A kind of preparation method of regenerative sintered NdFeB permanent magnet

A permanent magnet, NdFeB technology, used in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem of low resource reserves and high price, and achieve the effect of high resource reserves, low price and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

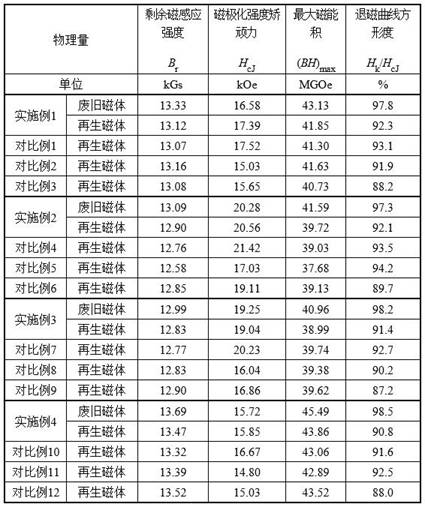

Examples

Embodiment 1

[0021] (1) Use sand blasting + ultrasonic cleaning to remove the coating / plating layer, oxide layer and other pollutants on the surface of the waste sintered NdFeB permanent magnet, and then use hydrogen crushing + jet mill to crush it into an average particle size of 3.2 μm the initial magnetic powder;

[0022] (2) According to the ratio of 98.5 : 1.5, the initial magnetic powder and DyH with an average particle size of 3.0 μm x After the powders were mixed, they were heat-treated at 600 °C for 10 h with constant stirring to make DyH x The Dy atoms in the NdFeB powder diffuse into the surface layer of waste NdFeB powder to obtain modified magnetic powder;

[0023] (3) Ce with an average particle size of 2.5 μm at a ratio of 2:100 80 al 20 Mixed alloy powder and modified magnetic powder to obtain mixed magnetic powder;

[0024] (4) Place the mixed magnetic powder in a 1.7T magnetic field to make a green compact through orientation pressing;

[0025] (5) The compact is sin...

Embodiment 2

[0034] (1) Use dilute hydrochloric acid cleaning + ultrasonic cleaning to remove the coating / plating layer, oxide layer and other pollutants on the surface of the waste sintered NdFeB permanent magnet, and then use hydrogen crushing + ball milling to crush it into an average particle size of 3.5 μm the initial magnetic powder;

[0035] (2) According to the ratio of 98:2, the initial magnetic powder and TbF with an average particle size of 2.5 μm 3 After mixing the powders, heat treatment at 650 °C for 8 hours with constant stirring, so that the TbF 3 The Tb atoms in the NdFeB powder diffuse into the surface layer of waste NdFeB powder to obtain modified magnetic powder;

[0036] (3) According to the ratio of 2 : 100, CeH with an average particle size of 2.9 μm x The powder is mixed with modified magnetic powder to obtain mixed magnetic powder;

[0037] (4) Place the mixed magnetic powder in a magnetic field above 2.0T to make a green compact through orientation pressing;

...

Embodiment 3

[0045] (1) Use sandpaper to remove the coating / plating, oxide layer and other pollutants on the surface of the waste sintered NdFeB permanent magnet, and then use hydrogen crushing + jet milling to crush it into initial particles with an average particle size of 2.6μm magnetic powder;

[0046] (2) Mix the initial magnetic powder with TbH with an average particle size of 2.2 μm at a ratio of 99:1 x After the powders were mixed, they were heat-treated at 600 °C for 5 h with constant stirring to make the TbH x The Tb atoms in the NdFeB powder diffuse into the surface layer of waste NdFeB powder to obtain modified magnetic powder;

[0047] (3) Add LaH with an average particle size of 2.5 μm in a ratio of 4:100 x The powder is mixed with modified magnetic powder to obtain mixed magnetic powder;

[0048] (4) Place the mixed magnetic powder in a magnetic field above 1.8T to make a compact by orientation pressing;

[0049] (5) The compact is sintered at high temperature and tempered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com