Hydrocarbon catalytic cracking catalyst and preparation method thereof

A catalytic cracking and catalyst technology, used in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of equipment corrosion environment and pollution, and achieve the effect of increasing solid content, avoiding environmental pollution and low curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

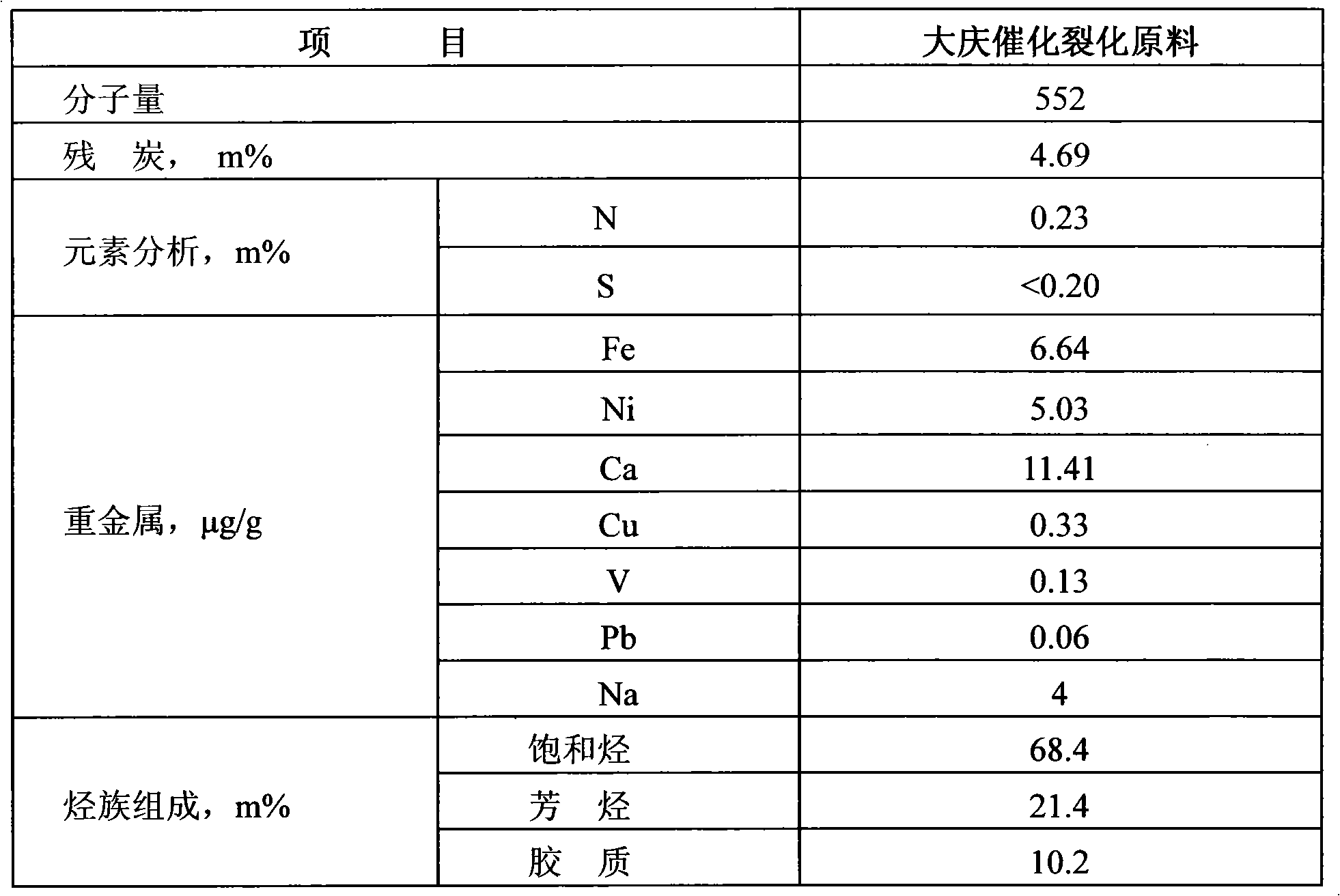

[0055] This example illustrates the preparation of an aluminum phosphate sol binder for use with catalysts according to the invention.

[0056] 4.7 kg of pseudoboehmite (containing Al 2 o 3 3 kilograms) and 10.0 kilograms of decationized water beating for 30 minutes, under stirring, add 9.7 kilograms of 85% concentrated phosphoric acid in the slurry, then add 5.4 kilograms of 68% concentrated nitric acid, continue to stir and react for 45 minutes, and then obtain a colorless and transparent phosphoraluminum sol. Its pH is 1.5. After analysis, the aluminum phosphate sol contains 8.7% by weight of P, 5.3% by weight of Al, P / Al (weight)=1.6, HNO 3 The content is 12% by weight, and the sol viscosity (25° C.) is 40 mPa·s.

Embodiment 2

[0058] This example illustrates the preparation of an aluminum phosphate sol binder used in the catalyst of the present invention.

[0059] 3.0 kg of aluminum nitrate Al(NO 3 ) 3 ·6H 2 O adds 4.3 kilograms of decationized water to dissolve, adds 967 grams of pseudo-boehmite (containing Al 2 o 3 612 grams), beat for 40 minutes, add 2.3 kilograms of 90% phosphoric acid to the slurry under stirring, and continue stirring for 50 minutes to obtain a colorless and transparent aluminum phosphate sol with a pH of 1.7. After analysis, the aluminum phosphate sol contains P 7.9% by weight, Al 6.1% by weight, P / Al (weight)=1.3, HNO 3 The content is 14% by weight, and the sol viscosity (25° C.) is 56 mPa·s.

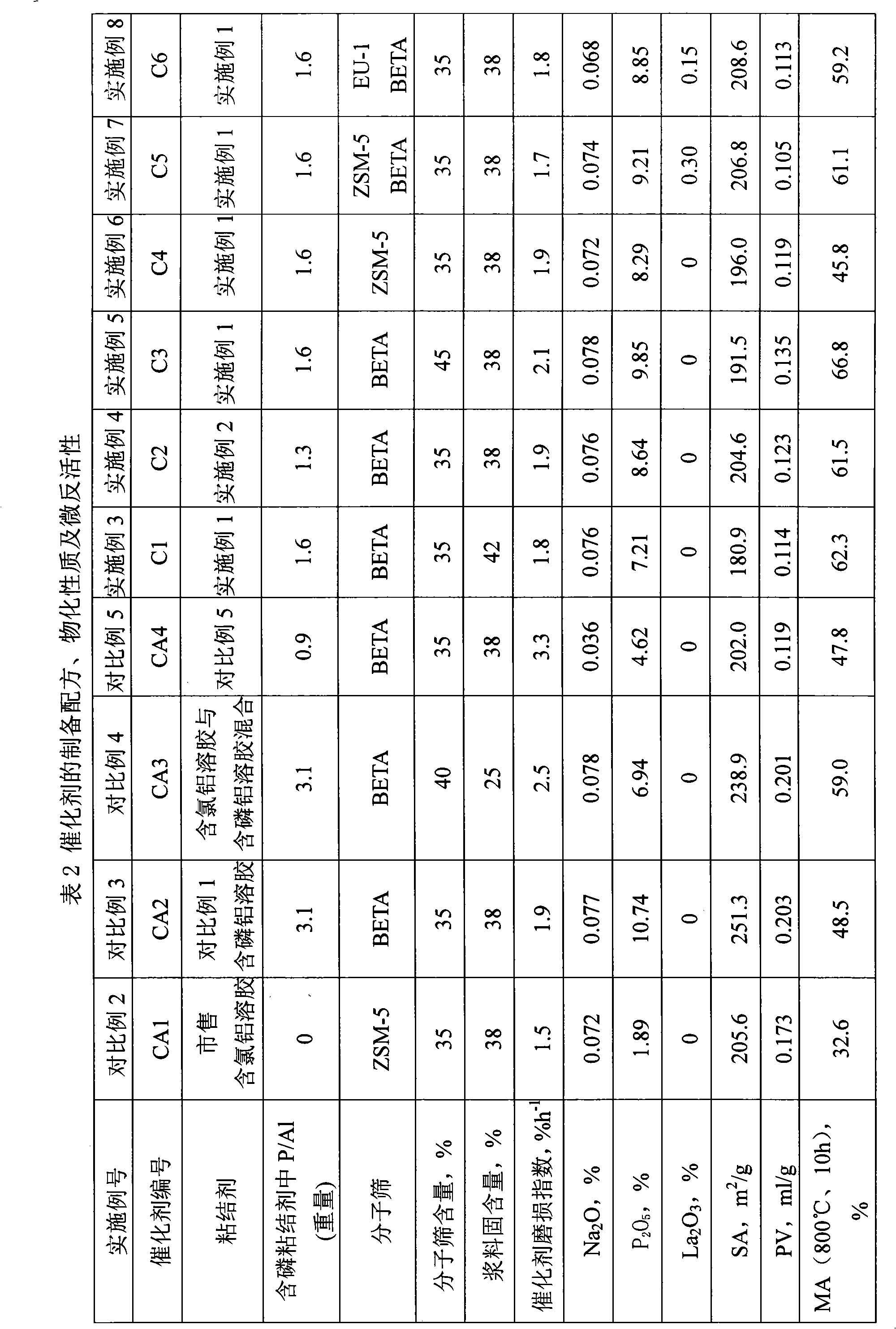

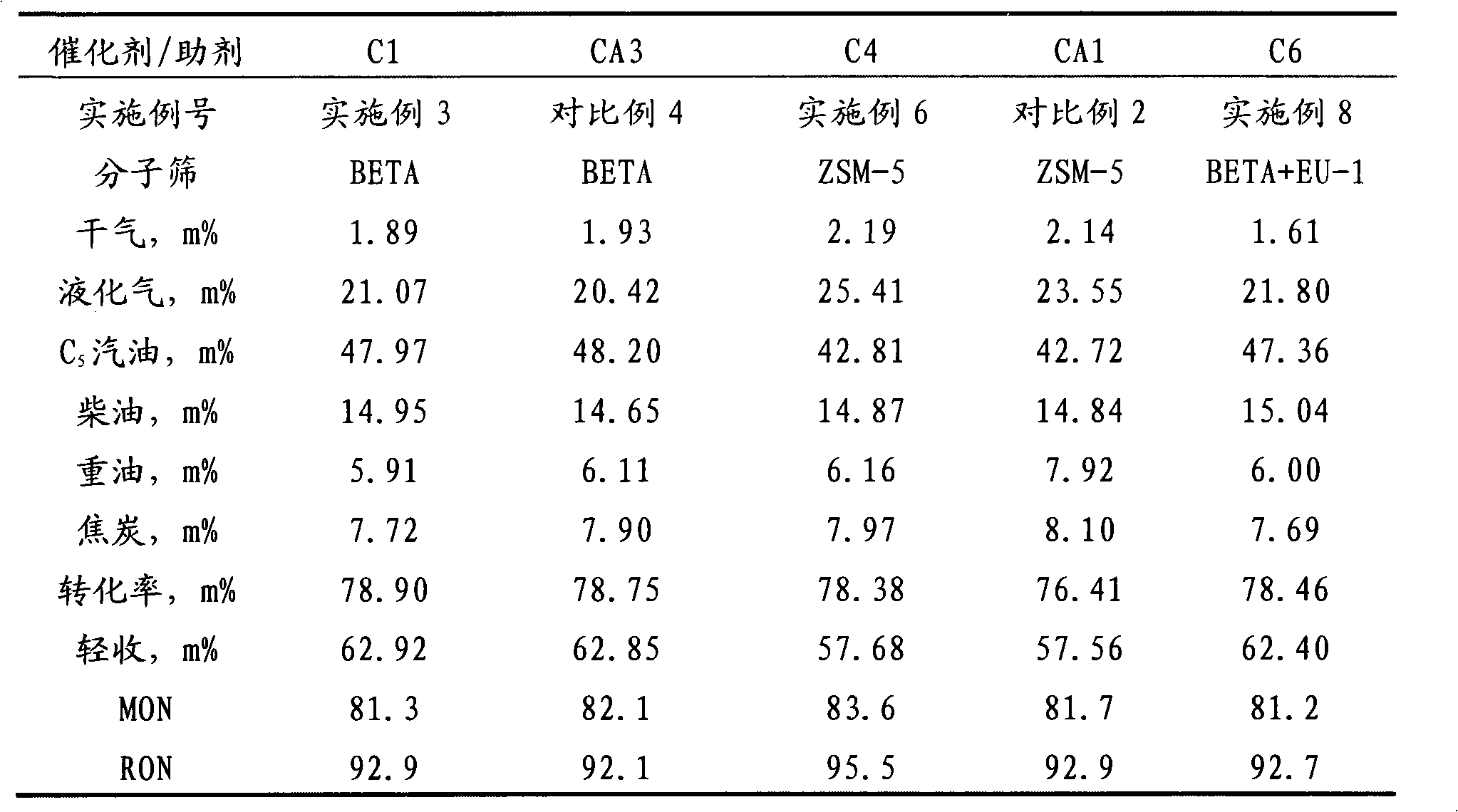

Embodiment 3

[0064] Add 1.28 kg of water to 1.21 kg (dry basis) of BETA molecular sieve, and homogenize with a shearing machine to prepare BETA molecular sieve slurry.

[0065]Under stirring, 1875g of kaolin and 2010ml of water were mixed and beaten for 30min, 1.2kg of the binder prepared according to the method in Example 1 was added to the kaolin slurry, and the stirring was continued for 1h, then the BETA molecular sieve slurry was added, stirred for 2h, and the resulting slurry was The solids content of the feed was 38% by weight. After the slurry was homogenized, it was spray-dried to obtain a catalyst containing 35% by weight of BETA molecular sieve, which was designated as C1. The composition, physicochemical properties and microreaction activity of the catalyst are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com