One-step synthesizing method for hollow type multilevel-hole Fe-Silicalite-1

A multi-level porous and hollow technology, applied in the direction of crystalline aluminosilicate zeolite, can solve the problems of few, high cost, complicated process, etc., and achieve the effects of slowing down side reactions, large carbon capacity, and simple synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 15.4 mL of ethyl orthosilicate to 16.5 mL of tetrapropylammonium hydroxide aqueous solution (1.14 mol / L), stir at room temperature for 3 h, add 0.71 g of ferric citrate and 33 mL of water, continue stirring for 2 h, and then add crystal Crystallize at 170°C for 3 days in a furnace, centrifuge, wash, dry overnight at 100°C, and roast at 540°C for 6 hours to obtain Fe-Silicalite-1. Raw materials used, in terms of molar ratio of pure substances, SiO in silicon source 2 : Fe in iron source 2 o 3 : TPA in the templating agent + : OH in alkali source - :H 2 O=1:0.021:0.27:0.27:37;

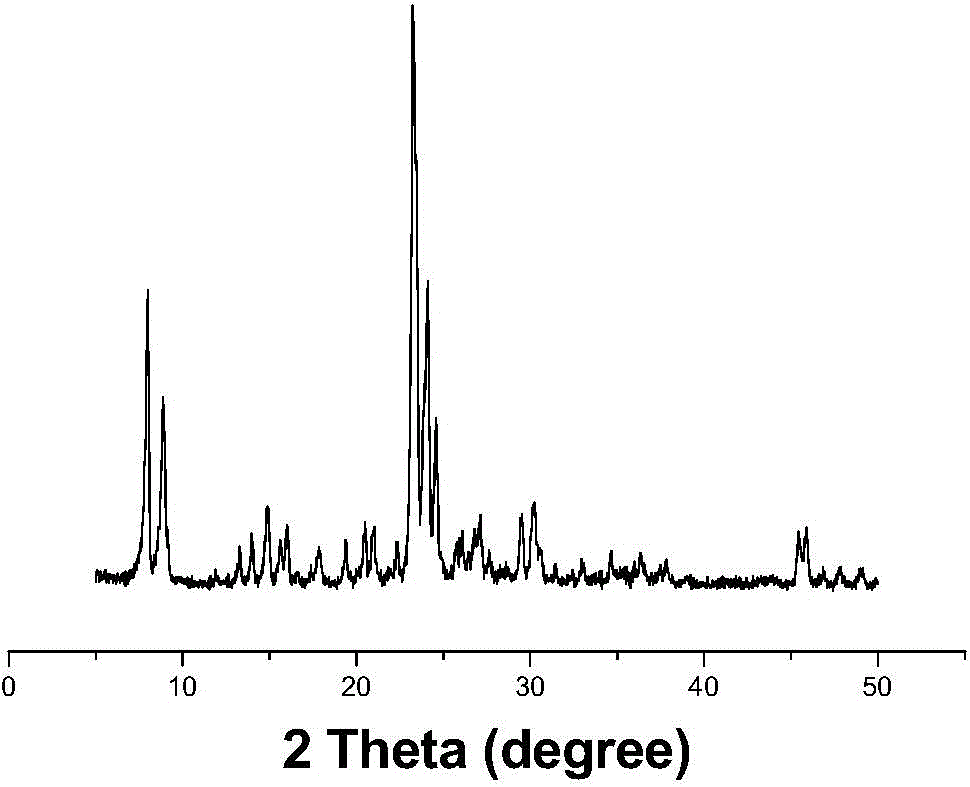

[0032] figure 1 is the XRD pattern of the sample, it can be seen from the figure that the sample has an MFI structure;

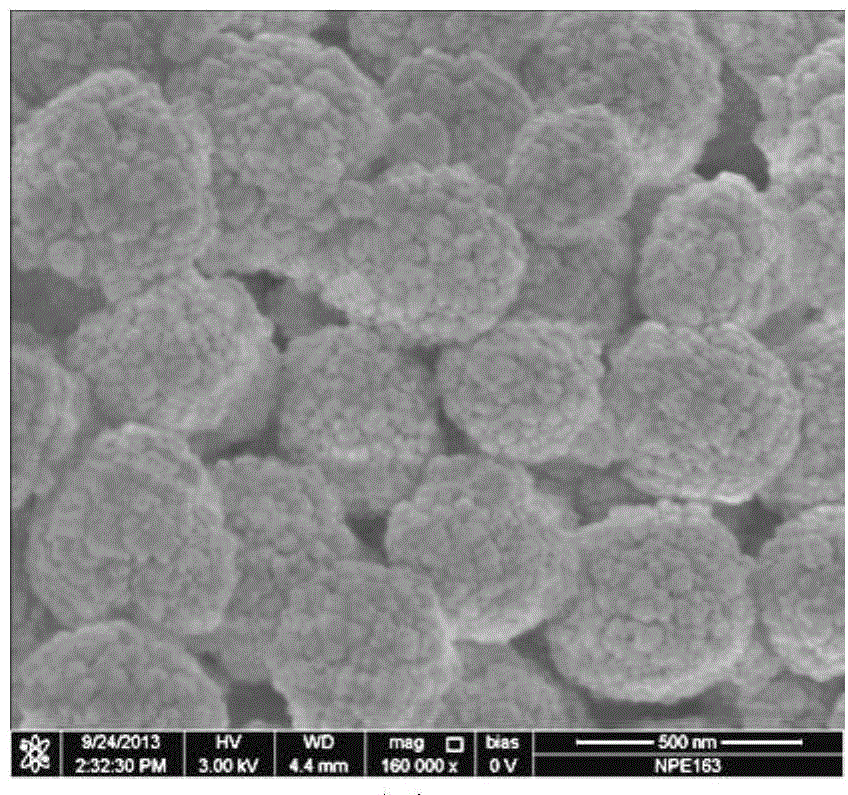

[0033] figure 2 It is the SEM picture of the sample. It can be seen from the picture that the particle size of the sample is uniform, and it is a small grain aggregate of about 400nm;

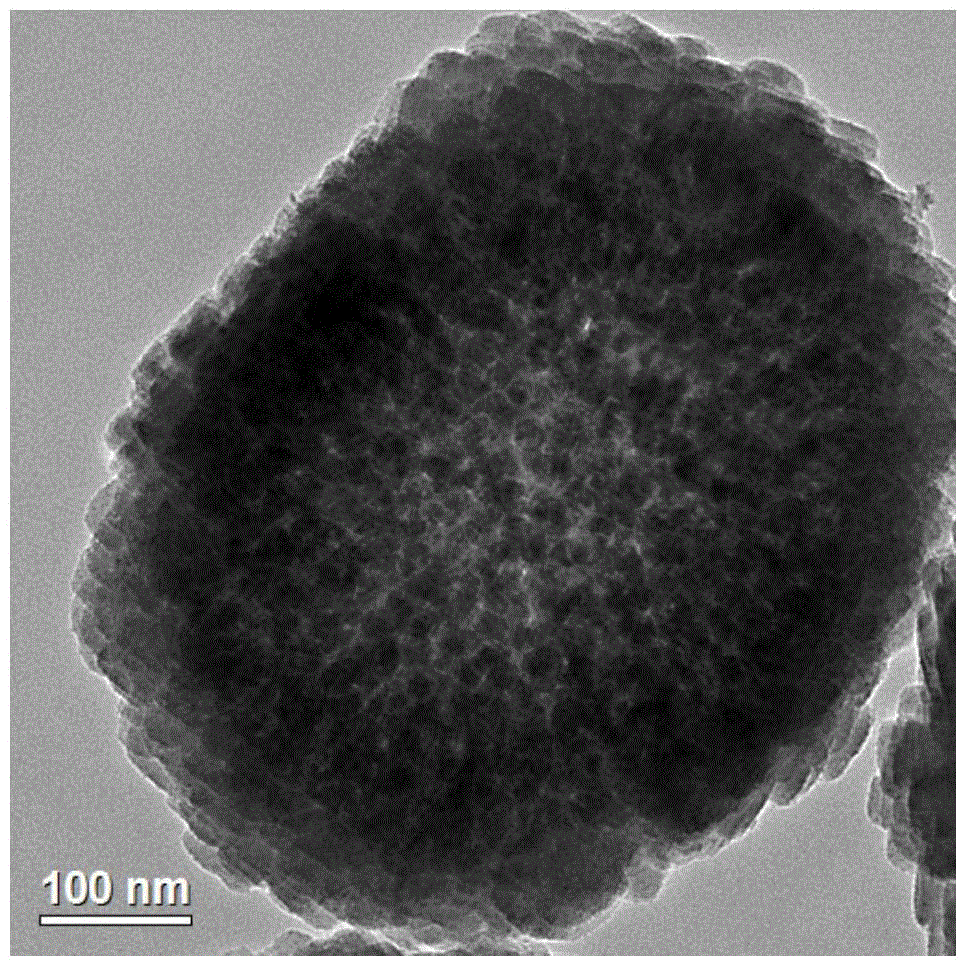

[0034] image 3 It is the TEM picture of the sample. It can be seen from the f...

Embodiment 2

[0038] Add 15.4mL tetrapropylammonium hydroxide aqueous solution (1.14mol / L) to 15.4mL tetrapropylammonium hydroxide aqueous solution (1.14mol / L), stir at room temperature for 3h, add 1.01g ferric citrate and 33mL water, continue to stir for 2h, and then add crystal Crystallize at 80°C for 5 days in a furnace, centrifuge, wash, dry overnight at 100°C, and roast at 540°C for 6 hours to obtain Fe-Silicalite-1. Raw materials used, in terms of molar ratio of pure substances, SiO in silicon source 2 : Fe in iron source 2 o 3 : TPA in the templating agent + : OH in alkali source - :H 2 O=1:0.03:0.27:0.27:37.

Embodiment 3

[0040]Add 15.4 mL of ethyl orthosilicate to 16.5 mL of an aqueous solution of tetrapropylammonium hydroxide (1.14 mol / L), stir at room temperature for 3 h, add 0.10 g of ferric citrate and 33 mL of water, continue stirring for 2 h, and then add crystal Crystallize at 200°C for 1 day in a furnace, centrifuge, wash, dry overnight at 100°C, and roast at 540°C for 6 hours to obtain Fe-Silicalite-1. Raw materials used, in terms of molar ratio of pure substances, SiO in silicon source 2 : Fe in iron source 2 o 3 : TPA in the templating agent + : OH in alkali source - :H 2 O=1:0.003:0.27:0.27:37.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com