Y type zeolites containing rare-earth and high content of silicon and method of making the same

A zeolite and rare earth technology, which is applied in the field of Y-type zeolite and its preparation, can solve the problems of reducing zeolite selectivity, high Y-type zeolite, destroying zeolite structure, etc., and achieves enhanced heavy oil conversion capacity, improved thermal stability, and increased rare earth content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

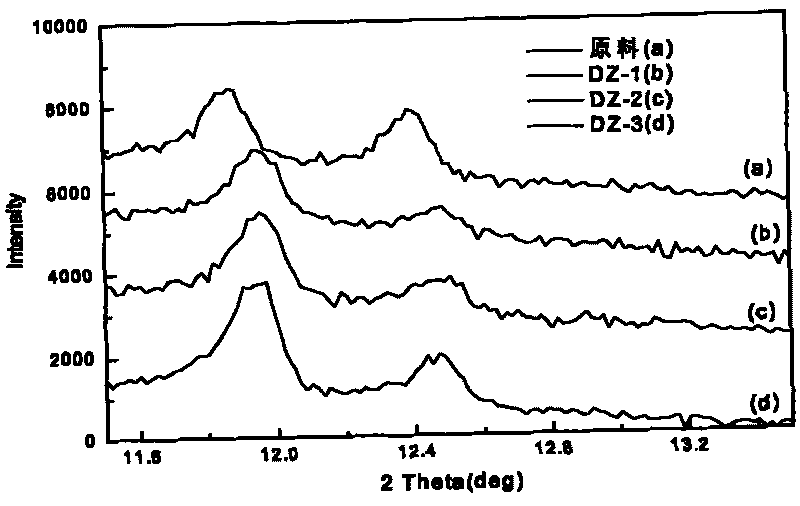

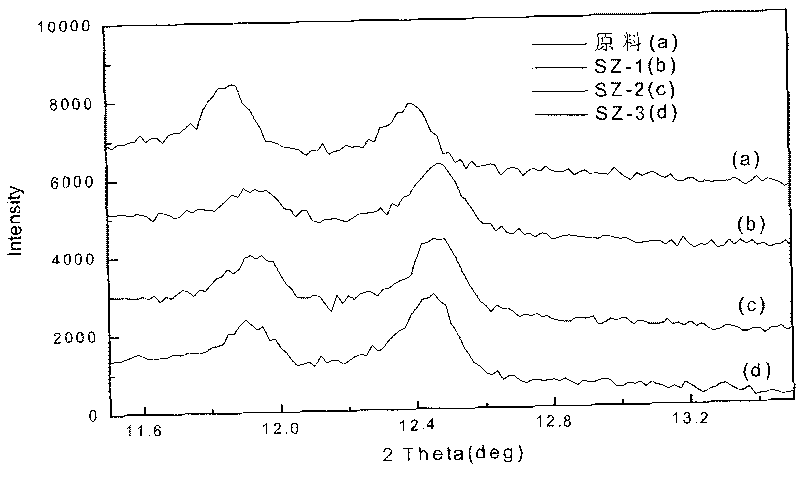

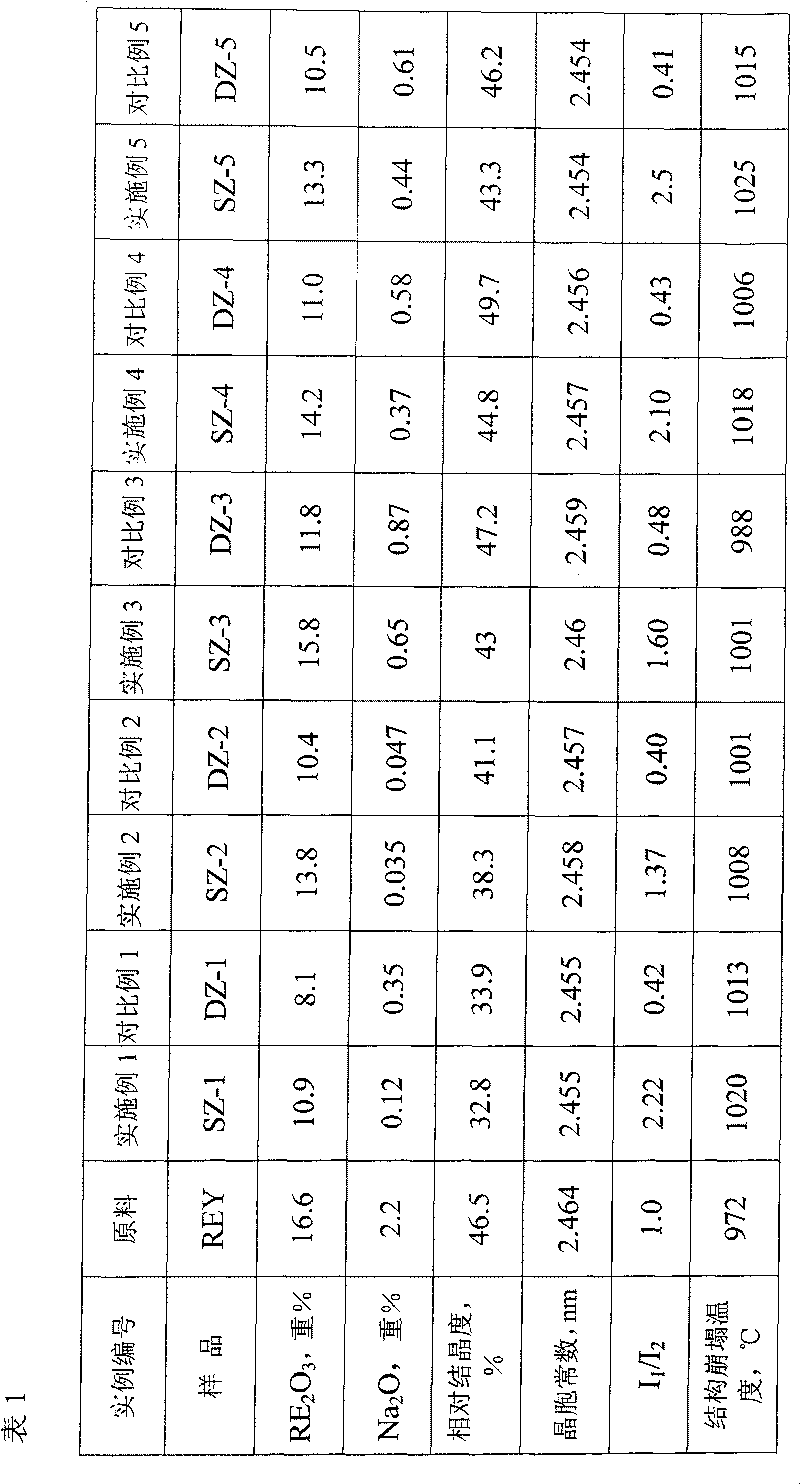

[0037] Get the sample DZ-1 in Comparative Example 1 to carry out rare earth exchange modification, DZ-1: RECl 3 :H 2 O=1:0.06:10 ratio exchange RECl 3 , the rare earth was exchanged for 30 minutes at a temperature of 90°C, and then filtered, washed and dried, and the sample was designated as SZ-1. Its physical and chemical properties are listed in Table 1, and its XRD diffraction pattern is shown in figure 2 .

[0038] After aging SZ-1 in the bare state at 800°C and 100% water vapor for 17 hours, the unit cell constant and relative crystallization retention of aged SZ-1 zeolite were analyzed and calculated by XRD method. The results are shown in Table 2.

Embodiment 2

[0043] Get the sample DZ-2 in comparative example 2 to carry out rare earth exchange modification, press DZ-2: RECl 3 :H 2 O=1:0.08:10 ratio exchange RECl 3 , carried out rare earth exchange at 90°C for 30 minutes, then filtered, washed and dried, and the sample was designated as SZ-2. Its physical and chemical properties are listed in Table 1, and its XRD diffraction pattern is shown in figure 2 .

[0044] After aging SZ-2 in the bare state at 800°C and 100% steam for 17 hours, the unit cell constant and relative crystallization retention of SZ-2 zeolite after aging were analyzed and calculated by XRD. The results are shown in Table 2.

Embodiment 3

[0049] Get sample DZ-3 in comparative example 3 and carry out rare earth exchange modification, press DZ-3: RECl 3 :H 2 O=1:0.08:10 ratio exchange RECl 3 , carried out rare earth exchange at 90°C for 30 minutes, then filtered, washed and dried, and the sample was designated as SZ-3. Its physical and chemical properties are listed in Table 1, and its XRD diffraction pattern is shown in figure 2 .

[0050] After aging SZ-3 in the bare state at 800°C and 100% water vapor for 17 hours, the unit cell constant and relative crystallization retention of SZ-3 zeolite after aging were analyzed and calculated by XRD. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com