Catalyst for degrading organic wastewater and preparation method thereof

An organic waste water and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, energy waste water treatment, etc., can solve the problems of fine particle size of titanium dioxide powder, difficult recovery of titanium dioxide, unfavorable light transmission, etc. And the density is moderate, the sewage treatment effect is improved, and the manufacturing difficulty is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a catalyst for degrading organic wastewater and a preparation method of the catalyst. The catalyst is based on a zeolite with an average particle size of 3mm as a carrier, and a cobalt-titania composite material layer of about 150nm is coated on the surface of the zeolite, and the molar ratio of cobalt to titanium dioxide in the cobalt-titania composite layer is about 1: 70; the density of the catalyst is 1.13g / cm 3 .

[0030] The preparation method of this catalyst is as follows:

[0031] a. Put 1000g of zeolite in a calciner at 900°C for 1.5 hours and calcine for 1.5 hours. After cooling, rinse with water to remove soluble salts, and dry at 200°C for later use.

[0032] b. Dissolve cobalt acetate in water to prepare cobalt-containing 0.1M cobalt salt solution, add glacial acetic acid to acidify to pH about 5.5, and prevent cobalt ion precipitation.

[0033] c. Take 10 mL and add 90 mL of absolute ethanol to prepare cobalt ethanol solution f...

Embodiment 2

[0037] This embodiment provides a catalyst for degrading organic wastewater and a preparation method of the catalyst. The catalyst uses zeolite with an average particle size of 3 mm as a carrier, and coats a layer of titanium dioxide layer of about 100 nm on the surface of the zeolite, and then coats a layer of cobalt-titania composite material layer of about 150 nm. The cobalt-titania composite material The molar ratio of cobalt to titanium dioxide in the layer is about 1:150; the density of the catalyst is 1.2g / cm 3 .

[0038] The preparation method of this catalyst is as follows:

[0039] a. Put 1000g of zeolite in a calciner at 900°C for 2 hours, then rinse with water after cooling to remove soluble salts, and dry at 200°C for later use.

[0040] b. Add 200mL absolute ethanol to the reactor, add 3.5mL acetylacetone, 6mL glacial acetic acid, stir well, add 34mL butyl titanate, stir well. Another 15 mL of ethanol with a volume fraction of 90% was slowly added dropwise int...

Embodiment 3

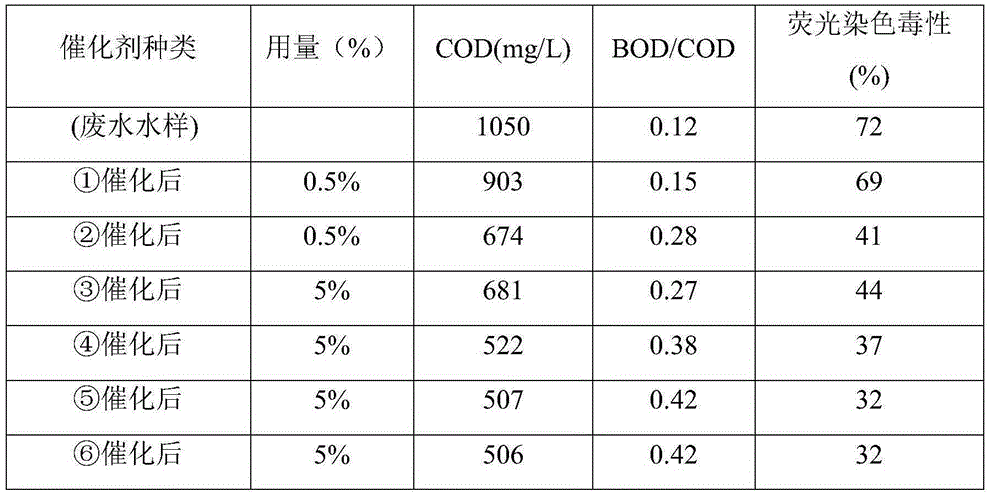

[0047] In order to verify the catalytic effect of the prepared catalyst of embodiment 1 and embodiment 2, carried out catalytic effect experiment and comparison, concrete experiment is as follows:

[0048] The refractory organic wastewater sample was taken from a petrochemical enterprise, COD (chemical oxygen demand) = 1050mg / L, BOD (biological oxygen demand) / COD = 0.12, and the fluorescence dyeing toxicity test was 72%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com