Method of using gold-supported molecular sieve catalyst to convert methanol to methyl acetate

A technology of methyl acetate and catalyst, applied in the field of application of supported nano-gold catalyst in methanol carbonylation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

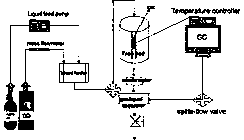

Method used

Image

Examples

Embodiment 1

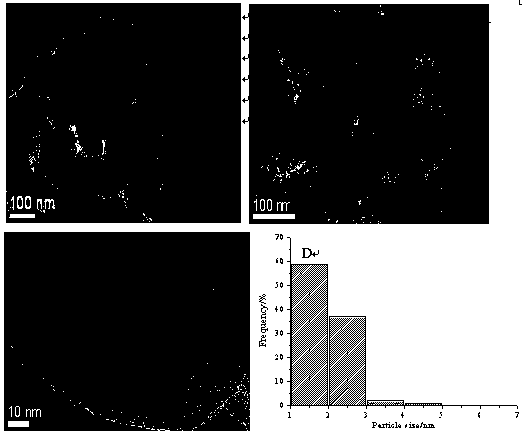

[0088] The preparation method of 0.1%Au / TS-1:

[0089] (1). ZSM-5 molecular sieves were synthesized by referring to published patent CN100364890C and TS-1 molecular sieves by referring to the method disclosed in published patent CN100457622A (2001) to synthesize ZSM-5 molecular sieves and TS-1 molecular sieve raw powders. Then roasting at 540 ° C for 4 hours to obtain TS-1 molecular sieve and ZSM-5 molecular sieve. (2). Ammonium exchange treatment: exchange the roasted molecular sieve with ammonium salt solution at a certain temperature. Then, washing, drying and roasting are carried out to obtain a hydrogen type molecular sieve catalyst. The ammonium salt is ammonium nitrate, the concentration is 0.6mol / L, the liquid-solid volume ratio of the catalyst and the ammonium salt solution is 5:1, the exchange temperature is 30°C, the exchange time is 1 hour, and the exchange times are 2 times. 110 DEG C of drying temperature, 12 hours of drying time, 540 DEG C of roasting temperat...

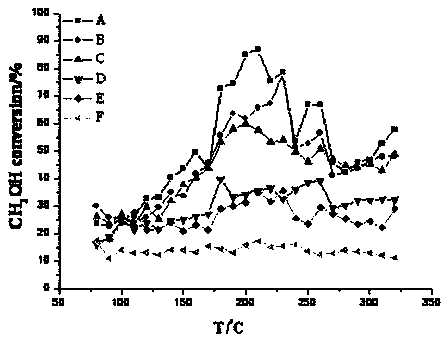

Embodiment 2

[0091] Repeat Example 1, but change the amount of chloroauric acid solution into 3.14ml and add water to 10ml, and the roasting temperature is 300°C. A supported gold catalyst 0.3%Au / TS-1 was obtained. Labeled: A-2.

Embodiment 3

[0093] Repeat embodiment 1, but change the degree of vacuum into-0.05MPa, and the consumption of chloroauric acid solution is changed into 10.46ml. The supported gold catalyst 1.0%Au / TS-1 was obtained. Labeled: A-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com