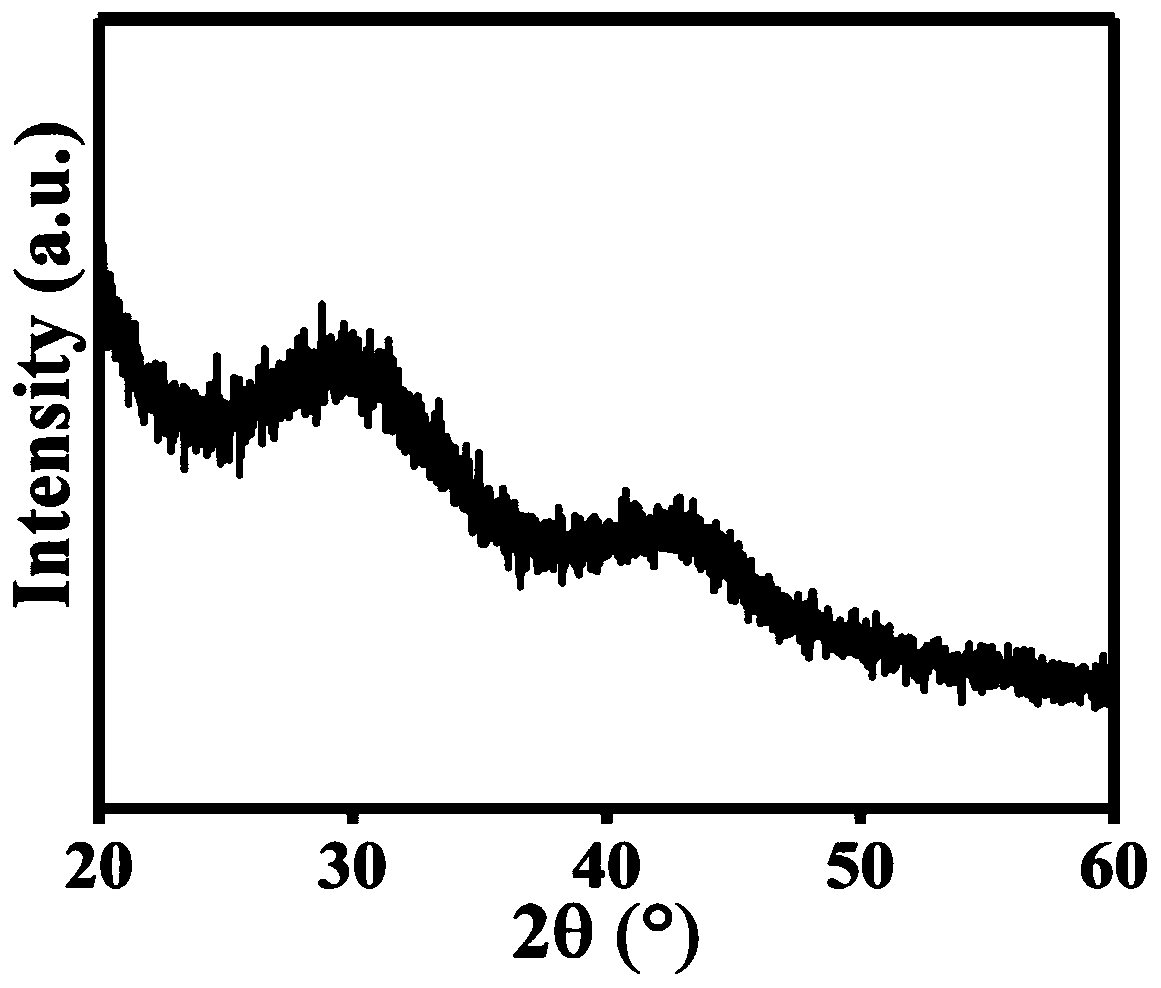

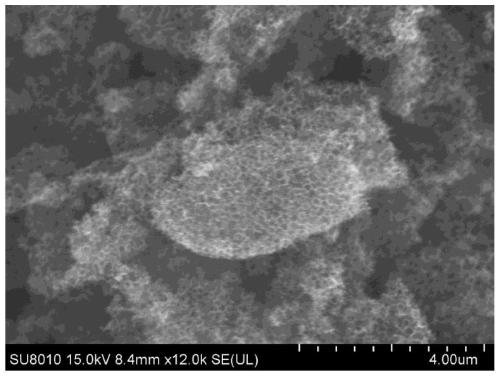

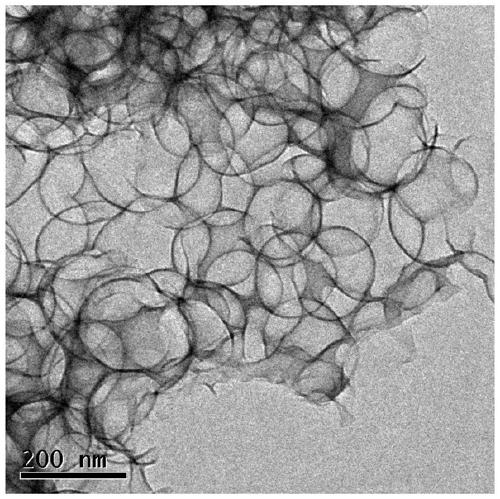

Bimetallic atom hollow carbon nanosphere catalyst and preparation method thereof

A carbon nanosphere, catalyst technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of large overpotential and difficult large-scale preparation, and achieve large half-wave potential, preparation The method is simple and the effect of low initial potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing FeCu-N-HC nanosphere catalyst includes the following steps:

[0036] Step 1: Add 3g pyrrole, 0.15g ferric nitrate, 0.19g copper nitrate and 30g hydrogen peroxide to 50ml deionized water, stir until the color of the solution changes from black to ocher, then dry the solution at 80℃, then Prepared into powder A;

[0037] Step 2: ber method synthesizes SiO with a diameter of 200nm 2 Ball: Mix 3mL of ammonia, 74mL of absolute ethanol and 10mL of deionized water and stir for 0.5h, then add 6mL of ethyl orthosilicate and stir for 6h, wait for it to turn into a milky white mixture, centrifuge to obtain a white precipitate of SiO 2 , Dry for use;

[0038] Step 3: Add 2.5g of sodium chloride and 2.5g of SiO prepared in step 2 to 50ml of deionized water in sequence 2 The template and 0.5 g of powder A prepared in step 1 are stirred until they are evenly dispersed, then placed in a freeze dryer, and freeze-dried at -40°C to obtain solid B;

[0039] Step 4: Grind th...

Embodiment 2

[0045] A method for preparing FeCu-N-HC nanospheres includes the following steps:

[0046] Step 1: Add 1g imidazole, 0.1g ferric chloride, 0.13g copper chloride and 10g hydrogen peroxide to 50ml deionized water, stir until the color of the solution changes from black to ocher, and dry the solution at 80℃ , And then prepared into powder A;

[0047] Step 2: ber method synthesizes SiO with a diameter of 200nm 2 Ball: 3mL ammonia water, 74mL absolute ethanol and 10mL deionized water were mixed and stirred for 0.5h, then 6mL ethyl orthosilicate was added and stirred for 6h to become a milky white mixture, centrifuged to obtain a white precipitate of SiO 2 , Dry for use;

[0048] Step 3: Add 3g sodium chloride and 3g SiO to 50ml deionized water in sequence 2 And 0.5g of powder A, stir until evenly dispersed, place in a freeze dryer, freeze-dry at -40°C to obtain solid B;

[0049] Step 4: Grind solid B to powder, carbonize under the protection of nitrogen atmosphere, carbonization temperatu...

Embodiment 3

[0052] A method for preparing FeCu-N-HC nanosphere catalyst includes the following steps:

[0053] Step 1: Add 1g imidazole, 0.1g ferric chloride, 0.13g copper chloride and 10g hydrogen peroxide to 50ml deionized water, stir until the color of the solution changes from black to ocher, and dry the solution at 80℃ , And then prepared into powder A;

[0054] Step 2: ber method synthesizes SiO with a diameter of 200nm 2 Ball: 3mL ammonia water, 74mL absolute ethanol and 10mL deionized water were mixed and stirred for 0.5h, then 6mL ethyl orthosilicate was added and stirred for 6h to become a milky white mixture, centrifuged to obtain a white precipitate of SiO 2 , Dry for use.

[0055] Step 3: Add 3g sodium chloride and 3g SiO to 50ml deionized water in sequence 2 And 0.5g of powder A, stir until the dispersion is evenly distributed, then place at 80°C for rotary evaporation, and dry to obtain solid B;

[0056] Step 4: Grind solid B to powder, carbonize under the protection of nitrogen a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com