Synthesis method of methyl chloroformate

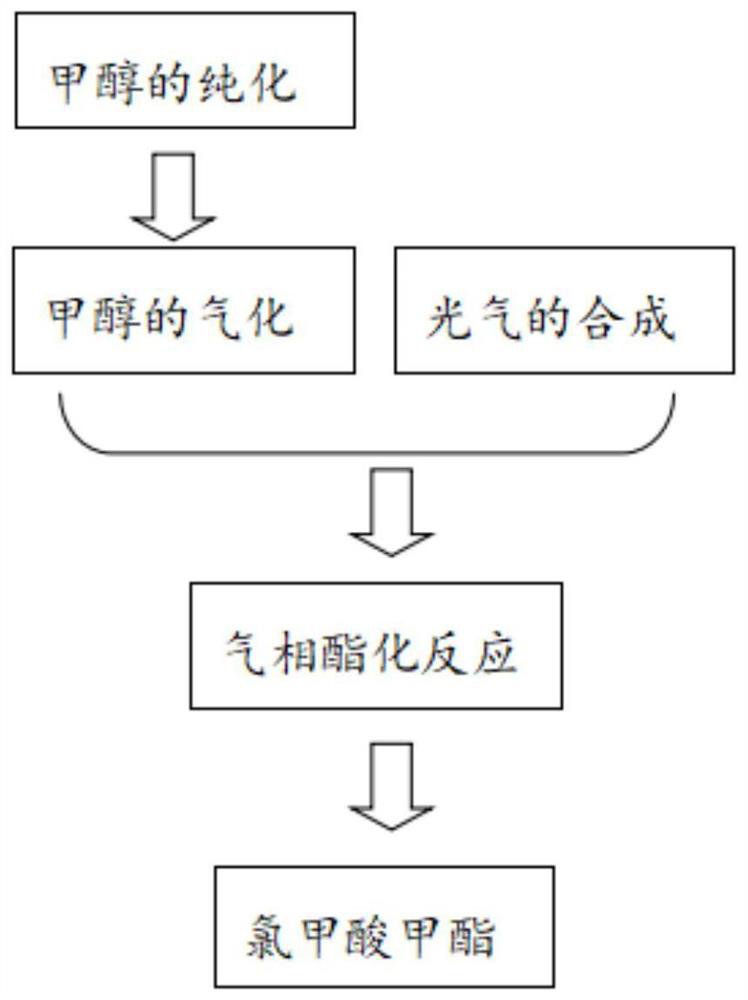

A technology of methyl chloroformate and a synthesis method, applied in the field of synthesis of methyl chloroformate, can solve problems such as many by-products, and achieve the effects of improving conversion rate, sufficient methanol reaction, and avoiding side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

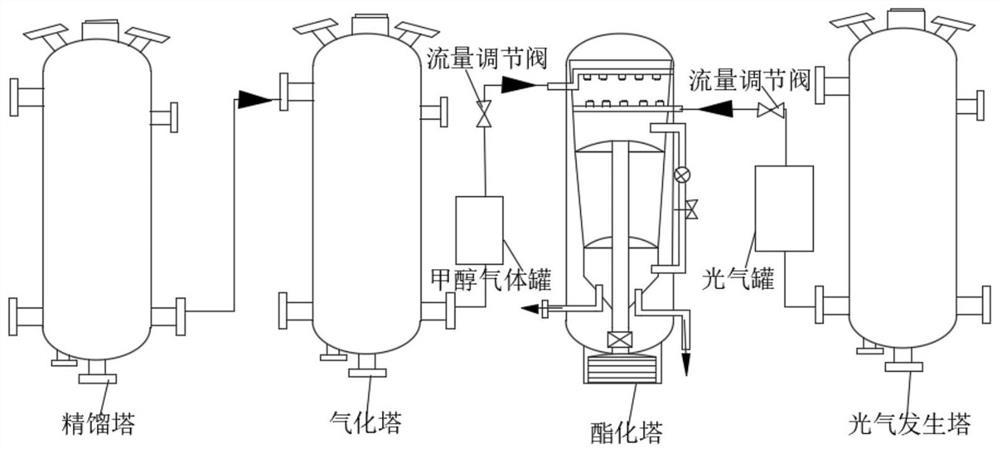

[0040] A synthetic method for methyl chloroformate, comprising the following steps:

[0041] Step 1. Purification of methanol: put methanol into a rectification tower, and carry out rectification and purification of methanol to reduce the occurrence of side reactions in the subsequent esterification reaction, wherein the rectification temperature is controlled at 65°C;

[0042] Step 2. Gasification of methanol: Put the purified methanol into the gasification tower to gasify the methanol to obtain methanol gas, wherein the gasification temperature is set to 70°C;

[0043] Step 3, the synthesis of phosgene: pass carbon monoxide and chlorine gas into the phosgene generating tower according to the molar ratio of 1:1.05, and synthesize and react to generate phosgene under the catalytic action of activated carbon;

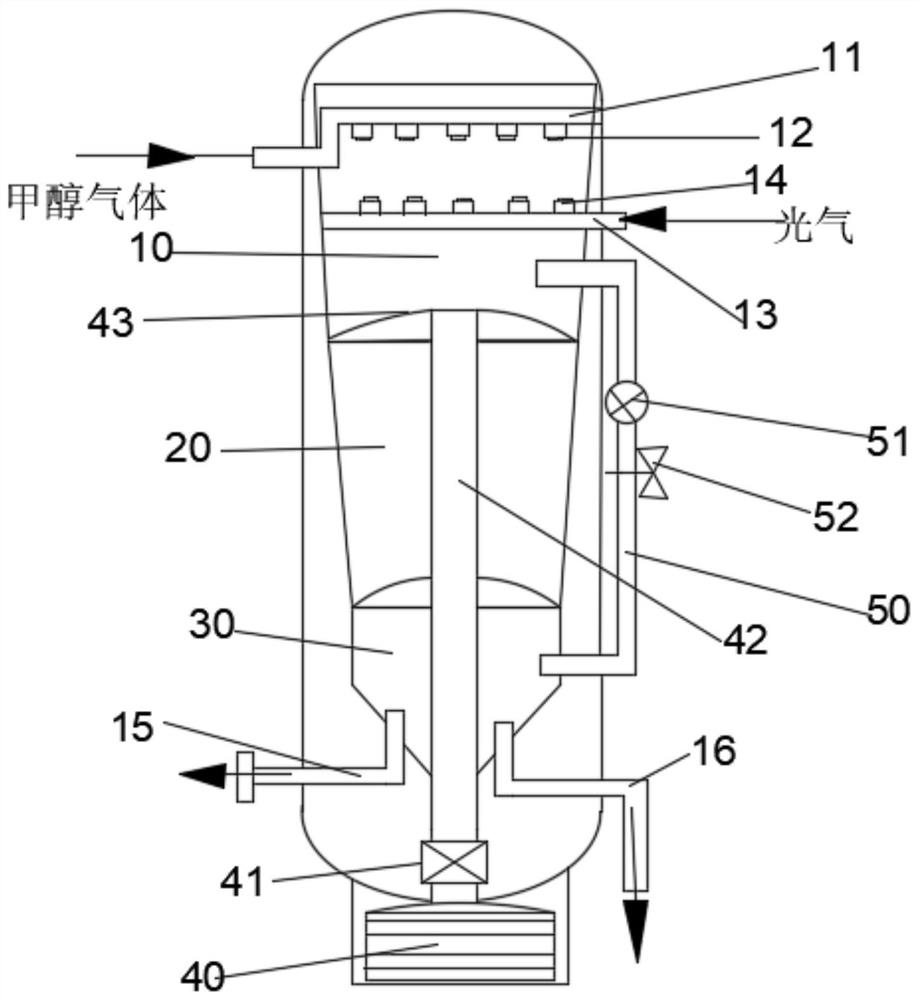

[0044] Step 4, gas phase esterification reaction: Introduce nitrogen into the esterification tower for 15 minutes, drive away the air in the esterification tower, contro...

Embodiment 2

[0047] A synthetic method for methyl chloroformate, comprising the following steps:

[0048] Step 1. Purification of methanol: put methanol into a rectification tower, and carry out rectification and purification of methanol to reduce the occurrence of side reactions in the subsequent esterification reaction, and the rectification temperature is controlled at 68°C;

[0049] Step 2. Gasification of methanol: Put the purified methanol into the gasification tower to gasify the methanol to obtain methanol gas, wherein the gasification temperature is set to 75°C;

[0050] Step 3, the synthesis of phosgene: pass carbon monoxide and chlorine into the phosgene generating tower according to the molar ratio of 1:1.05, and synthesize and react to generate phosgene under the catalytic action of activated carbon;

[0051] Step 4, gas-phase esterification reaction: feed nitrogen into the esterification tower for 15 minutes, drive away the air in the esterification tower, control the flow of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com