A kind of preparation method of Y-type molecular sieve containing rare earth

A technology of molecular sieves and rare earth ions, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems such as the reduction of silicon-aluminum ratio of molecular sieves, achieve the improvement of rare earth utilization rate, improve patency, and improve ultra-stable level of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 30 grams of sodium hydroxide and dissolve it in 970 grams of distilled water, stir evenly to make an alkali solution and then heat up to 85°C. Get 200 grams (dry basis) NaY molecular sieve (sample name Y-A, crystallinity 95%, SiO 2 / Al 2 o 3 = 6.15, self-synthesized with reference to the method described in CN1785808), added to the above alkaline solution, stirred at 85°C for 2 hours, filtered, fully washed with deionized water until the pH of the filtrate was less than 10, collected samples and dried.

[0037] Get 30 grams of above-mentioned alkali treatment product, mix with 20mL rare earth chloride solution (RE 2 o 3content 300g / L) were added into 300 g of distilled water and stirred evenly, and then stirred and exchanged at 70°C for 1 hour. During the exchange process, 1mol / L hydrochloric acid solution was used to adjust the pH value of the exchange slurry to 3.5 and maintain it. After the exchange is completed, filter and fully wash with water to obtain ...

Embodiment 2

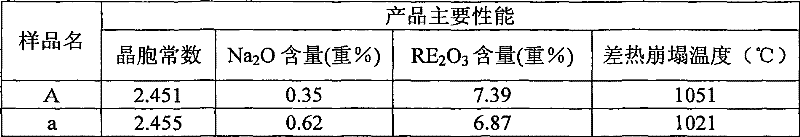

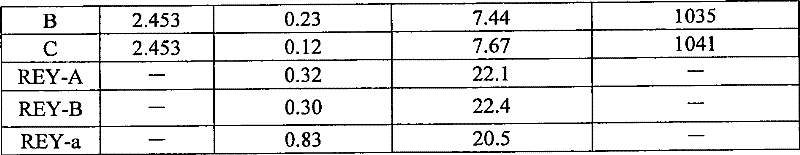

[0041] Put the rare earth ion-exchanged product in Example 1 in a muffle furnace at 550°C for 2 hours, and then conduct an ion exchange on the obtained product according to the rare earth ion exchange conditions described in Example 1, and then place it again at 550°C Roasted in a muffle furnace for 2 hours, the obtained molecular sieve sample was rinsed with 300 g of an ammonium salt solution with a temperature of 60 ° C and an ammonium chloride content of 5 wt%, and then washed with water and dried. The resulting product was named REY-A, and its Na 2 0.32 wt% residual O, RE 2 o 3 The content is 22.1% by weight, and the rare earth utilization rate is 55.3%.

Embodiment 3

[0045] Dissolve 100 grams of sodium hydroxide in 1000 grams of distilled water, stir evenly to make an alkali solution, cool it, and then place it in an ice-water mixed bath to keep the temperature constant. Take by weighing 200 grams of NaY molecular sieves (mass on a dry basis, sample name Y-A, crystallinity 95%, skeleton SiO 2 / Al 2 o 3 =6.15) Add the above-mentioned alkali solution, treat with alkali in an ice-water bath at 0°C for 20 minutes under continuous stirring, then filter and wash until the pH of the filtrate is less than 10, then collect samples and dry them.

[0046] Take out 50 grams from above-mentioned alkali treatment sample, carry out ion exchange treatment to this molecular sieve according to the ion exchange condition described in embodiment 1, Na in the gained product 2 O residues are 4.33% by weight, RE 2 o 3 The content is 13.8% by weight, and the rare earth utilization rate is 69%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com