Catalytic cracking catalyst and preparation method and application thereof

A catalytic cracking and catalyst technology, used in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problem of high coke selectivity, achieve low coke selectivity, be conducive to diffusion and cracking, and high gasoline yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

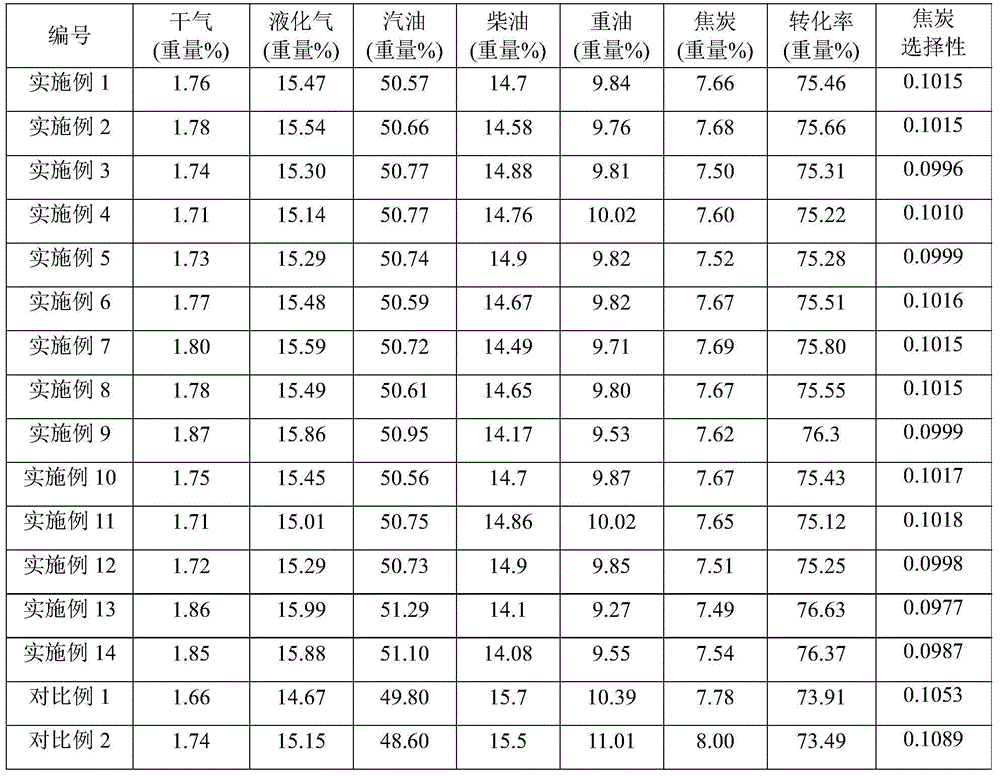

Examples

preparation example Construction

[0023] In the preparation process of the above-mentioned modified aluminum sol, water can be introduced into the reactor by a soluble silicon-containing compound solution, a chloride solution, a soluble phosphorus-containing compound solution, by adding water such as deionized water, or a combination of the above methods. Water is introduced into the reactor. Preferably, the weight ratio of the water introduced into the reactor before adding chloride to the soluble silicon-containing compound (calculated as Si element) introduced into the reactor before adding chloride is 100:0.1- 10, for example, 100:1-10 or 100:0.1-5 or 100:0.15-1.4 or 100:0.2-1.3:1.

[0024] The content of silicon (calculated as silicon element) in the modified aluminum sol obtained in the present invention is 0.1-1% by weight, preferably 0.2-0.9% by weight, for example, 0.3-0.85% by weight.

[0025] In the preparation process of the above modified aluminum sol, the added amount of the metallic aluminum (calcula...

preparation example

[0069] In the following preparation examples, comparative preparation examples, examples and comparative examples:

[0070] The purity of the aluminum chips used is 99.2% by weight, and the purity of aluminum particles is 98.8% by weight; the 1:1 chemically pure hydrochloric acid used is a mixture of 1 volume of 36% by weight chemically pure hydrochloric acid and 1 volume of water; the 1:1 chemically pure phosphoric acid used It is a mixture of 1 volume of chemically pure phosphoric acid with a concentration of 85% by weight and 1 volume of water; the rare earth chloride is purchased from Baotou Steel Rare Earth High-Tech Co., Ltd., and the rare earth elements are La and Ce.

[0071] The specific surface area, pore volume and average pore diameter are all measured by the low-temperature nitrogen adsorption-desorption method. The instrument used is the Physicochemical Adsorption Analyzer ASAP2400 from Micromeritics, USA; Na 2 O, Al 2 O 3 , SiO 2 , P 2 O 5 The content of X-ray fluores...

preparation example 1

[0076] This preparation example is used to illustrate the preparation method of the silicon modified aluminum sol provided by the present invention.

[0077] 286 grams of aluminum scraps (calculated as Al), 1481 grams of deionized water, and 119 grams of water glass aqueous solution (containing 9.33% by weight of Si element and 4.63% by weight of Na element) were put into a three-necked flask and heated to 60°C. Slowly add 921 ml of 1:1 chemically pure hydrochloric acid into a three-necked flask to make it react with aluminum chips. The addition time of hydrochloric acid is 3 hours; after adding hydrochloric acid, react at a reaction temperature of 90-95°C for 20 hours, and then The product was cooled to 60-70°C and filtered to obtain modified aluminum sol SA-1. The aluminum scraps remaining in the reaction were weighed to 36 grams, that is, the aluminum excess was 14.8% by weight. After analysis of the modified aluminum sol SA-1, the results are as follows: Al content is 9.0% b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell constant | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com