High-cost-performance rare earth permanent magnet and preparation method

A rare earth permanent magnet, cost-effective technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the unbalanced application of rare earth resources, the low application value of high-abundance rare earths, and the low cost performance of NdFeB recycled materials Advanced problems, to achieve good comprehensive magnetic properties, cost reduction, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

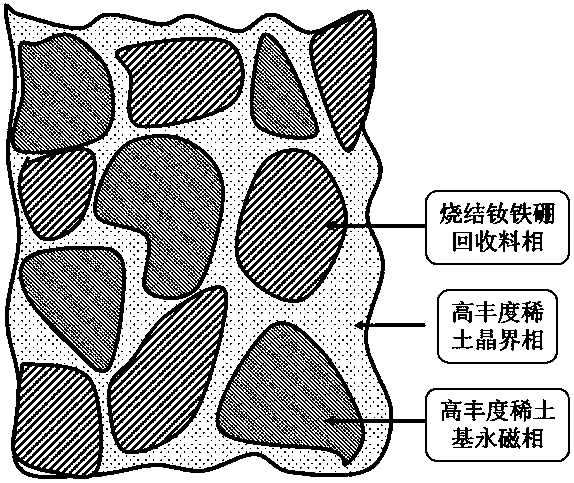

[0049] The preparation method of the cost-effective rare earth permanent magnet includes: sintered NdFeB reclaimed materials are classified into reclaimed materials-surface decoating-surface degreasing-recycled materials are crushed-screened to obtain small particle powder; the second main phase (and the first Three main phases) through batching-smelting quick-setting to obtain quick-setting sheets; after mixing small particles of NdFeB recycled material with quick-setting sheets, hydrogen breaking-jet mill-orientation molding-sintering and tempering treatment is performed to obtain cost-effective magnets.

[0050] Its preparation steps are as follows:

[0051] 1) Classification of recycled materials: classify different grades of NdFeB recycled materials, and store each kind of NdFeB recycled materials with similar components separately for future use;

[0052] 2) De-coating on the surface: removing the surface coating by pickling the recycled neodymium-iron-boron materials cl...

Embodiment 1

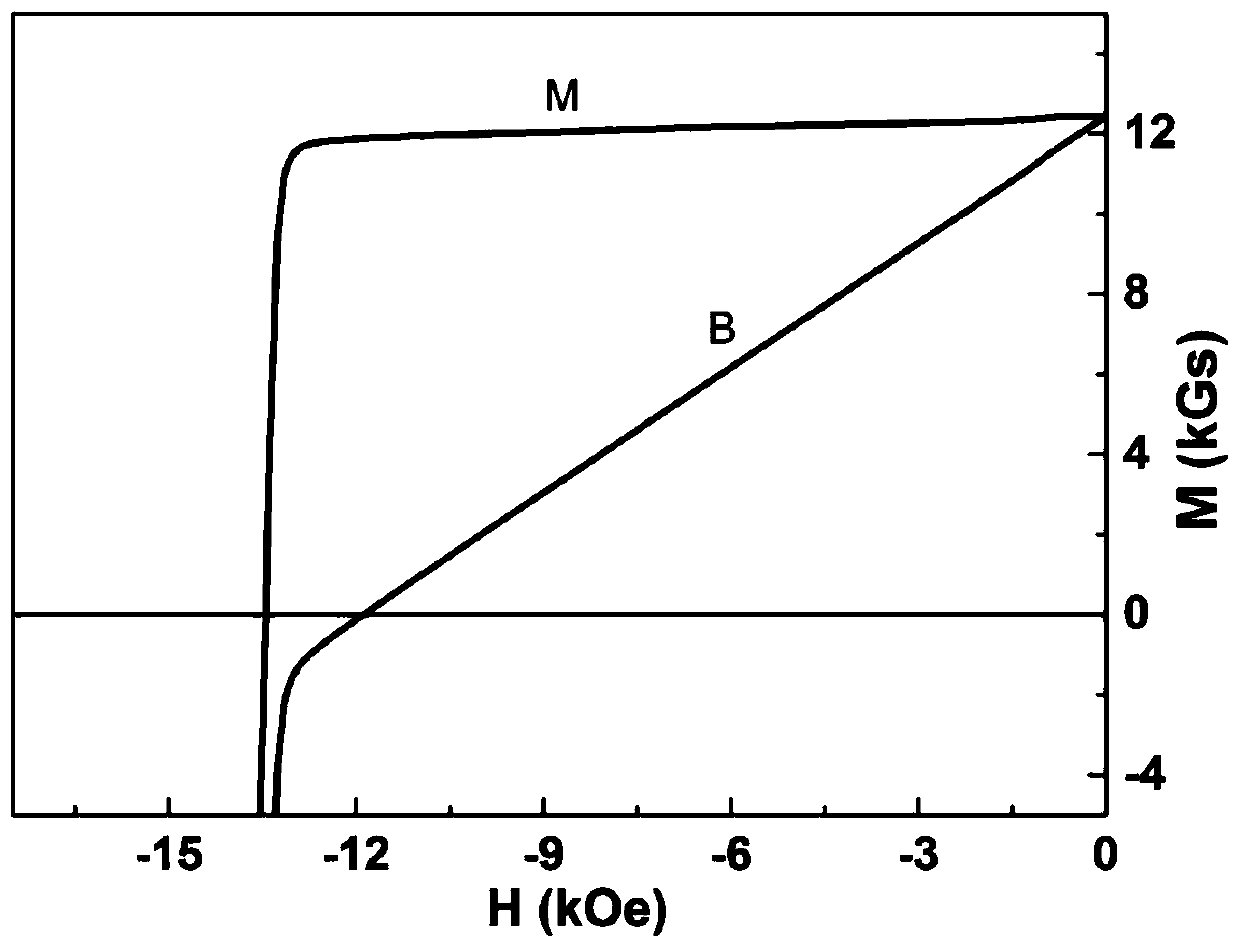

[0063] Example 1: 38M grade NdFeB magnetic steel recycled particles + Ce-based quick-setting tablets

[0064] 1. Classify and collect 38M brand NdFeB magnet recycle materials;

[0065] 2. Put the magnetic steel into the pickling tank, use hydrochloric acid with a concentration of 5% as the pickling solution, remove the electroplating layer on the surface, and obtain the reclaimed NdFeB magnetic steel without coating;

[0066] 3. Put the recovered NdFeB material obtained in step 2 into the degreasing tank, wash the recovered material by alkali washing method to remove surface impurities and oil stains, and then use a high-pressure water gun to clean the degreased NdFeB recovered material Rinse and dry to obtain clean NdFeB recycled materials;

[0067] 4. The NdFeB recycled material obtained in step 3 is roughly crushed by a jaw crusher, and sieved by magnetic suction to remove oxide layer particles to obtain small NdFeB recycled material particles with an average particle size...

Embodiment 2

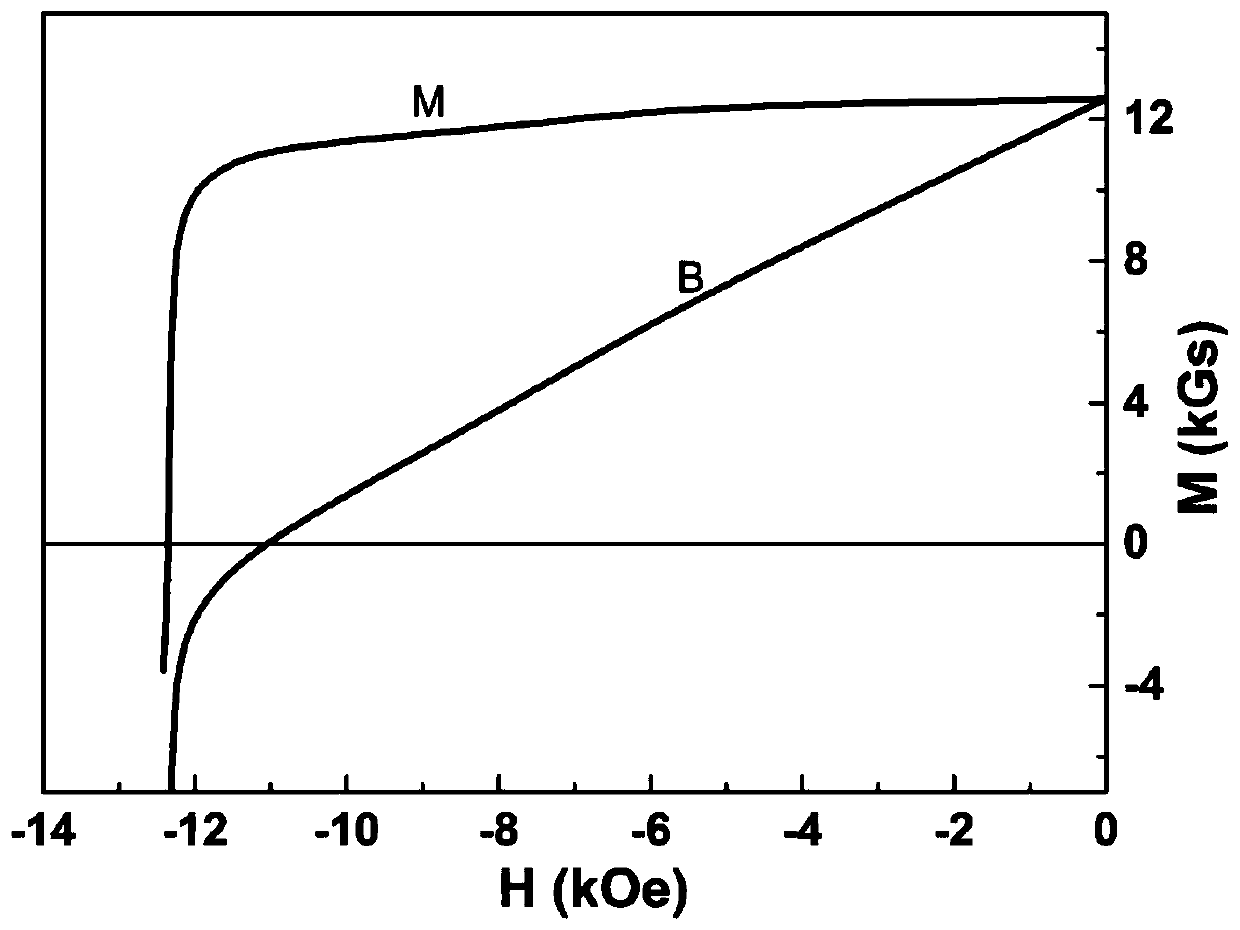

[0075] Example 2: N38 brand NdFeB magnetic steel recycled material particles + Ce-based quick-setting tablets + Gd-based quick-setting tablets

[0076] 1. Classify and collect N38 grade NdFeB magnet reclaimed materials;

[0077] 2. Put the magnetic steel into the pickling tank, use hydrochloric acid with a concentration of 5% as the pickling solution, remove the electroplating layer on the surface, and obtain the reclaimed NdFeB magnetic steel without coating;

[0078] 3. Put the recovered NdFeB material obtained in step 2 into the degreasing tank, wash the recovered material by alkali washing method to remove surface impurities and oil stains, and then use a high-pressure water gun to clean the degreased NdFeB recovered material Rinse and dry to obtain clean NdFeB recycled materials;

[0079] 4. The NdFeB recycled material obtained in step 3 is roughly crushed by a jaw crusher, and sieved by magnetic suction to remove oxide layer particles to obtain small NdFeB recycled mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com