Patents

Literature

52results about How to "High rare earth content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for raising content of rare earth of ultra stable Y type zeolite

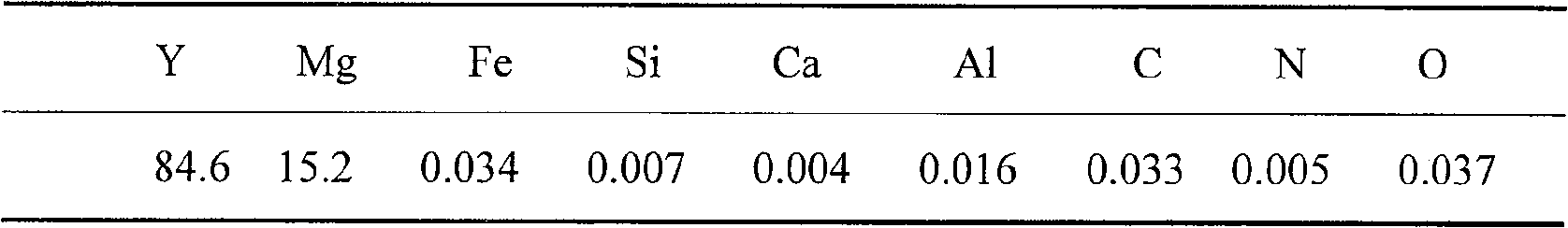

ActiveCN1958452AHigh cracking activityStrong ability to convert heavy oilFaujasite aluminosilicate zeoliteRare earth ionsActive component

This invention discloses a method for raising rare earth content in super-stable Y-type zeolite. The method comprises: mixing super-stable Y-type zeolite and 0.01-2 N acid solution at a liquid / solid ratio of 4-20 at 20-100 deg.C, treating for 10-300 min, washing, filtering, adding rare earth salt solution for rare earth ion exchange, washing, filtering, and drying to obtain rare earth reinforced super-stable Y-type zeolite. The obtained rare earth reinforced super-stable Y-type zeolite has through pores without any blockage, and has obviously raised rare earth content. Cracking catalyst containing the rare earth reinforced super-stable Y-type zeolite as the active component has high heavy oil conversion ability.

Owner:CHINA PETROLEUM & CHEM CORP +1

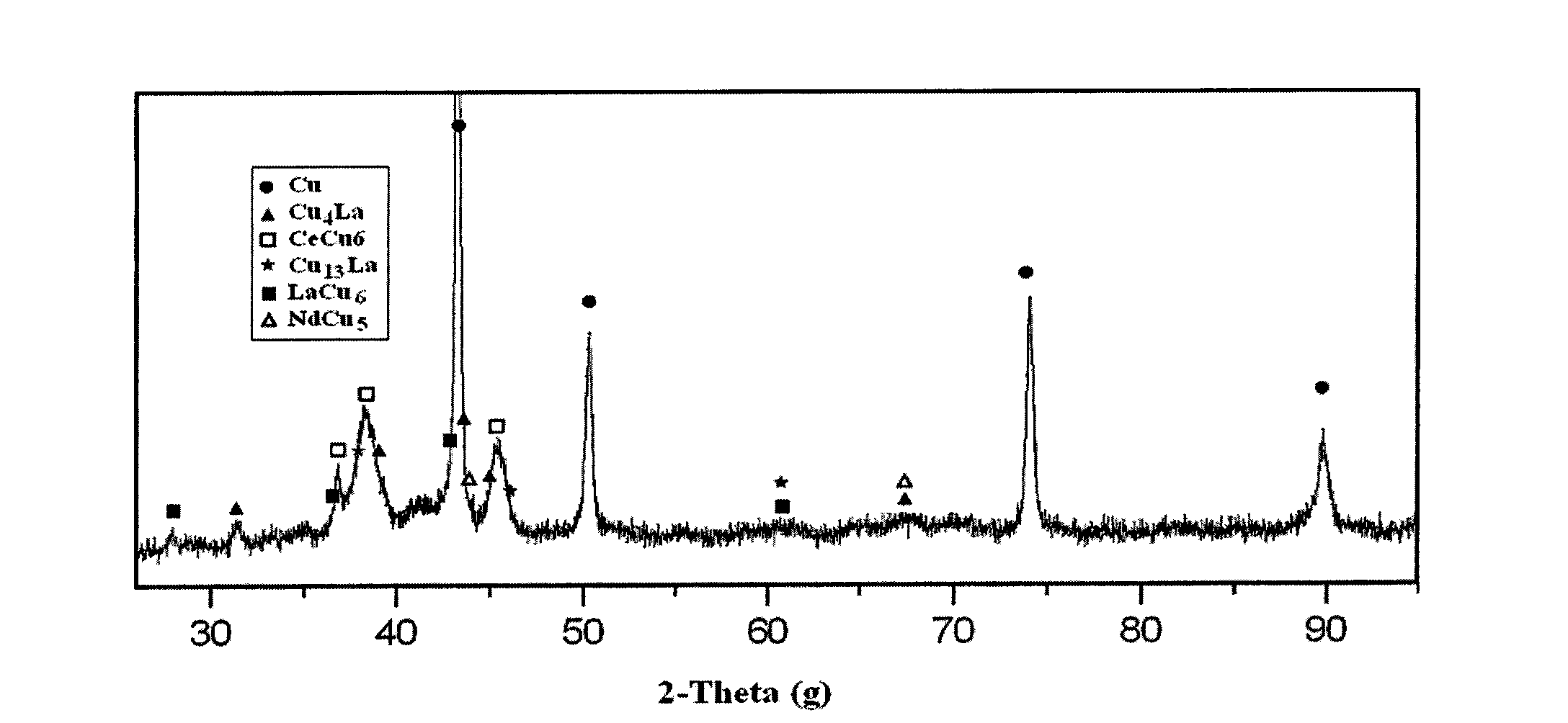

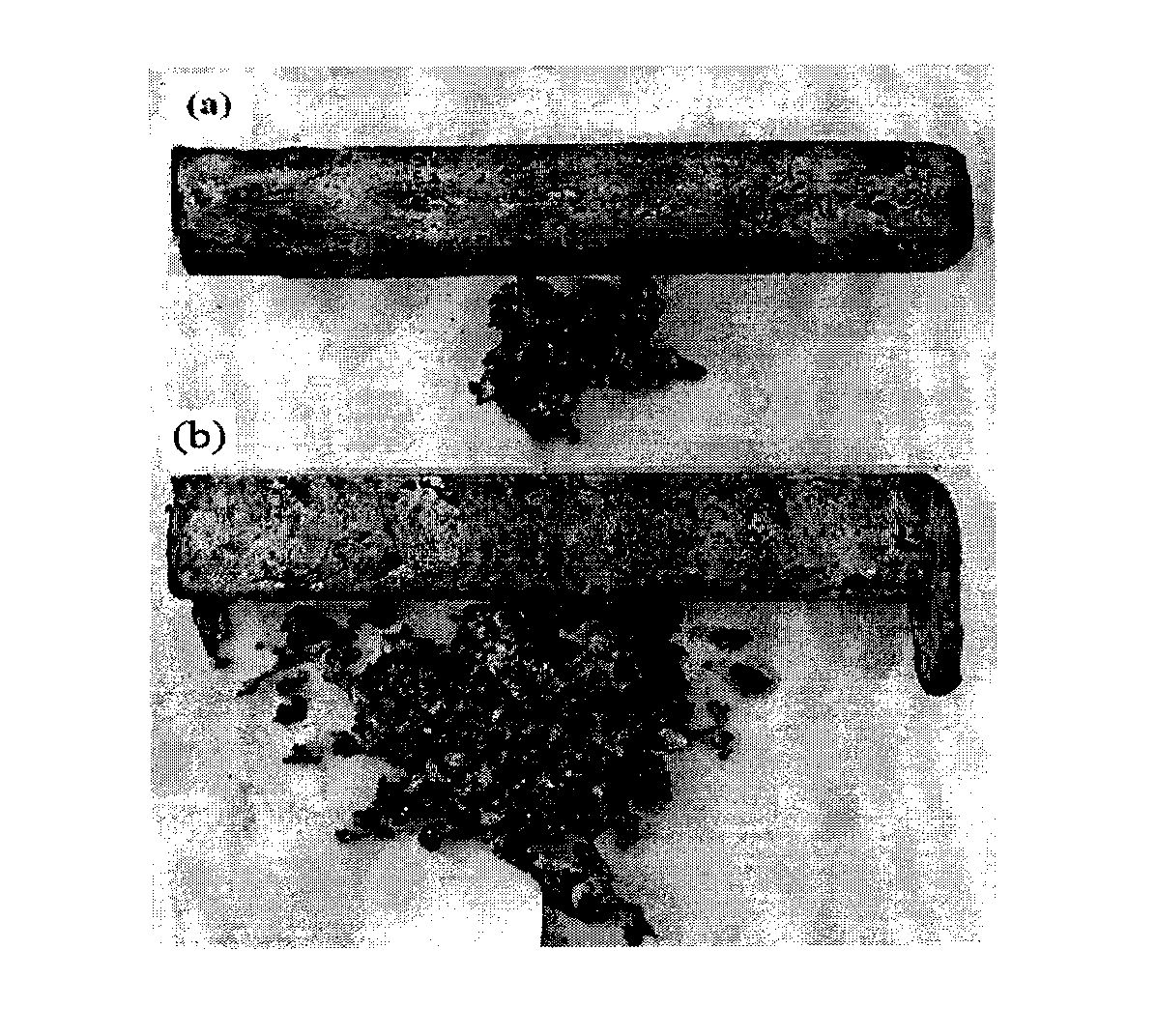

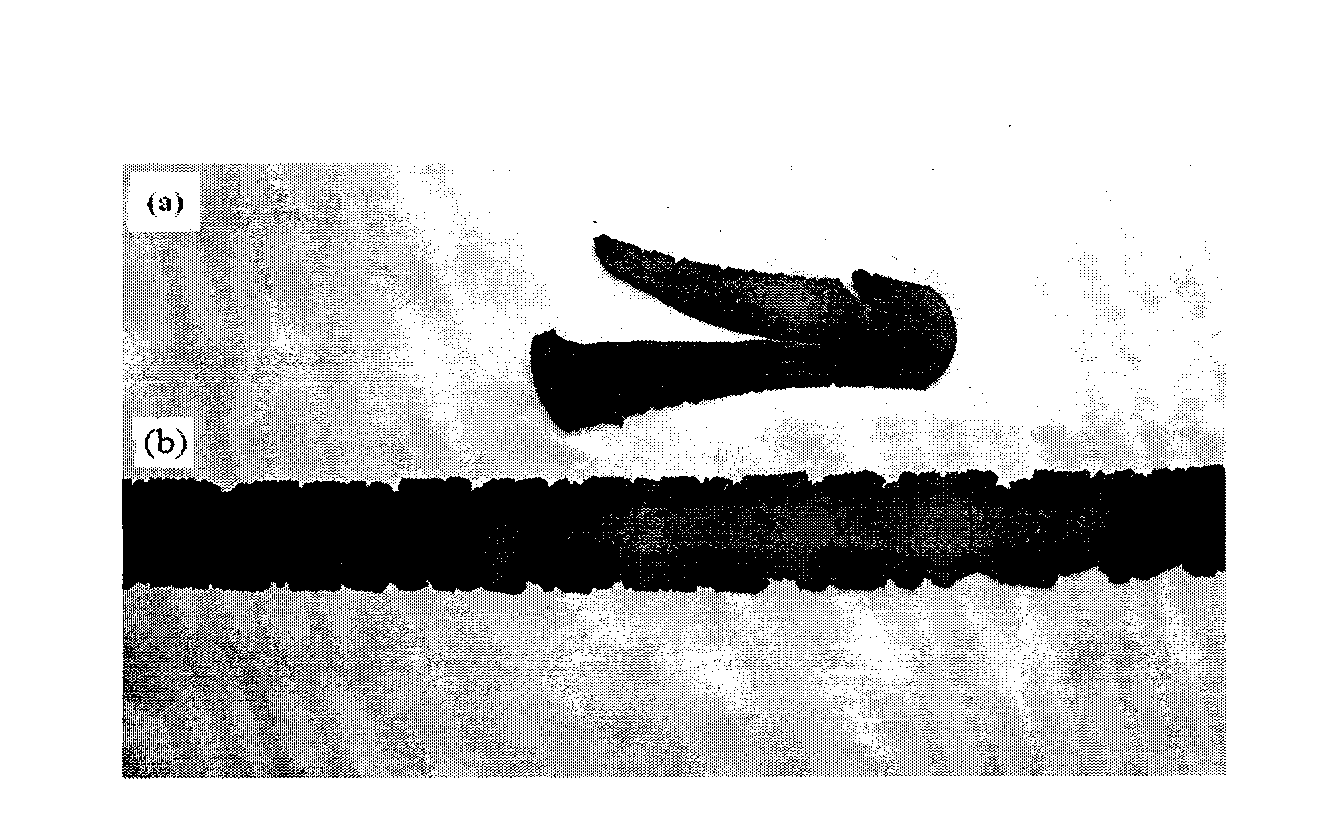

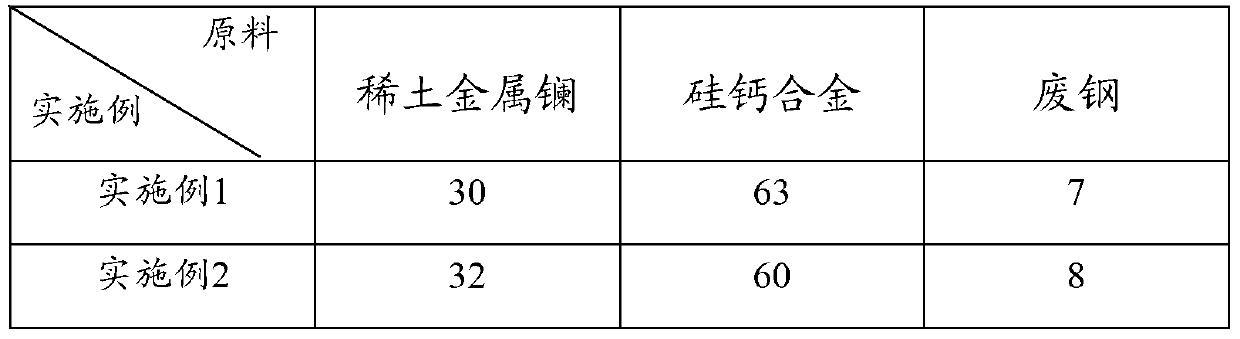

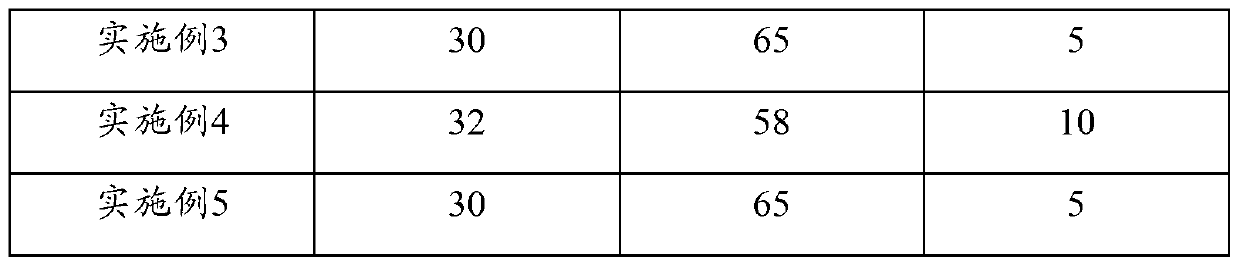

High Cu-RE interalloy refining agent for refining scrap copper and preparation and application thereof

The invention relates to a high Cu-RE refining agent which has high efficiency and low burning loss rate and can be used for copper and copper alloy, applied to mass refining of the copper and the copper alloy, especially applied to refining and modification of red impure copper and white impure copper. The Cu-RE interalloy refining agent is prepared by a vacuum melting method, wherein, rare earth content is up to 30-65%; and only 2-6g / kg refining agent is added while the Cu-RE interalloy refining agent is applied to remelting refining of scrap copper. The Cu-RE refining agent enhances slagging and deslagging of copper fused mass, reduces deleterious substances in the fused mass of the scrap copper, and improves texture and performance of the copper and the copper alloy, therefore, products prepared from the red impure copper as a raw material reach or exceed the quality of the products prepared from electrolytic copper as a raw material, and the white copper process waste can be used for directly producing high-quality products after remelting refined, thus promoting recycle and reutilization of the scrap copper, saving energy and resource, reducing environmental pollution and generating significant economic and social benefits.

Owner:CENT SOUTH UNIV

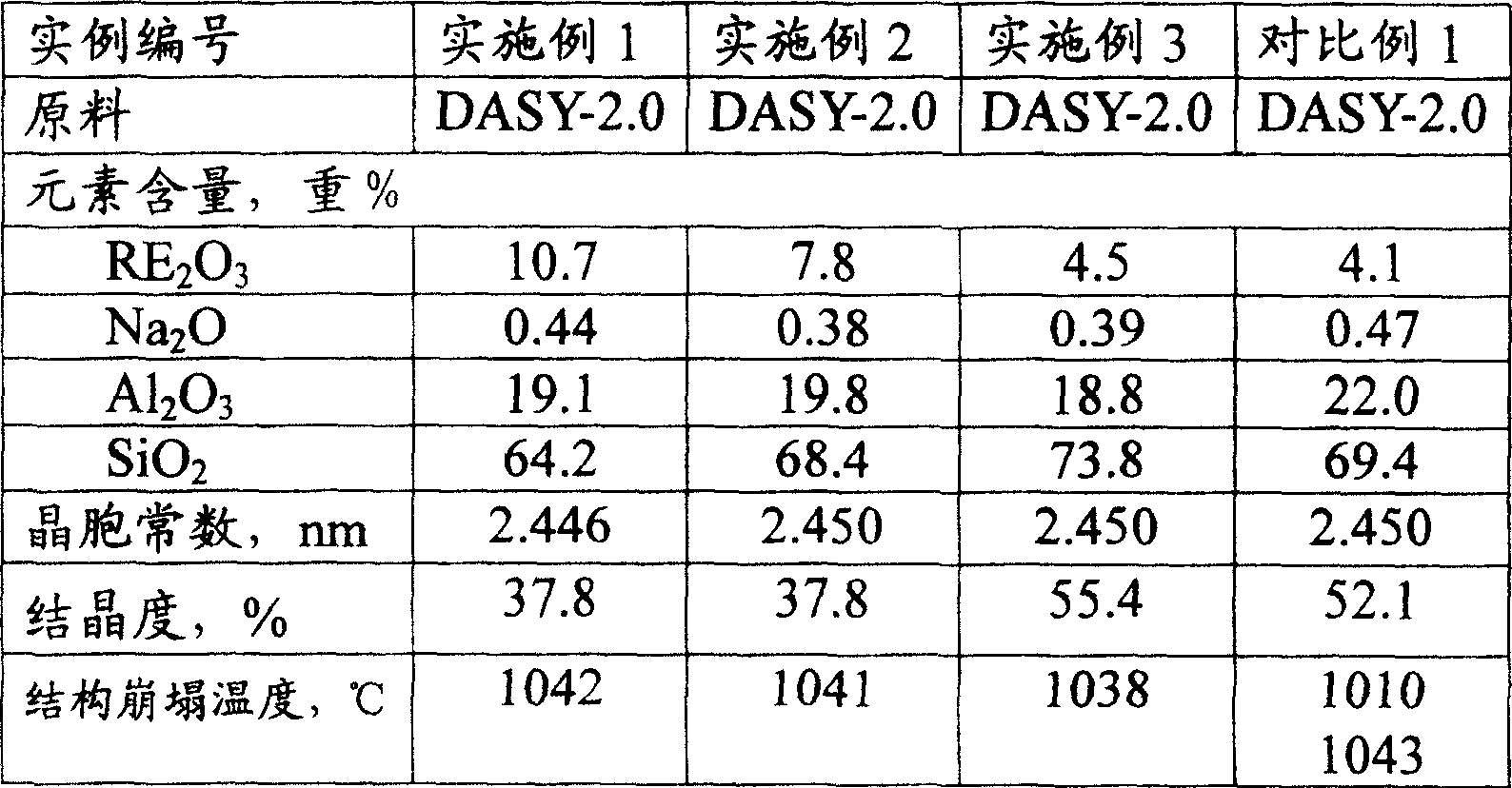

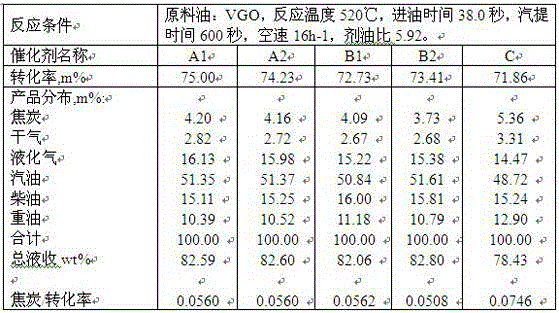

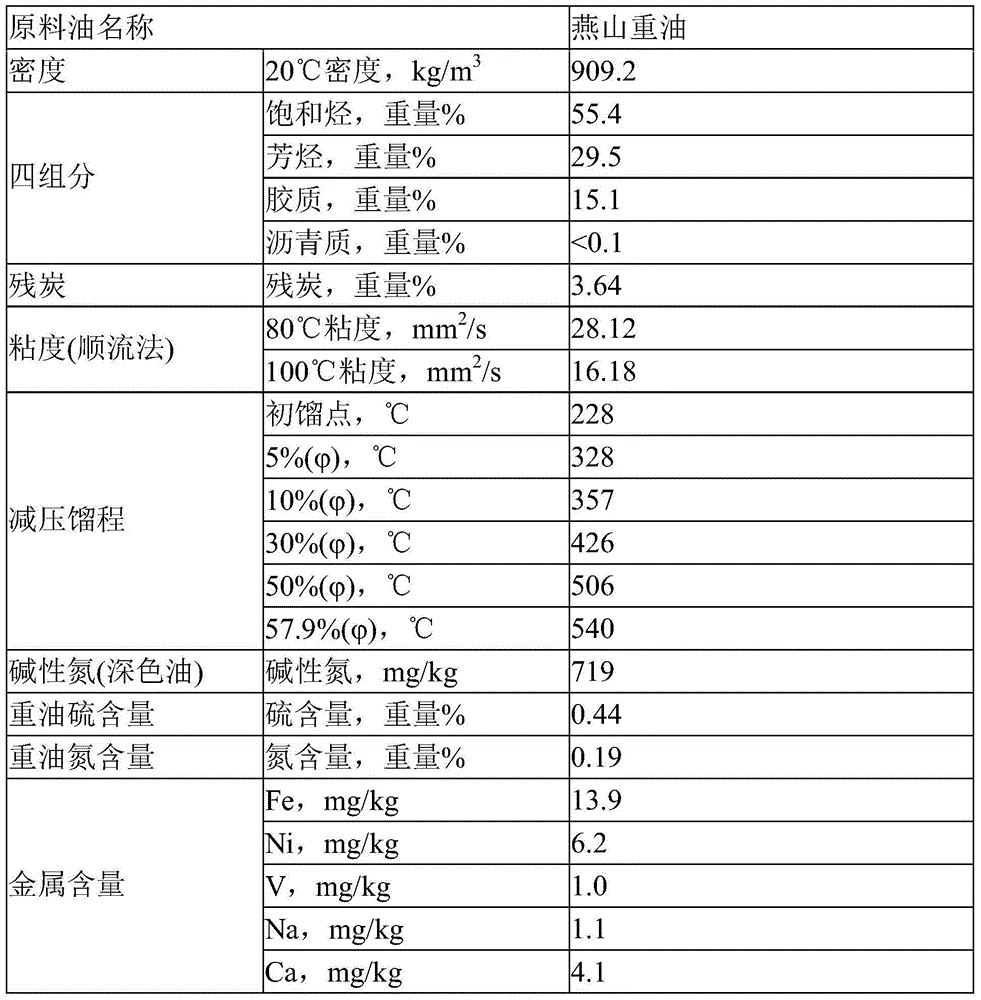

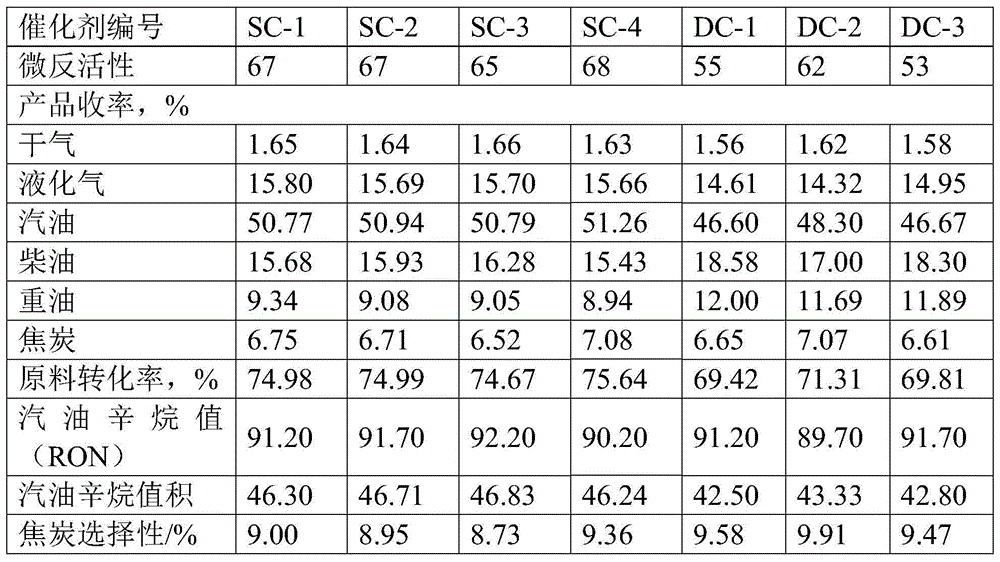

Catalytic cracking catalyst

The present invention relates to a cracking catalyst. Its composition contains (by wt%) 10%-50% of high rare earth ultrastable Y-type molecular sieve, 10%-40% of aluminium oxide adhesive and 10%-70% of clay. The preparation method of described high rare earth ultrastable Y-type molecular sieve includes the following steps: fully mixing ultrastable Y-type zeolite and acid solution whose equivalent concentration is 0.01N-2N according to the solid-liquid ratio of 20:4 at temperature range of 20deg.C-100deg.C, stirring them for 10min-300min, then washing, filtering, adding rare earth salt solution to make rare earth ion exchange, after the exchange washing, filtering and drying so as to obtain the high rare earth ultrastable Y-type molecutar sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of preparing high rare-earth content magnesium intermediate alloy

The invention discloses a making method of intermediate alloy of high rare earth magnesium, which is characterized by the following: adding RE-O and MgO in the REF3-LiF or REF3-MgF2-LiF fusing salt system; electrolyzing; proceeding eutectoid; making the product with high receiving rate.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

Method of preparing ceria by mixed precipitant

A method of preparing ceria by a mixed precipitant mainly comprises the steps of enabling a mixed solution of ammonium bicarbonate and ammonia as the precipitant to perform combined action with inoculating crystals, precipitating rare earth ions in a rare earth chloride solution to obtain a mixture with primary alkali type cerous carbonate and subsidiary cerous carbonate and cerium hydroxide, and further firing to prepare a rare earth ceria product. The prepared ceria accords with industry standards; reaction conditions of the method are mild; energy consumption during preparing process is obviously reduced, and the cost is low; meanwhile, the carbon dioxide emission is greatly reduced, and obvious social benefit and environmental benefit are achieved.

Owner:YANSHAN UNIV

Rare earth zirconium-based composite oxide with core-shell structure, and preparation method and application thereof

ActiveCN103182302AImprove performanceImprove high temperature stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsOxygen sensorRare earth

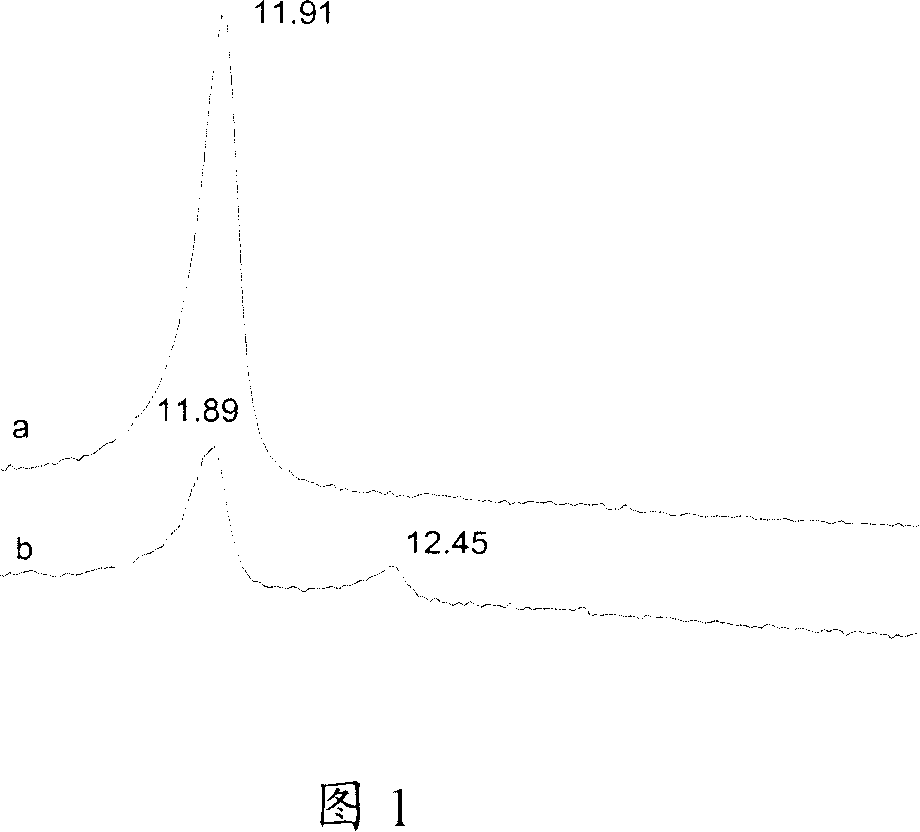

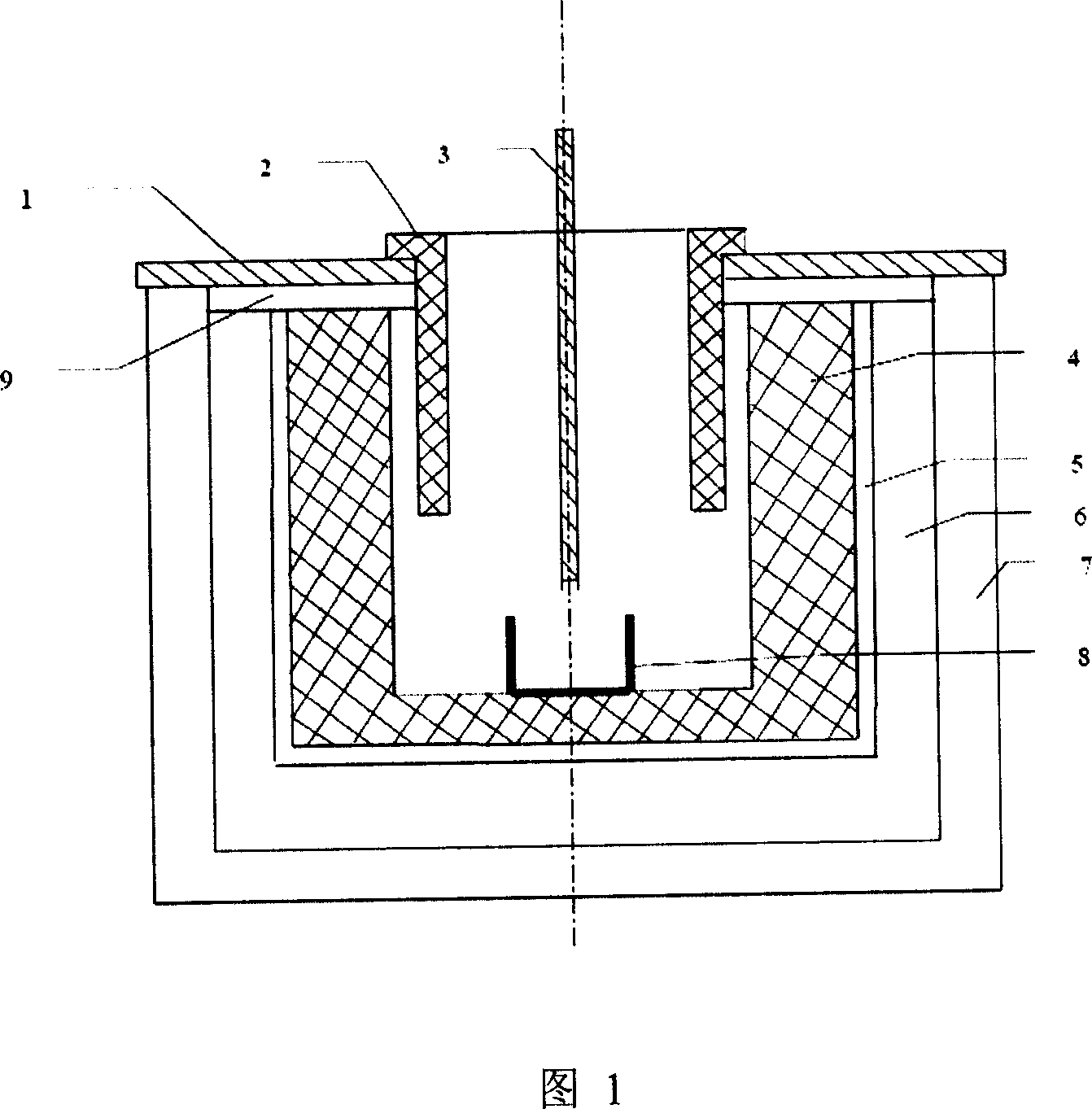

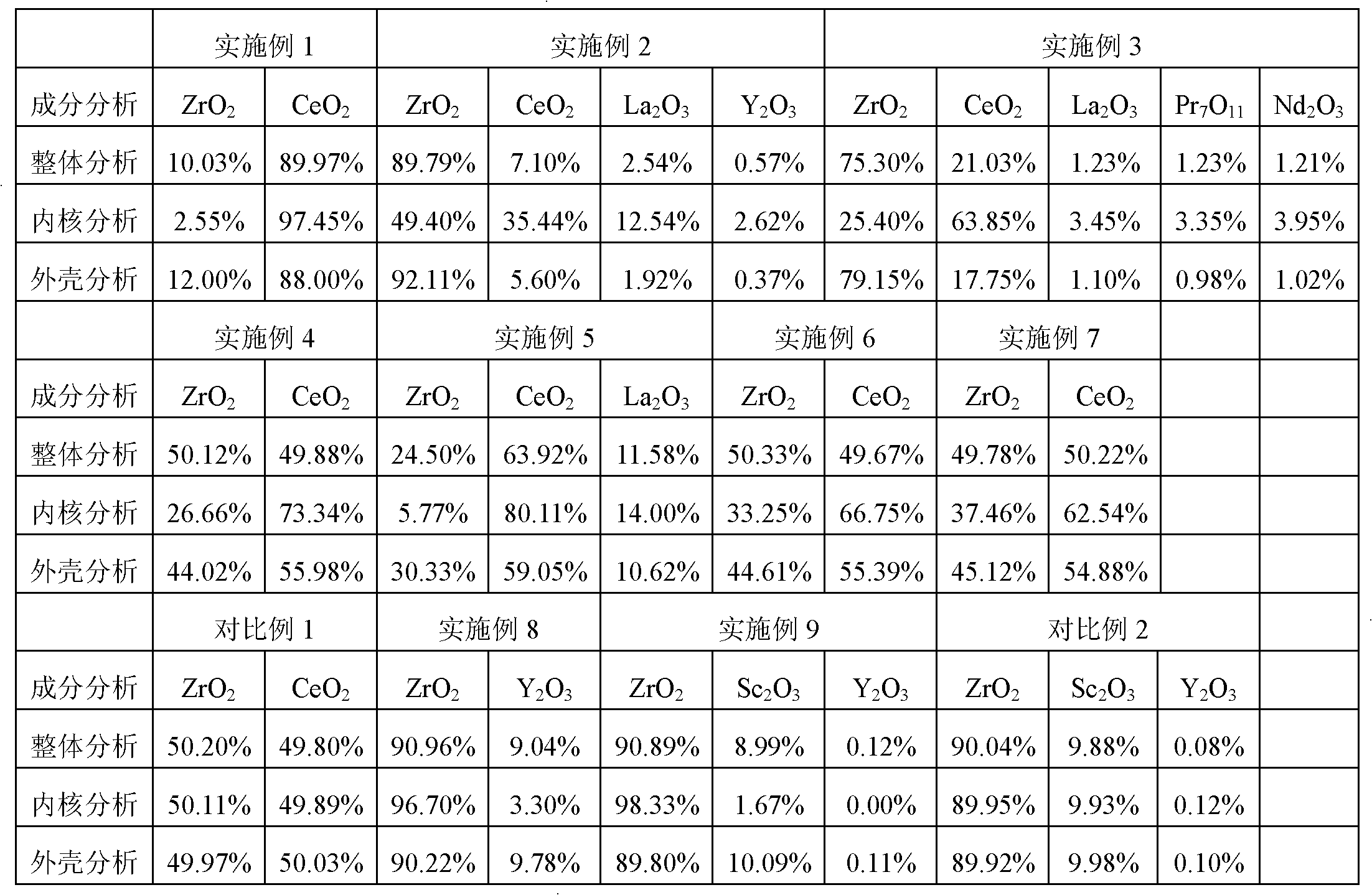

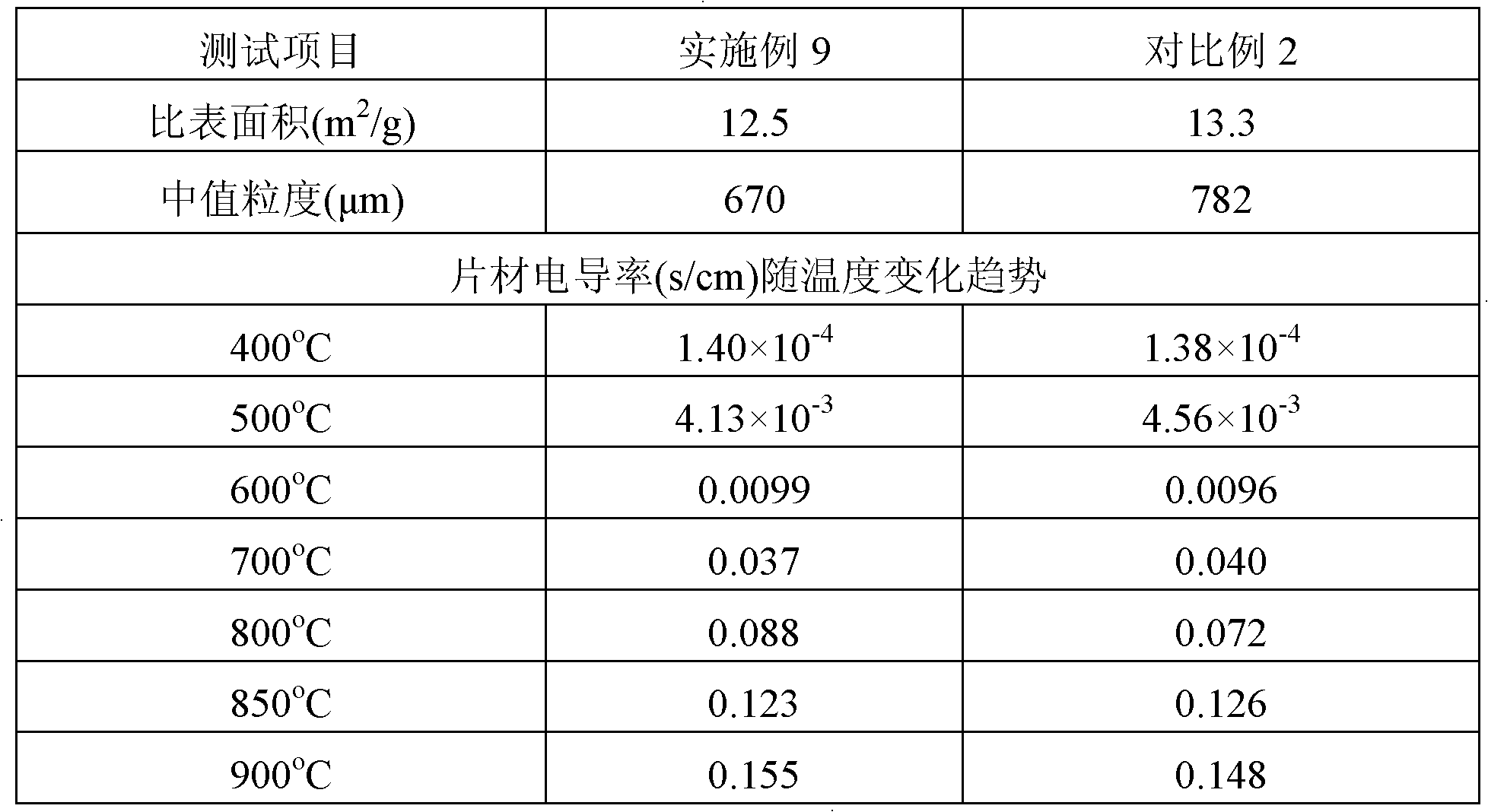

The invention relates to a rare earth zirconium-based composite oxide with a core-shell structure and a preparation method and application thereof. The rare earth zirconium-based composite oxide comprises, 5 to 95 mol% of a rare earth oxide and 95 to 5 mol% of a zirconium oxide; the rare earth zirconium-based composite oxide has a core-shell structure, and a difference between the content of the rare earth oxide in an internal layer and the content of the rare earth oxide in an external layer is more than 10% (relative content). The rare earth zirconium-based composite oxide with high temperature stability prepared by using the method provided in the invention has the advantages of low cost, high product quality and a specific surface area of more than 40 m<2> / g after ageing for 4 h at a temperature of 1000 DEG C and can be extensively used in fields like rare earth catalytic additives, oxygen storage materials, oxygen conduction materials, ceramic powder materials and oxygen sensors. The preparation method provided by the invention has the advantages of a wide source of the raw materials rare earth and zirconium, easiness, small investment for desired equipment, low preparation cost and good development and application prospects.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Method for raising content of rare earth of ultra stable Y type zeolite

ActiveCN100497175CHigh cracking activityStrong ability to convert heavy oilFaujasite aluminosilicate zeoliteRare earth ionsActive component

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing rear earth Y type molecular sieve

InactiveCN108097288AIncrease productivityHigh rare earth contentMolecular sieve catalystsIon exchangeHeat stability

The invention provides a preparation method of a rear earth Y type molecular sieve. The method comprises the following steps: firstly mixing a NaY molecular sieve, a rare earth chloride solution and deionized water to perform ion exchange, adding an oxalic acid solution in exchange fluid to enable unexchanged rear earth to be completely precipitated, adding rare earth chloride in a filter cake after filtration, so as to perform ion exchange with the deionized water, obtaining a filter cake and reuse filtrate through filtering, and performing muffle roasting on the filter cake, so as to obtaina product REY; completely or partly replacing the rare earth chloride solution with the reuse filtrate, and performing the ion exchange process of the next batch of NaY molecular sieve. The method canrecycle rear earth, ensures that the use ratio of rear earth almost reach 100 percent under the condition that equipment is not added, reduces the production cost, efficiently utilizes nonrenewable rear earth resources, can obtain REY with high content of rear earth, has the advantages of high activity and heat stability; in addition, the heavy oil fluid catalytic cracking activity of the molecular sieve is obviously improved after the formed REY is cleaned through channels of oxalic acid.

Owner:北京惠尔三吉绿色化学科技有限公司

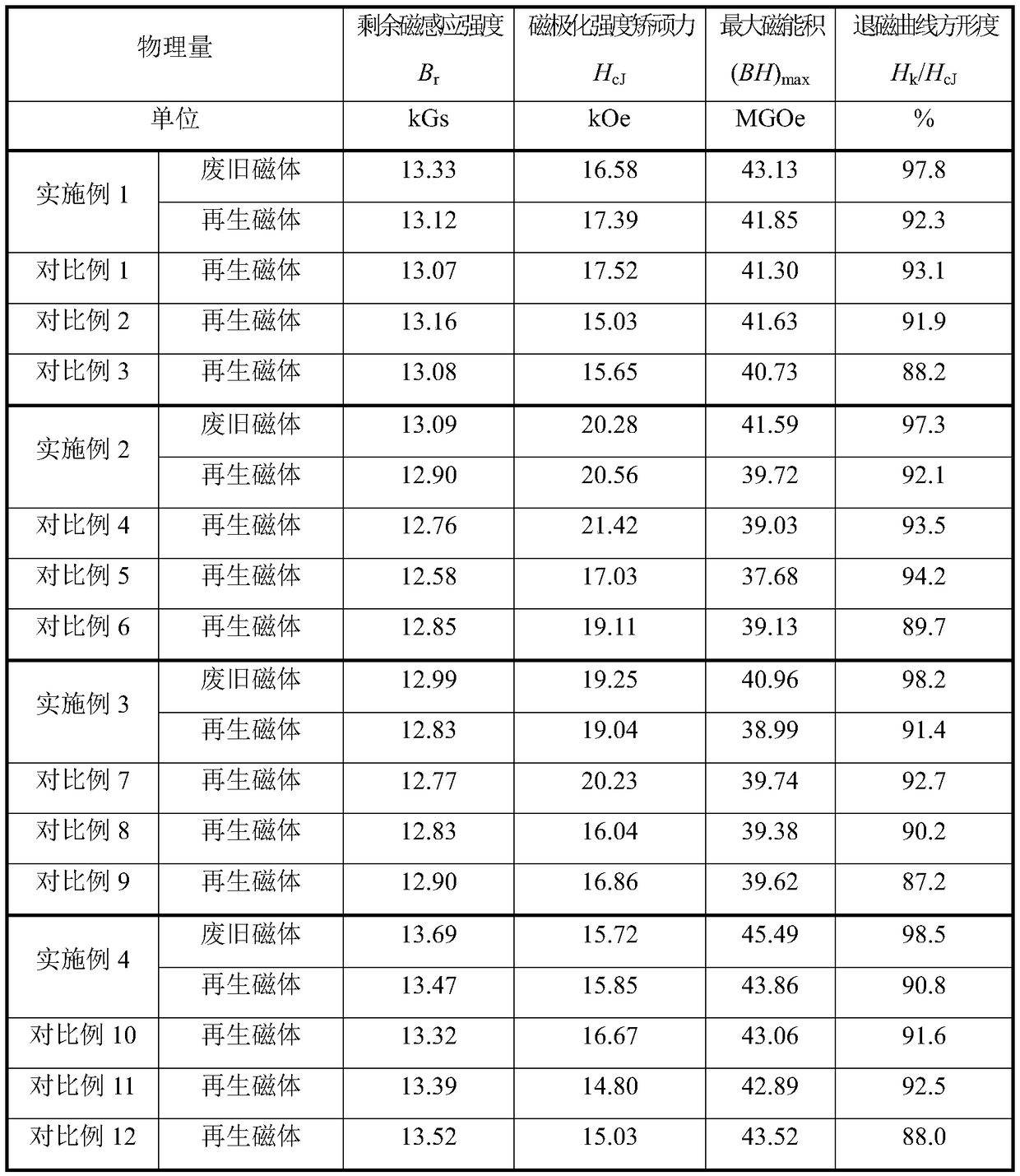

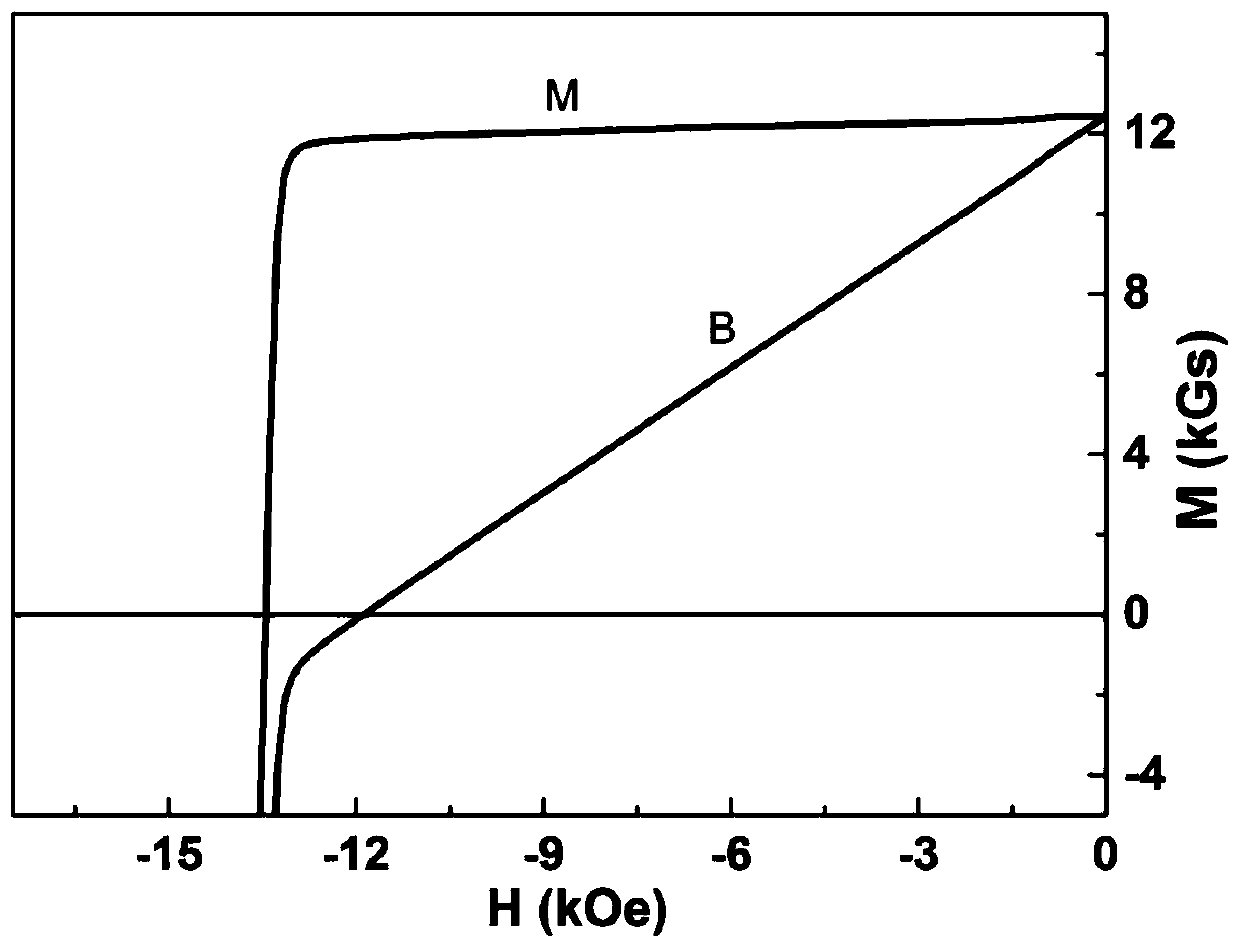

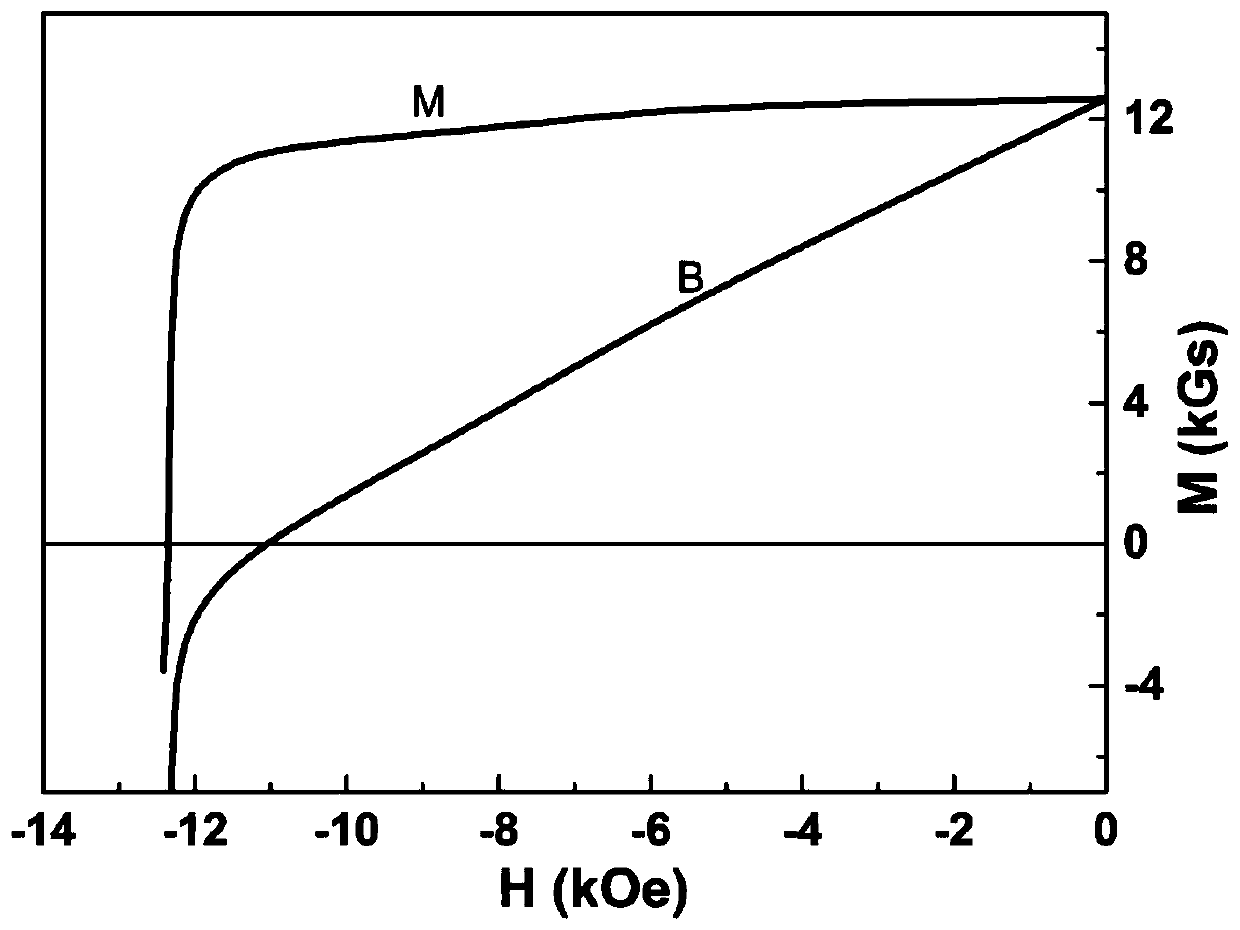

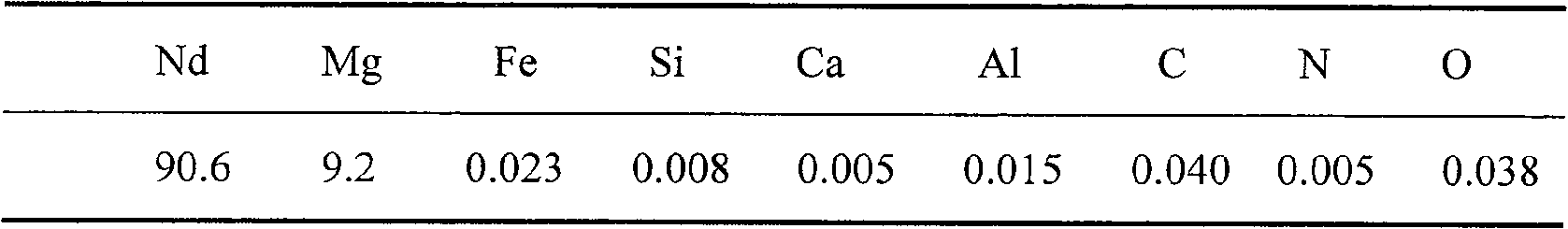

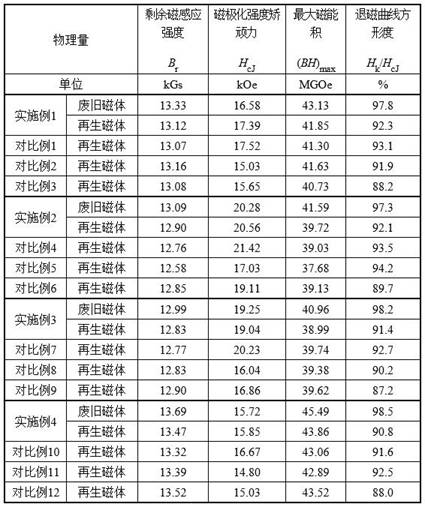

A preparation method of regenerative sintered Nd-Fe-B permanent magnet

ActiveCN109192495AStrengthen the grain surfaceImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsSurface layerRare earth

The invention provides a preparation method of regenerated sintered Nd-Fe-B permanent magnet, which comprises the following steps of: carrying out surface pretreatment on waste sintered Nd-Fe-B permanent magnet, and then crushing the waste Nd-Fe-B permanent magnet into magnetic powder with an average particle size of 2.0-4.0 mum; 2 to 99.5 to 0.5, so that that heavy rare earth atom diffuse into the surface layer of the magnetic powder to obtain the modified magnetic powder; 100 to 5:100 of rich and high-abundance rare earth powder and modified magnetic powder according to mass ratio to obtainmixed magnetic powder. The mixed magnetic powder is placed in a magnetic field with a magnetic field strength of more than 1.5 T, and then the magnetic powder is pressed into a compact by the orientedmoulding method. The regenerative sintered Nd-Fe-B permanent magnet is prepared by high temperature sintering and tempering. The regenerative sintered Nd-Fe-B permanent magnet prepared by the invention has high performance, low cost and high recovery efficiency for waste magnets.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

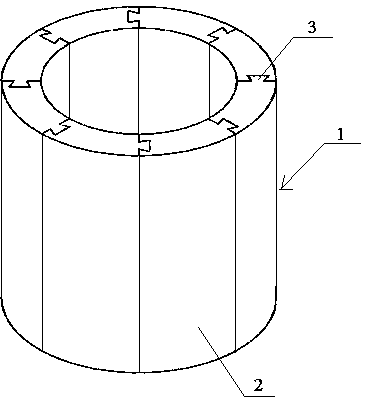

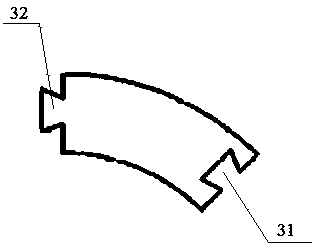

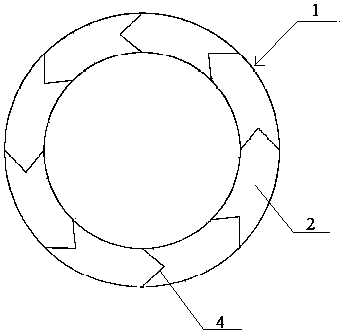

Radial magnet ring and production method thereof

ActiveCN103578702AGood formabilityEasy to processTransformers/inductances magnetic coresInductances/transformers/magnets manufactureDiameter ratioEngineering

The invention discloses a radial magnet ring and a production method thereof. The purpose of the invention is to solve the problem that the yield of directly produced one-piece magnet rings is low and that the magnetic properties of high-height-to-diameter ratio magnet rings are low. A plurality of arc-shaped magnetic tiles are assembled and bonded to form the radial magnet ring, and a positioning structure is arranged between every two neighboring arc-shaped magnetic tiles. The structure of the radial magnet ring is simple, fixtures are not needed besides the magnet ring, and the magnet ring has high strength and good magnetic properties.

Owner:浙江东阳东磁有限公司

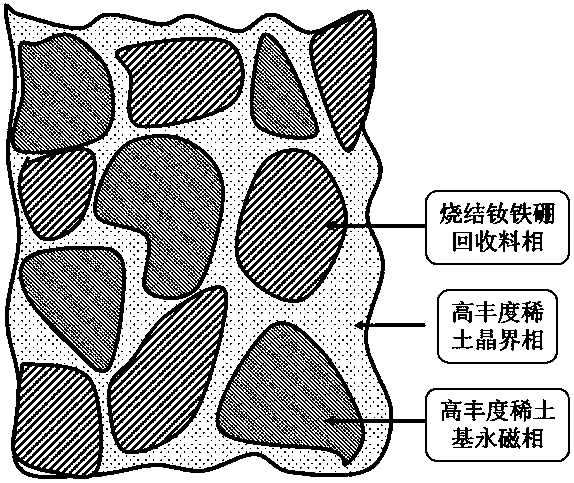

High-cost-performance rare earth permanent magnet and preparation method

ActiveCN111341512AReduce manufacturing costImprove magnetic propertiesInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementGrain boundary

The invention relates to the technical field of rare-earth permanent magnet materials, in particular to a high-cost-performance rare-earth permanent magnet prepared from a sintered neodymium-iron-boron recycled material and a preparation method of the high-cost-performance rare-earth permanent magnet. The permanent magnet at least comprises two main phases, the first main phase component is a sintered neodymium iron boron recycled material phase, and the second main phase component is a high-abundance rare earth-based permanent magnet phase. According to the invention, the sintered neodymium iron boron reclaimed material and the high-abundance rare earth element are effectively utilized, a grain boundary phase is provided by the high-abundance rare earth phase, and the microstructure of the magnet is controlled by the processes of multiple times of powder mixing, low-temperature sintering and the like, so that the manufacturing cost of the magnet is greatly reduced, and meanwhile, thegood comprehensive magnetic performance is obtained.

Owner:CENT IRON & STEEL RES INST

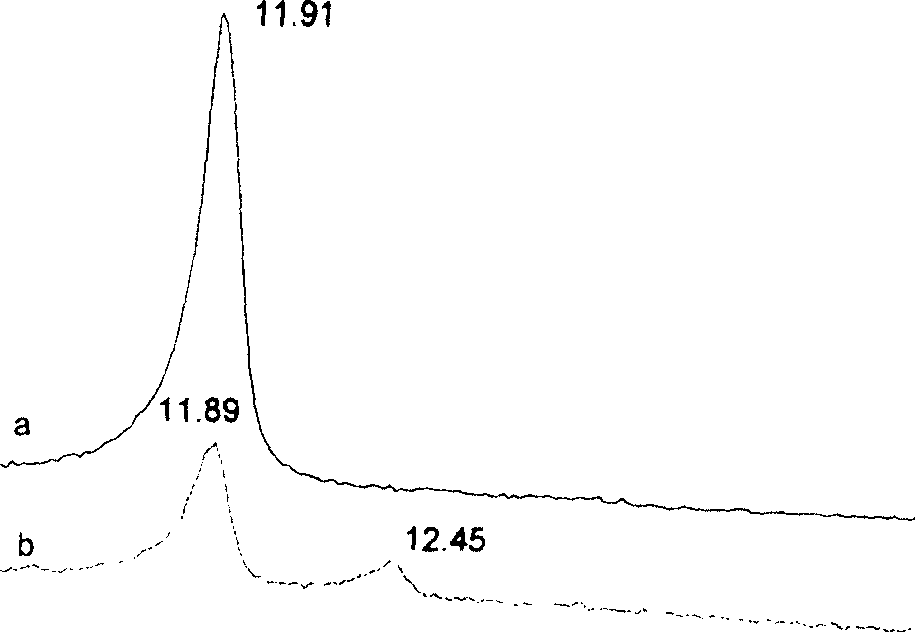

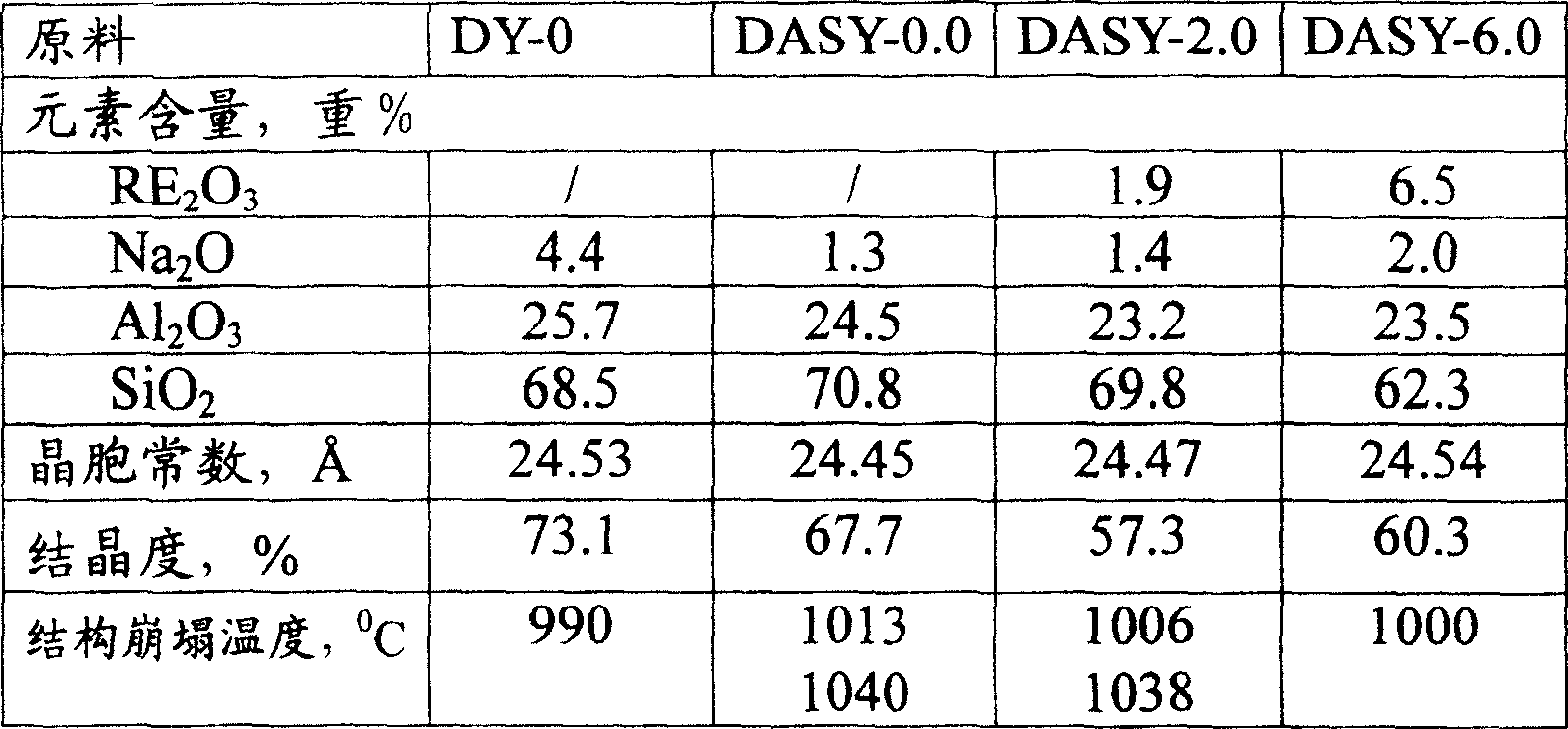

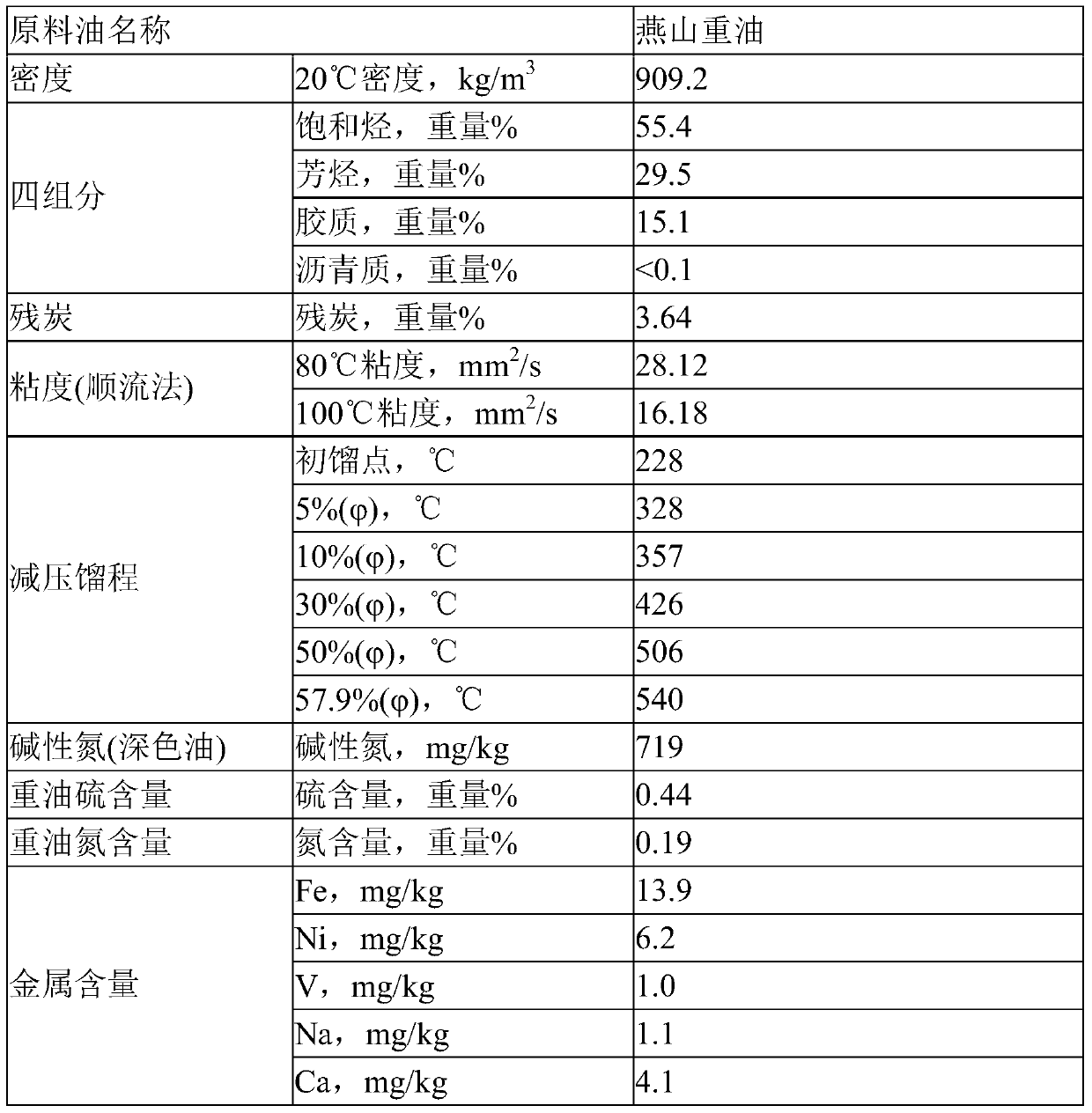

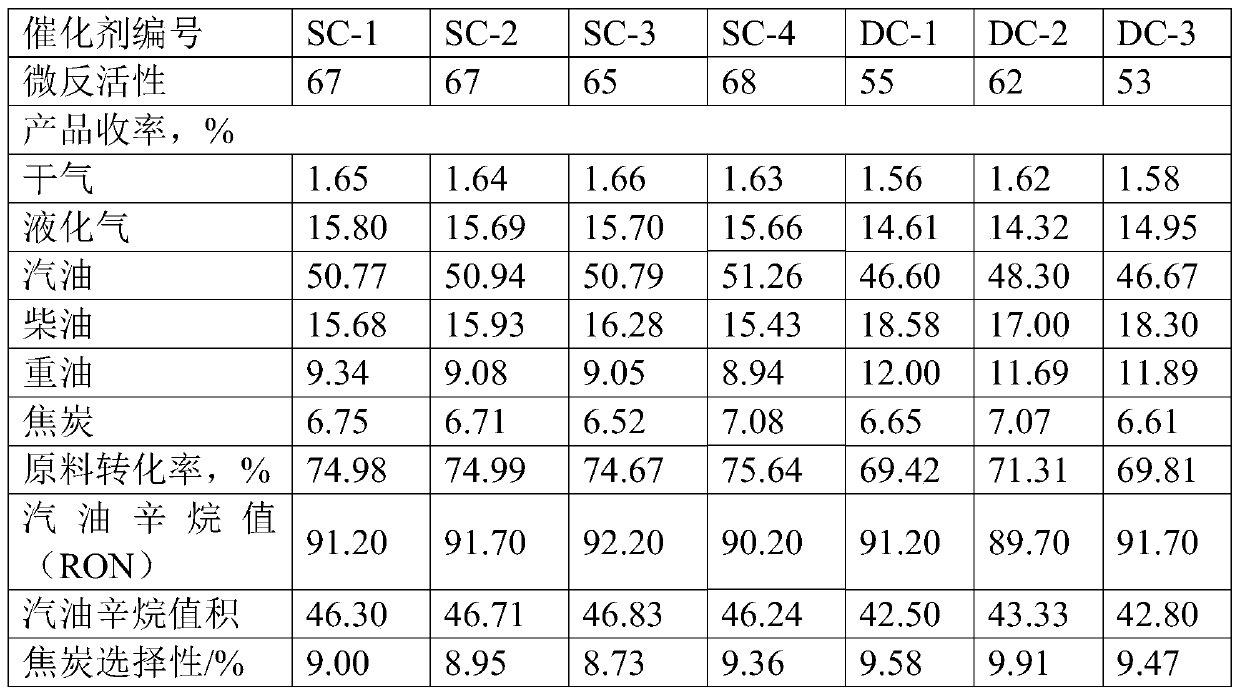

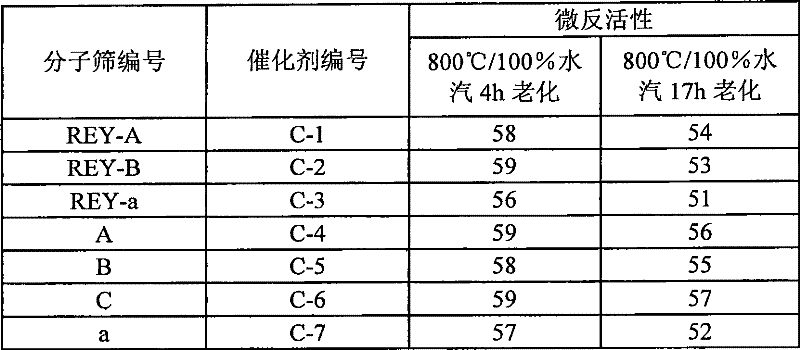

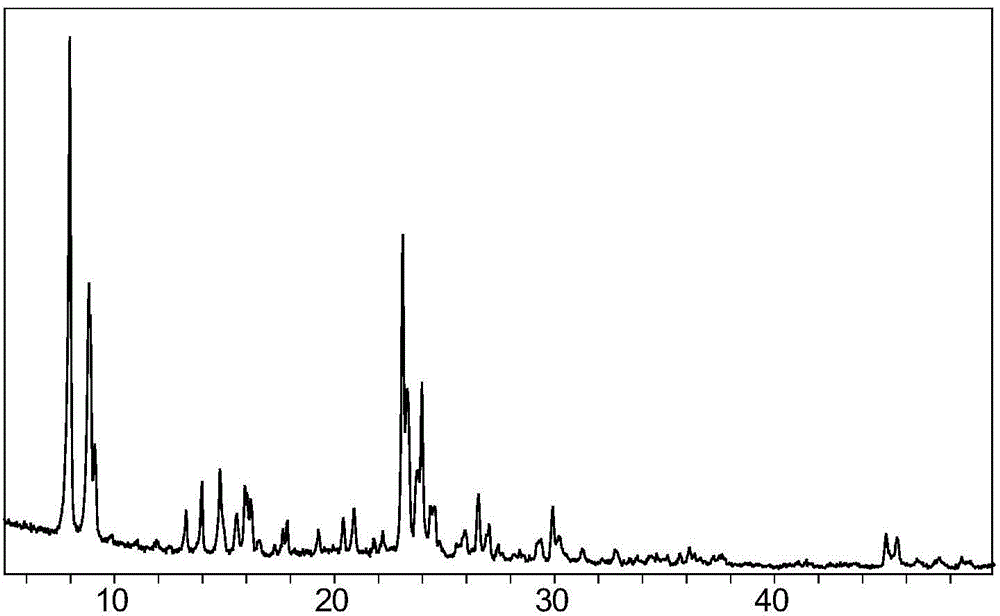

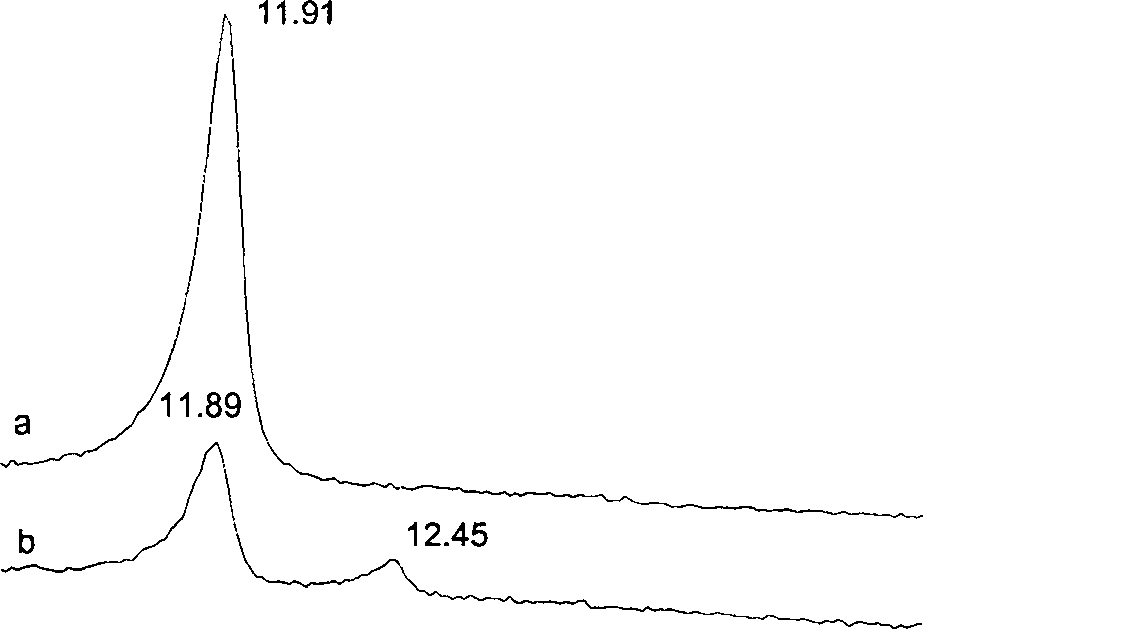

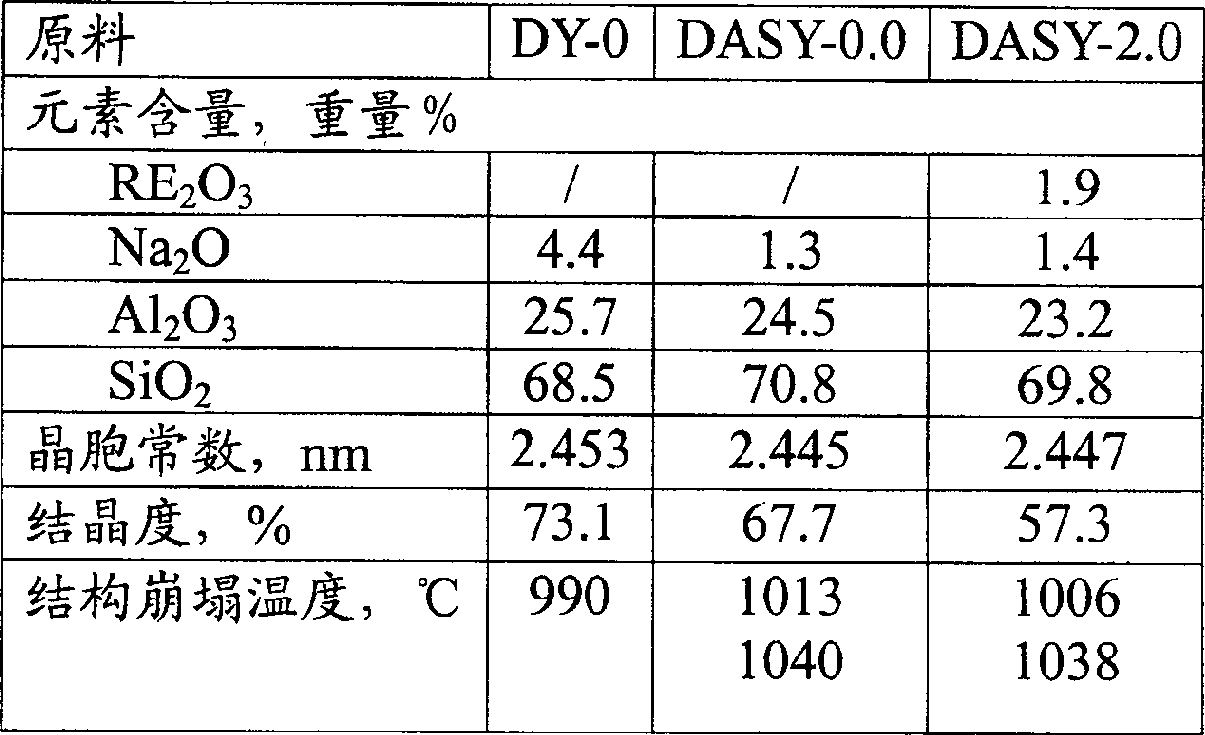

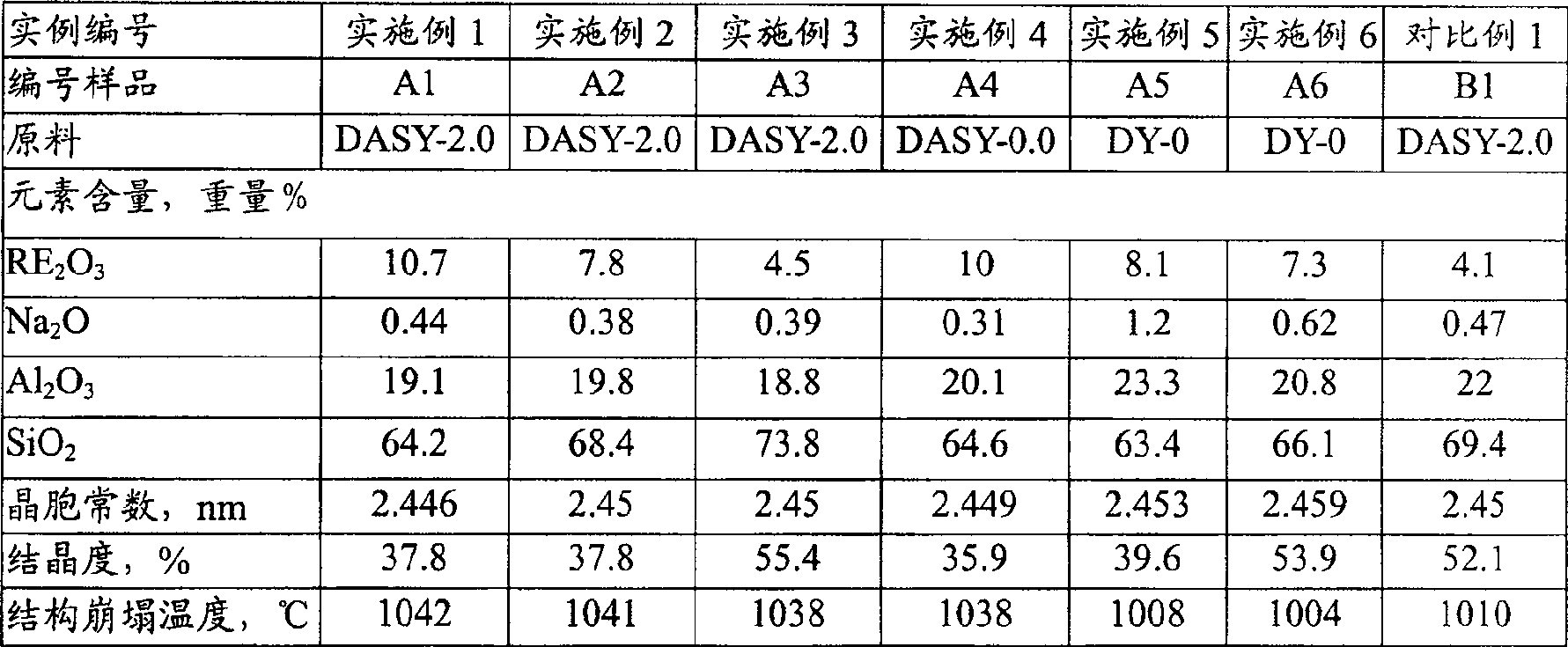

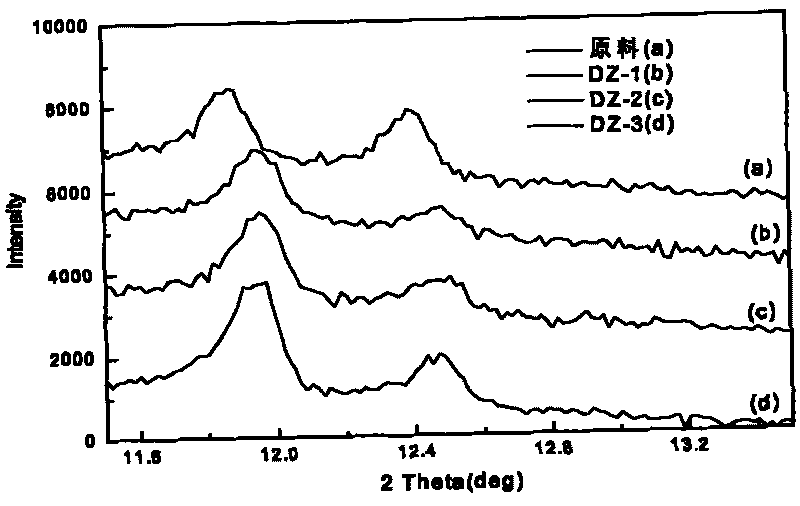

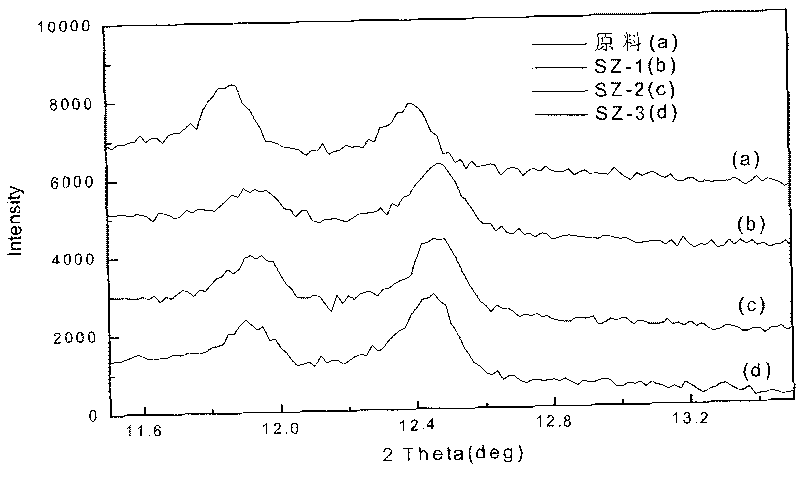

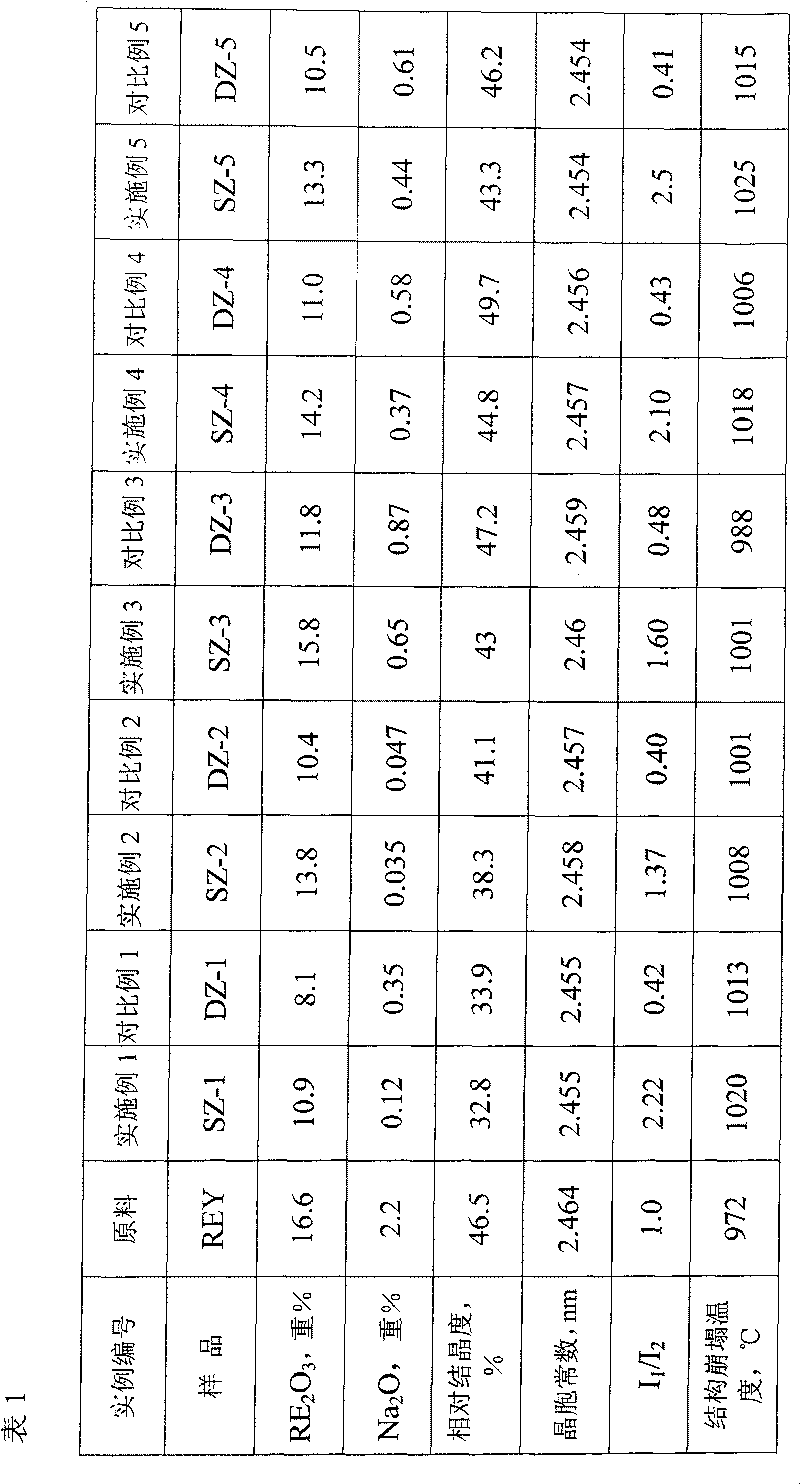

High-silicon rare earth Y type zeolite of small crystal grains with gas phase ultra-stabilization, catalytic cracking catalyst as well as preparation method thereof and catalytic cracking method

ActiveCN106276961AImprove stabilityComplete structureCatalytic crackingMolecular sieve catalystsGas phaseLattice constant

The invention relates to high-silicon rare earth Y type zeolite of small crystal grains with gas phase ultra-stabilization, a catalytic cracking catalyst as well as a preparation method and a catalytic cracking method. The crystal grain average diameter of the high-silicon rare earth Y type zeolite of small crystal grains with gas phase ultra-stabilization is 0.1-0.8 micrometer, lattice constant is 24.5-24.6 angstrom, and silica-alumina ratio is 7-10; the total weight of the zeolite is used as a reference, wherein the content of rare earth oxide is 6-16 wt.%, and the content of sodium oxide is lower than 2 wt.%; the zeolite is prepared by gas phase ultra-stabilization treatment, washing and rare earth ion exchange in order from Y type zeolite of small crystal grains. The catalytic cracking catalyst containing the zeolite has good stability, coke after catalytic cracking has good selectivity, and obtained gasoline product has extremely high gasoline octane number and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

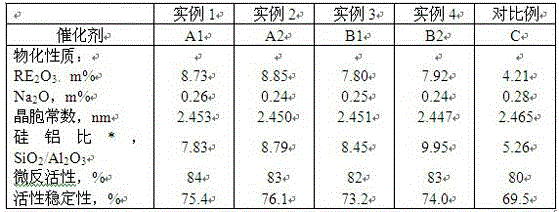

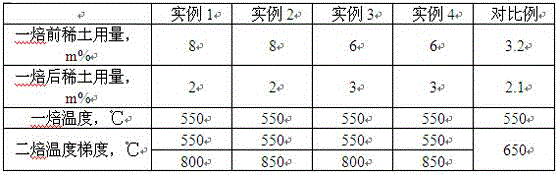

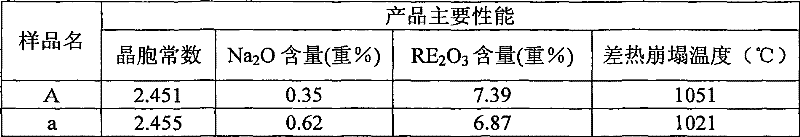

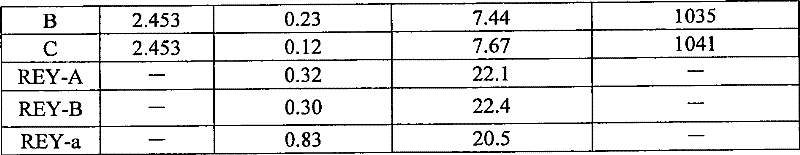

Ultra-stabilization treatment method of high-rare-earth-content in-situ crystallization catalyst

ActiveCN104923282AHigh rare earth contentSmall cell constantMolecular sieve catalystsPtru catalystRare earth ions

The invention discloses an ultra-stabilization treatment method of a high-rare-earth-content in-situ crystallization catalyst. The ultra-stabilization treatment method includes that the ultra-stabilization catalyst high in rare earth content and lower than 2.455nm in lattice constant is prepared by high-temperature hydrothermal calcining of NaY-type catalyst for in-situ crystallization under different temperature gradient conditions after multiple times of exchange of ammonium ions and rare earth ions. The high-rare-earth-content in-situ crystallization catalyst has the advantages of high rare earth content, high silicon-aluminum ratio, high activity, high stability and excellent coke selectivity.

Owner:湖北赛因斯科技开发有限公司

Catalyst for heavy oil catalytic cracking, preparation method thereof, and method for catalytic cracking of heavy oil

ActiveCN106268918BImprove stabilityGood hydrothermal stabilityCatalytic crackingMolecular sieve catalystsGas phaseFuel oil

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of preparing high rare-earth content magnesium intermediate alloy

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

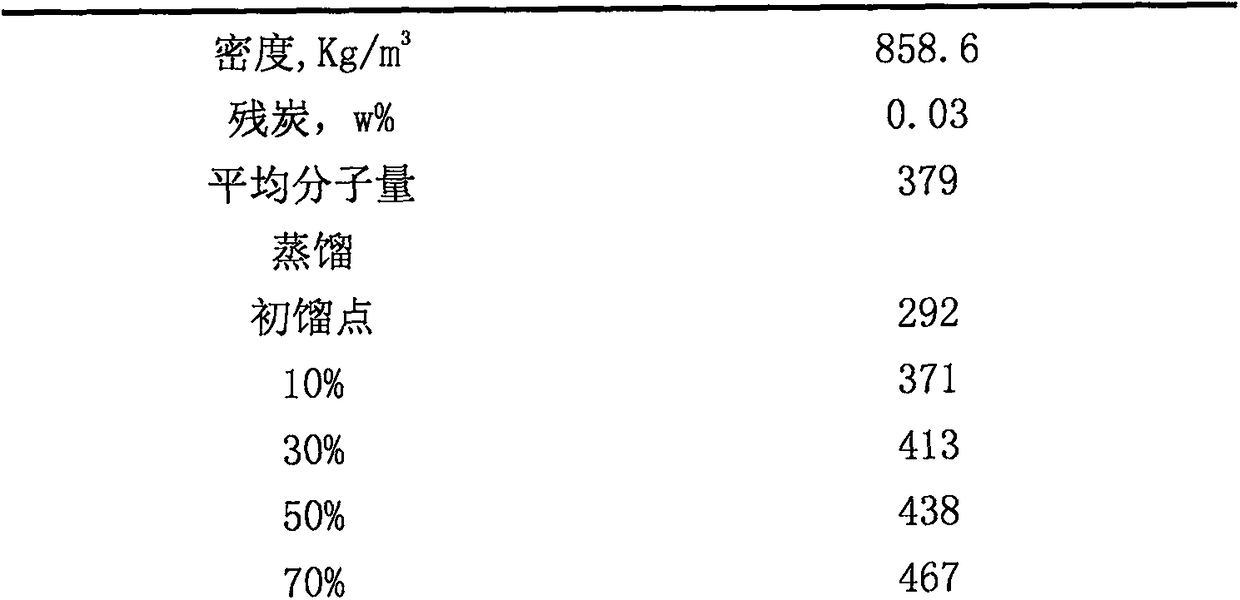

Heavy oil catalytic cracking catalyst, preparation method of heavy oil catalytic cracking catalyst and heavy oil catalytic cracking method

ActiveCN106268918AImprove stabilityGood hydrothermal stabilityCatalytic crackingMolecular sieve catalystsGas phaseFuel oil

The invention relates to a heavy oil catalytic cracking catalyst and its preparation method and a heavy oil catalytic cracking method. The heavy oil catalytic cracking catalyst comprises 10-40% by dry base weight of small crystal grain gas phase ultrastable high-silica rare earth Y-type zeolite, 10-60% by dry base weight of clay and 13-60% of by oxide weight of an inorganic oxide, the inorganic oxide contains at least one active alumina, the average diameter of the alumina crystal grains is in a range of 0.1-0.8 micrometers, a lattice constant is in a range of 24.5-24.6 angstroms and a silica-alumina ratio is in a range of 7-10. The small crystal grain gas phase ultrastable high-silica rare earth Y-type zeolite comprises, by weight, 6-16% of a rare earth oxide and less than 2% of sodium oxide. The Y-type zeolite is prepared from small crystal grain Y-type zeolite through gas phase ultrastable treatment, washing and rare earth ion exchange. The average aperture of the active alumina is in a range of 5-25nm. The catalytic cracking catalyst has good stability and good catalytic cracking coke selectivity and can produce a gasoline product with a high gasoline octane number and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of Y-type molecular sieve containing rare earth

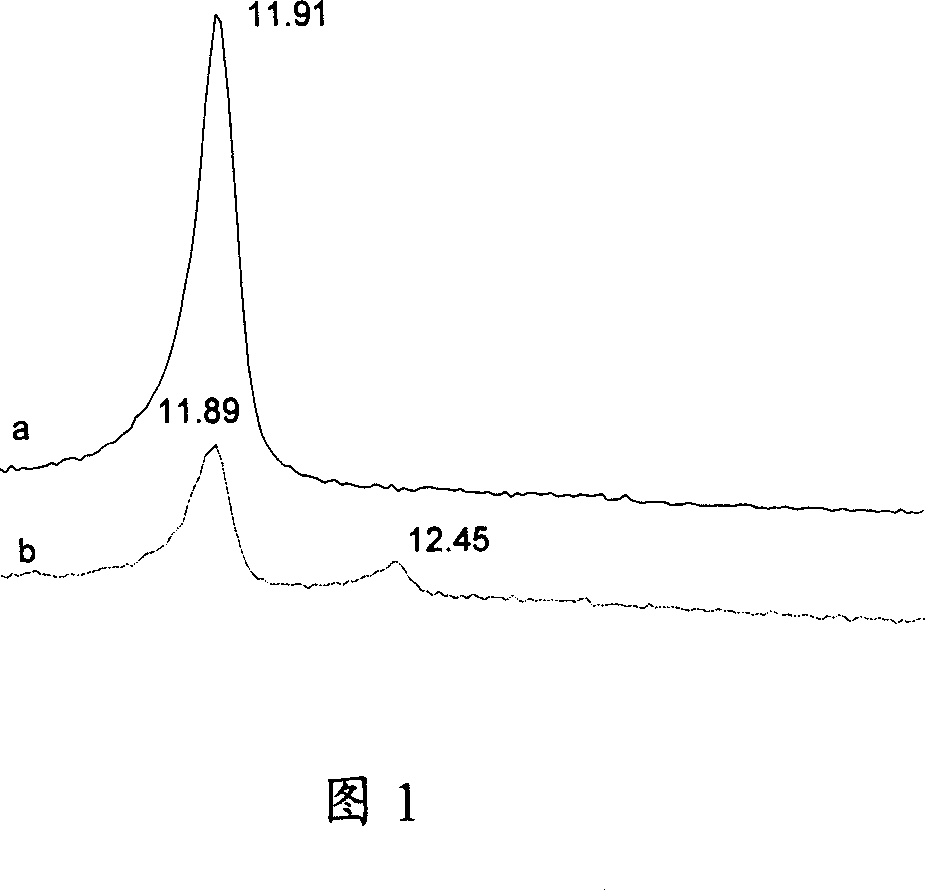

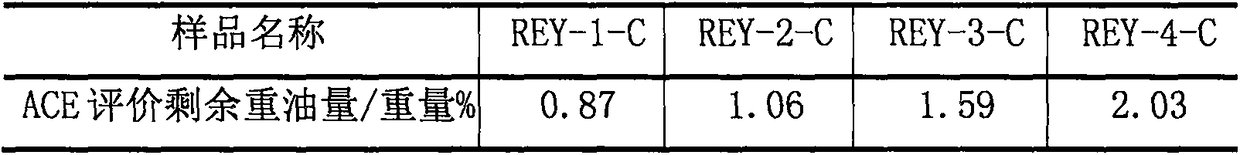

ActiveCN101722021BImprove patencyStrong ion exchange performanceMolecular sieve catalystsEvaluation resultMolecular sieve

The invention provides a method for preparing a rare earth-containing Y-type molecular sieve. The method includes firstly performing alkali treatment and modification on the raw material Y molecular sieve, and then performing ion exchange on the alkali-treated molecular sieve, or further performing hydrothermal ultra-stable treatment on it. , to obtain a rare earth Y-type molecular sieve or a rare earth ultra-stable Y-type molecular sieve. The alkali treatment condition is to mix NaY molecular sieve and alkali solution evenly according to the mass ratio of NaY (dry basis): alkali: H2O=(0.1~2): (0.05~2): (4~15). Alkali treatment is carried out on the molecular sieve under the temperature condition of 120° C. for 0.1 to 24 hours. The evaluation results of the catalytic cracking reaction show that the catalyst prepared by using the rare earth Y-type molecular sieve modified by the method of the present invention and the rare earth ultra-stable Y-type molecular sieve as active components has high micro-reaction activity when used for heavy oil cracking.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for synthesizing rare-earth containing MFI zeolite

The invention relates to a method for synthesizing rare-earth containing MFI zeolite. The method is mainly used for solving the problem in the prior art that the content of rare earths in MFI zeolite crystals is low. According to the method for synthesizing the rare-earth containing MFI zeolite, by adopting the technical scheme that the rare-earth containing MFI zeolite is obtained through mixing a rare-earth containing sheet silicate material, an aluminum source, a template agent and an alkali in water in accordance with that the mole ratio of SiO2 in the sheet silicate material to Al2O3 in the aluminum source to M2O in an alkali source to the template agent to H2O is 1: (0-0.05): (0.05-0.25): (0.01-0.5): (10-100) so as to obtain initial sol, then, crystallizing the initial sol for 20-120 hours in a closed system at the temperature of 130-200 DEG C so as to obtain a product, and subjecting the product to washing, drying and roasting according to conventional methods, the technical problem is better solved, and the rare-earth containing MFI zeolite can be applied to water vapor accompanied high-temperature catalytic reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Silicon, calcium and iron alloy with high rare earth lanthanum

The invention discloses a silicon, calcium and iron alloy with high rare earth lanthanum. The chemical components of the alloy comprise the components in percentage by mass: 27-31% of La, 34-40% of Si, 16-20% of Ca and 9.6-14.1% of Fe. The chemical components of the alloy are moderate in proportion and are uniform and stable. The yield of the rare earth lanthanum in steel is over 19%. The impact performance Akv at -20 DEG C is over 190J, and the alloy is higher in plasticity and toughness and low in cost.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

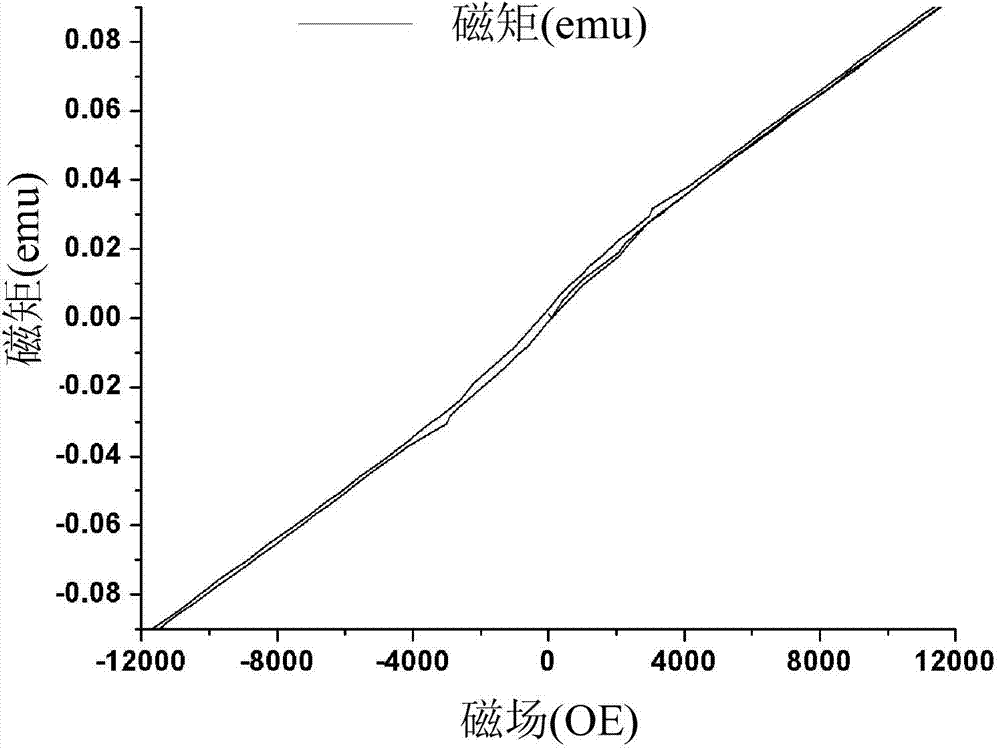

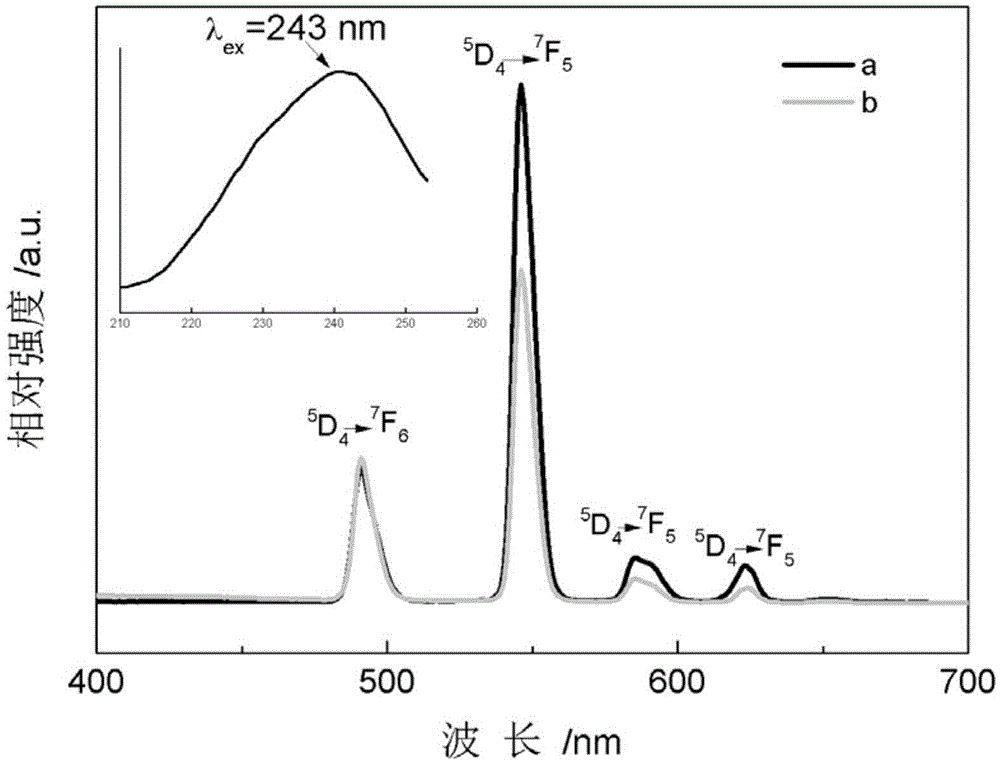

Bifunctional glass and preparation method thereof

The invention discloses a bifunctional glass and a preparation method thereof. The preparation method includes: firstly, in terms of molar percentage, placing 10-18% of Ga2O3, 15-28% of SiC, 14-25% of B2O3, 1-3% of GeO2, 5-40% of Eu2O3, 5-30% of Tb2O3, and 0.1-2% of CeO2 into a ball mill to conduct ball-milling till being able to pass a 200-mesh stand sieve, thus forming a batch; and then subjecting the batch to high temperature melting in air atmosphere into molten glass, finally pouring the molten glass in a graphite mold to undergo forming, and then carrying out precise annealing to obtain the bifunctional glass. The bifunctional glass prepared according to the invention has high light transmittance, strong magnetism, high luminescent intensity, high brightness, pure chroma, high quenching concentration and temperature, excellent glass forming properties, excellent thermal stability and chemical stability. And the preparation process is easy to operate, thus being suitable for industrialized production.

Owner:SHAANXI UNIV OF SCI & TECH

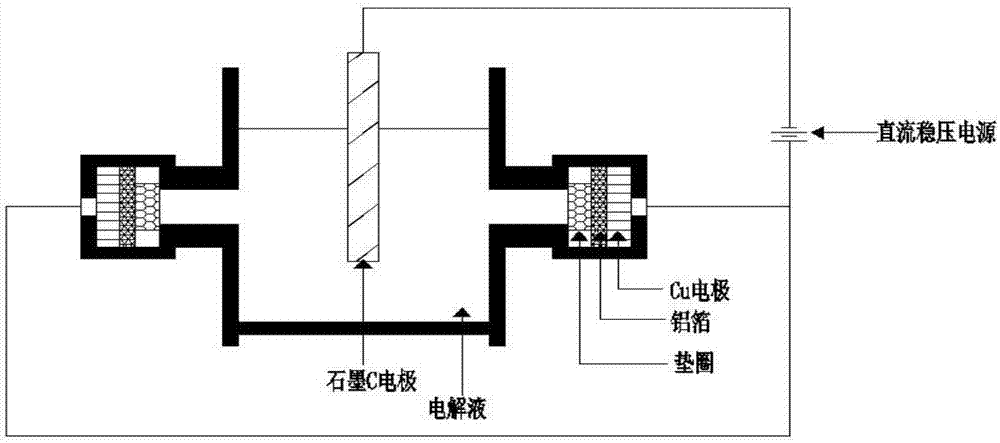

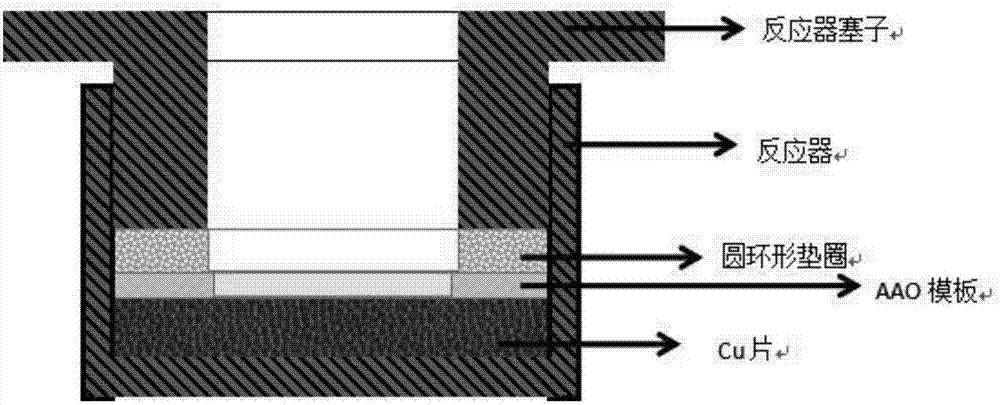

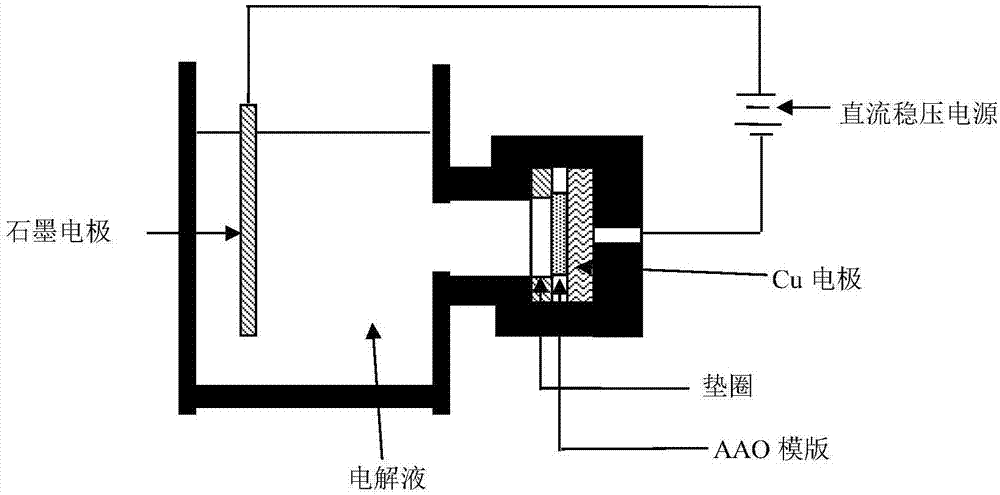

Preparation method for Tb-Fe-Co ternary rare earth alloy magnetic nano-wire film

ActiveCN107460505AFacilitate depositionAvoid hydrolysisNanotechnologyElectroforming nanostructuresGlycineNanowire

The invention discloses a preparation method for a Tb-Fe-Co ternary rare earth alloy magnetic nano-wire film. The method comprises the following steps: preparing a Tb-Fe-Co nano-wire film in an aqueous solution by utilizing an electrochemical deposition method; adding glycine into a Tb-Fe-Co solution system, so that the glycine and Tb form a complex compound; and enabling reducing potential to move positively, simultaneously, increasing a pH value, weakening a hydrogen evolution reaction, so that Tb<3+> is reduced from the solution. The preparation method is simple in process, low in cost and high in success rate; and the compositions of an alloy deposition film are regulated by controlling the proportions of electrolyte compositions and deposition process conditions.

Owner:HEBEI UNIV OF TECH

Method for recovering rare earth from rare earth secondary resources

InactiveCN111593212AHigh rare earth contentHigh recovery rateProcess efficiency improvementPhysical chemistryWastewater

The invention provides a method for recovering rare earth from rare earth secondary resources. The method comprises the following steps that wastewater deposit is put into a container filled with a sodium hydroxide solution, the wastewater deposit reacts with sodium hydroxide, and separation is carried out to obtain a solid product after the reaction is completed; the solid product is put into anacid decomposition tank filled with acid decomposition residues for acid decomposition reaction and then is leached to obtain a rare earth material liquid; and the rare earth material liquid is introduced into a rare earth separation process. According to the method, the wastewater deposit is subjected to alkali conversion through the sodium hydroxide solution, then hydrochloric acid leaching is carried out through the acid decomposition tank and the acid decomposition residues, and finally, the rare earth material liquid high in rare earth content is obtained; and the rare earth material liquid can return to the rare earth separation and production process for recycling. The rare earth recovery method is simple to operate, practical and effective, has high recovery rate, saves resources,and adds a new economic growth point for enterprises.

Owner:赣州稀土龙南冶炼分离有限公司

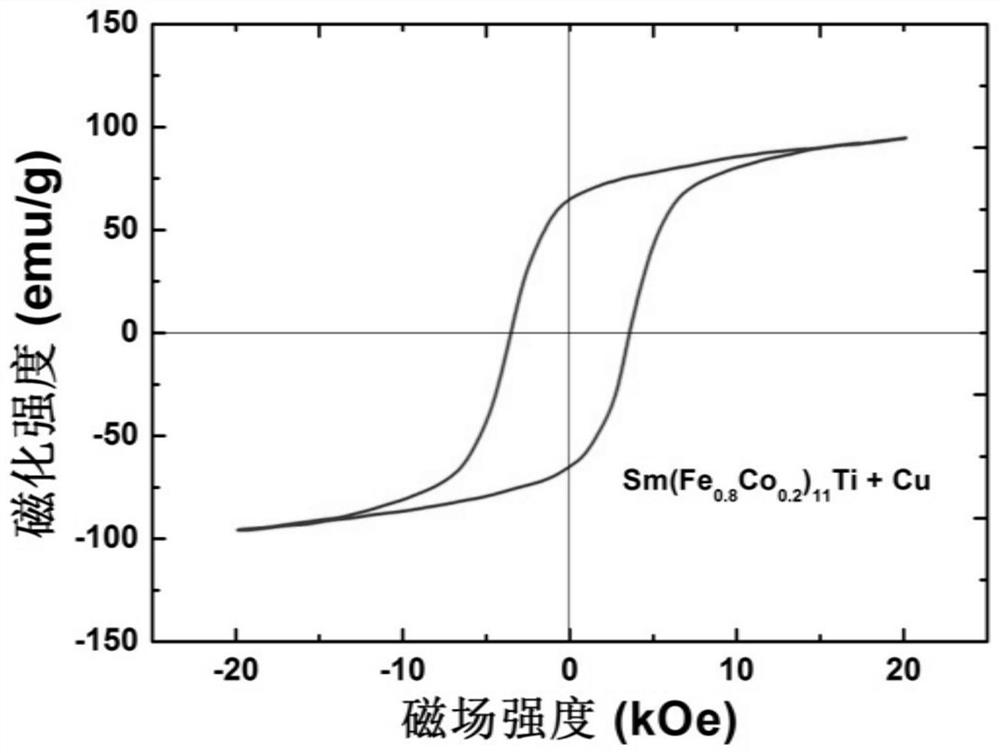

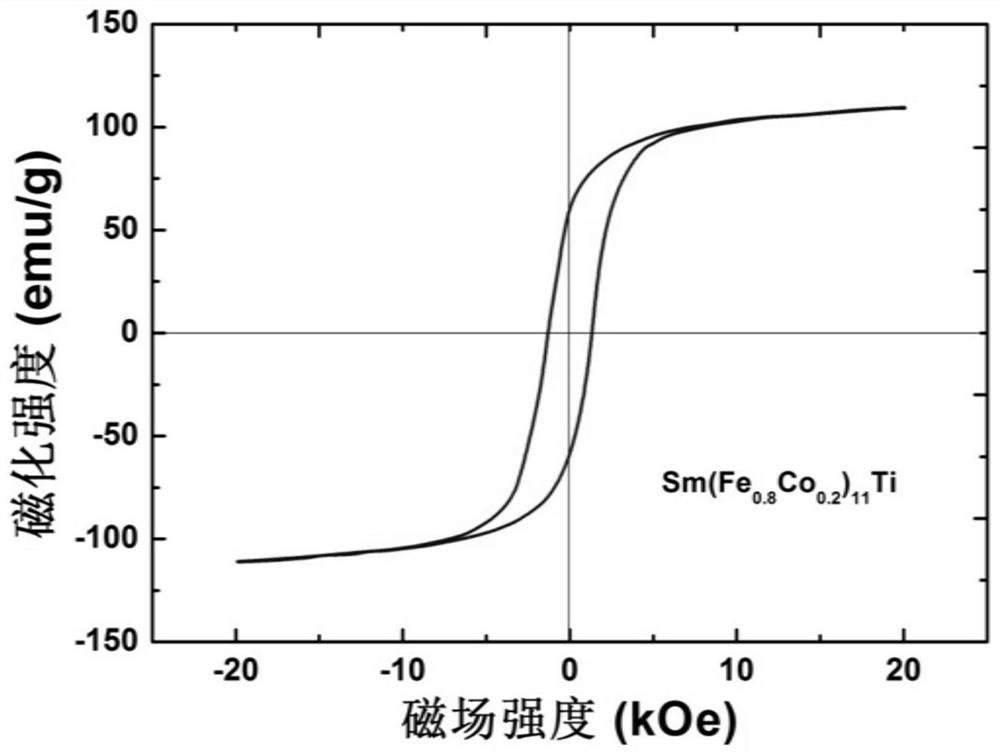

R(Fe,M)12 type rare earth permanent magnet material and preparation method thereof

PendingCN112259314ASolve the problem that the actual coercive force is low and cannot meet the application standardBreak through the fixed research trend of intrinsic characteristicsTransportation and packagingMetal-working apparatusChemical platingMagnetic phase

The invention belongs to the field of permanent magnet materials, and particularly relates to an R(Fe,M)12 type rare earth permanent magnet material and a preparation method thereof. According to theinvention, a Cu-rich grain boundary phase of a magnet is designed through a magnetic powder surface chemical Cu plating process, a hot-pressed magnet is prepared, the coercive force of the magnet is improved, and preparation of the novel R(Fe,M)12 hot-pressed block permanent magnet is achieved; through Cu plating treatment on the surface of the magnetic powder, the Cu-rich grain boundary phase perfectly coating grains can be formed in the hot-pressed magnet, so that the purpose of magnetic isolation between R(Fe,M)12 hard magnetic phase grains can be effectively achieved, reverse magnetizationdomain extension is inhibited, and the permanent magnet characteristic of the magnet is improved; and the grain boundary Cu-rich phase can also greatly improve the electrochemical potential of the grain boundary corrosion channel of the magnet, effectively improve the intrinsic corrosion resistance of the magnet and prolong the actual service life of the magnet.

Owner:NANJING UNIV OF SCI & TECH

A kind of preparation method of regenerative sintered NdFeB permanent magnet

ActiveCN109192495BStrengthen the grain surfaceImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsMetallurgyMagnetic field magnitude

The invention provides a preparation method of regenerated sintered Nd-Fe-B permanent magnet, which comprises the following steps of: carrying out surface pretreatment on waste sintered Nd-Fe-B permanent magnet, and then crushing the waste Nd-Fe-B permanent magnet into magnetic powder with an average particle size of 2.0-4.0 mum; 2 to 99.5 to 0.5, so that that heavy rare earth atom diffuse into the surface layer of the magnetic powder to obtain the modified magnetic powder; 100 to 5:100 of rich and high-abundance rare earth powder and modified magnetic powder according to mass ratio to obtainmixed magnetic powder. The mixed magnetic powder is placed in a magnetic field with a magnetic field strength of more than 1.5 T, and then the magnetic powder is pressed into a compact by the orientedmoulding method. The regenerative sintered Nd-Fe-B permanent magnet is prepared by high temperature sintering and tempering. The regenerative sintered Nd-Fe-B permanent magnet prepared by the invention has high performance, low cost and high recovery efficiency for waste magnets.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

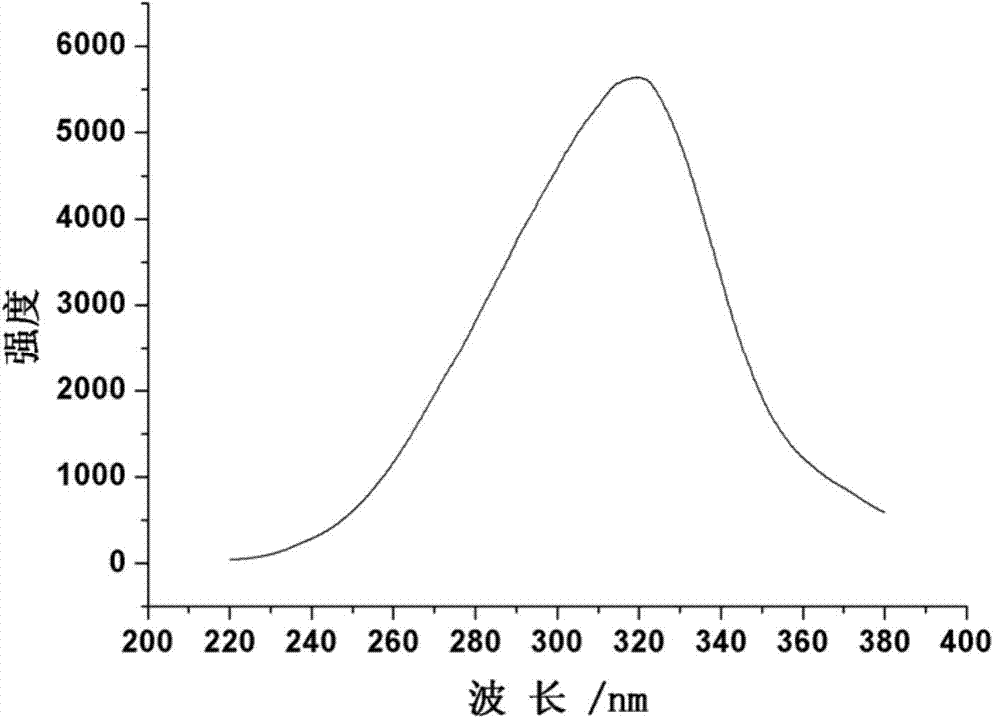

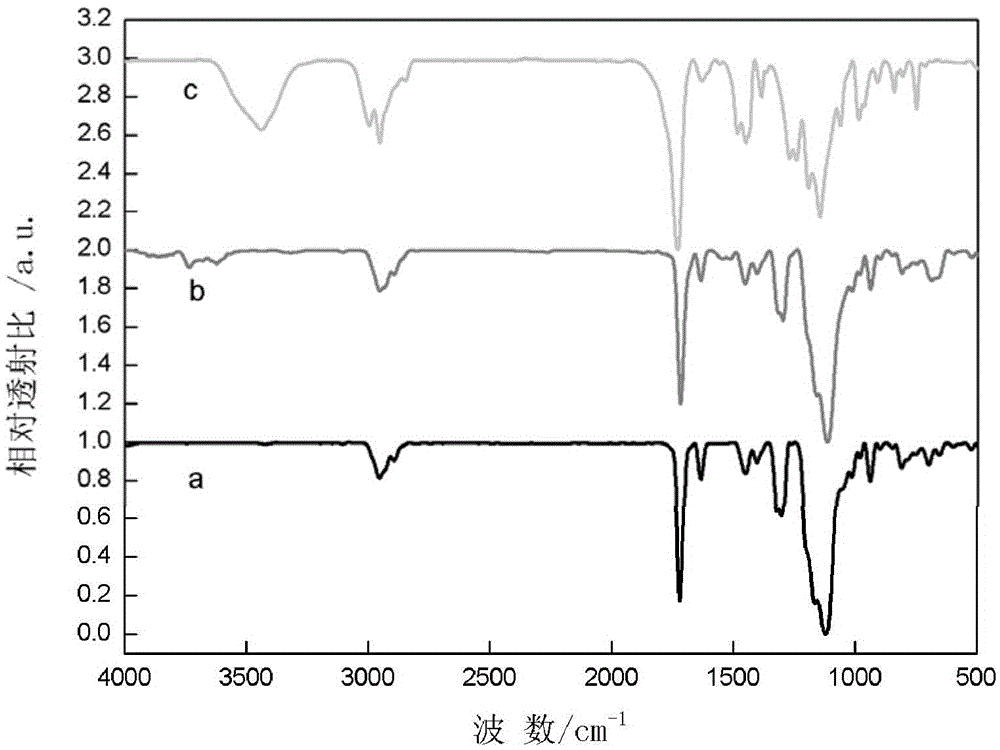

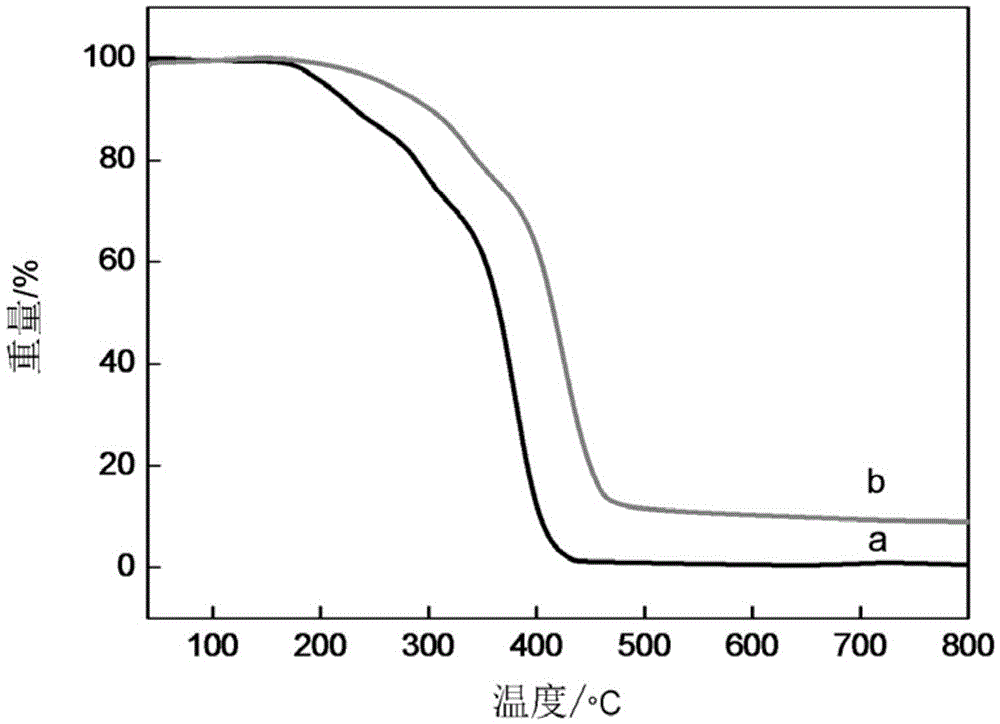

Synthetic method for light-emitting polyacrylic material containing acrylate functional group polyhedronal oligomeric silsesquioxane rare earth complex

ActiveCN105418831AOvercoming poor light and heat stabilityWide rare earth contentSilicon organic compoundsGroup 3/13 organic compounds without C-metal linkagesFluorescenceTransmittance

The invention relates to a synthetic method for a light-emitting polyacrylic material containing an acrylate functional group polyhedronal oligomeric silsesquioxane rare earth complex. The synthetic method comprises: firstly performing coordination on acrylate functional group polyhedronal oligomeric silsesquioxane and a rare earth compound by virtue of coordination chemistry principles; then dispersing the acrylate functional group polyhedronal oligomeric silsesquioxane rare earth complex in an acrylic monomer for in-situ mass polymerization; and finally obtaining the light-emitting polyacrylic material containing the acrylate functional group polyhedronal oligomeric silsesquioxane rare earth complex, wherein the material has good light transmittance, heat stability and a fluorescence property. The synthetic method provided by the invention is simple in synthetic steps, mild in condition, free of any additives and easy to control conditions, and the whole synthetic equipment is easy to construct and is of great innovation, so that industrial production of the light-emitting polyacrylic materials is facilitated.

Owner:SHANDONG UNIV

Catalytic cracking catalyst

ActiveCN100537029CHigh gasoline yieldHigh yieldMolecular sieve catalystsMolecular sieveRare earth ions

A cracking catalyst, containing 10% to 50% by weight of high rare earth ultra-stable Y-type molecular sieve based on dry basis, 10% to 40% by weight of alumina binder based on alumina and 10% by weight to 70% by weight of clay; the high-rare-earth ultra-stable Y molecular sieve is obtained by steps including the following method: ultra-stable Y-type zeolite and an acid solution with an equivalent concentration of 0.01N to 2N at a liquid-solid ratio of 4 to 20 at 20 Fully mix at a temperature range of ℃ to 100 ℃, stir for 10 minutes to 300 minutes, wash and filter, then add a rare earth salt solution to perform rare earth ion exchange, wash, filter and dry after the exchange. The catalyst of the invention is used for catalytic cracking of heavy oil, and has high gasoline yield and high conversion rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

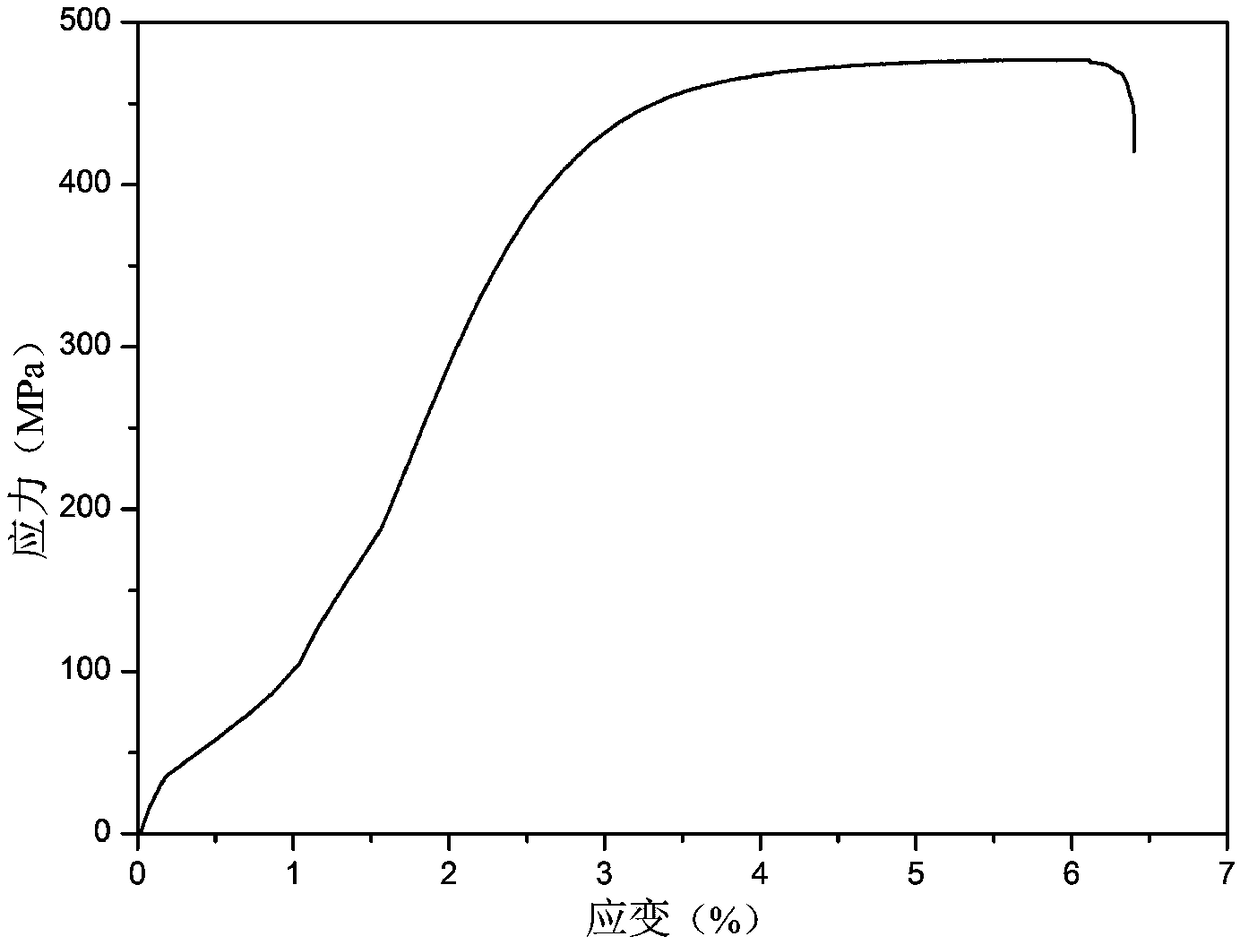

Preparation method for magnesium-titanium alloy plate with high rare earth content

InactiveCN108823475AHigh rare earth contentAdvanced technologyFoundry mouldsFoundry coresGadoliniumRare earth

The invention relates to a preparation method for a magnesium-titanium alloy plate with high rare earth content. The magnesium-titanium alloy plate with high rare earth content is prepared from magnesium, zinc, titanium, a magnesium-yttrium intermediate alloy and a magnesium-gadolinium intermediate alloy through melting in a vacuum melting furnace, casting molding, homogenization treatment, rolling forming and aging treatment, and has tensile strength of up to 477 MPa and elongation percentage of 6.4%. The preparation method is advanced in technology and accurate and detailed in data, and is an advanced preparation method for the magnesium-titanium alloy plate with high rare earth content.

Owner:ZHONGBEI UNIV

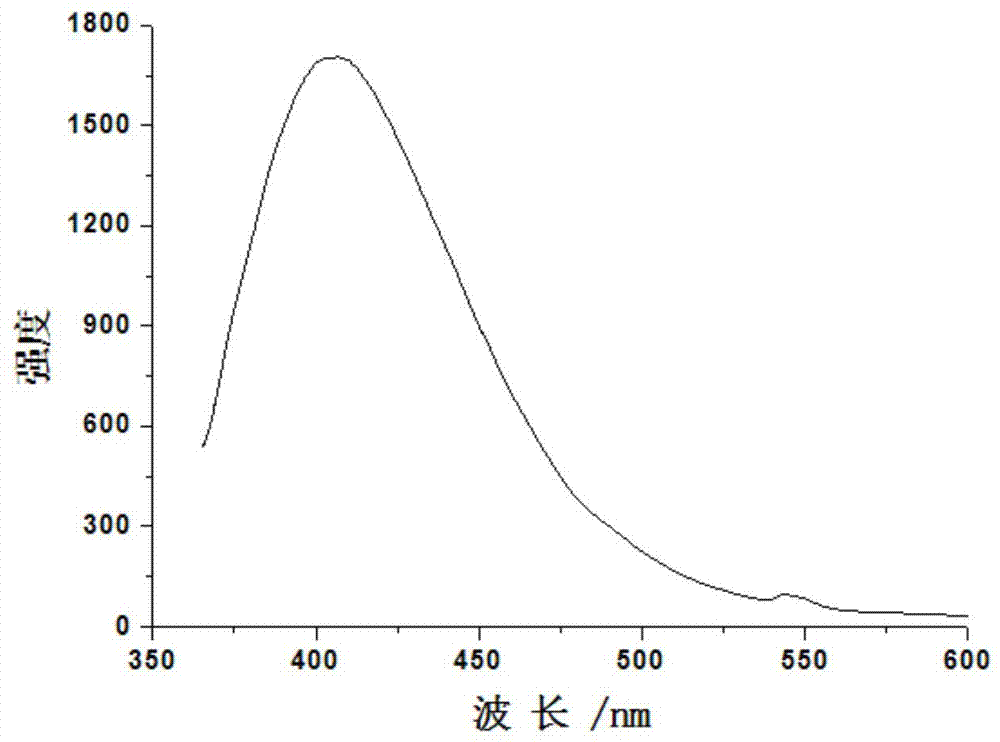

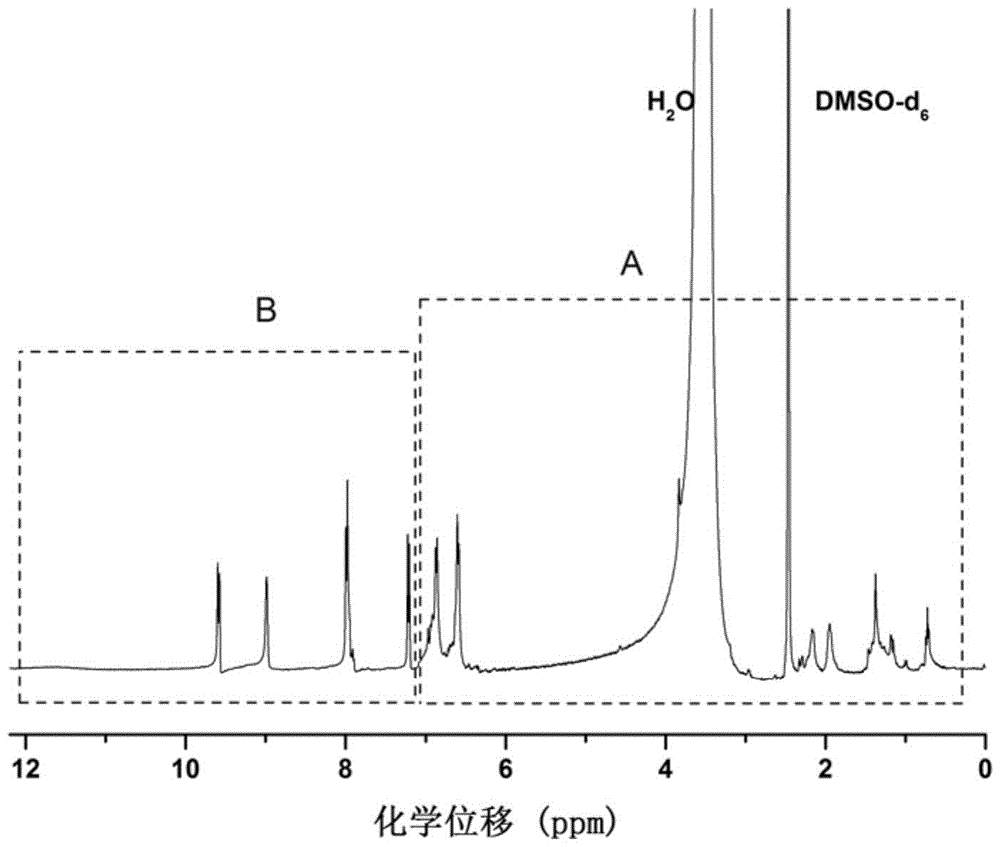

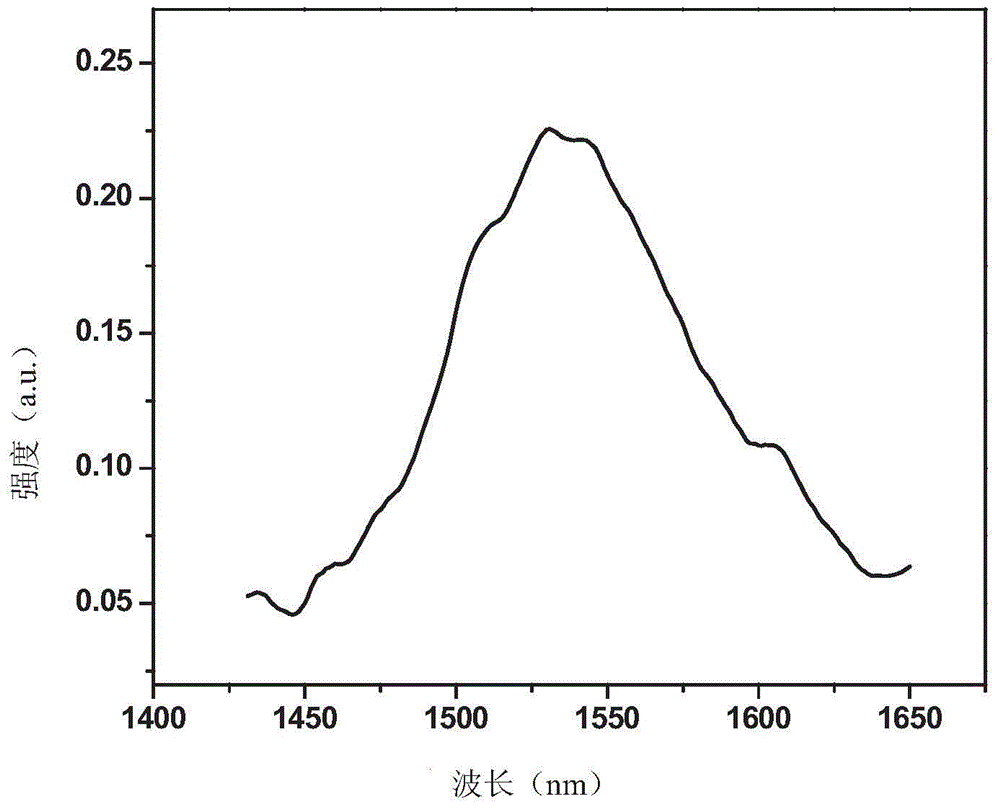

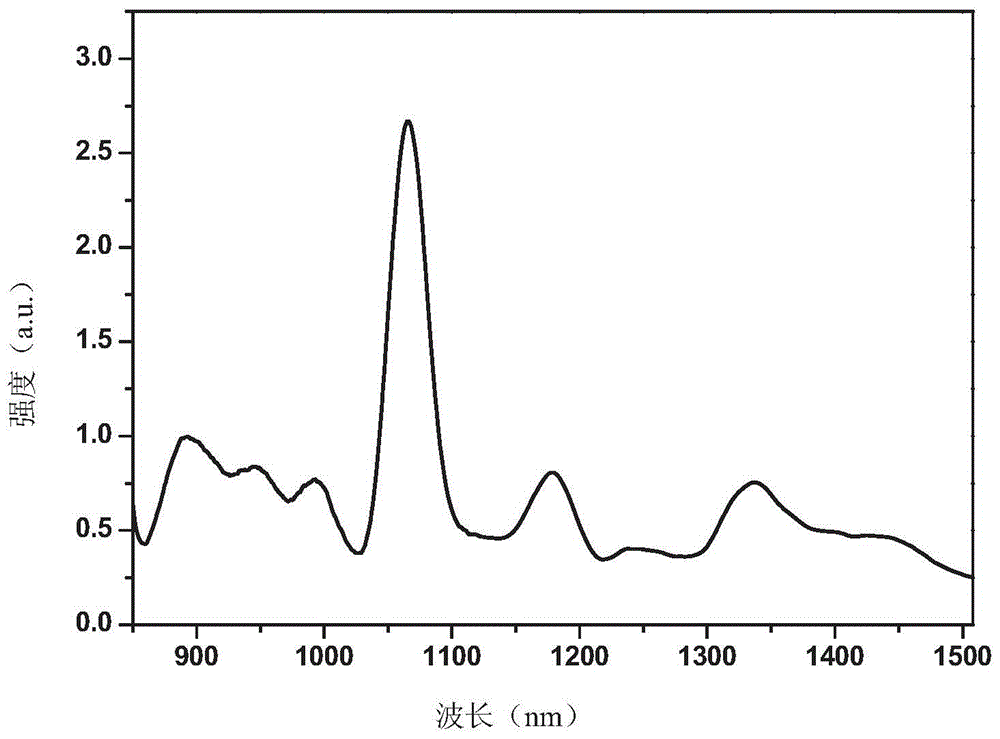

8-hydroxyquinoline-terminated hyperbranched polyester rare earth complex and its preparation method and application

ActiveCN104788667BShort synthetic routeEasy to prepareLuminescent compositionsOrganic solventFluorescence

The invention discloses an 8-hydroxyquinoline terminated hyperbranched polyester rare earth complex as well as a preparation method and an application thereof. The structural formula of the complex is represented in the formula (I). The preparation method comprises steps as follows: (1), hydroxyl-terminated hyperbranched polyester is modified by a modifying agent, and an 8-hydroxyquinoline structure is connected onto the terminal hydroxyl group to obtain 8-hydroxyquinoline terminated hyperbranched polyester; (2), 8-hydroxyquinoline terminated hyperbranched polyester, a second ligand and soluble salt of rare earth are dissolved in an organic solvent for an reaction, and after the reaction is finished, the 8-hydroxyquinoline terminated hyperbranched polyester rare earth complex is obtained through separation in a reaction liquid. The 8-hydroxyquinoline terminated hyperbranched polyester rare earth complex has a function of fluorescence emission in a near-infrared communication window, is suitable as a gain medium of an active optical waveguide amplifier, has the larger fluorescence half-width (FWHM), and is expected to obtain the larger gain bandwidth.

Owner:JIAXING UNIV

Y type zeolites containing rare-earth and high content of silicon and method of making the same

ActiveCN101081369BSimple structureImprove thermal stabilityMolecular sieve catalystsGas phaseRare earth

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of paramagnetic optically active glass and preparation method thereof

InactiveCN103708726BHigh rare earth contentRare earth ions have low valenceAir atmosphereVerdet constant

The invention discloses paramagnetic faraday rotator glass and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing tetraterbium heptaoxide, boric acid, aluminium oxide, ammonium dihydrogen phosphate, antimony oxide and silicon carbide so as to obtain mixed batch; and then melting the mixed batch into molten glass at a high temperature in air atmosphere, finally pouring the molten glass into a stainless steel mold for forming, and precisely annealing so as to obtain the paramagnetic faraday rotator glass. The preparation method has the advantages that through the oxidation-reduction characteristic of the mixed batch, the low valence of rare earth ions in the glass is ensured, a platinum crucible is protected from corrosion, and platinum ions are prevented from entering the glass. The optical quality of the paramagnetic faraday rotator glass is improved; a founding technology of the paramagnetic faraday rotator glass is improved and simplified. The prepared paramagnetic faraday rotator glass is high in rare earth content, low in rare earth ion valence, high in Verdet constant, high in light transmittance, absorption-free in a visible light range, simple in preparation technology and operational operation and suitable for industrial production.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com