Ultrasonic-assisted methanol steam reforming hydrogen production reactor

A steam reforming and hydrogen production reactor technology, applied in hydrogen, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low reforming hydrogen production efficiency and low methanol conversion rate, and achieve reforming hydrogen production efficiency High, high methanol conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

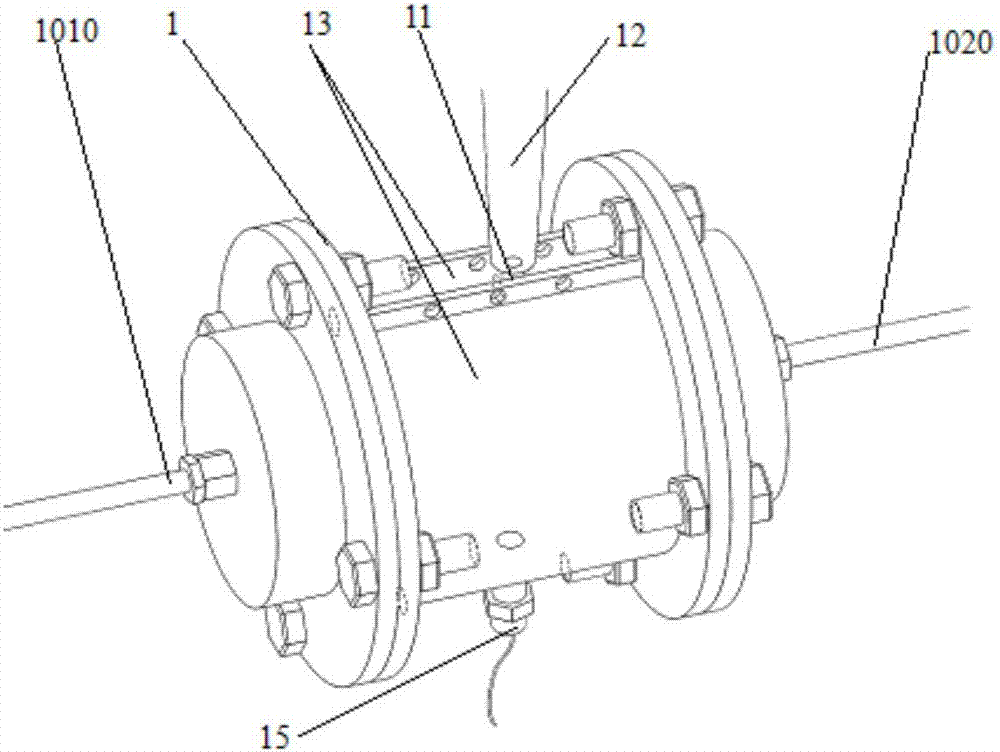

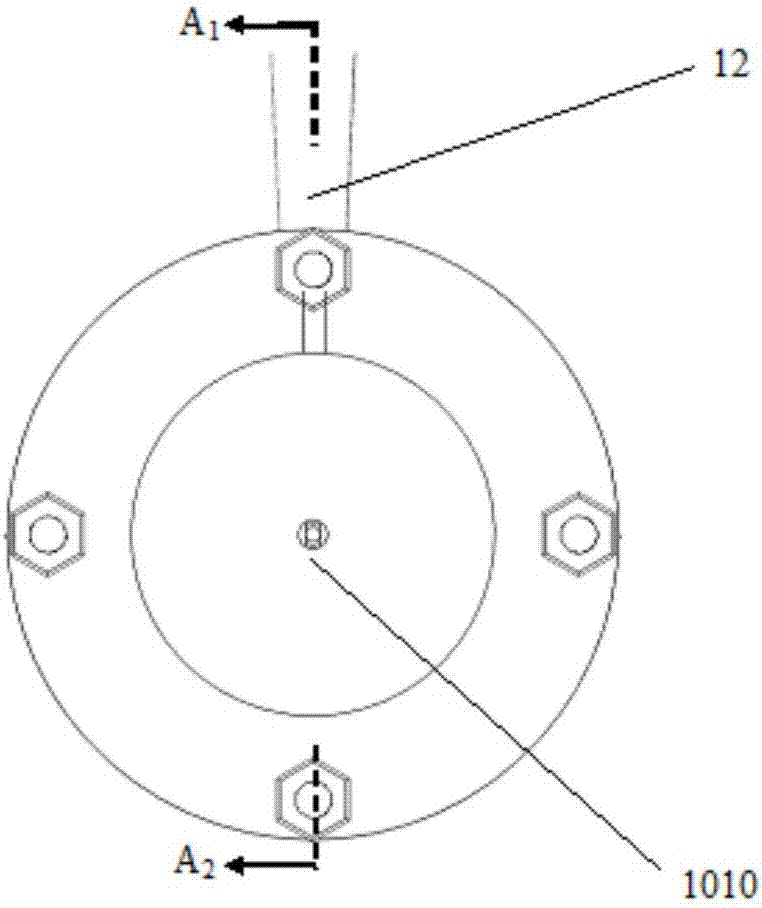

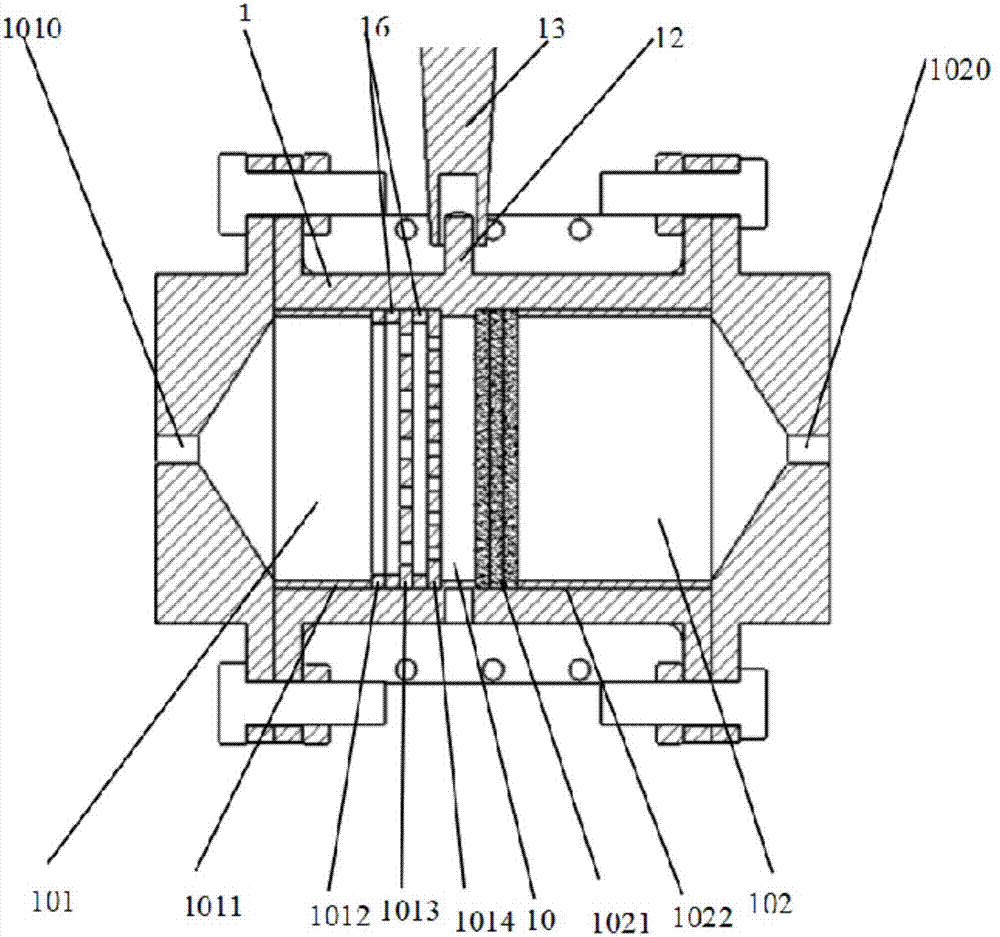

[0081] use Figure 1-4 The ultrasonic-assisted methanol steam reforming hydrogen production reactor produces hydrogen from methanol aqueous solution. specifically:

[0082] The volume of the reaction chamber of the ultrasonic-assisted methanol steam reforming hydrogen production reactor is 55.26cm 3 , the cross-sectional area of the reaction chamber is 12.56cm 2 . Metal carrier reaction plates 1021 with porosities of 70%, 80%, and 90% are stacked from left to right in the reforming section 102 (specifically, containing copper-based catalysts (Cu(NO 3 ) 2 , Zn(NO 3 ) 2 , Al(NO 3 ) 3 and Ar(NO 3 ) 4The mol ratio is 11:6:4:1) copper fiber sintered board); The strip-shaped channels in the first evaporation plate are arranged in parallel, and the width of the interval between the strip-shaped channels is the same as that of the strip-shaped channels. The width is equal, both are 0.3mm; the second evaporating plate and the third evaporating plate are provided with circu...

Embodiment 2

[0085] The ultrasonic-assisted methanol steam reforming hydrogen production reactor in this embodiment is similar to that in Embodiment 1, the difference is that in this embodiment, the porosity is 80% and stacked from left to right in the reforming zone 102 %, 80%, 80% of the metal carrier reaction plate (the catalyst in the metal carrier reaction plate is exactly the same as that in Example 1, and it is also a copper fiber sintered plate). All the other are the same as in Example 1.

[0086] After testing, the hydrogen production efficiency in this embodiment is 94%, and the methanol conversion rate is 96%.

Embodiment 3

[0088] The ultrasonic-assisted methanol steam reforming hydrogen production reactor in this example is similar to that in Example 1, the difference is that in this example, the outermost layer of the reactor body is not provided with a ring-shaped heating plate, but a Four identical long cylindrical heating rods at a temperature of 250° C. are arranged equidistantly instead, that is, four heating rods are arranged on the outer periphery of the reactor body, and the diameter of the heating rods is 6 mm and the length is 20 mm.

[0089] All the other are the same as in Example 1.

[0090] After testing, the hydrogen production efficiency in this embodiment is 90%, and the methanol conversion rate is 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com