Catalytic cracking catalyst

A cracking catalyst, catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low rare earth content, heavy oil conversion rate and low gasoline yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

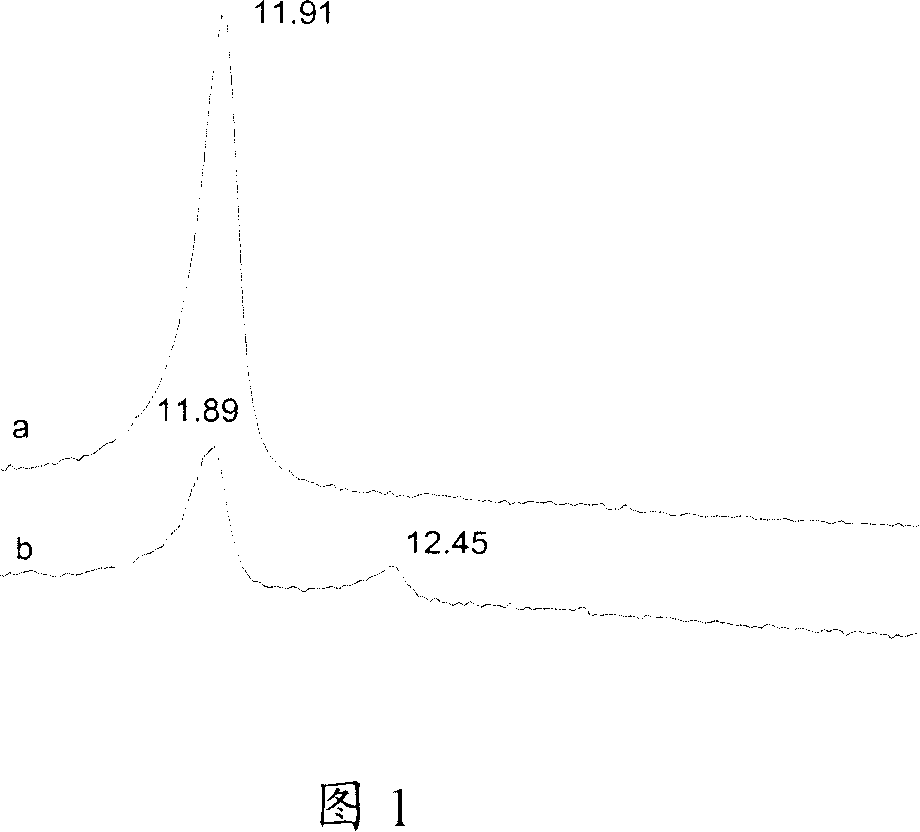

Image

Examples

Embodiment 1

[0040] Take 1500 grams of DASY2.0 (dry basis), add it to 15 liters of 0.2N oxalic acid aqueous solution and stir to mix evenly, raise the temperature to 90-100°C and keep it for 1 hour, then filter, wash with water, take out the filter cake, and place it in a 15-liter decanter. In cationic water, add 480ml of RECl 3 Solution (RE in solution 2 o 3 content is 319g / L), stirred, heated to 90-95°C and kept for 1 hour, then filtered, washed, and the filter cake was dried at 120°C to obtain a rare earth ultra-stable Y-type zeolite sample, which was recorded as A1, and its physical data is shown in Table 2.

[0041] Take 952 grams of aluminum sol with an alumina content of 21% by weight and add it to 2086 grams of decationized water, start stirring, add 2105 grams of kaolin with a solid content of 76% by weight and beat for 60 minutes. Get 1311 grams of pseudo-boehmite with an alumina content of 61% by weight and add it to 5212 grams of decationized water, add 128ml of chemically p...

Embodiment 2

[0043] Take 1500 grams of DASY2.0 (dry basis), add it to 15 liters of 0.1N oxalic acid aqueous solution and stir to make it evenly mixed, raise the temperature to 90-100°C and keep it for 1 hour, filter, wash with water, take out the filter cake, and place it in a 15-liter decationized water and add 480ml of RE(NO 3 ) 3 Solution (solution concentration: in RE 2 o 3 Calculated as 319g / L), stirred, heated up to 90-95°C and kept for 1 hour, then filtered, washed, and the filter cake was dried at 120°C to obtain a rare earth ultra-stable Y-type zeolite sample, which was recorded as A2, and its physical properties are shown in the table 2.

[0044] 952 grams of aluminum sol with an alumina content of 21% by weight was added to 834 grams of decationized water, stirring was started, and 1947 grams of kaolin with a solid content of 76% by weight was added for beating for 60 minutes. Get 1311 grams of pseudo-boehmite with an alumina content of 61% by weight and add it to 6529 grams...

Embodiment 3

[0046] Take 1000 grams of DASY2.0 (dry basis), add it to 10 liters of 0.2N citric acid aqueous solution and stir to make it evenly mixed, raise the temperature to 90-100 ° C and keep it for 1 hour, filter, wash with water, take out the filter cake, and place it in 10 liters of deionized water and add 320ml of RECl 3 Solution (solution concentration: in RE 2 o 3 Calculated as 319g / L), stirred, heated up to 90-95°C and kept for 1 hour, then filtered, washed, and the filter cake was dried at 120°C to obtain a rare earth ultra-stable Y-type zeolite sample, which was recorded as A3, and its physical properties are shown in the table 2.

[0047] 952 grams of aluminum sol with an alumina content of 21% by weight was added to 1522 grams of decationized water, stirring was started, and 1947 grams of kaolin with a solid content of 76% by weight was added for beating for 60 minutes. Get 1311 grams of pseudoboehmite with an alumina content of 61% by weight and add it to 4243 grams of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com