Preparation method for magnesium-titanium alloy plate with high rare earth content

A high rare earth content, magnesium-titanium alloy technology, applied in metal processing equipment, manufacturing tools, casting molding equipment, etc., to achieve the effect of accurate and detailed data and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

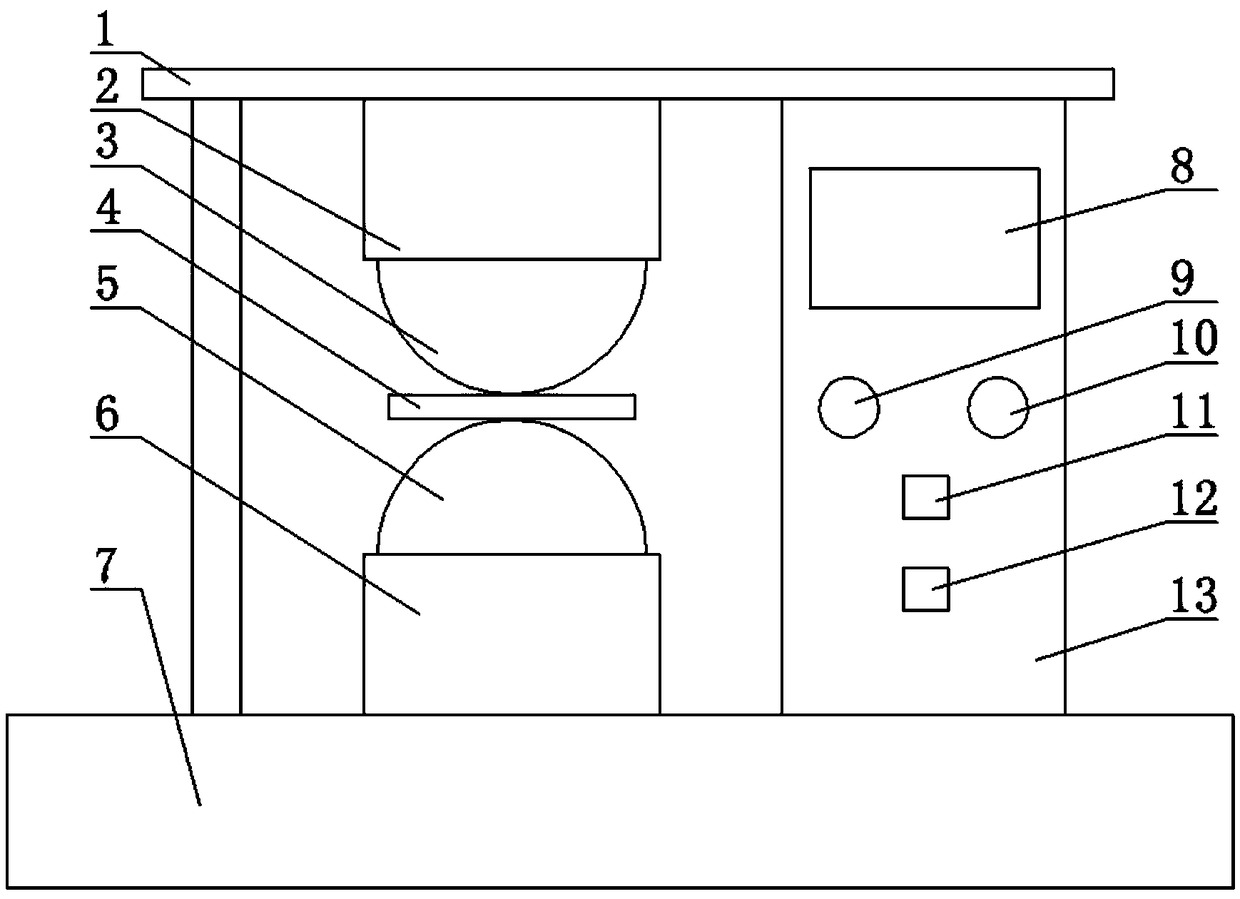

[0075] The present invention will be further described below in conjunction with accompanying drawing:

[0076] figure 1 As shown in the figure, it is a rolling state diagram of magnesium-titanium alloy sheet with high rare earth content. The position of each part must be correct, set according to the amount, and operate in sequence.

[0077] The amount of chemical substances used in the preparation is determined according to the pre-set range in millimeters, milliliters, centimeters 3 is the unit of measurement.

[0078] The rolling of the magnesium alloy sheet is carried out on a two-roll mill, which is completed in the process of heating the slab, pressing the roll, and deforming the material;

[0079] The twin-roll mill is vertical, the upper right part of the twin-roll mill base 7 is the twin-roll mill electric control box 13, and the twin-roll mill electric control box 13 is provided with a twin-roll spacing regulator 8, a roll working indicator light 9, and a twin-rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com