Preparation method and application of efficient and stable molybdenum carbide catalyst for dimethyl ether steam reforming hydrogen production

A steam reforming and catalyst technology, applied in physical/chemical process catalysts, hydrolysis preparation, molecular sieve catalysts, etc., can solve the problems of exceeding fuel cell tolerance, high content of by-products, poor thermal stability, etc., and achieve the source of catalysts. Wide range, high hydrogen production efficiency and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

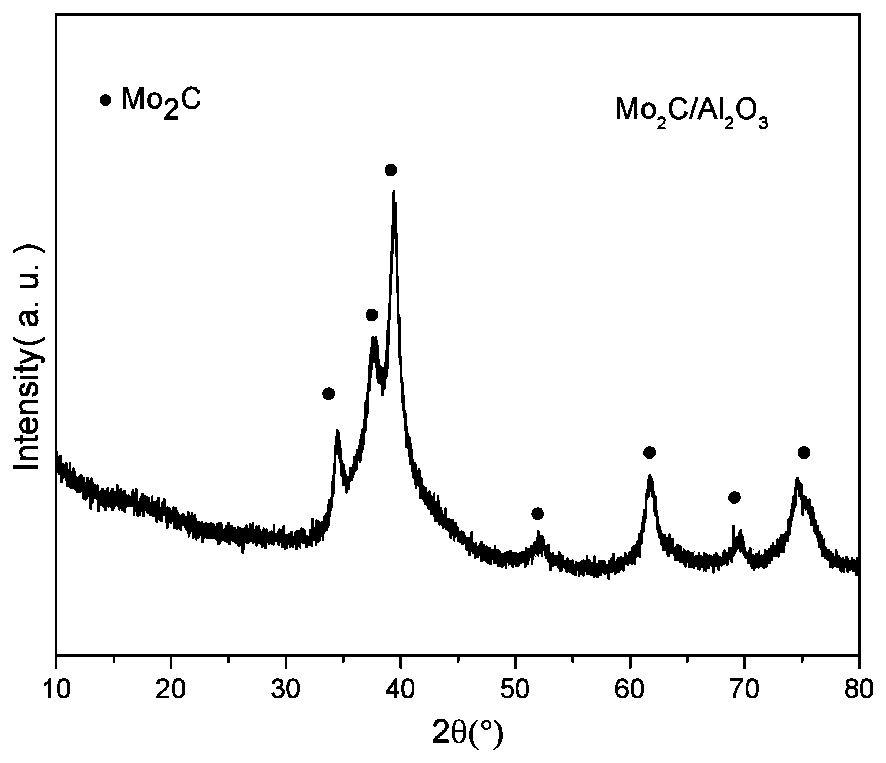

[0035] Catalyst preparation

[0036] Dissolve 4.88g of aluminum nitrate and 2.30g of ammonium paramolybdate in 50ml of deionized water respectively, and stir until fully dissolved. Slowly add the aluminum nitrate solution drop by drop to the ammonium paramolybdate solution, stir for 4 hours, then place the mixed solution in an 80°C oil bath and evaporate to dryness, and dry the evaporated solid in an oven at 120°C for 12 hours, then place In a muffle furnace, the temperature was raised to 500°C at a rate of 10°C / min, and then roasted at 500°C for 4 hours to obtain MoO 3 / Al 2 o 3 Precursor, resulting MoO 3 / Al 2 o 3 Molybdenum and Al in the precursor 2 o 3 The molar ratio is 1:0.5.

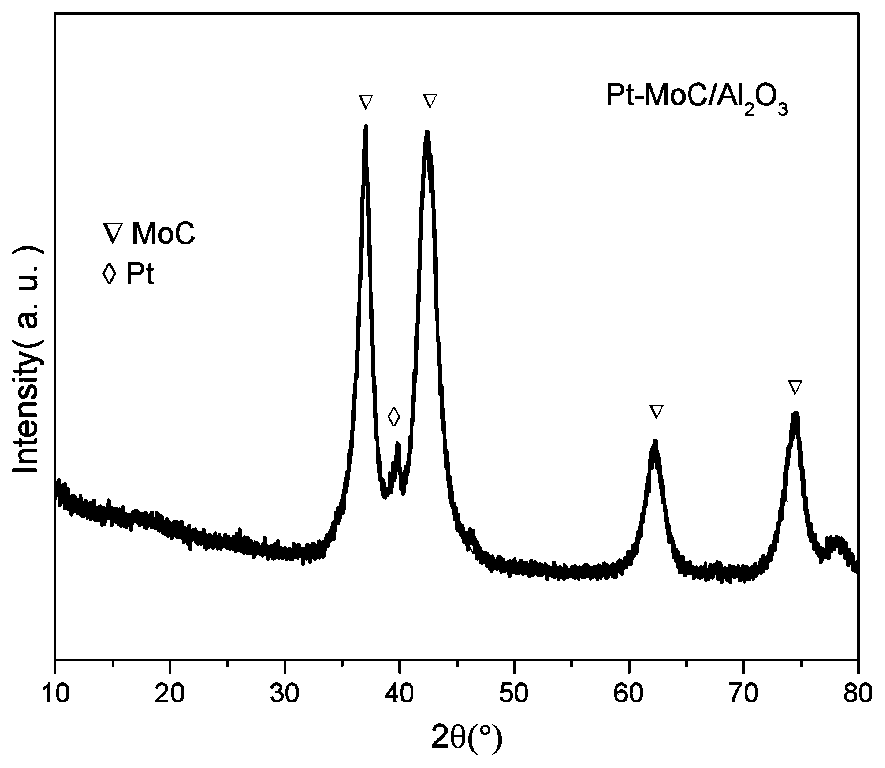

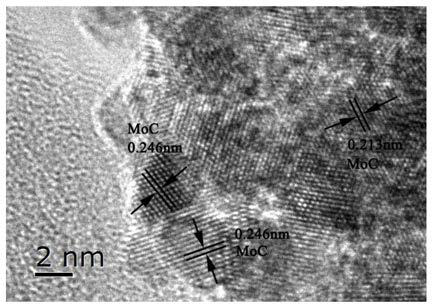

[0037] Dissolve 0.042g of chloroplatinic acid in water to form a solution, take 1gMoO 3 / Al 2 o 3 Precursor, chloroplatinic acid solution was impregnated in MoO by equal volume impregnation method 3 / Al 2 o 3 precursor, and dried in a vacuum oven at 60°C to obtain Pt-MoO 3 / Al 2 o ...

Embodiment 2

[0054] The specific implementation steps of this embodiment are basically the same as those of Embodiment 1, except that the chloroplatinic acid solution is replaced with a solution prepared by 0.3 g of copper nitrate, and the rest of the steps remain unchanged.

Embodiment 3

[0056] The specific implementation steps of this embodiment are basically the same as in embodiment 2, the only difference is that aluminum nitrate is replaced by nanometer γ-Al 2 o 3 , and the rest of the steps remain unchanged.

[0057] Specific steps are as follows:

[0058] 2. Dissolve 30g of ammonium paramolybdate in 50ml of deionized water and stir until fully dissolved. 1.325g nanometer γ-Al 2 o 3 Add water and stir well, and mix the two liquids, stir for 4 hours and evaporate to dryness in an 80°C oil bath, and dry the evaporated solid in an oven at 120°C for 12 hours, and then place it in a muffle furnace to 10°C / min heating rate to 500°C, and calcination at 500°C for 4 hours to obtain MoO 3 / γ-Al 2 o 3 Precursor.

[0059] Dissolve copper nitrate in water, impregnate copper nitrate solution in MoO by equal volume impregnation method 3 / γ-Al 2 o 3 on the precursor, and dried in an oven to obtain Cu-MoO 3 / γ-Al 2 o 3 .

[0060] Cu-MoO 3 / γ-Al 2 o 3 Pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com