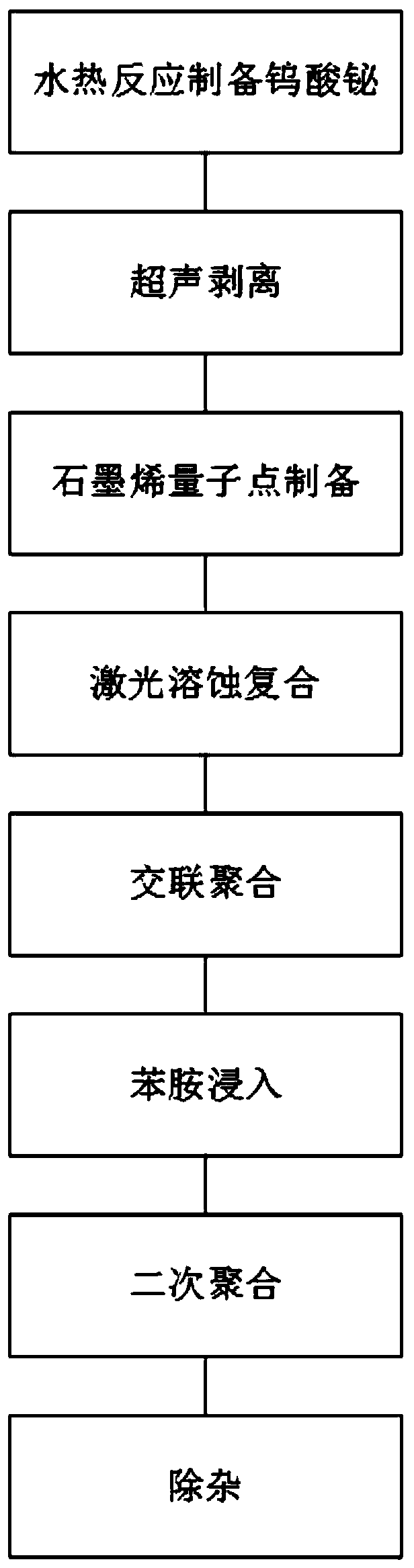

Preparation method and application of bismuth tungstate-graphene-conductive hydrogel

A conductive hydrogel, bismuth tungstate technology, applied in chemical instruments and methods, electrodes, electrolysis processes, etc., can solve the problems of poor catalytic performance and inability to recycle, and achieve the advantages of preventing agglomeration, improving electrocatalytic performance, and convenient recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1, weigh 1mmol sodium tungstate (Na2WO 4 2H 2 O), 2mmol bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) mix with 0.05gCTAB and dissolve in 80ml deionized water, stir at 60°C at a speed of 500r / min for 30min until uniform, transfer to a hydrothermal kettle for hydrothermal reaction, wherein the temperature of the hydrothermal reaction is 120°C, The hydrothermal reaction time is 20h. After the hydrothermal reaction is completed, the lamellar bismuth tungstate is obtained by washing and drying in sequence; the washing method is three times with water and ethanol respectively, and the drying method is: drying at 60°C for 10 hours.

[0041] Step 2: Take 400 mg of the lamellar bismuth tungstate obtained in the previous step, dissolve it in 200 ml of deionized water, and ultrasonically peel it off after dissolving to obtain dispersed two-dimensional bismuth tungstate nanosheets; wherein, the frequency of ultrasonic dispersion is 20KHz, and the time of ultrasonic dispersion is ...

Embodiment 2

[0049] Step 1, weigh 1mmol sodium tungstate (Na2WO 4 2H 2 O), 2mmol bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) mix with 0.05gCTAB and dissolve in 80ml deionized water, stir at 70°C at a speed of 800r / min for 10min until uniform, transfer to a hydrothermal kettle for hydrothermal reaction, wherein the temperature of the hydrothermal reaction is 130°C, The hydrothermal reaction time is 24h. After the hydrothermal reaction is completed, the lamellar bismuth tungstate is obtained by washing and drying in sequence; the washing method is three times with water and ethanol respectively, and the drying method is: drying at 60°C for 10 hours.

[0050] Step 2: Take 400 mg of the lamellar bismuth tungstate obtained in the previous step, dissolve it in 200 ml of deionized water, and ultrasonically peel it off after dissolving to obtain dispersed two-dimensional bismuth tungstate nanosheets; wherein, the frequency of ultrasonic dispersion is 25KHz, and the time of ultrasonic dispersion is ...

Embodiment 3

[0058] Step 1, weigh 1mmol sodium tungstate (Na2WO 4 2H 2 O), 2mmol bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) mix with 0.05gCTAB and dissolve in 80ml deionized water, stir at 80°C at a speed of 1000r / min for 20min until uniform, transfer to a hydrothermal kettle for hydrothermal reaction, wherein the temperature of the hydrothermal reaction is 160°C, The hydrothermal reaction time is 18h. After the hydrothermal reaction is completed, the lamellar bismuth tungstate is obtained by washing and drying in sequence; the washing method is three times with water and ethanol respectively, and the drying method is: drying at 60°C for 10 hours.

[0059] Step 2: Take 400mg of bismuth tungstate flakes obtained in the previous step, dissolve them in 200ml of deionized water, and ultrasonically peel off after dissolving to obtain dispersed two-dimensional bismuth tungstate nanosheets; wherein, the frequency of ultrasonic dispersion is 22KHz, and the time of ultrasonic dispersion is for 3h. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com