Method for preparing aluminium-containing MCM-41 molecular sieve

A technology of MCM-41 and molecular sieve, applied in the field of preparation of MCM-41 molecular sieve, can solve problems such as disadvantages, limited application scope, and cost reduction, and achieve high thermal stability and hydrothermal stability, low raw material cost, and hydrothermal stability. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

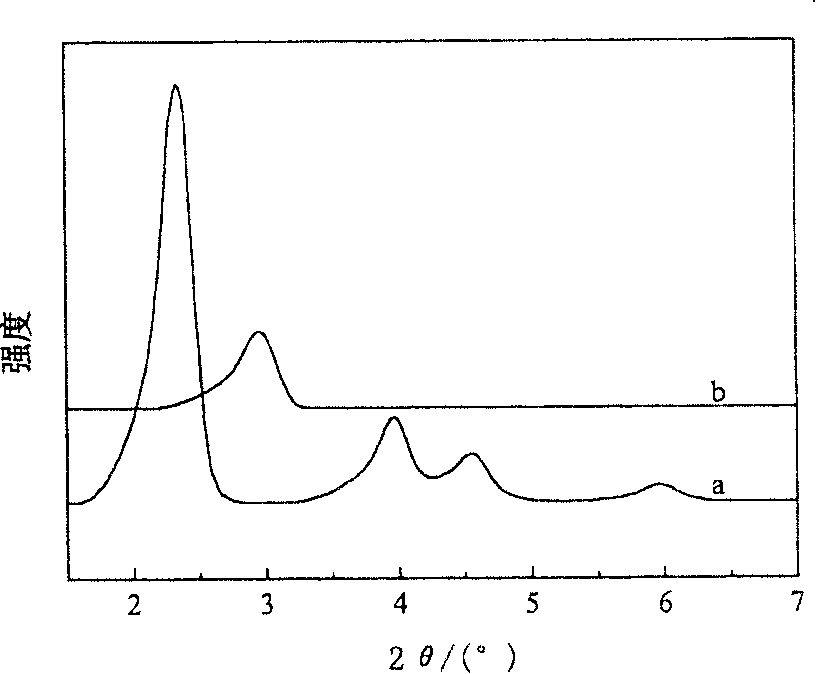

Embodiment 1

[0025] Dissolve 14.6 grams of CTMAB (content 99%) in 110 milliliters of distilled water, and stir in a water bath at 20°C for 5 hours to form a concentration of 0.13 g / ml of CTMAB solution, then according to the proportion: 100SiO 2 :Al 2 o 3 : 4000H 2 O: 30Na 2 O, while stirring, add water glass (SiO 2 : 5.243 mol / L, Na 2 O: 1.552 mol / L) 38.2 milliliters, and 0.267 grams of pseudo-boehmite (Al 2 o 3 mass content 76.4%), stirred in a water bath at 40°C for 2 hours and mixed evenly to generate a white gel, which was washed with dilute H 2 SO 4 (2 mol / liter) to adjust the pH value to 9-9.5, and the molar composition of the final crystallization reaction system is: 100SiO 2 :20CTMAB:Al 2 o 3 : 4000H 2 O: 30Na 2 O. Continue to stir for 0.5 hours, then transfer to a stainless steel reaction kettle, age at room temperature for 4 hours, crystallize at 120°C for 24 hours, cool to room temperature, filter the product, wash, and dry at 100°C for 12 hours. Roasting at 550° ...

Embodiment 2

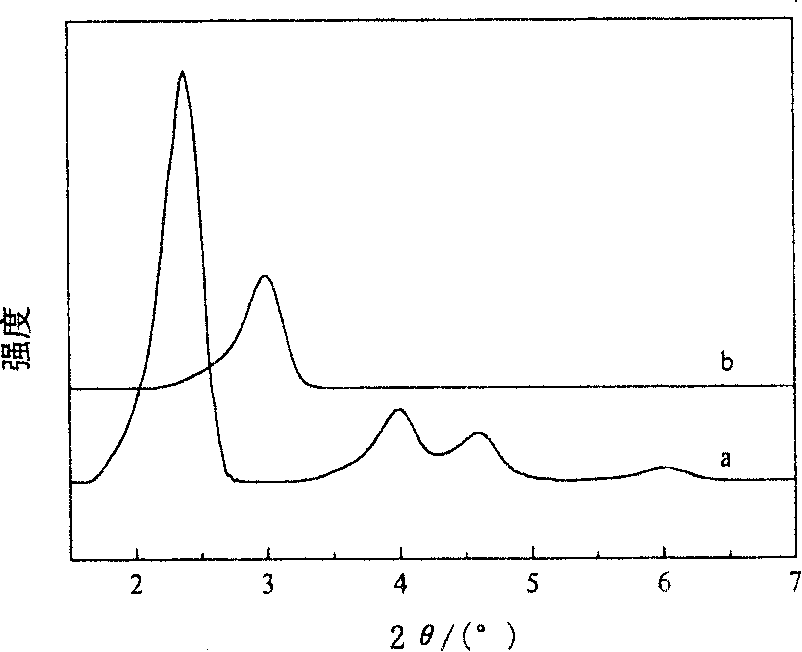

[0028] Dissolve 7.3 grams of CTMAB (content 99%) in 55 milliliters of distilled water, and stir in a water bath at 40°C for 0.5 hour to form a concentration of 0.13 g / ml of CTMAB solution, then according to the proportion: 50SiO 2 :Al 2 o 3 : 1000H 2 O: 15Na 2 O, while stirring, add water glass (SiO2 : 5.243 mol / L, Na 2 O: 1.552 mol / L) 38.2 milliliters, and 0.534 grams of pseudo-boehmite (Al 2 o 3 mass content 76.4%). Stir in a water bath at 40°C for 2 hours and mix evenly to form a white gel. 2 SO 4 (2 mol / liter) to adjust the pH value to about 10, and the molar composition of the final crystallization reaction system is: 50SiO 2 :5CTMAB:Al 2 o 3 : 1000H 2 O: 15Na 2 O. Continue to stir for 0.5 hours, then transfer to a stainless steel reactor, age at room temperature for 4 hours, crystallize at 100°C for 72 hours, cool to room temperature, filter the product, wash, and dry at 100°C for 12 hours. Roasting at 550° C. for 6 hours to remove the template agent, obtai...

Embodiment 3

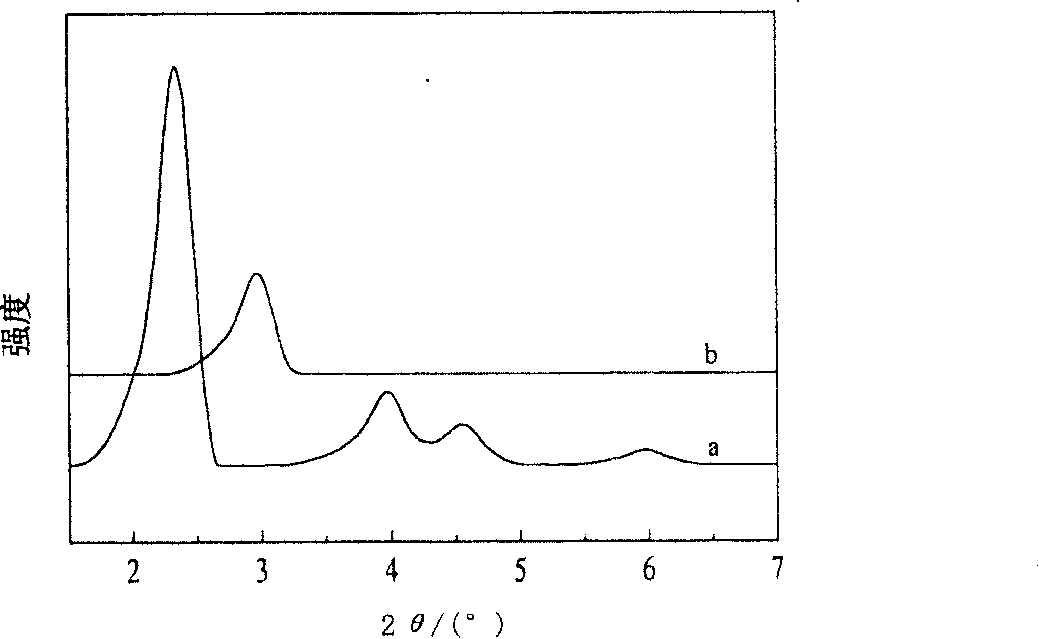

[0031] Dissolve 21.9 grams of CTMAB (content 99%) in 193 milliliters of distilled water, and stir in a water bath at 40°C for 0.5 hour to form a concentration of 0.11 g / ml of CTMAB solution, then according to the proportion: 25SiO 2 : Al 2 o 3 : 1700H 2 O: 30Na 2 O, while stirring, add water glass (SiO 2 : 5.243 mol / L, Na 2 O: 1.552 mol / L) 38.2 milliliters, and 1.068 grams of pseudo-boehmite (Al 2 o 3 mass content 76.4%). Stir in a water bath at 40°C for 2 hours and mix evenly to form a white gel. 2 SO 4 (2 mol / liter) to adjust the pH value to 10.5, the molar composition of the final crystallization reaction system is: 25SiO 2 :7.5CTMAB:Al 2 o 3 : 1700H 2 O: 7.5Na 2 O. Continue to stir for 0.5 hours, then transfer to a stainless steel reaction kettle, age at room temperature for 4 hours, crystallize at 120°C for 48 hours, cool to room temperature, filter the product, wash, and dry at 100°C for 12 hours. Roasting at 550° C. for 6 hours to remove the template agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com