Titanium alloy methanol-water reformer and hydrogen production device

A technology for reforming hydrogen and titanium alloys, which is applied in the production of hydrogen, non-metallic elements, hydrogen/synthesis gas, etc. It can solve the problems of low strength, heavy weight, and easy corrosion of the reformer, so as to achieve the goal of not being easily corroded, High combustion efficiency and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

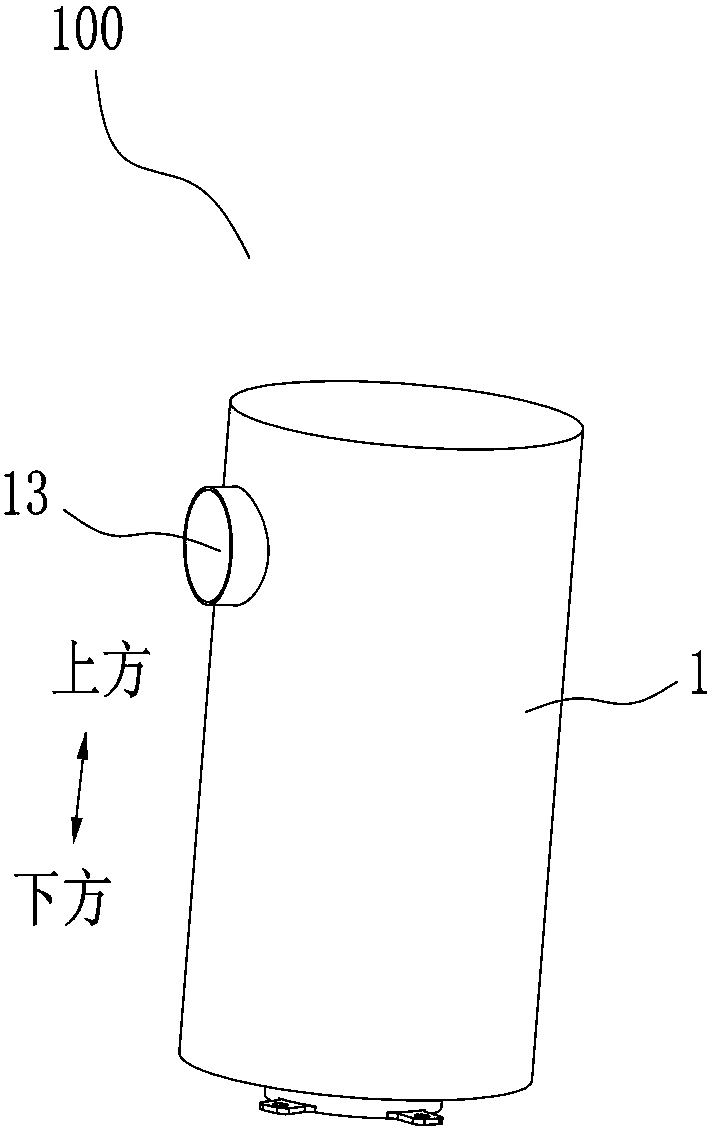

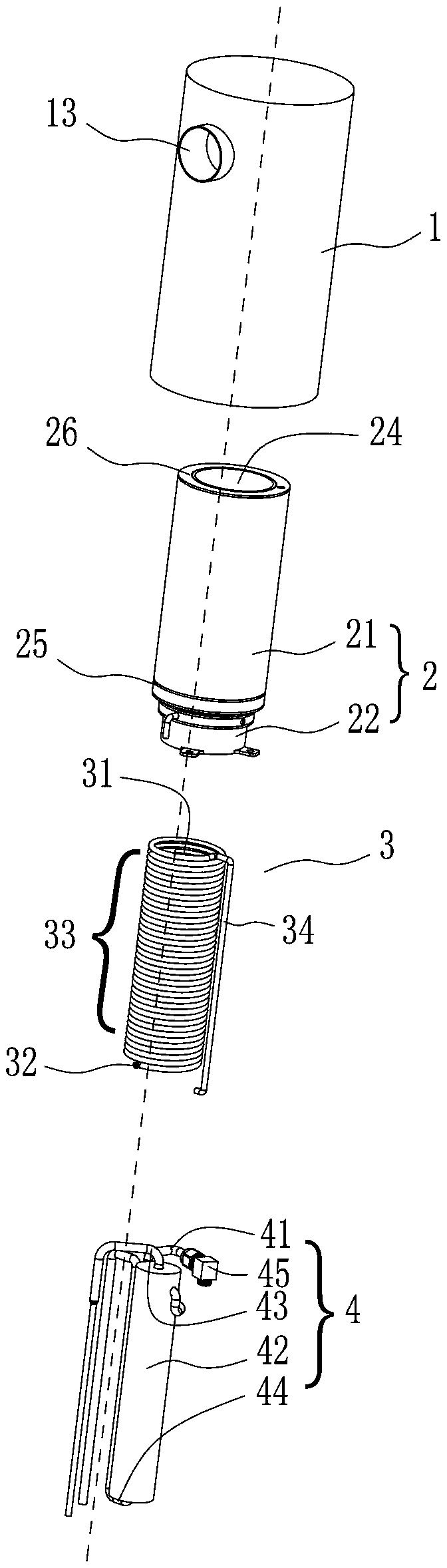

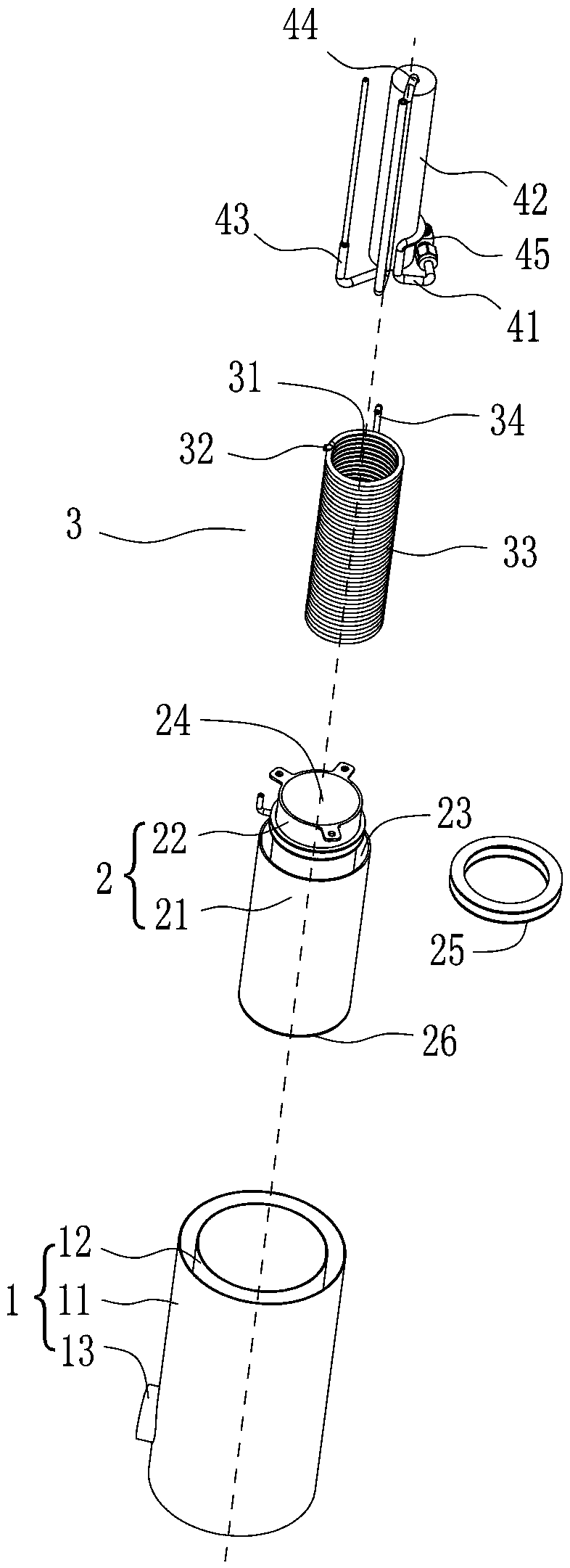

[0025] like Figure 1-Figure 4 As shown, a titanium alloy water methanol reformer 100 includes a titanium alloy shell 1, a titanium alloy reforming cavity 2, a titanium alloy vaporization coil 3, a titanium alloy purification device 4 and a combustion chamber 5; the titanium alloy The reforming cavity 2 is installed in the titanium alloy shell 1, and the titanium alloy reforming cavity 2 includes a cylindrical outer cavity wall 21 and a cylindrical inner cavity wall 22, and the cylindrical inner cavity wall 22 is installed on the Inside the cylindrical outer cavity wall 21, the chamber between the cylindrical outer cavity wall 21 and the cylindrical inner cavity wall 22 is a methanol water reforming hydrogen production chamber 23, and the cylindrical inner cavity wall 22 There is a cylindrical through hole 24 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com