Wax oil processing method

A processing method and wax oil technology, applied in the petroleum industry, hydrotreating process, hydrocarbon oil treatment, etc., can solve the problems of difficult balance between selectivity and different product quality, product quality decline, heavy naphtha fraction aromatic potential reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

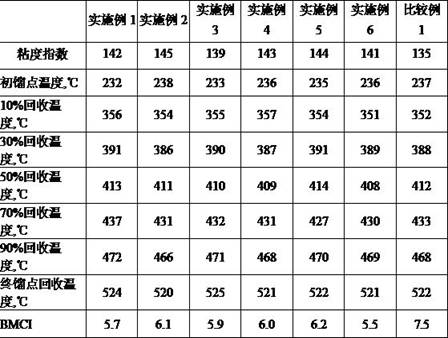

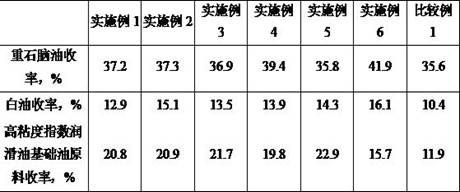

Examples

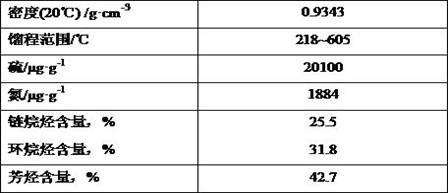

Embodiment 1

[0036] (1) At a pressure of 0.5MPa, an adsorption temperature of 50°C, and a liquid phase volumetric space velocity of 2h -1 Under the conditions of , the saturated and unsaturated components were separated by a switched fixed bed separation device, and iron-modified 4A-type molecular sieve was used as the adsorbent, in which the iron content was 5.0%, and dodecane was used as the analytical solvent. The wax oil fraction enters the fixed bed 1, and the unsaturated components are selectively adsorbed in the fixed bed 1. The effluent 1 is the wax oil fraction rich in saturated components. When the unsaturated component content in the effluent 1 is ≮ 2% At the same time, the wax oil fraction is switched into the fixed bed 2 for selective adsorption of unsaturated components, and the effluent 2 is wax rich in saturated components. Oil fraction, when the content of unsaturated components in effluent 2 is ≮ 2%, the feed of fixed bed 2 is changed from wax oil fraction to desorption s...

Embodiment 2

[0041] (1) At normal pressure, the adsorption temperature is 100°C, and the liquid volume space velocity is 3h -1 Under the conditions of , the saturated and unsaturated components were separated by a switched fixed bed separation device, manganese-modified alumina was used as the adsorbent, the manganese content was 3.5%, and ethylene glycol monomethyl ether was used as the analytical solvent. The wax oil fraction enters the fixed bed 1, and the unsaturated components are selectively adsorbed in the fixed bed 1. The effluent 1 is a wax oil fraction rich in saturated components. When the unsaturated component content in the effluent 1 is ≮5% At the same time, the wax oil fraction is switched into the fixed bed 2 for selective adsorption of unsaturated components, and the effluent 2 is wax rich in saturated components. Oil fraction, when the content of unsaturated components in the effluent 2 is ≮ 5%, the feed of the fixed bed 2 is replaced by the wax oil fraction for the desor...

Embodiment 3

[0046] (1) At normal pressure, the adsorption temperature is 100°C, and the liquid volume space velocity is 3h -1 Under the condition of , the saturated and unsaturated components were separated by switching the fixed bed separation device, nickel-modified alumina was used as the adsorbent, and the nickel content was 4%, and ethylene glycol monomethyl ether was used as the analytical solvent. The wax oil fraction enters the fixed bed 1, and the unsaturated components are selectively adsorbed in the fixed bed 1. The effluent 1 is a wax oil fraction rich in saturated components. When the unsaturated component content in the effluent 1 is ≮ 10% At the same time, the wax oil fraction is switched into the fixed bed 2 for selective adsorption of unsaturated components, and the effluent 2 is wax rich in saturated components. Oil fraction, when the content of unsaturated components in effluent 2 is ≮ 10%, the feed of fixed bed 2 is changed from wax oil fraction to desorption solvent f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com