Hydrocracking method for producing chemical industry raw materials from diesel oil distillate

A technology of hydrocracking and chemical raw materials, which is applied in the fields of hydrocarbon oil cracking, petroleum industry, hydroprocessing technology, etc., and can solve the problems of undisclosed production of chemical raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] Preferably, the preparation method of the hydrated alumina composition containing Y-type molecular sieve comprises: mixing the components in a raw material composition to obtain the hydrated alumina composition, the raw material composition containing hydrated alumina Aluminum wet gels, Y-type molecular sieve molecular sieves and compounds having at least two proton acceptor sites, the i value of said hydrated alumina wet gels is not less than 50%,

[0063] The i value is determined by the following method: 10g of alumina hydrate wet gel is dried in an air atmosphere at 120°C for 240 minutes, and the mass of the dried sample is recorded as w 2 , using formula II to calculate the value of i,

[0064]

[0065] Preferably, the i value of the hydrated alumina wet gel is not higher than 95%, preferably not higher than 90%, more preferably not higher than 85%, further preferably not higher than 82%; the hydration The i value of the alumina wet gel is not less than 55%, pr...

specific Embodiment approach 1

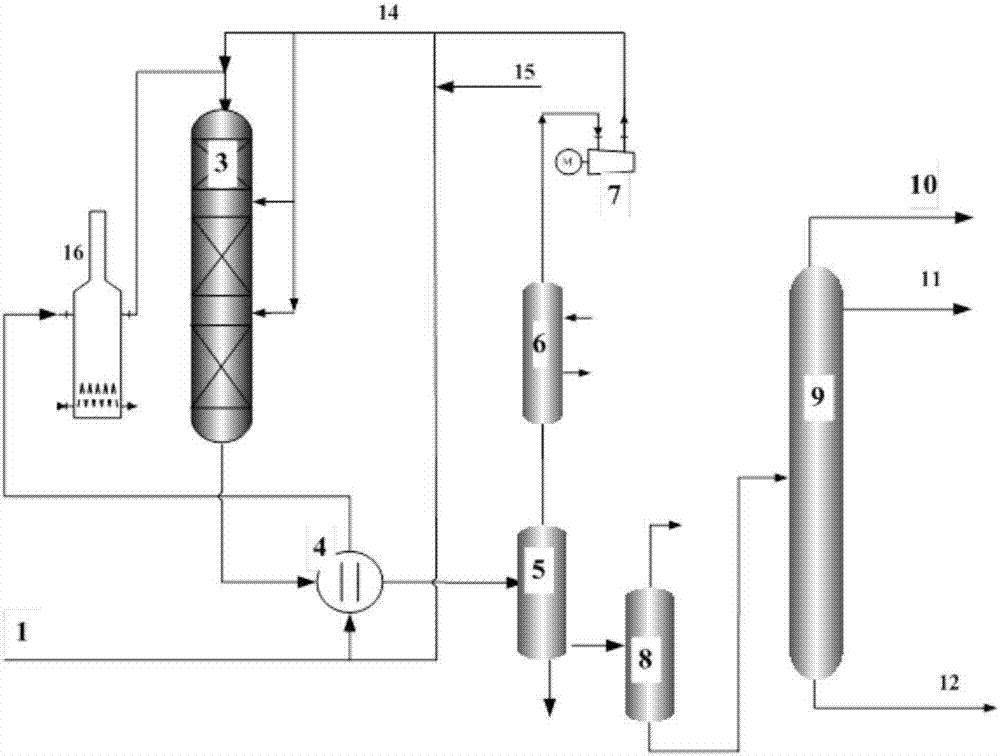

[0096] Embodiment 1: The aforementioned hydrocracking method for producing chemical raw materials from diesel fractions of the present invention is based on figure 1 The process flow shown is carried out, specifically:

[0097] The raw oil 1, circulating hydrogen 14, and supplementary hydrogen 15 are mixed and then heated by the heat exchanger 4 and the heating furnace 16 to carry out a contact reaction with the hydrocracking catalyst in the hydrocracking unit 3, and the contacted reaction effluent enters the high-pressure separator In 5, the hydrogen-rich gas, liquid phase components and acidic water are separated; the hydrogen-rich gas enters the circulating hydrogen desulfurization system 6, and after removing hydrogen sulfide, enters the circulating hydrogen compressor 7 to circulate to obtain the circulating hydrogen 14; The components enter the low-pressure separator 8 to separate low-fraction gas and low-fraction oil, and the low-fraction oil enters the fractionation sy...

specific Embodiment approach 2

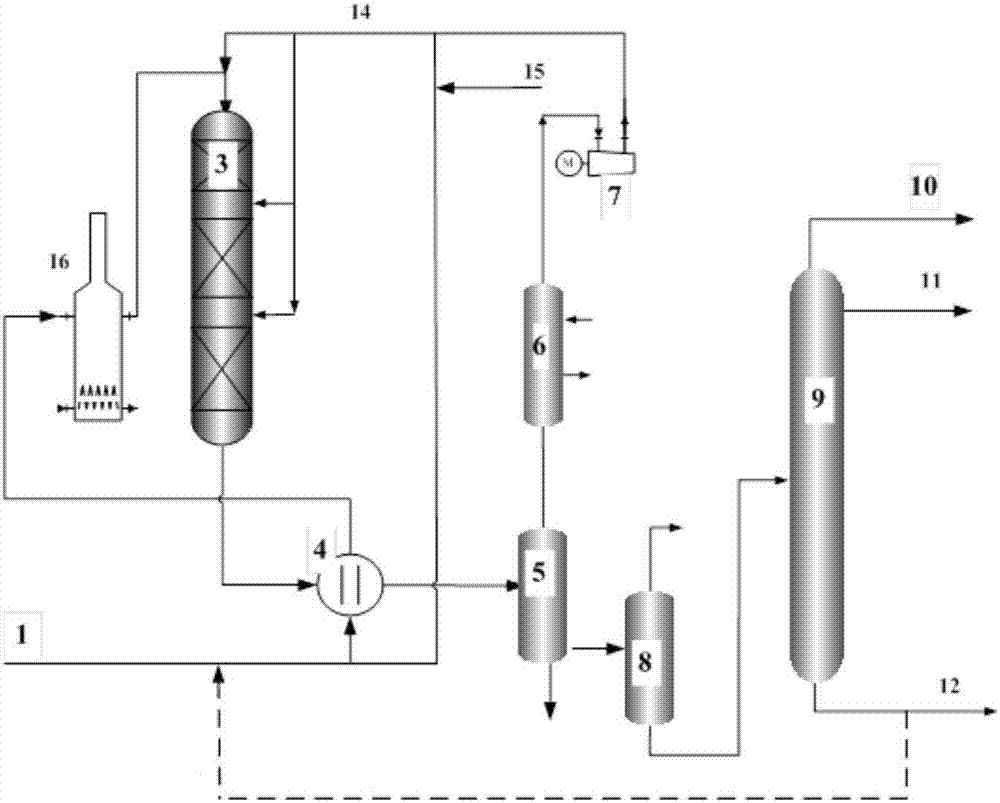

[0098] Embodiment 2: The aforementioned hydrocracking method for producing chemical raw materials from diesel fractions of the present invention is based on figure 2 The process flow shown is carried out, figure 2 and figure 1 The difference is that part of the tail oil fraction 12 is recycled back to the hydrocracking unit for reaction, specifically:

[0099] The raw oil 1, circulating hydrogen 14, and supplementary hydrogen 15 are mixed and then heated by the heat exchanger 4 and the heating furnace 16 to carry out a contact reaction with the hydrocracking catalyst in the hydrocracking unit 3, and the contacted reaction effluent enters the high-pressure separator In 5, the hydrogen-rich gas, liquid phase components and acidic water are separated; the hydrogen-rich gas enters the circulating hydrogen desulfurization system 6, and after removing hydrogen sulfide, enters the circulating hydrogen compressor 7 to circulate to obtain the circulating hydrogen 14; The components...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Most probable aperture | aaaaa | aaaaa |

| Most probable aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com