Hydro-cracking method for producing middle distillate and tail oil rich in chain alkane

A middle distillate and hydrocracking technology, which is applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problem of difficult to balance the production of high-quality middle distillate oil and high-quality tail oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

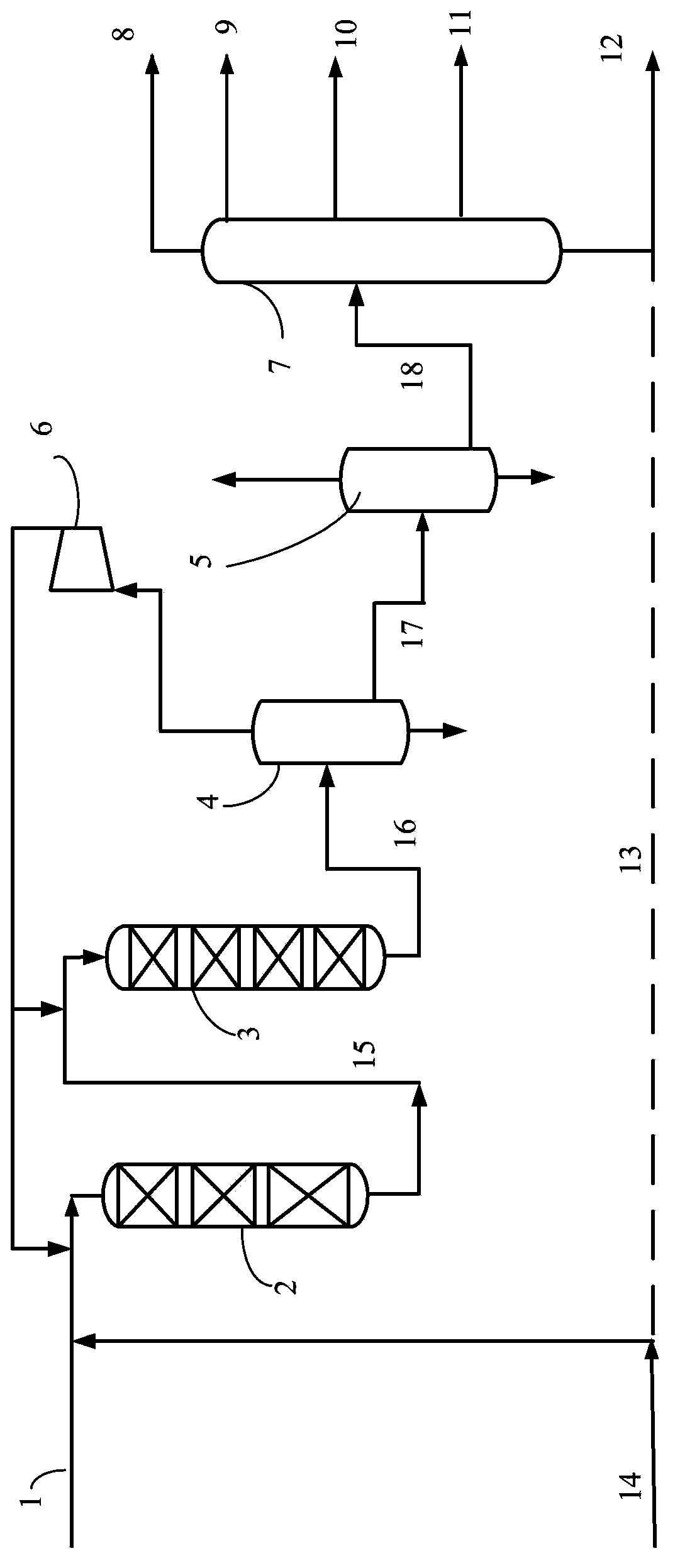

Method used

Image

Examples

Embodiment 1

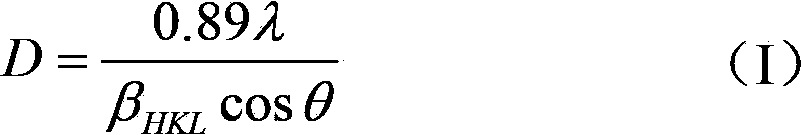

[0059] Take C powder (taken from Changling Catalyst Factory, which is a kind of pseudo-boehmite), 130.4g, silica-alumina powder (taken from Changling Catalyst Factory), silicon oxide content 38.2%) 45.2g, HY type molecular sieve (taken from From Changling Catalyst Factory, sodium oxide 0.19%) 28.5g, several kinds of powders were combined and mixed evenly to obtain dry powder. Add 7.5mL of concentrated nitric acid (analytical pure) into 162mL of ionized water, and mix well to obtain an acid solution. The acid liquid and the dry powder were mixed and stirred uniformly to obtain a raw material mixture for extrusion, and the temperature of the deionized water was such that the temperature of the obtained raw material mixture was 65°C. The obtained mixture with a temperature of 65° C. was fed into an extruder, and the mixture was extruded into a trilobal strip with a circumscribed circle diameter of 1.6 mm. The temperature of the extrudate at the exit of the extruder was 88° C. Th...

Embodiment 2

[0062] Take 152.1g of D powder (taken from Changling Catalyst Factory, which is a kind of pseudo-boehmite), 48.1g of HY molecular sieve (taken from Changling Catalyst Factory, sodium oxide 0.38%), and add 4g of Sinensis powder to dry mix evenly. to obtain dry powder. Add 6 mL of concentrated nitric acid and 5 g of urea into a beaker filled with 146 mL of deionized water, and mix well to obtain an acid solution. Mix the acid solution and the dry powder, and stir evenly, extrude into a butterfly bar with a circumscribed circle diameter of 1.4 mm, and the extrudate temperature at the outlet of the extruder is 80°C. The extrudates were dried at 120°C for 5 hours. Then, under an air atmosphere, at a temperature of 610° C., calcined for 3 hours and cooled down to room temperature to obtain a carrier, which is designated as carrier B1. The most probable pore size and pore size concentration of the carrier are listed in Table 1.

Embodiment 3

[0069] Using the method provided by the present invention, when the reaction pressure is 14.0MPa, the reaction temperature of the hydrofinishing reactor is 380°C, the reaction temperature of the hydrocracking reactor is 393°C, and the total volume space velocity is 0.68h -1 Under the reaction conditions, with the hydrocracking method that the present invention provides, adopt raw material A to carry out test. The raw material A passes through the hydrogenation protection catalyst, the hydrofinishing catalyst and the hydrocracking catalyst A in sequence, and the obtained tail oil fraction is not recycled.

[0070]The test results are shown in Table 3. Based on 100% fresh raw materials, the yields of jet fuel and diesel are 22.85% and 33.45%, respectively, the total yield of middle distillates exceeds 55%, and the yield of tail oil is 20.24%. The paraffin content of the obtained hydrocracking tail oil reaches 68.9%, the sum of paraffin and monocyclic cycloalkane is 89.2%, close ...

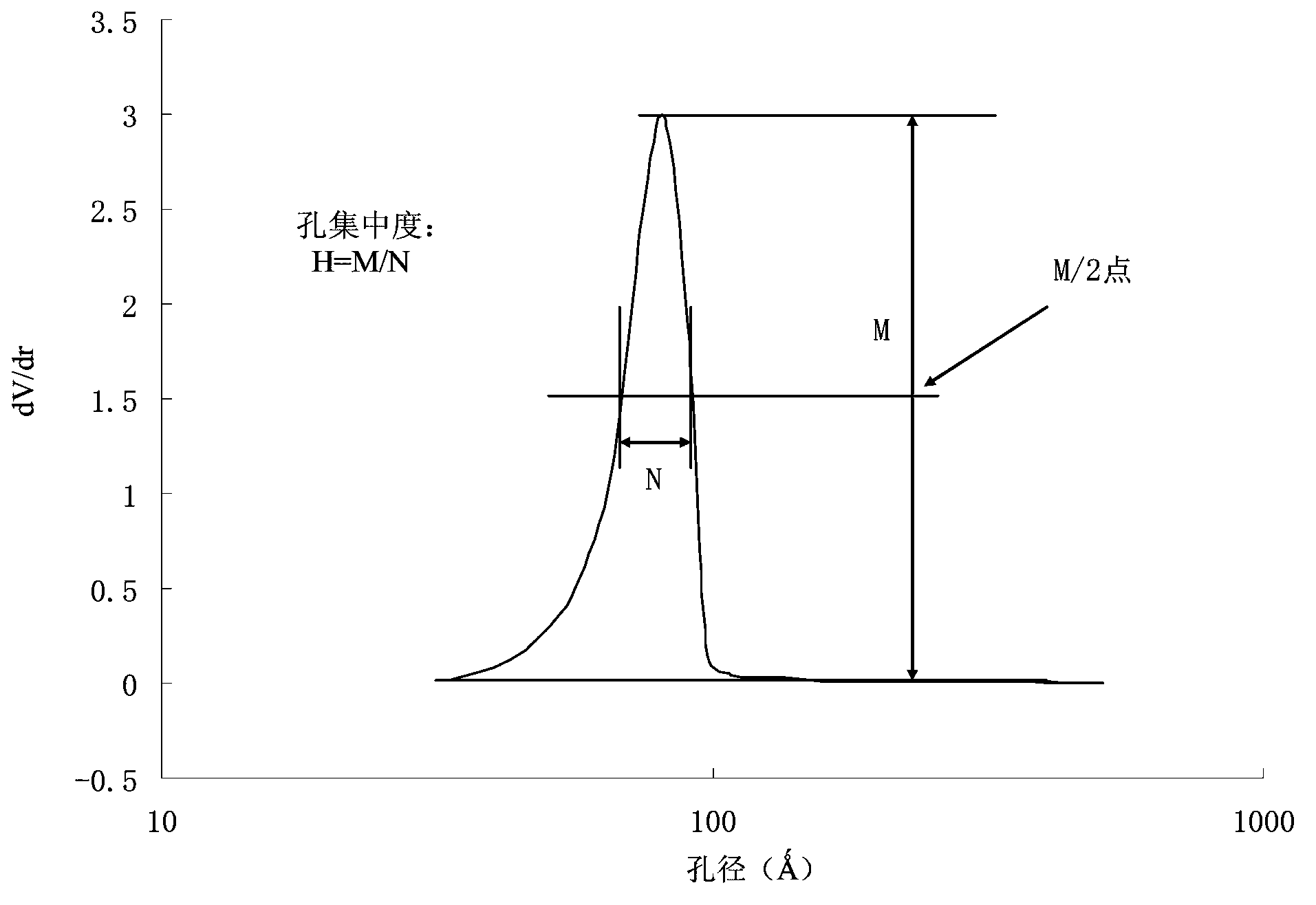

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com