A cracking method aimed at producing more light olefins and light aromatics from feedstock oil containing many naphthenic rings

A technology of low-carbon olefins and polycyclic aromatic hydrocarbons, applied in the direction of hydrocarbon cracking, cracking, catalytic cracking, etc., can solve the problems of low yield of propylene and butene, low concentration of low-carbon olefins, low BTX concentration, etc. Achieve high propylene and butene yield, reduce olefin content, and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

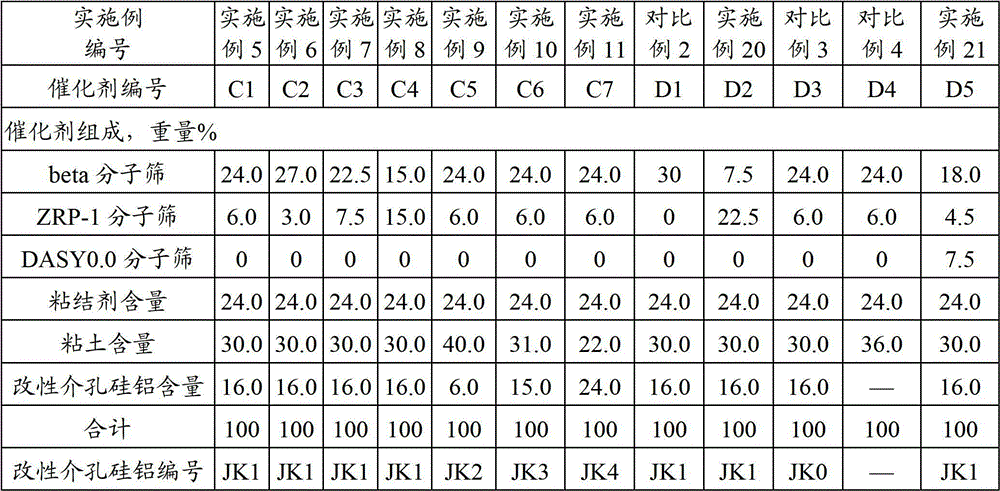

Examples

preparation example Construction

[0031] The non-ion-exchanged mesoporous silica-alumina material in the present invention can be various mesoporous silica-alumina materials without any ion exchange commonly used in the art. The non-ion-exchanged mesoporous silica-alumina material can be prepared according to conventional methods, and the preparation method can include, for example, neutralizing the aluminum source and alkali solution at room temperature to 85°C to form a gel, and the final pH of the gel is 7 -11; then follow SiO 2 :Al 2 o 3 =1: The weight ratio of (0.6-9) is added to the silicon source, aged at room temperature to 90°C for 1-10 hours, and then filtered. In the present invention, the silica-alumina precipitate obtained after the filtration can be directly used as the non-ion-exchanged mesoporous silica-alumina material, or it can be used as the ion-free mesoporous silica-alumina material after being dried and / or calcined. Exchanged mesoporous silica-alumina materials. The aluminum source m...

Embodiment 1

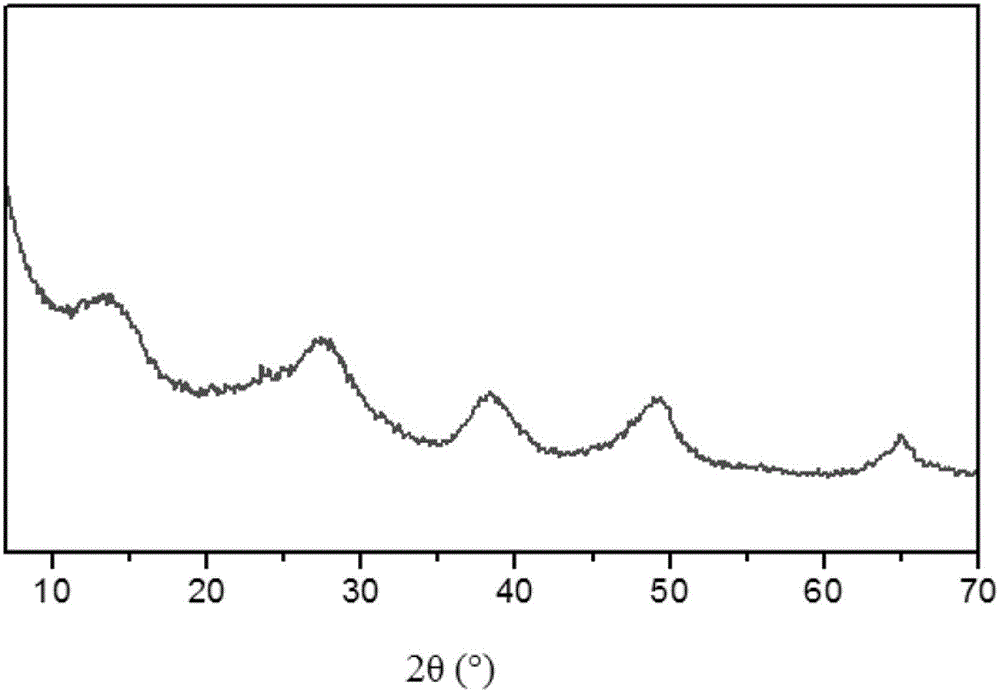

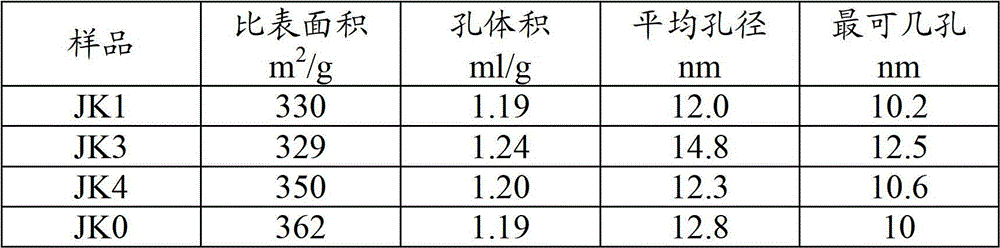

[0046] Preparation of Modified Mesoporous Si-Al Materials

[0047] The concentration is 90g Al 2 o 3 / L Al 2 (SO 4 ) 3 solution and concentration is 102g Al 2 o 3 / L, NaAlO with a caustic ratio of 1.7 2 The solution is fed into the continuous gelling kettle in parallel, the effective volume of the gelling kettle is 200ml, Al 2 (SO 4 ) 3 The flow rate of the solution is 20ml / min, adjust NaAlO 2 The flow rate keeps the gelling pH value at 9, and the gelling temperature is 55°C; collect 300ml of the gelled slurry, and add 127ml of SiO with a content of 60g under stirring conditions 2 / L water glass (modulus 3.1) aqueous solution, heated to 80°C for aging for 4 hours, and then filtered.

[0048] Mix the silica-aluminum precipitate obtained after filtration with water at a weight ratio of 1:12 for beating, and then add hydrochloric acid solution according to the weight ratio of the silica-alumina precipitate (dry basis): HCl=1:0.14 for beating to obtain In the slurry, t...

Embodiment 2

[0050] According to the method of implementation 1 in CN1854258A, the mesoporous silicon-aluminum material SH-SA-1 is obtained, and the present invention is designated as JK2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com