Two-stage hydrogenation cracking method for producing industrial chemicals

A technology of hydrocracking and chemical raw materials, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, etc., which can solve the problems of limited quantity of processing raw materials, production of chemical raw materials, complicated process, etc., and reduce investment cost and operating cost , the content of aroma potential is increased, and the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

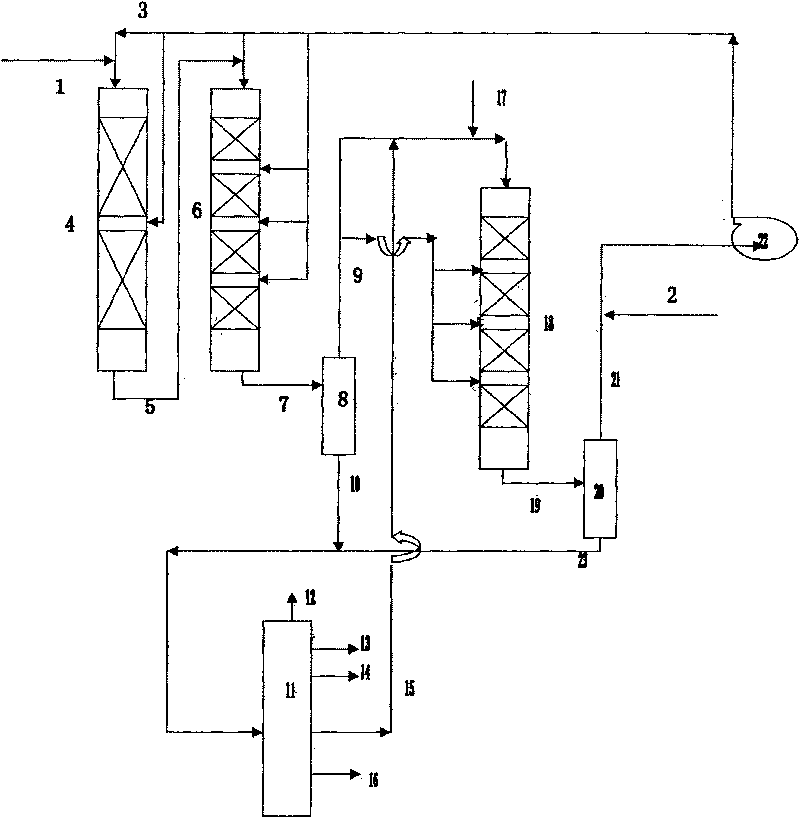

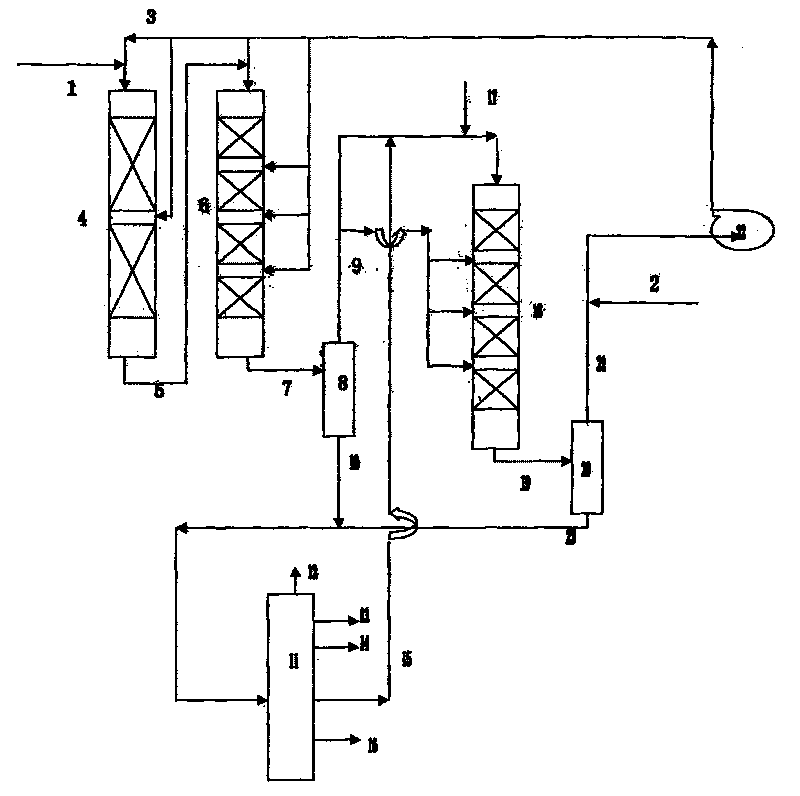

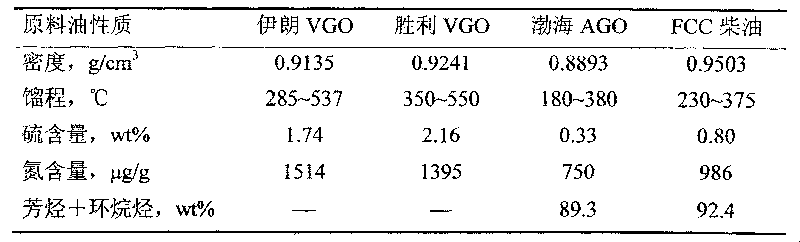

[0025] figure 1 Shown is a process flow diagram of the present invention, wherein the first section adopts a series flow process, and the first section and the second section share a fractionation tower. As figure 1As shown, the preheated feed oil 1 is mixed with circulating hydrogen 3 and then enters the hydrocracking pretreatment reactor 4, and the obtained hydrogenation effluent 5 is mixed with cold hydrogen and then continues to enter the hydrocracking reactor 6 to obtain hydrocracking The effluent 7 and the hydrocracking effluent 7 are separated in the separator 8 to obtain a hydrogen-rich gas 9 and a liquid stream 10, and the hydrogen-rich gas 9 directly enters the second-stage hydrocracking reactor 18, and the separated liquid stream 10 and the second-stage processing The liquid stream 23 obtained by hydrocracking is mixed into the fractionation tower 11, and fractionation is carried out in the fractionation tower 11 to obtain gas products 12, light naphtha 13, heavy na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com