A kind of zsm-5 and zsm-11 eutectic molecular sieve and its preparation method and application

A ZSM-11, ZSM-5 technology, applied in the field of molecular sieve synthesis, ZSM-5 and ZSM-11 eutectic molecular sieves and their preparation, to achieve the effects of improving the yield of aromatic hydrocarbons, improving the degree of greenness, and reducing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

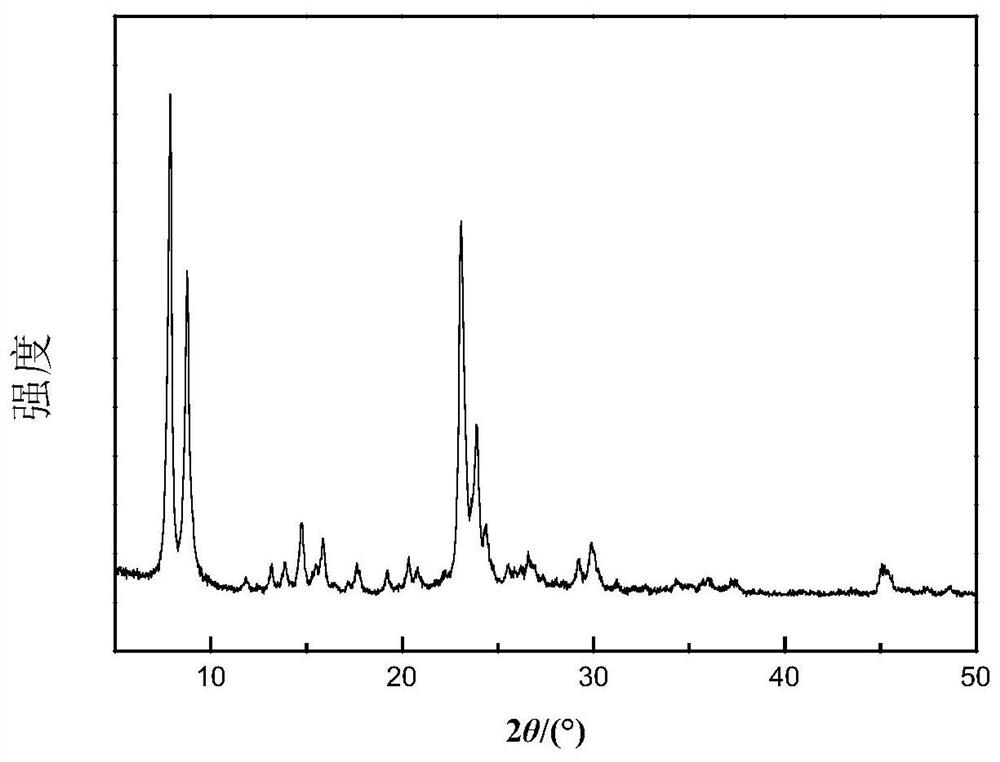

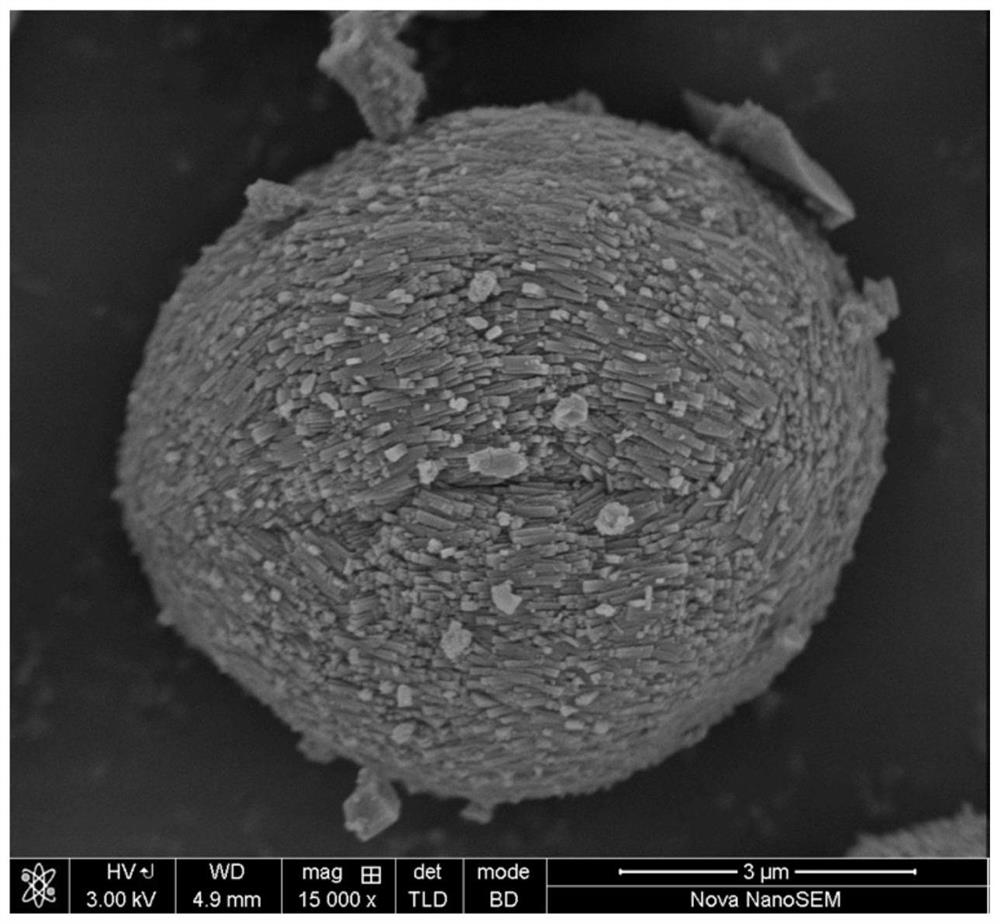

Embodiment 1

[0053] The preparation method of ZSM-5 and ZSM-11 eutectic molecular sieve of the present embodiment comprises the following steps:

[0054] 1) Add 36ml of deionized water to a beaker, add 0.246g tetrapropylammonium bromide (TPABr, 99wt%), 7.442g tetrabutylammonium bromide (TBABr, 99wt%), 15.2g silicon Sol (40wt% SiO 2 meter), 0.487g sodium metaaluminate (41wt%, as Al 2 o 3 ) and 0.584g of sodium hydroxide, and kept stirring at room temperature for 12 hours until uniformly mixed to obtain a mixed gel;

[0055] Among them, the molar ratio of each substance in the raw material is 1SiO 2 : 0.02Al 2 o 3 : 0.07Na 2 O: 0.01TPA + : 0.23TBA + : 20H 2 O.

[0056] 2) Transfer the mixed gel in step 1) to a petri dish, perform drying treatment, and then perform grinding treatment to obtain gel powder;

[0057] Wherein, the temperature of the drying treatment is 25° C., and the time of the drying treatment is 36 hours.

[0058] 3) Put the gel powder obtained in step 2) in a sma...

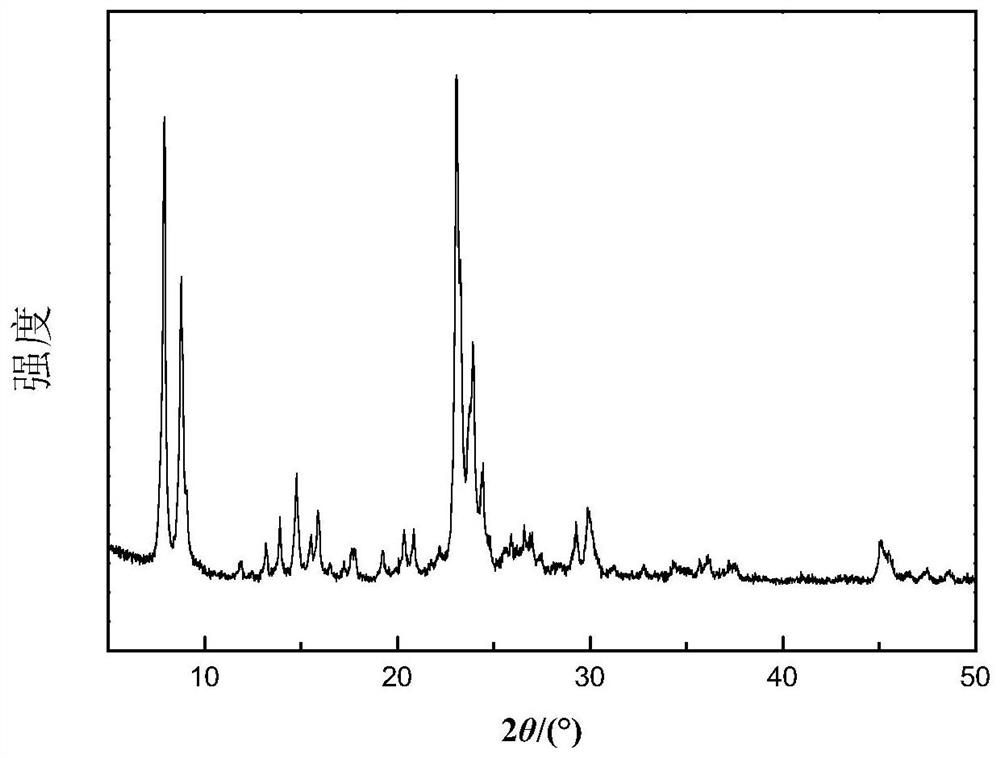

Embodiment 2

[0069] The preparation method of ZSM-5 and ZSM-11 eutectic molecular sieve of the present embodiment comprises the following steps:

[0070] 1) Add 27ml of deionized water into the beaker, and add 0.469g of tetrapropylammonium hydroxide (TPA + , 40wt%), 14.9694g tetrabutylammonium hydroxide (TBA + , 40wt%), 14.93g silica sol (40wt% with SiO 2 meter), 0.487g sodium metaaluminate (41wt%, as Al 2 o 3 ) and 0.584g of sodium hydroxide, and kept stirring at room temperature for 12 hours until uniformly mixed to obtain a mixed gel;

[0071] Among them, the molar ratio of each substance in the raw material is 1SiO 2 : 0.02Al 2 o 3 : 0.07Na 2 O: 0.01TPA + : 0.23TBA + : 20H 2 O.

[0072] 2) Transfer the mixed gel in step 1) to a petri dish, perform drying treatment, and then perform grinding treatment to obtain gel powder;

[0073] Wherein, the temperature of the drying treatment is 25° C., and the time of the drying treatment is 36 hours.

[0074] 3) Put the gel powder obt...

Embodiment 3

[0086] The preparation method of ZSM-5 and ZSM-11 eutectic molecular sieve of the present embodiment comprises the following steps:

[0087] 1) Add 36ml of absolute ethanol to a beaker, add 0.738g tetrapropylammonium bromide (TPABr, 99wt%), 7.442g tetrabutylammonium hydroxide (TBABr, 40wt% aqueous solution), 21.458g orthosilicon Ethyl acetate (TEOS, 28wt% as SiO 2 ), 1.651g aluminum isopropoxide (24.7wt%, as Al 2 o 3 Meter) and 0.584g sodium hydroxide; Continue stirring at room temperature for 12 hours to mix evenly, obtain mixed gel;

[0088] Among them, the molar ratio of each substance in the raw material is 1SiO 2 : 0.04Al 2 o 3 : 0.07Na 2 O: 0.03TPA + : 0.226TBA + : 10EtOH.

[0089] 2) Transfer the mixed gel in step 1) to a petri dish, perform drying treatment, and then perform grinding treatment to obtain gel powder;

[0090] Wherein, the temperature of the drying treatment is 40° C., and the time of the drying treatment is 28 hours.

[0091] 3) Put the gel po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com