A kind of zsm-5/mcm-48 composite molecular sieve and its preparation method and application

A technology of composite molecular sieve and MCM-48, which is used in the preparation of molecular sieve catalysts, liquid hydrocarbon mixtures, chemical instruments and methods, etc., can solve the problems of high cost, modulation of reaction products, complicated catalyst preparation process, etc., so as to improve low-temperature activity. , the effect of extending the length of the carbon chain and improving the hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

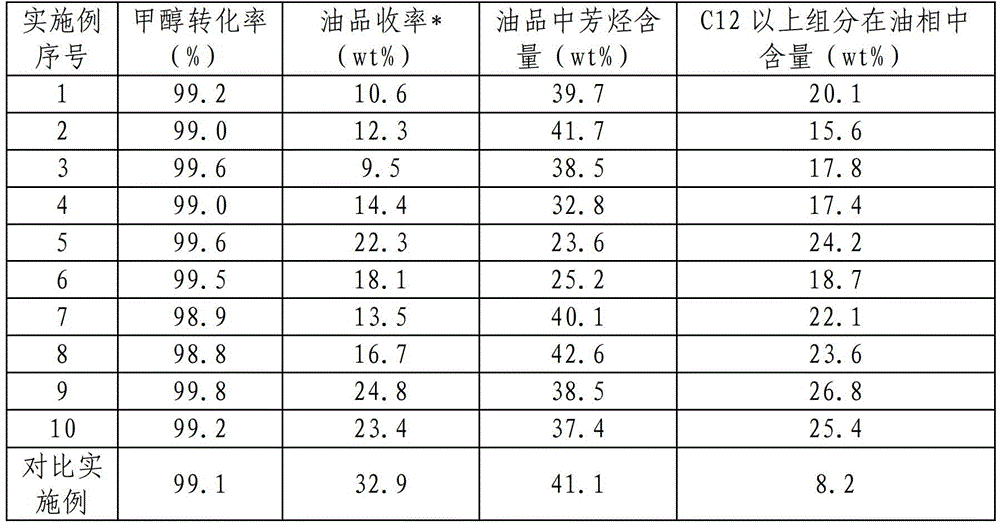

Examples

Embodiment 1

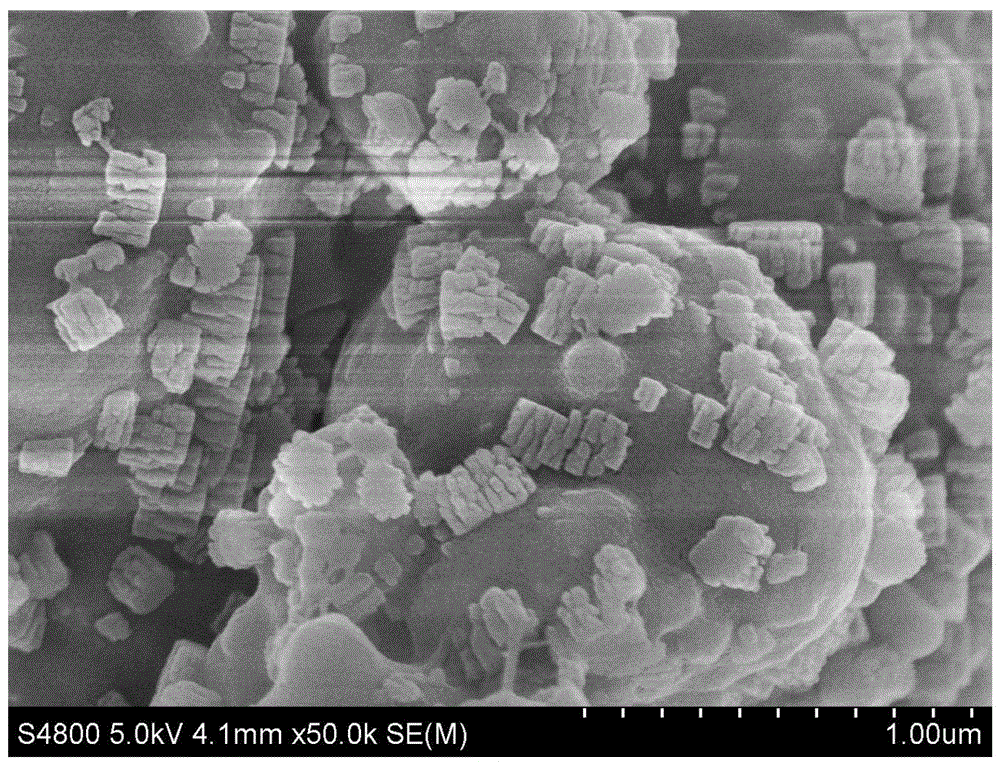

[0043] Preparation of ZSM-5 / MCM-48 composite molecular sieve:

[0044] The molar ratio of each raw material in the preparation of ZSM-5 / MCM-48 composite molecular sieve is: TEOS:CTAB:NaOH:Al:H2O=1.0:0.12:0.4:0.0125:56.

[0045] Mix 4.459g of cetyltrimethylammonium bromide (CTAB), 1.432g of sodium hydroxide and 100.89g of deionized water, add 0.26g of aluminum isopropoxide to the above solution, stir at a constant temperature of 35°C until clear, gradually Add 21.24g tetraethyl orthosilicate (TEOS) dropwise, adjust the pH to 10-11 with 50wt% acetic acid aqueous solution, and stir for 4 hours to prepare the MCM-48 precursor solution.

[0046] ZSM-5 (Si / Al=38, Nankai Catalyst Factory) was stirred in 0.5mol / L NaOH aqueous solution at 75°C for 4h, filtered, washed until the filtrate was neutral, dried at 110°C for 12h, and calcined at 550°C for 6h. Then grind it into 280-300 mesh particles, slowly add it to the precursor solution of MCM-48, stir at room temperature for 2h, crystal...

Embodiment 2

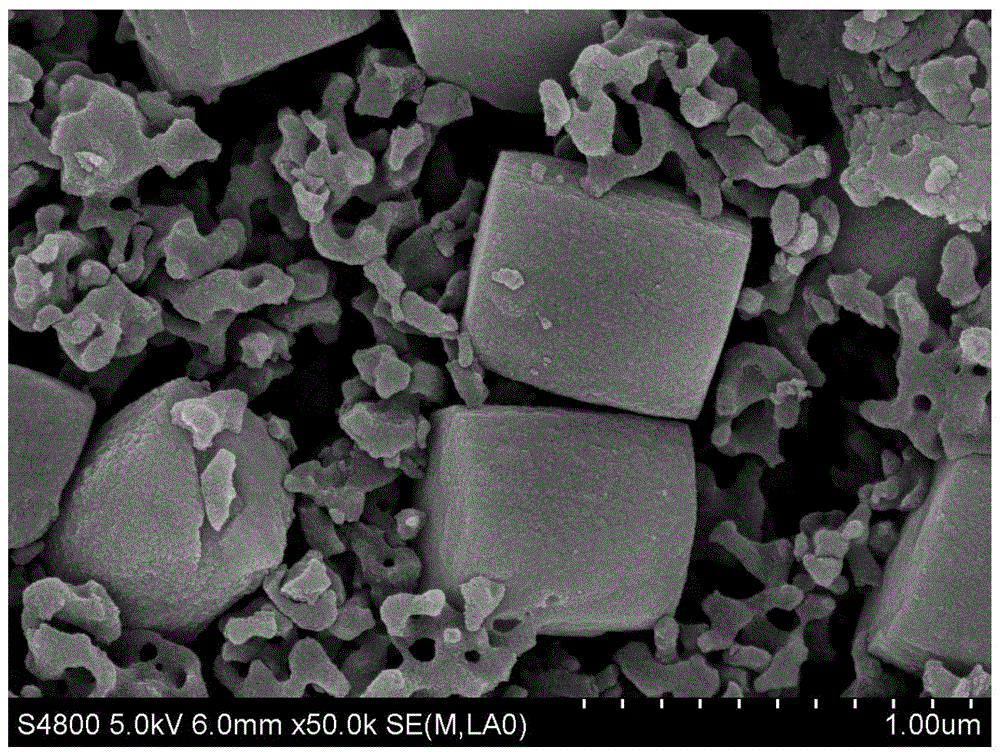

[0053] Preparation of ZSM-5 / MCM-48 composite molecular sieve:

[0054] The molar ratio of each raw material prepared by ZSM-5 / MCM-48 composite molecular sieve is: Na 2 SiO 3 :OTAC:NaOH:Al:H 2 O=0.8:0.4:0.55:0.025:120.

[0055] Mix 13.922g of octadecyltrimethylammonium chloride (OTAC), 2.212g of sodium hydroxide with 216.45g of deionized water, add 0.511g of aluminum isopropoxide to the above solution, stir at a constant temperature of 35°C until clear, gradually Add dropwise 9.765 sodium silicate (Na 2 SiO 3 ), adjust the pH=10-11 with 50wt% acetic acid aqueous solution, stir for 4h, and prepare the MCM-48 precursor solution.

[0056] ZSM-5 (Si / Al=38, Nankai Catalyst Factory) was treated in 0.3mol / L NaF aqueous solution, stirred at 60°C for 6h, filtered, the filtrate was washed until neutral, dried at 100°C for 16h, and calcined at 550°C for 6h. Then grind it into 280-300 mesh particles, slowly add it to the precursor solution of MCM-48, stir at room temperature for 2h, ...

Embodiment 3

[0060] Preparation of ZSM-5 / MCM-48 composite molecular sieve:

[0061] The molar ratio of each raw material prepared by ZSM-5 / MCM-48 composite molecular sieve is: Na 2 SiO 3 :CTAB:NaOH:Al:H 2 O=1.4:0.75:0.7:0.0355:165.

[0062] 27.333g cetyltrimethylammonium bromide (CTAB) 2.812g sodium hydroxide mixed with 297.02g deionized water, 1.215g aluminum sulfate (Al 2 (SO4) 3 ) into the above solution, stirred at a constant temperature of 35°C until clear, then added 17.088 sodium silicate (Na 2 SiO 3 ), adjust the pH=10-11 with 50wt% acetic acid aqueous solution, stir for 4h, and prepare the MCM-48 precursor solution.

[0063] ZSM-5 (Si / Al=38, Nankai Catalyst Factory) was treated in 0.7mol / L NaOH aqueous solution, stirred at 80°C for 3h, filtered, the filtrate was washed until neutral, dried at 120°C for 10h, and calcined at 550°C for 6h. Then grind it into 280-300 mesh particles, slowly add it to the precursor solution of MCM-48, stir at room temperature for 2h, crystallize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com