Miniature methanol and steam reforming chamber

A technology of steam reforming and methanol, which is applied in the field of reforming chambers, can solve the problems that the coating technology is not well resolved, the purity requirements of the reaction materials are particularly strict, and the energy consumption of the system is increased, so as to improve the catalyst attachment surface area and occupy space The effect of small, short response times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

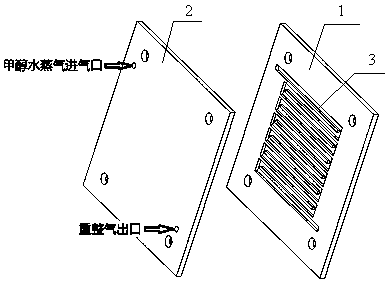

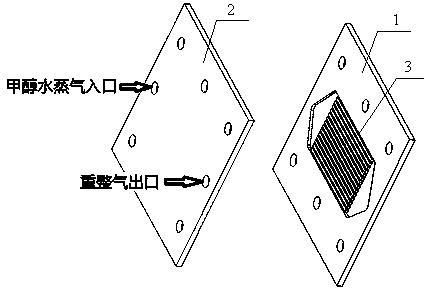

[0018] Specific implementation mode 1: The structure of the methanol steam reforming chamber described in this implementation mode is an aluminum alloy main body, and a microflow field structure 3 is designed on its surface. For the overall structure diagram, please refer to figure 1 and 2 , using the combination of the package end plate 2 and the aluminum alloy main body 1 to form the reaction chamber of the reforming chamber as a reforming chamber for methanol water vapor, and one side of the reforming chamber has a micro flow field structure.

[0019] The surface micro-flow field structure described in this embodiment is to process gas flow channels with a width of 0.1-0.5mm on the surface of the aluminum alloy body, and the processed flow channels are used as the reforming chamber of the methanol steam reforming hydrogen production reactor. Gas transmission channels.

[0020] Such as figure 1 As shown, the micro-flow field structure 3 of the reforming chamber in this emb...

specific Embodiment approach 2

[0022] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mixed solution contains 10 g / L sodium silicate and 1 g / L sodium hypophosphite.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the mixed solution contains 15 g / L sodium aluminate and 2.5 g / L sodium hypophosphite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com