Preparation method for asymmetric hollow fiber type solid oxide fuel cell

A solid oxide and fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, battery electrodes, etc., to achieve good compactness, fast gas transmission, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

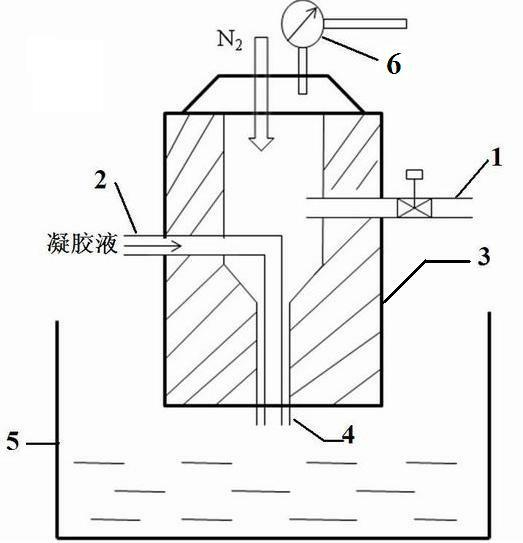

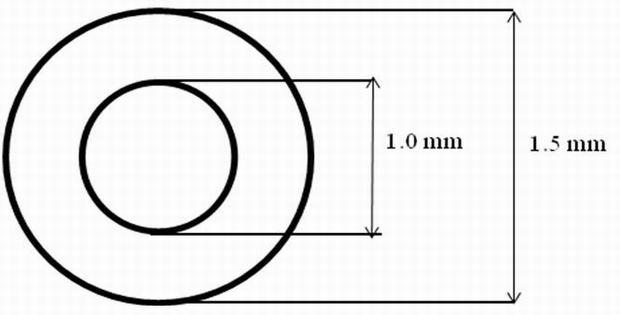

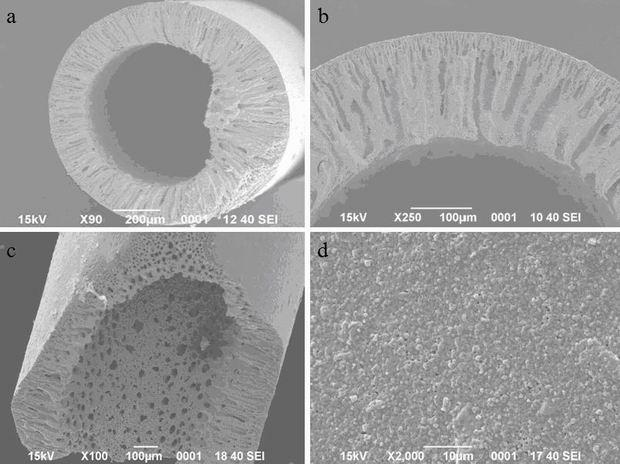

[0039] (1) Dissolve 0.6g polyvinylpyrrolidone in 16g N -Add 4g of polyethersulfone to methylpyrrolidone, stir until dissolved, add 15g of nickel oxide (chemical formula: NiO) and 15g of yttrium-stabilized zirconia (abbreviation: YSZ), stir at 400rpm for 12h to disperse the powder evenly, and get a mixture Uniform textile liquid; to figure 1 Injected into the inner ring of the spinneret of the textile equipment shown N -Methylpyrrolidone, inject deionized water into the water tank, inject the textile liquid into the reaction tank of the textile equipment, and vacuumize it for 1 hour to remove the air bubbles. 2 Driven, the spinning solution is formed through a spinneret with an outer diameter of 1.5 mm and an inner diameter of 1 mm and enters the water tank, and placed in deionized water for 48 hours to obtain a tubular asymmetric hollow fiber SOFC anode green body;

[0040] (2) Cut the asymmetric hollow fiber SOFC anode green body obtained in step (1) into 8 cm, hang it in t...

Embodiment 2

[0052] (1) Dissolve 0.6g polyvinylpyrrolidone in 12g N -Add 3.6g polyethersulfone to methylpyrrolidone, stir until dissolved, add 12.96g nickel oxide (chemical formula: NiO) and 19.44g gadolinium-doped cerium oxide (abbreviation: GDC), stir at 400rpm for 10h to make the powder uniform Disperse to obtain a uniformly mixed textile liquid; figure 1 Injected into the inner ring of the spinneret of the textile equipment shown N -Methylpyrrolidone, inject deionized water into the water tank, inject the textile liquid into the reaction tank of the textile equipment, and vacuumize it for 0.5h to remove the air bubbles, then in the N with a pressure of 80kPa 2 Driven, the spinning liquid is formed through a spinneret with an outer diameter of 1.5 mm and an inner diameter of 1 mm and enters the water tank, and placed in deionized water for 24 hours to obtain a tubular asymmetric hollow fiber SOFC anode green body;

[0053] (2) Cut the asymmetric hollow fiber SOFC anode green body obta...

Embodiment 3

[0058] (1) Dissolve 0.6g polyvinylpyrrolidone in 30g N -Add 12g of polyethersulfone to methylpyrrolidone, stir until dissolved, add 9.6g of nickel oxide (chemical formula: NiO) and 6.4g of lanthanum-gallium-based perovskite oxide (abbreviation: LSGM), stir at 400rpm for 20h, and make the powder The body is evenly dispersed to obtain a uniformly mixed textile liquid; figure 1 Injected into the inner ring of the spinneret of the textile equipment shown N -Methylpyrrolidone, inject deionized water into the water tank, inject the textile liquid into the reaction tank of the textile equipment, and vacuumize for 2 hours to remove the air bubbles, and then in N with a pressure of 120kPa 2 Driven, the spinning liquid is formed through a spinneret with an outer diameter of 1.5 mm and an inner diameter of 1 mm and enters the water tank, and placed in deionized water for 72 hours to obtain a tubular asymmetric hollow fiber SOFC anode green body;

[0059] (2) Cut the asymmetric hollow f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com