Flexible single-stage hydrocracking process

A technology for hydrocracking and hydroisomerization cracking, which can be used in hydrotreating process, petroleum industry, hydrocarbon oil treatment products, etc., and can solve problems such as poor operation flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

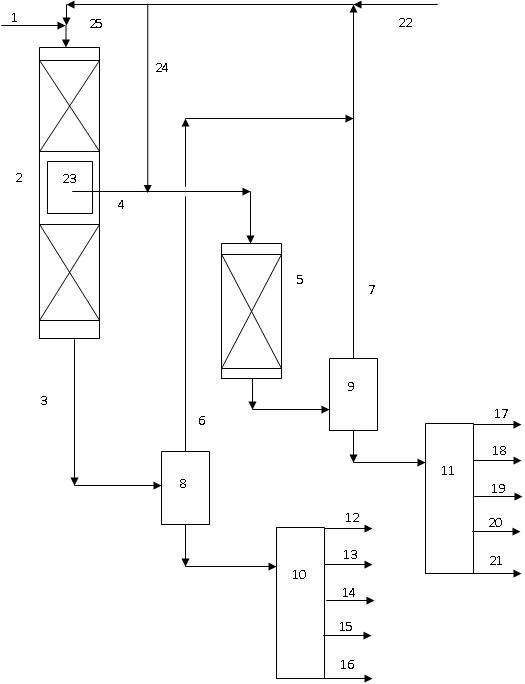

Image

Examples

Embodiment 1-3

[0042]Protective agents FZC-100, FZC-105 and FZC106 are hydrogenation protective agents developed and produced by Sinopec Fushun Petrochemical Research Institute; catalyst FF-56 is developed and produced by Sinopec Fushun Petrochemical Research Institute Hydrotreating catalyst; Catalyst FC-28 is a single-stage hydrocracking catalyst developed and produced by Sinopec Fushun Petrochemical Research Institute, containing Y-type molecular sieve; Catalyst ZHC-02 is Sinopec Fushun Petrochemical The single-stage hydrocracking catalyst developed and produced by the research institute does not contain molecular sieves; the catalyst FC-14 is a single-stage hydroisomerization cracking catalyst developed and produced by Sinopec Fushun Petrochemical Research Institute, which contains β-type molecular sieves.

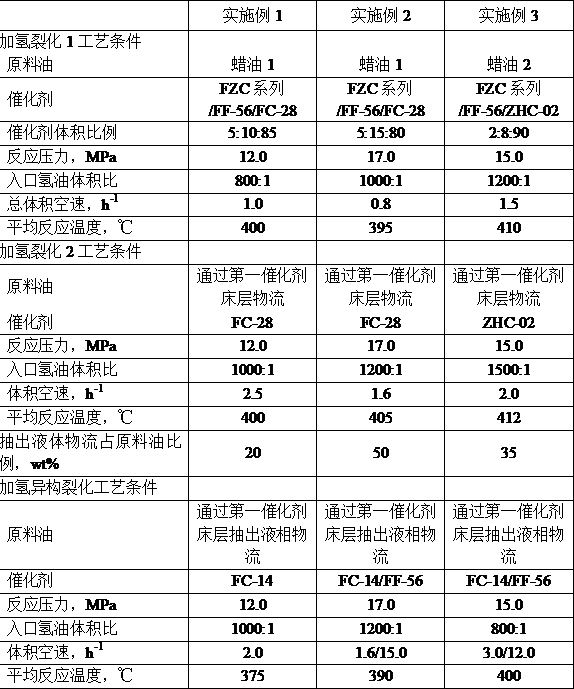

[0043] Table 1 Main properties of wax oil feedstock

[0044]

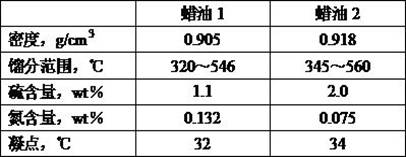

[0045] Table 2 process conditions

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com