Radial magnet ring and production method thereof

A magnetic ring and magnetic tile technology, which is applied in the manufacture of inductors/transformers/magnets, transformer/inductor magnetic cores, electrical components, etc., can solve the problem of inability to prepare high-performance radially oriented magnetic rings with large aspect ratios and the utilization of magnetic properties Improve efficiency, increase the volume of the magnetic ring, etc., to achieve the effect of improving the magnetic uniformity of the magnetic ring surface, making the processing difficult, and improving the strength of the magnetic ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Permanent magnet powder composition ratio: Nd: 29wt%, Dy: 4wt%, B: 1wt%, Al: 1wt%, Cu: 0.1wt%, Co: 2wt%, Nb: 0.5wt%, Ga: 0.2wt%, The balance is Fe and unavoidable impurities.

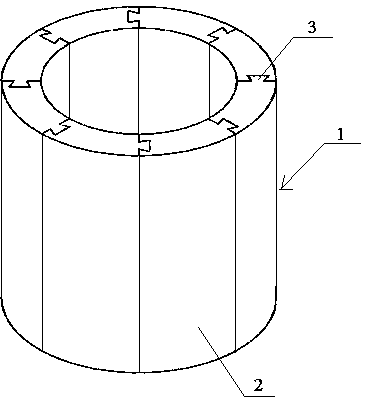

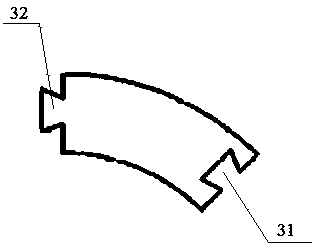

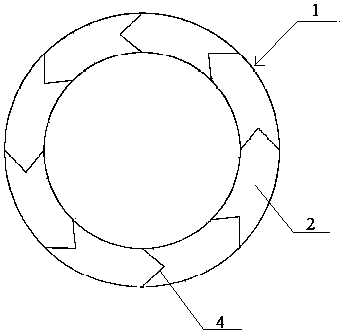

[0034] According to the above composition ratio, the raw materials are melted together to make R 2 T 14 The alloy of compound B as the main phase is ground into permanent magnetic powder with an average particle size of 3-5 μm. The permanent magnet powder is oriented in the magnetic field and then pressed into shape, and then sintered to obtain a magnetic block. After processing the magnetic block (including processing the arrow structure and grinding to the set size), the arc-shaped magnetic tile can be obtained, and the surface of the arc-shaped magnetic tile can be further anti-corrosion Treatment, such as electroplating nickel, phosphating and other conventional means, the specification is R25 mm×R10 mm×15mm (wall thickness)×80 mm (height)×45°. like Figure 4 As shown, one end of the arc-...

Embodiment 2

[0038] Permanent magnet powder composition ratio: Nd: 31wt%, B: 0.9wt%, Cu: 0.05wt%, Co: 1.5wt%, Nb: 0.5wt%, Ti: 0.2%, Ga: 0.05wt%, the balance is Fe and unavoidable impurities. Other schemes of this embodiment are the same as in Embodiment 1.

Embodiment 3

[0040] Permanent magnet powder composition ratio: Nd: 29wt%, Y: 4wt%, B: 1wt%, Al: 1wt%, Cu: 0.1wt%, Co: 2wt%, Nb: 0.5wt%, Ga: 0.2wt%, The balance is Fe and unavoidable impurities.

[0041] According to the above composition ratio, the raw materials are melted together to make R 2 T 14 The alloy of compound B as the main phase is ground into permanent magnetic powder with an average particle size of 3-5 μm. The permanent magnet powder is oriented in a magnetic field and then pressed into shape, and then sintered to obtain a magnetic block. After processing the magnetic block (including processing the dovetail groove structure and grinding to the set size), the arc-shaped magnetic tile can be obtained, and the surface of the arc-shaped magnetic tile can also be further modified. Anti-corrosion treatment, such as electroplating nickel, phosphating and other conventional methods, the specification is R20mm×R15 mm×5mm (wall thickness)×50 mm (height)×30°. like figure 2 As show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com