Bifunctional glass and preparation method thereof

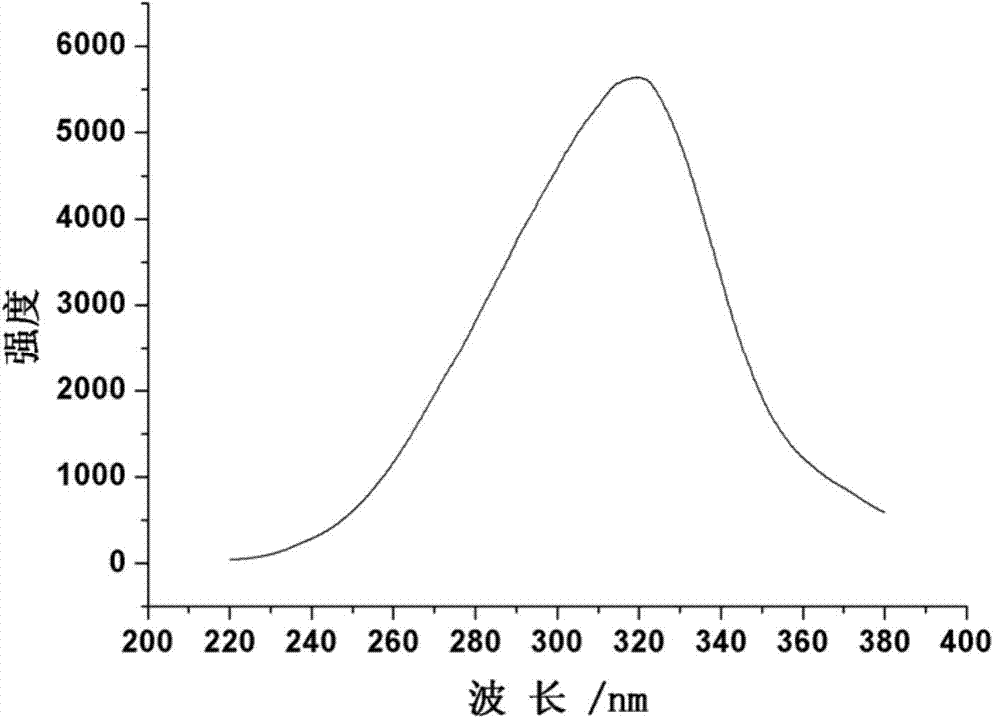

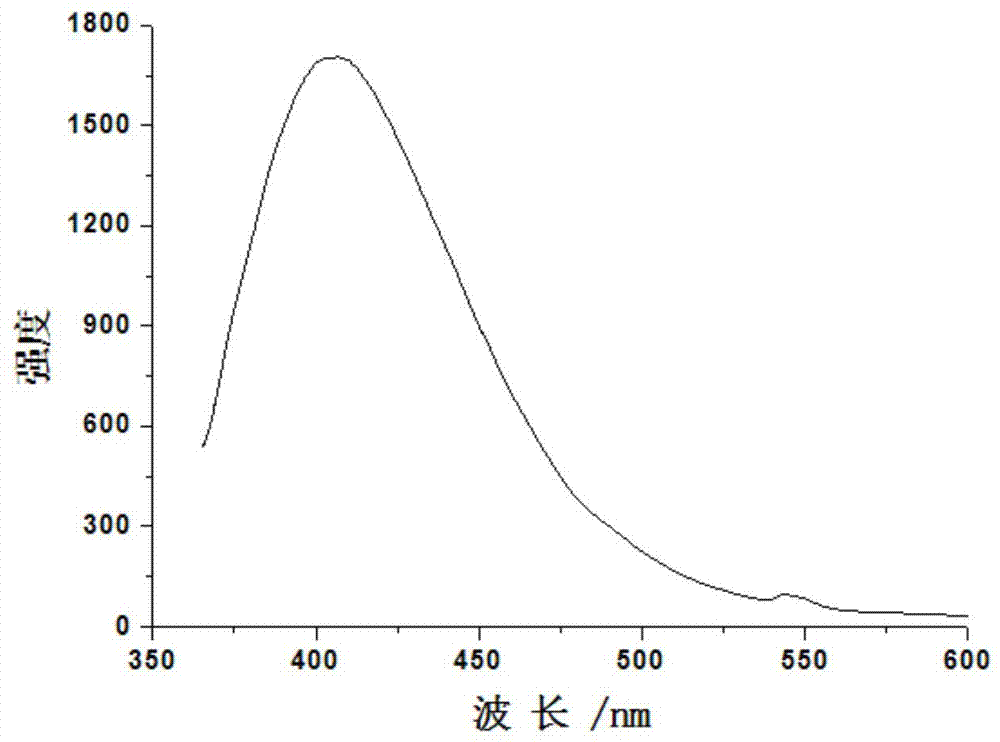

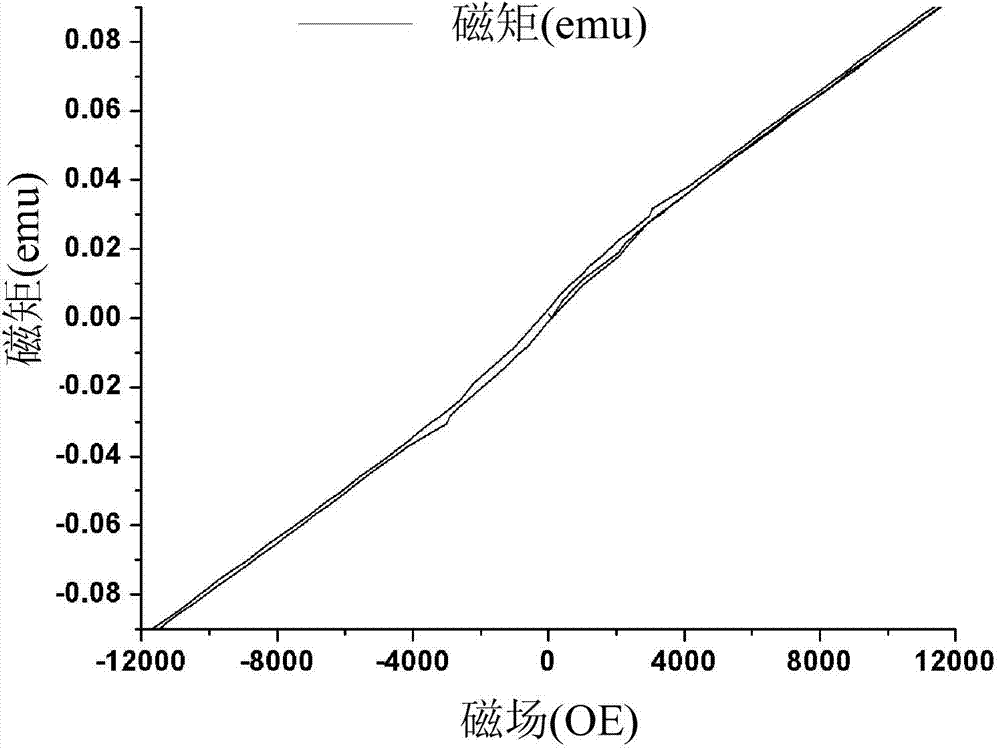

A dual-function, glass technology, applied in the field of dual-function glass and its preparation, achieves the effects of pure chromaticity, high luminous intensity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of dual function glass of the present invention comprises the following steps:

[0029] 1) First, 10-18% of Ga 2 o 3 , 15-28% SiC, 14-25% B 2 o 3 , 1~3% GeO 2 , 5~40% Eu 2 o 3 , 5~30% Tb 2 o 3 And 0.1~2% CeO 2 Put it into a ball mill and mill until it can pass through a 200-mesh standard sieve to form a batch; wherein, SiC is introduced from analytically pure silicon carbide, the particle size is greater than 600 mesh, and the content of ferric oxide in silicon carbide is less than 50ppm; Tb 2 o 3 , Ga 2 o 3 , B 2 o 3 、Eu 2 o 3 , CeO 2 、GeO 2 They are respectively introduced from analytically pure tetraterbium heptoxide, gallium trioxide, anhydrous boric acid, europium oxide, cerium oxide, and germanium oxide; after weighing and mixing silicon carbide, boric acid, and cerium oxide, they need to be calcined at 300°C for 3 Hours, crushed and then mixed with the other several raw materials to form a batch.

[0030] 2) Then, take ou...

Embodiment 1

[0035] 1) First, according to the mole percentage, 12% Ga 2 o 3 , 22% SiC, 18% B 2 o 3 , 1% GeO 2 , 26% Eu 2 o 3 , 20% of Tb 2 o 3 , 1% CeO 2 Put it into a ball mill and mill it until it can pass through a 200-mesh standard sieve to form a batch of 90 grams;

[0036] 2) Then, take out 30 grams of the batch material and add it to the platinum crucible that has been heated to 1380 ° C; then, within 10 minutes, raise the temperature to 1480 ° C and keep it warm for 30 minutes, then take out 30 grams of the batch material and add it to the platinum crucible, and in the Raise the temperature to 1480°C within 10 minutes, and keep it warm for 30 minutes, then take out 30 grams of batch materials and add them to the platinum crucible, and melt the prepared batch materials into molten glass sequentially according to the same process above, and keep them at 1480°C for 120 minutes. , using a platinum stirring paddle to stir the molten glass at 120 rpm for 2 hours;

[0037] 3) T...

Embodiment 2

[0043] 1) First, according to mole percentage, 13.8% Ga 2 o 3 , 28% SiC, 20% B 2 o 3 , 3% GeO 2 , 5% Eu 2 o 3 , 30% of Tb 2 o 3 , 0.2% CeO 2 Put it into a ball mill and mill it until it can pass through a 200-mesh standard sieve to form a batch of 90 grams;

[0044] 2) Then, take out 30 grams of the batch material and add it to the platinum crucible that has been heated to 1380 ° C; then, within 10 minutes, raise the temperature to 1490 ° C and keep it warm for 30 minutes, then take out 30 grams of the batch material and add it to the platinum crucible, and in the Raise the temperature to 1490°C within 10 minutes, and keep it warm for 30 minutes, then take out 30 grams of batch materials and add them to the platinum crucible, and melt the prepared batch materials into molten glass sequentially according to the same process as above, and keep them at 1490°C for 60 minutes. , using a platinum stirring paddle to stir the molten glass at 120 rpm for 2 hours;

[0045] 3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com