Synthetic method for light-emitting polyacrylic material containing acrylate functional group polyhedronal oligomeric silsesquioxane rare earth complex

A polysilsesquioxane and acrylate technology is applied in the synthesis field of luminescent polyacrylic materials, and can solve the problems of complex preparation process, inability to carry out copolymerization reaction, inability to directly coordinate rare earth elements, etc., and achieve simple synthesis steps. , It is convenient for industrial application and overcomes the effect of poor photothermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

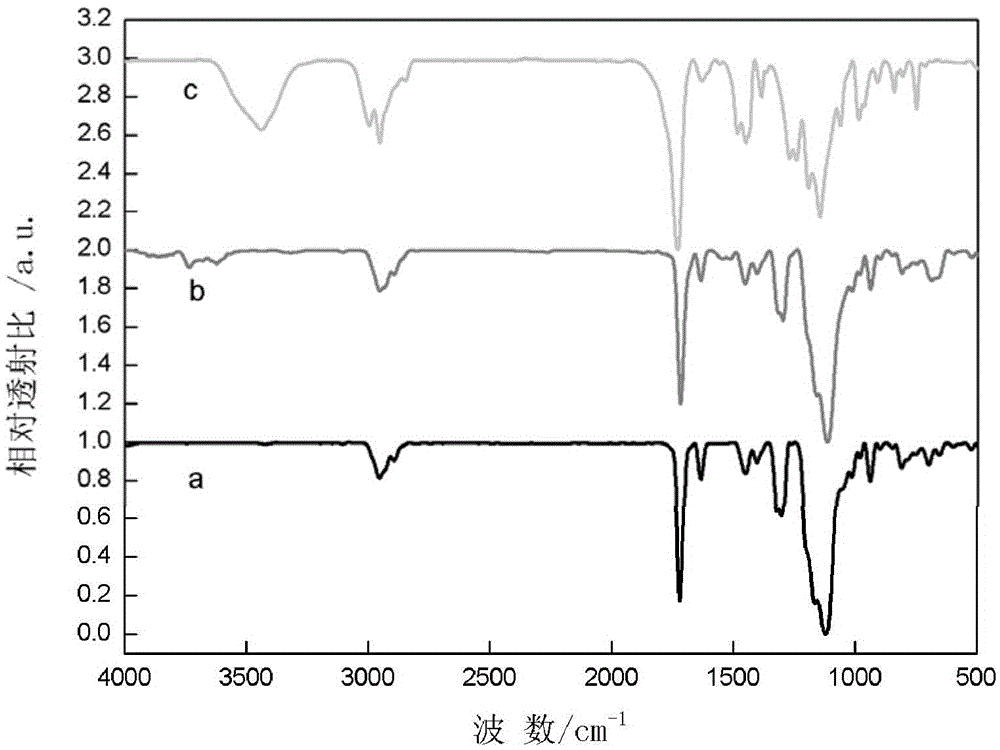

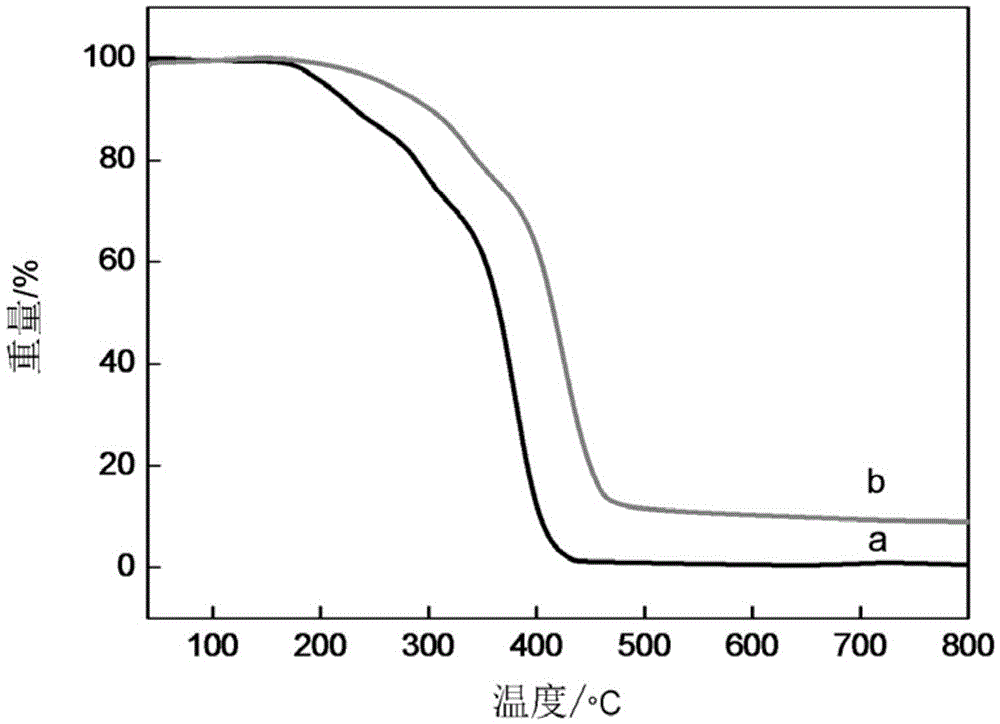

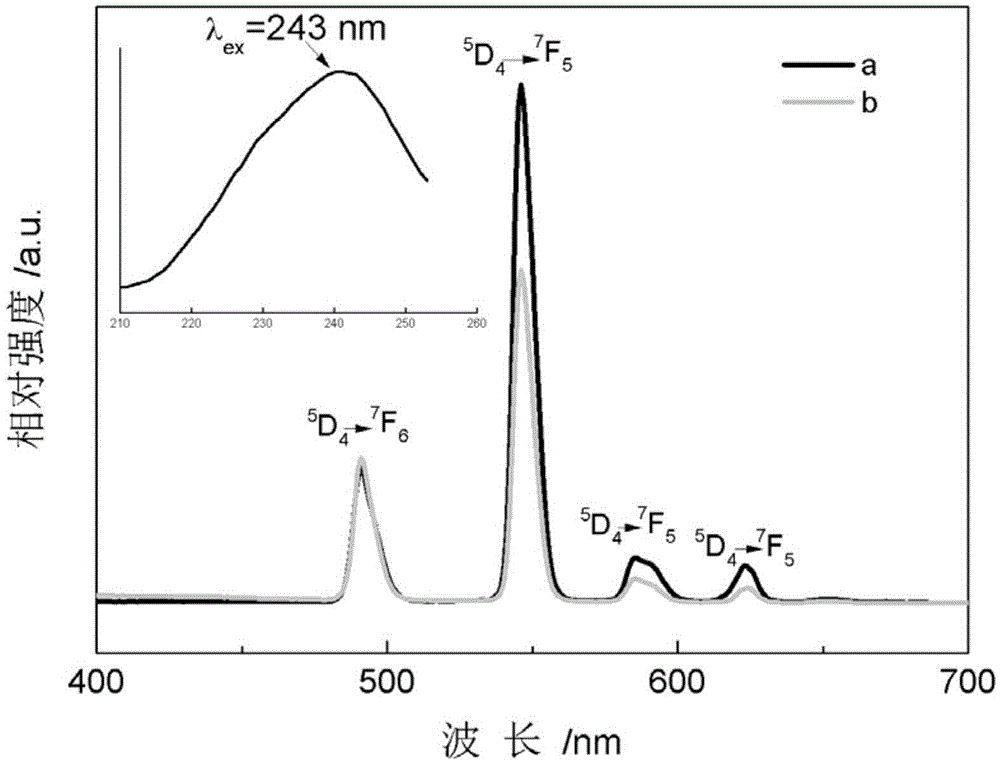

[0044] A method for synthesizing a luminescent polyacrylic material containing an acrylic functional group polyhedral oligomeric silsesquioxane rare earth complex includes the following steps:

[0045] (1) Preparation of acrylate functional group polyhedral oligomeric silsesquioxane rare earth complex

[0046] Put 0.388g terbium nitrate into a weighing bottle, add 20mL tetrahydrofuran, stir the solution until terbium nitrate is completely dissolved, weigh out 0.612g acrylic functional group polyhedral oligomeric silsesquioxane, and stir at room temperature for 1-10h, Rotary evaporation of the obtained reaction liquid, and the obtained compound is an acrylic functional group polyhedral oligomeric silsesquioxane rare earth terbium complex.

[0047] The acrylate functional group polyhedral oligomeric silsesquioxane is octamethacrylate-based oligomeric silsesquioxane, decamethacrylate-based oligomeric silsesquioxane and dodecamethacrylate A mixture of methyl acrylate-based oligomeric si...

Embodiment 2

[0055] A method for synthesizing a luminescent polyacrylic material containing an acrylic functional group polyhedral oligomeric silsesquioxane rare earth complex includes the following steps:

[0056] (1) Preparation of acrylate functional group polyhedral oligomeric silsesquioxane rare earth complex

[0057] Put 0.768g of terbium nitrate into a weighing bottle, add 20mL of tetrahydrofuran, stir the solution until the terbium nitrate is completely dissolved, add 1.226g of octamethacrylate methyl oligomeric silsesquioxane, deca methyl methacrylate The mixture of oligomeric silsesquioxane and dodecamethacrylate-based oligomeric silsesquioxane is stirred at room temperature for 1-10 hours, and the resulting reaction liquid is rotary evaporated, and the obtained compound is acrylate-based Base polyhedral oligomeric silsesquioxane rare earth terbium complex.

[0058] (2) Preparation of luminescent polyacrylic materials containing polyhedral oligomeric silsesquioxane rare earth complexes...

Embodiment 3

[0064] A method for synthesizing a luminescent polyacrylic material containing an acrylic functional group polyhedral oligomeric silsesquioxane rare earth complex includes the following steps:

[0065] (1) Preparation of acrylate functional group polyhedral oligomeric silsesquioxane rare earth complex

[0066] Put 1.162g of terbium nitrate into a weighing bottle, add 20mL of tetrahydrofuran, stir the solution until the terbium nitrate is completely dissolved, add 1.838g of octamethacrylate methyl oligomeric silsesquioxane, deca methyl methacrylate The mixture of oligomeric silsesquioxane and dodecamethacrylate-based oligomeric silsesquioxane is stirred at room temperature for 1-10h, and the resulting reaction liquid is rotary evaporated, and the obtained compound is acrylate-based Base polyhedral oligomeric silsesquioxane rare earth terbium complex.

[0067] (2) Preparation of luminescent polyacrylic materials containing polyhedral oligomeric silsesquioxane rare earth complexes with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com