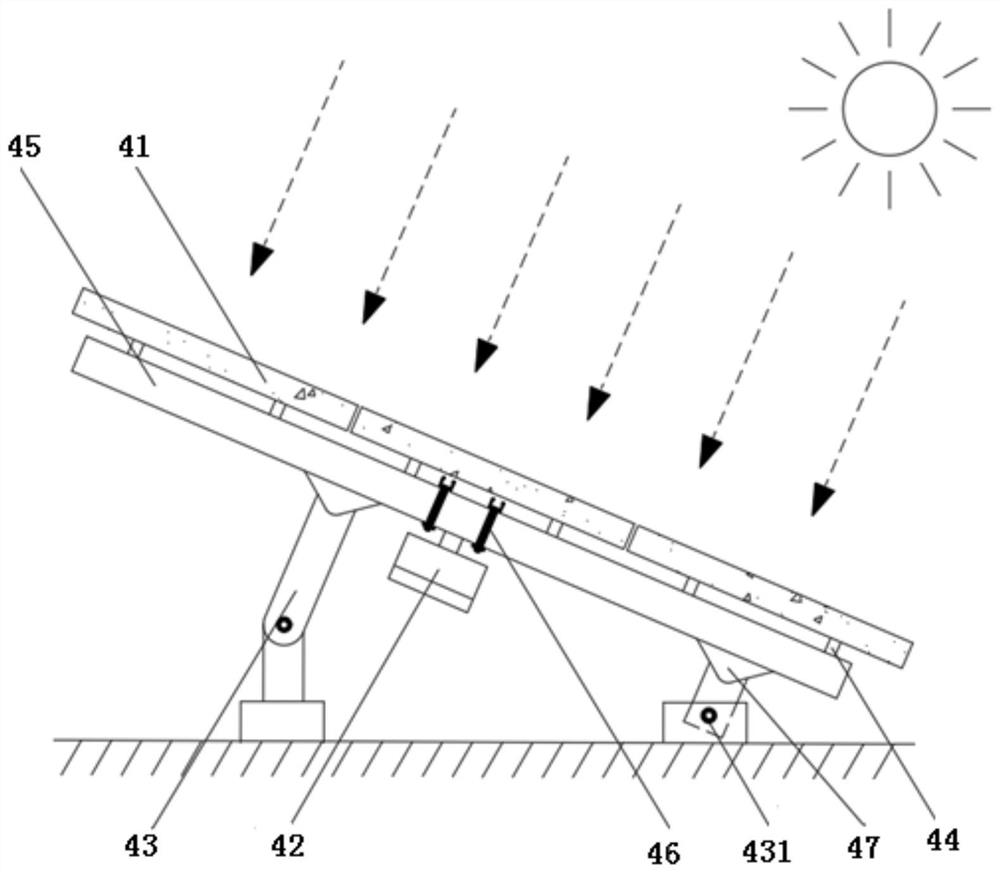

Fireless field food heating system based on solar catalytic oxidation

ActiveCN112880214AImprove heating efficiencyFast heatingPhotovoltaic supportsBatteries circuit arrangementsCatalytic oxidationEngineering

The invention discloses a fireless field food heating system based on solar catalytic oxidation, and relates to the technical field of solar application. The fireless field food heating system comprises a pot body, a methanol-air spray tank, a heat exchanger and a photovoltaic module; the pot body comprises a heating cavity used for containing food, an annular flue arranged on the outer side of the heating cavity, a catalysis chamber and a spraying chamber, the catalysis chamber and the spraying chamber are arranged between the heating cavity and the annular flue, an opening of the heating cavity faces upwards, the spraying chamber is located above the catalysis chamber, and a fan is arranged in the spraying chamber; the methanol-air spray tank is arranged on the outer side of the heating cavity, and an outlet of the methanol-air spray tank sequentially communicate with the spraying chamber, the catalysis chamber and the annular flue; the heat exchanger is arranged below the heating cavity and on the side far away from the methanol-air spray tank; the photovoltaic module is arranged on the outer side of the annular flue, the photovoltaic module can store electric energy and assist the heat exchanger in heating food, and the photovoltaic module can further provide the electric energy for the fan. The performance of the field food heating system is improved.

Owner:CHANGZHOU UNIV

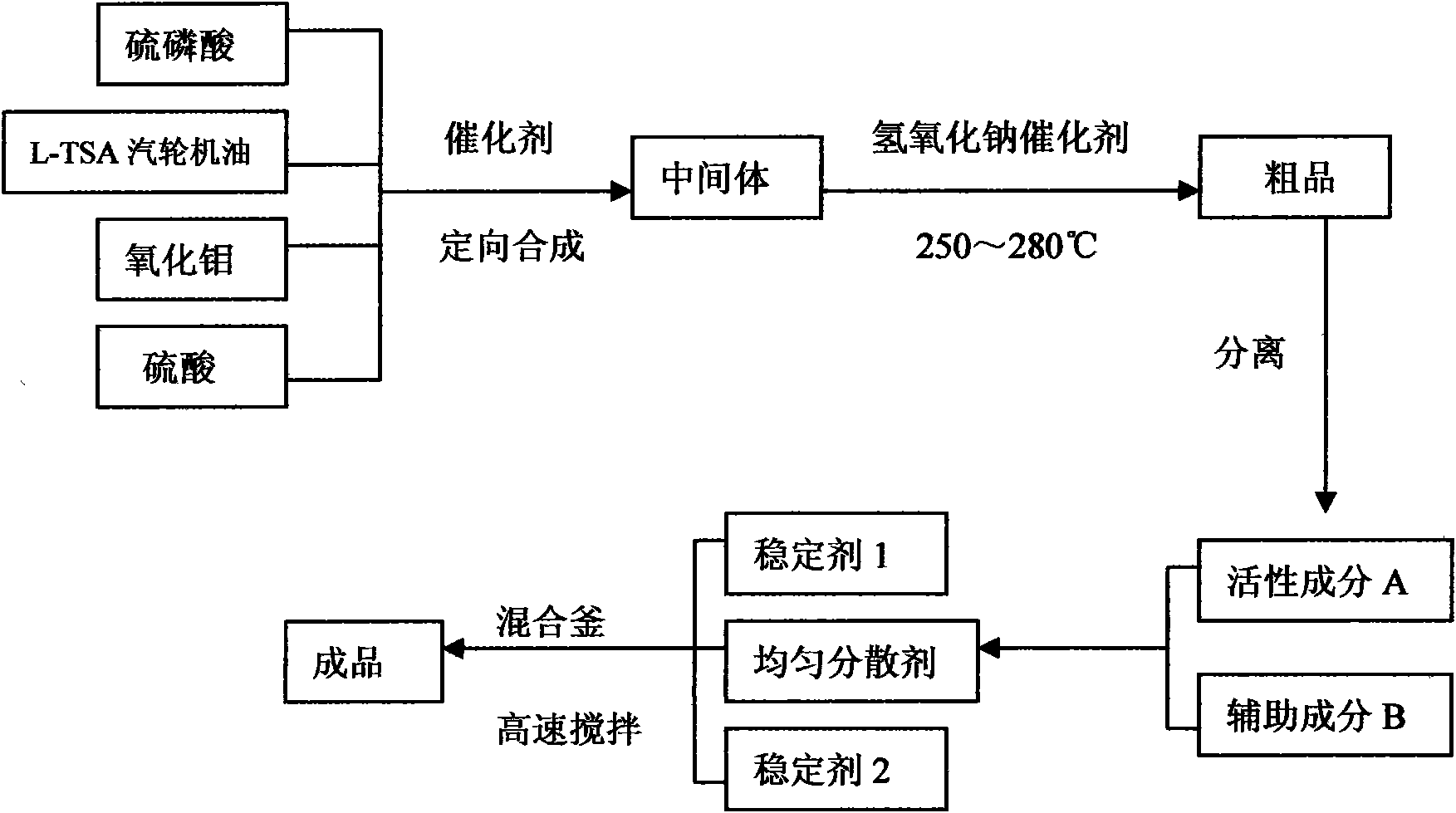

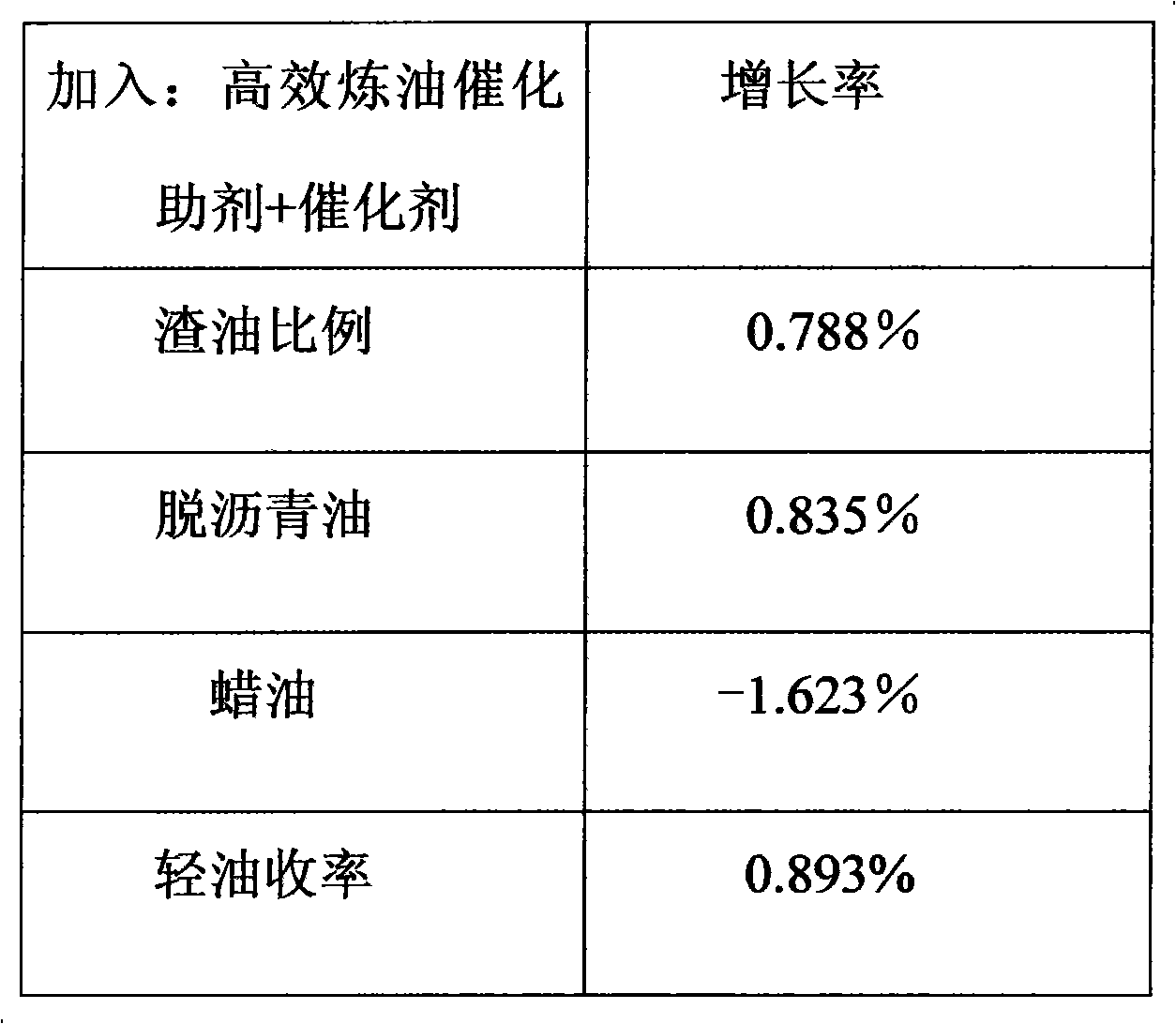

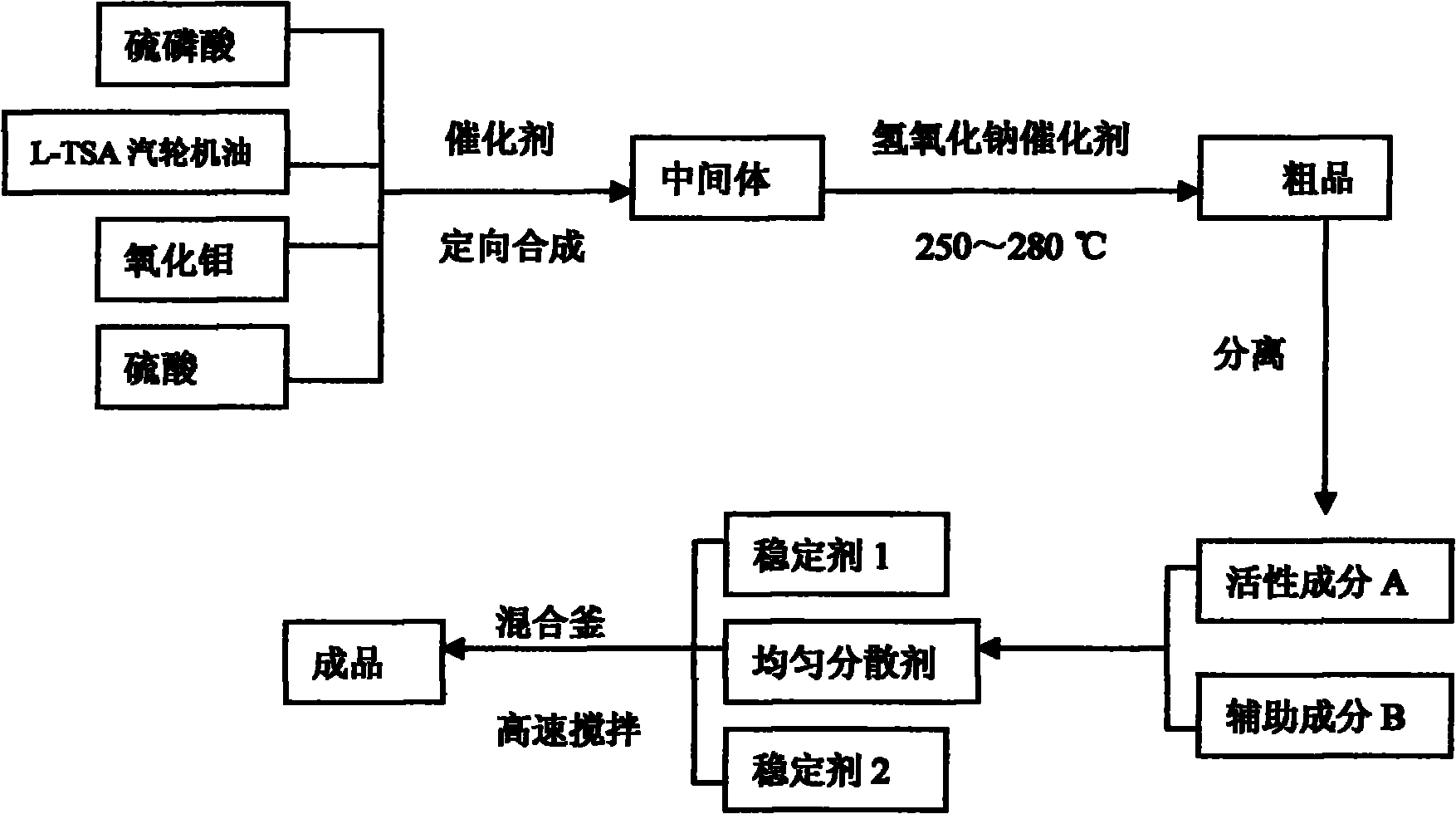

Novel high-efficiency refining catalytic aid and preparation method thereof

InactiveCN101905164AReduce hydrogen contentPoor cracking performanceCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsCompound (substance)Alkyl side chain

The invention discloses a novel high-efficiency refining catalytic aid and a preparation method thereof, and belongs to the field of chemical engineering. The high-efficiency refining catalytic aid contains the following components: thiophosphoric acid, molybdenum oxide, L-STA turbine oil and sulfuric acid. The preparation method comprises the following steps of: mixing the components to prepare an intermediate; mixing the 90 to 95 percent of intermediate with 5 to 10 percent of sodium hydroxide solution with the concentration of 5 to 8 percent, reacting at the temperature of between 250 and 280 DEG C and under the pressure of 2 to 5 MPa for 1 to 2 hours, reducing the temperature to 30 DEG C, and standing for demixing for 2 to 3 hours to prepare an upper oil substance, namely an active ingredient A; and reacting 95 to 98 volume percent of active ingredient A with 2 to 5 volume percent of alkyl side chain-containing auxiliary component B at the temperature of between 50 and 70 DEG C and at the normal pressure for 0.5 to 1 hour, sequentially adding 0.5 to 1 percent of stabilizer 1, 1 to 3 percent of stabilizer 2 and a homogenizing-dispersing agent, and stirring in a mixing kettle at a speed of 300 to 400 revolutions per minute for 1 to 1.5 hours to prepare the finished product of the high-efficiency refining catalytic aid.

Owner:SHANGHAI YOUHAO CHEM

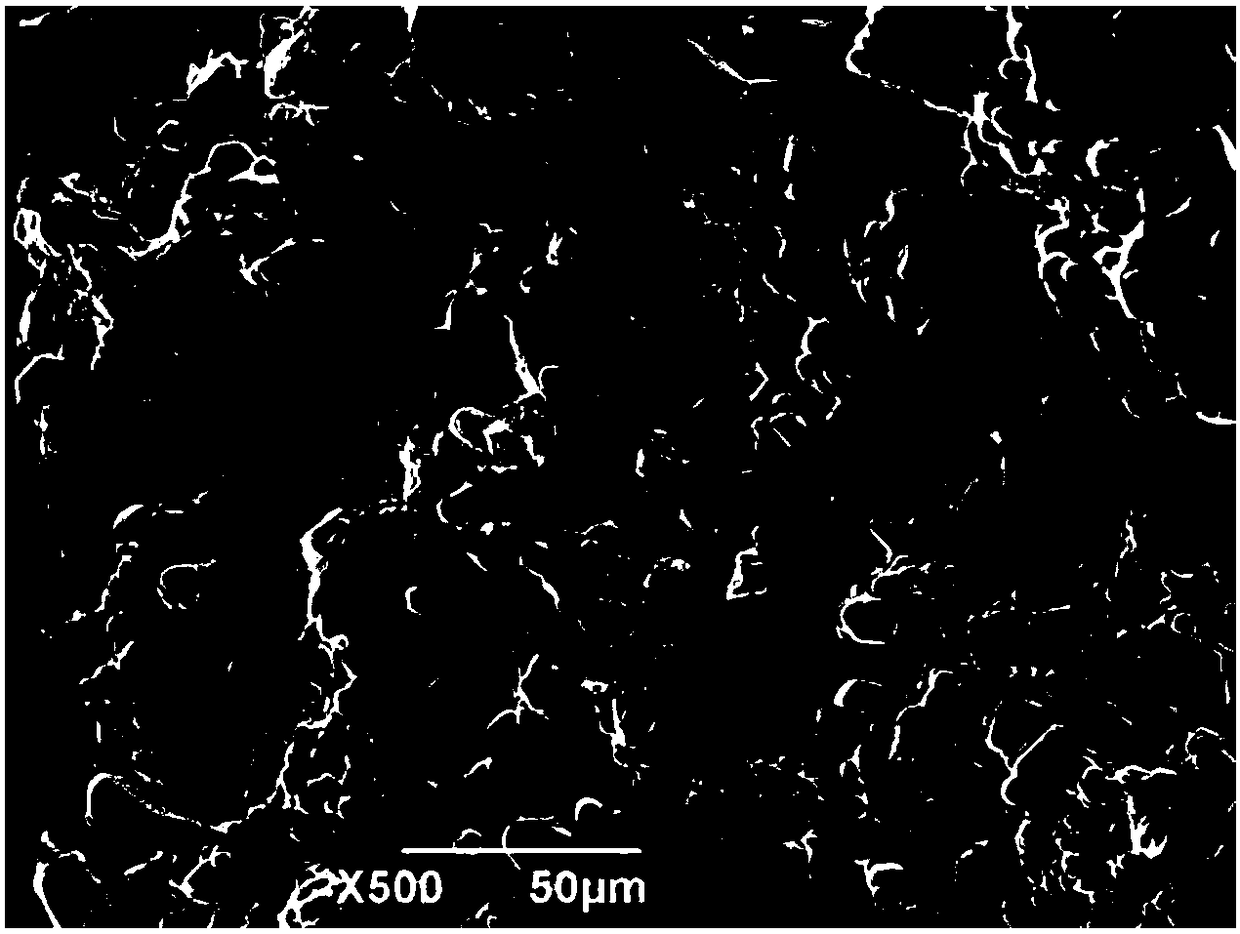

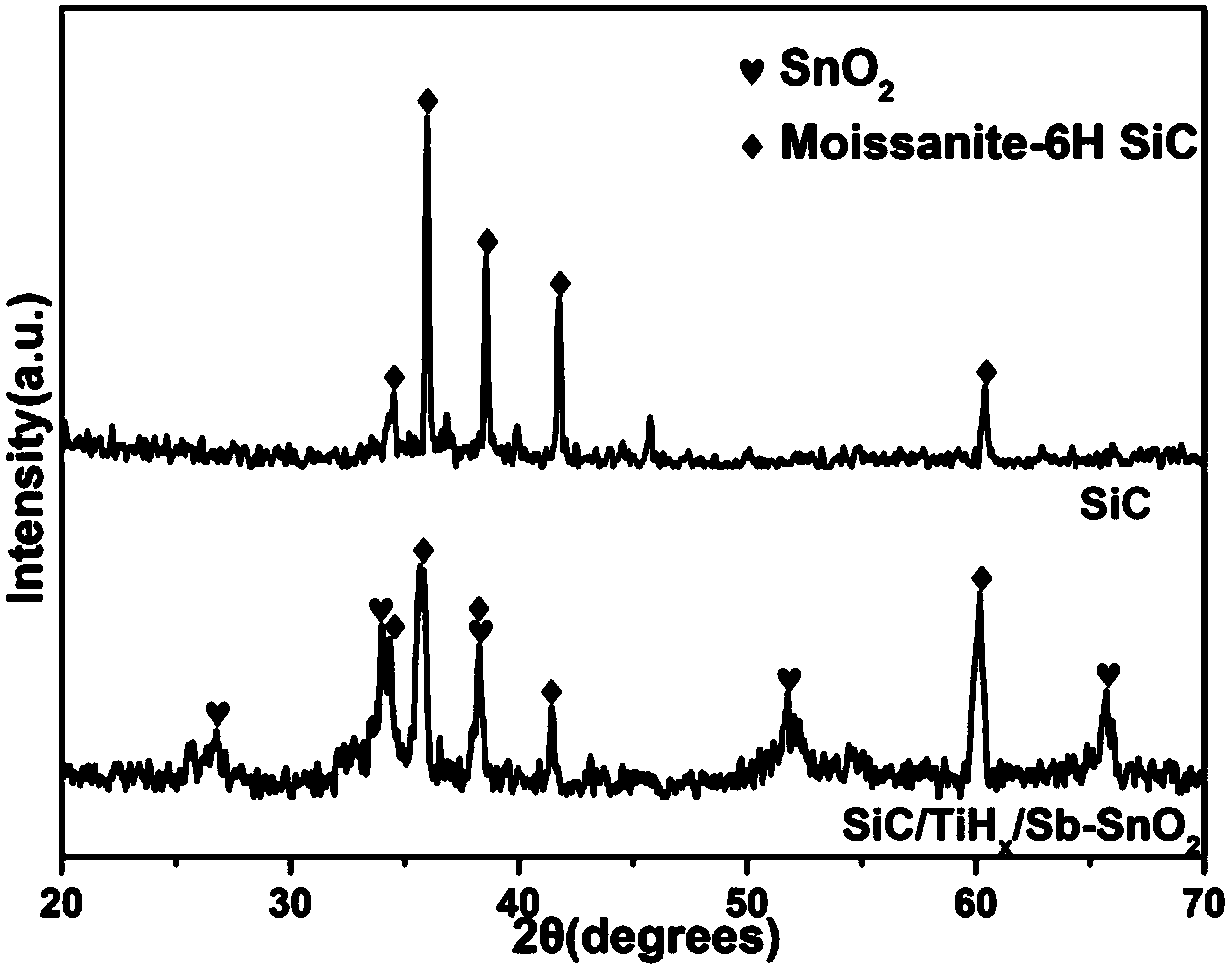

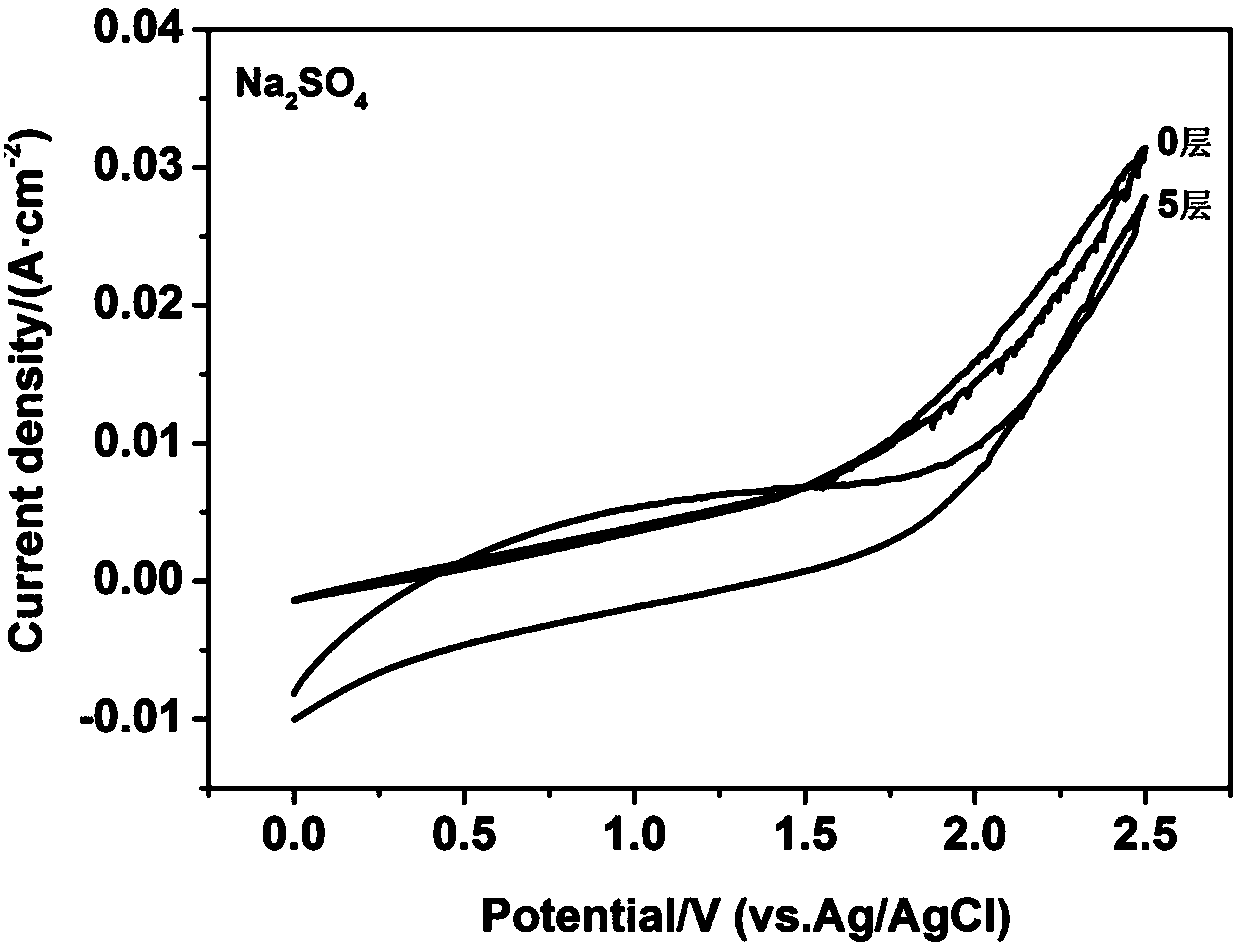

Preparation method of high-catalytic activity ceramic-based stannic oxide anode

InactiveCN108130575ALarge catalytic areaMany catalytically active sitesElectrolytic inorganic material coatingWater/sewage treatmentTitanium oxideHydride

A preparation method of a high-catalytic activity ceramic-based stannic oxide anode comprises the following steps of after ultrasonic treatment on a silicon carbide matrix in tetrabutyl titanate-contained precursor solution, forming a titanium oxide layer on the surface of the silicon carbide matrix through a thermal oxidation method; then, performing reduction treatment on the titanium oxide layer on the surface of the silicon carbide matrix by utilizing an electric reduction method under room temperature to form a titanium hydride interlayer; and connecting an electrically-reduced silicon carbide matrix as a cathode with the negative pole of a power supply, and preparing an antimony doped stannic oxide coating on the surface of the silicon carbide matrix by utilizing an electro-deposition-thermal oxidation method in electroplate liquid containing stannum and antimony. As the anode is of a porous structure, the actual catalytic area of the anode is increased; active sites are increased, so that the anode is high both in electrocatalytic activity and oxygen evolution potential; and the anode is more ideal than a traditional electrode both in organic matter removal efficiency and energy consumption. As the increase of coating capacity, the service life of the anode is effectively prolonged, and the anode is suitable for being applied to industrially electrolyzing waste water ona large scale.

Owner:SHAANXI UNIV OF SCI & TECH

Catalyst for organic wastewater treatment and preparation method thereof

ActiveCN105413691BLow costReduce manufacturing difficultyWater/sewage treatment by irradiationEnergy based wastewater treatmentWastewaterSilicon oxide

The invention discloses a catalyst for organic wastewater treatment and a preparation method thereof. The catalyst is prepared by coating a cobalt-doped composite material layer on a granular silicon-containing carrier. The thickness of the cobalt-doped composite material layer is 100-240 nm. The cobalt-doped composite material layer takes a silicon oxide-titanium oxide composite layer as a base body and cobalt as an enhancer. The molar ratio of the enhancer to the base body in the cobalt-doped composite material layer is 1: (50-200). The molar ratio of silicon oxide to titanium oxide in the silicon oxide-titanium oxide composite layer is 1: (1-3). The catalyst is good in catalytic effect and long in service life.

Owner:HUNAN YONKER ENVIRONMENTAL PROTECTION RES INST

A Fireless Field Food Heating System Based on Solar Catalytic Oxidation

ActiveCN112880214BImprove heating efficiencyFast heatingPhotovoltaic supportsBatteries circuit arrangementsCatalytic oxidationEngineering

The application discloses a fireless outdoor food heating system based on solar catalytic oxidation, which relates to the technical field of solar energy application. The heating system includes a pot body, a methanol-air spray tank, a heat exchanger and a photovoltaic module; the pot body includes a heating chamber for placing food, an annular flue arranged outside the heating chamber, and an Between the catalytic chamber and the spray chamber, the opening of the heating chamber is upward, and the spray chamber is located above the catalytic chamber; a fan is arranged in the spray chamber; the methanol-air spray tank is arranged on the outside of the heating chamber, and the outlets of the methanol-air spray tank are sequentially The spray chamber, the catalytic chamber and the annular flue are connected; the heat exchanger is arranged under the heating chamber and on the side away from the methanol-air spray tank, and the photovoltaic module is arranged outside the annular flue. The photovoltaic module can store electric energy and assist the heat exchanger To heat food, photovoltaic modules can also provide electricity for fans. This application is used to improve the performance of outdoor food heating systems.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com